A tidal current power generation cast-in-place pile with a pile core steel pipe and its construction method

A technology of tidal current power generation and construction method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high cost of large-diameter cast-in-situ pile engineering, influence on tidal current energy utilization, and inability to bear loads, etc., and achieve simple construction procedures, The effect of pile foundation structure optimization and casting quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to describe the present invention more specifically, the technical solution of the present invention and its construction process will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

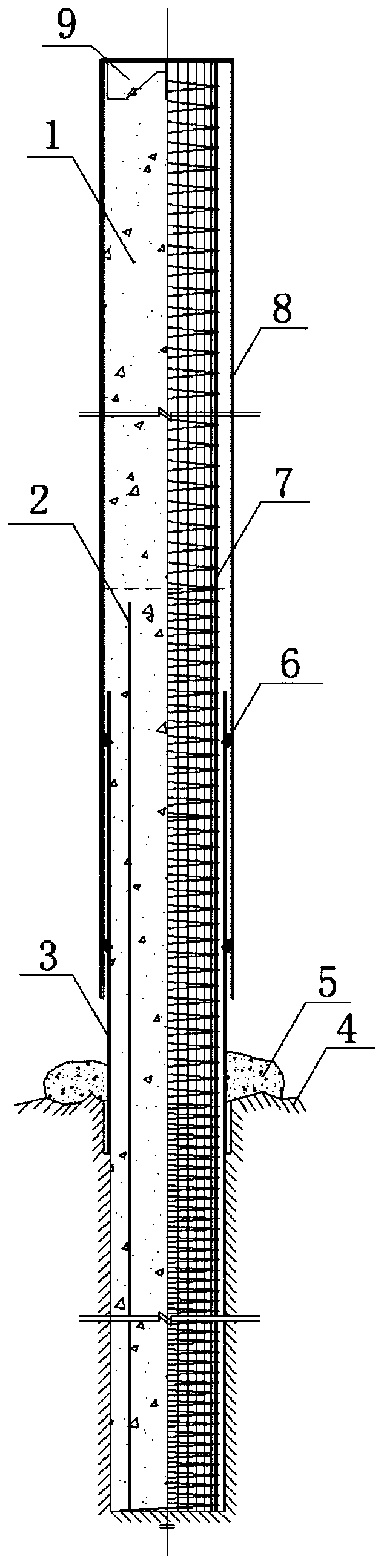

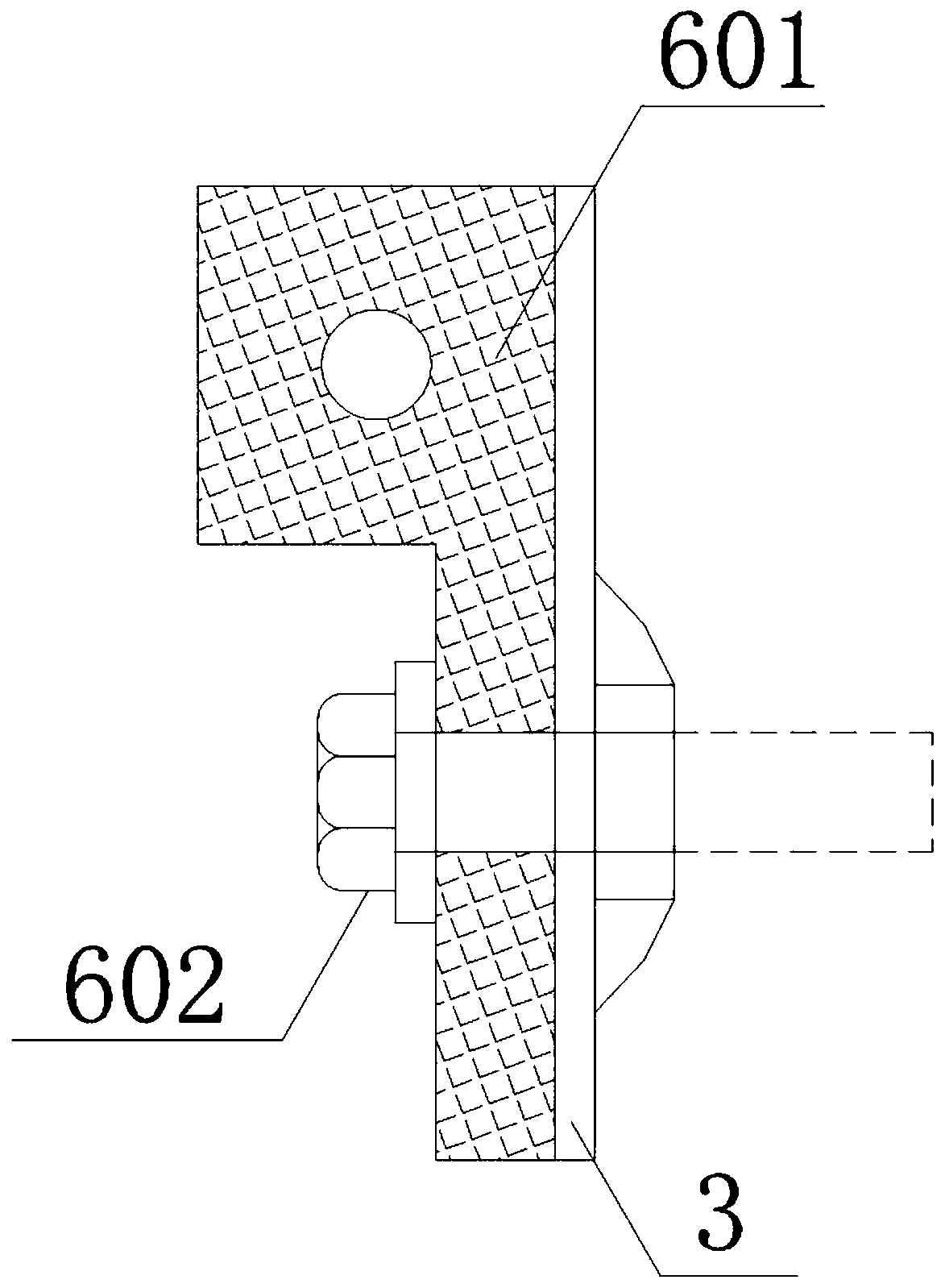

