Falling plate connection structure and construction method thereof

A technology for connecting structures and construction methods, which is applied to floors, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

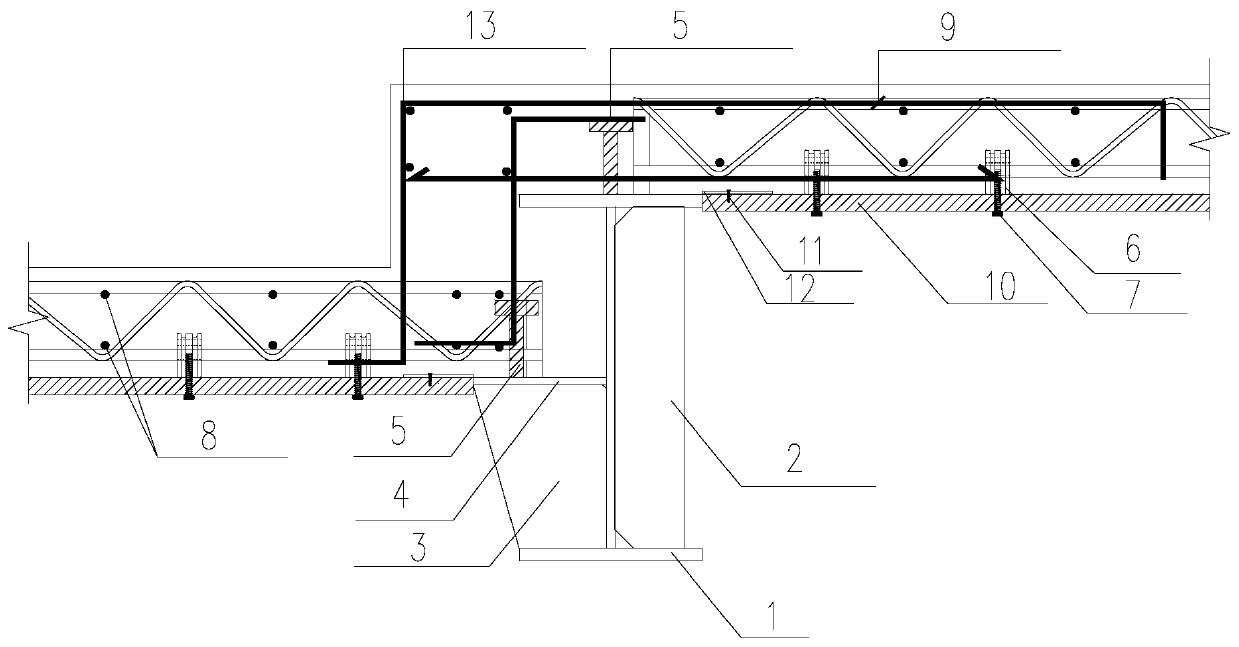

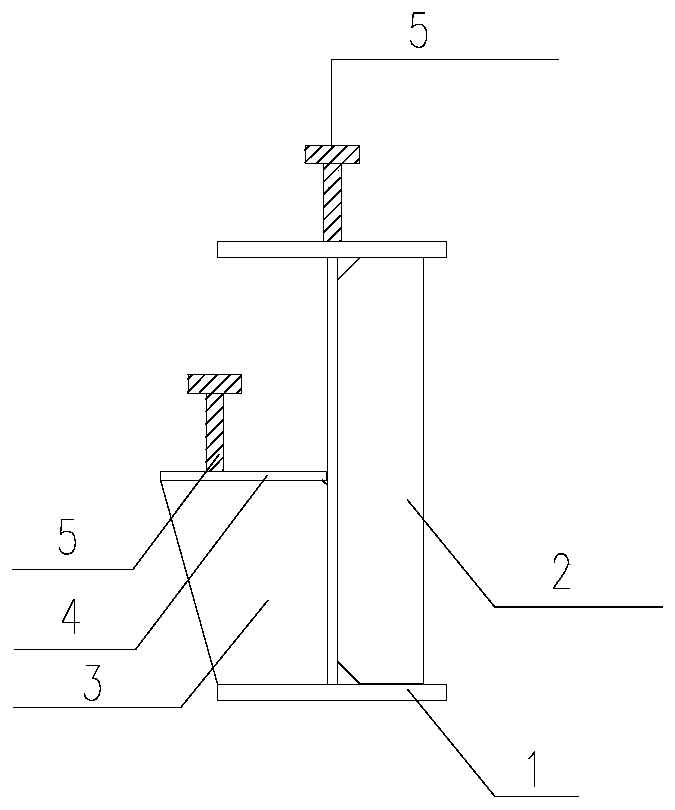

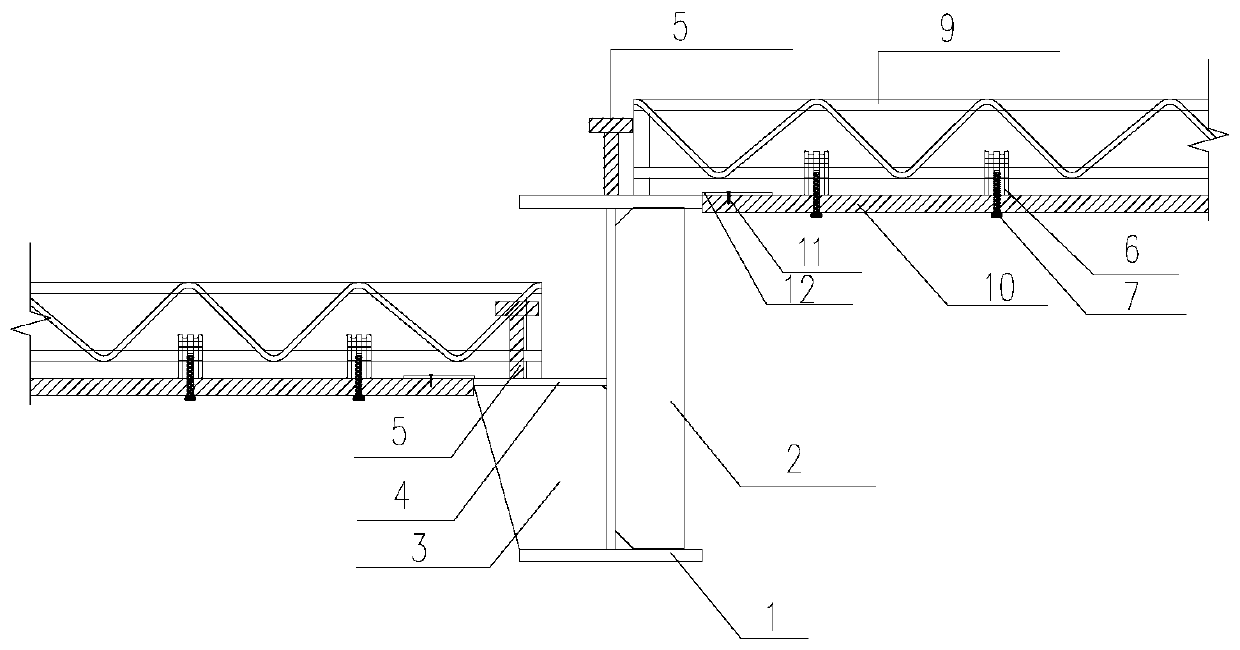

[0035] The lower plate connection structure provided by this embodiment, such as Figure 1 to Figure 4 As shown, the lowering plate connection structure includes a steel beam 1 and a supporting plate 4; the steel beam 1 has a web 2 and an upper flange, and the supporting plate 4 is fixed on the web 2 of the steel beam 1; the upper flange is cast with a The bearing plate on the first floor is poured with the bearing plate on the second floor on the supporting plate 4 .

[0036] Among them, the web 2 is arranged vertically, the upper flange and the web 2 are arranged vertically, the supporting plate 4 and the steel beam 1 can be prefabricated in the workshop, which can not only ensure accurate positioning, but also ensure the welding quality, and directly install the steel beam 1 on site. Finally, the first floor deck is poured on the upper wing plate, and the second floor deck is poured on the supporting plate 4 to form a descending deck connection structure, without redundant ...

Embodiment 2

[0055] The construction method of the lowering plate connection structure provided by the present embodiment comprises the following steps:

[0056] Prefabricate the steel beam 1 and supporting plate 4 provided in Example 1, fix the supporting plate 4 on the web 2 of the steel beam 1, and set the reinforcement 3 between the supporting plate 4 and the web 2;

[0057] The first bottom form 10 is detachably connected to the first truss 9 in advance, and the second bottom form is detachably connected to the second truss;

[0058] Weld studs 5 on the upper wing plate and supporting plate 4 on site, hoist the first truss 9, overlap and weld the first truss 9 on the upper wing plate, and make one end of the first bottom form 10 and the upper edge of the steel beam 1 One end of the wing plate is in contact; the second truss is hoisted, and the second truss is lapped and welded on the supporting plate 4, so that one end of the second bottom form is in contact with one end of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com