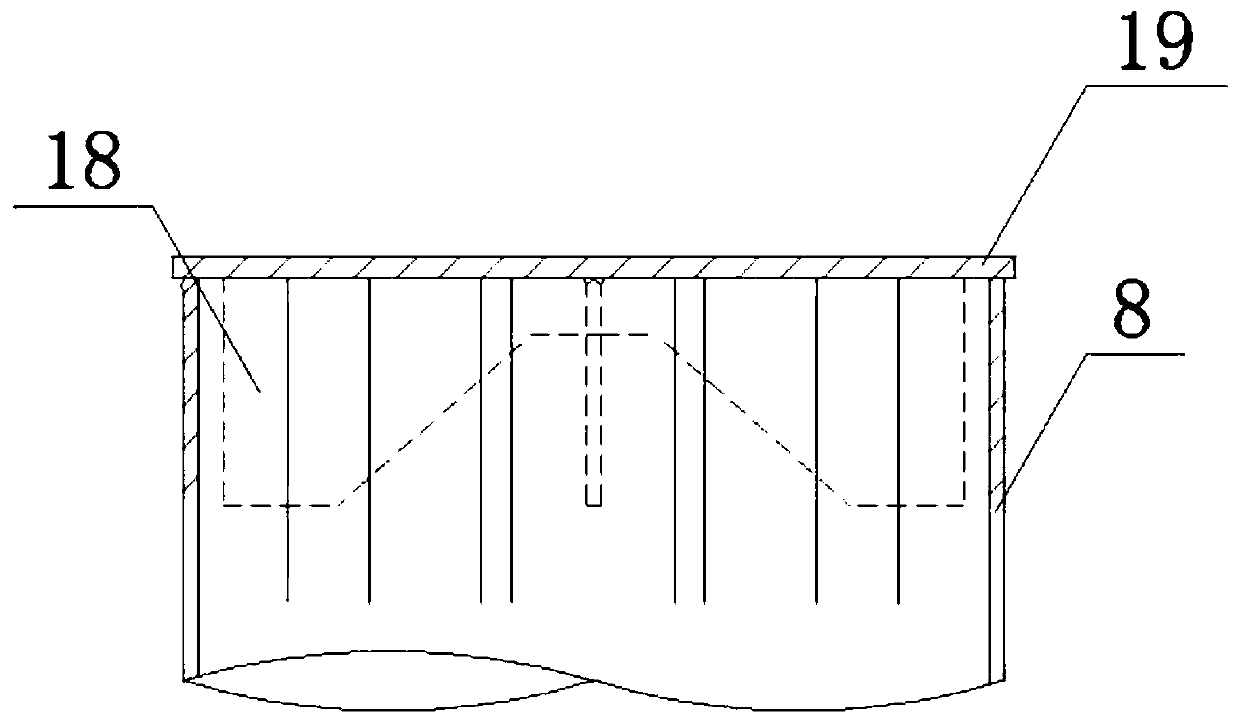

[0035] Such as figure 1 As shown, the tidal current power generation cast-in-situ pile 1 with a pile core steel pipe of the present invention includes a connecting sleeve 3, an outer sleeve 8, a reinforcement cage 7, a capping steel plate 9 and a pile core steel pipe 2, and the outer sleeve 8 is connected to the outer frame of the assembly platform In one piece, the outer sleeve 8 is provided with a reinforcement cage 7, the top of the outer sleeve 8 is welded to the capping steel plate 9, the lower part of the outer sleeve 8 is overlapped with the connecting sleeve 3 through the water-stop rubber 6, and the connecting sleeve 3 is embedded in the In the seabed bedrock layer 4, the cast-in-place pile 1 is poured from the embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com