A kind of construction method of wire box installation point

A construction method and installation point technology, which is applied to the installation of cables, cable installation devices, electrical components, etc., can solve the problems of increased labor costs and unsatisfactory results, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

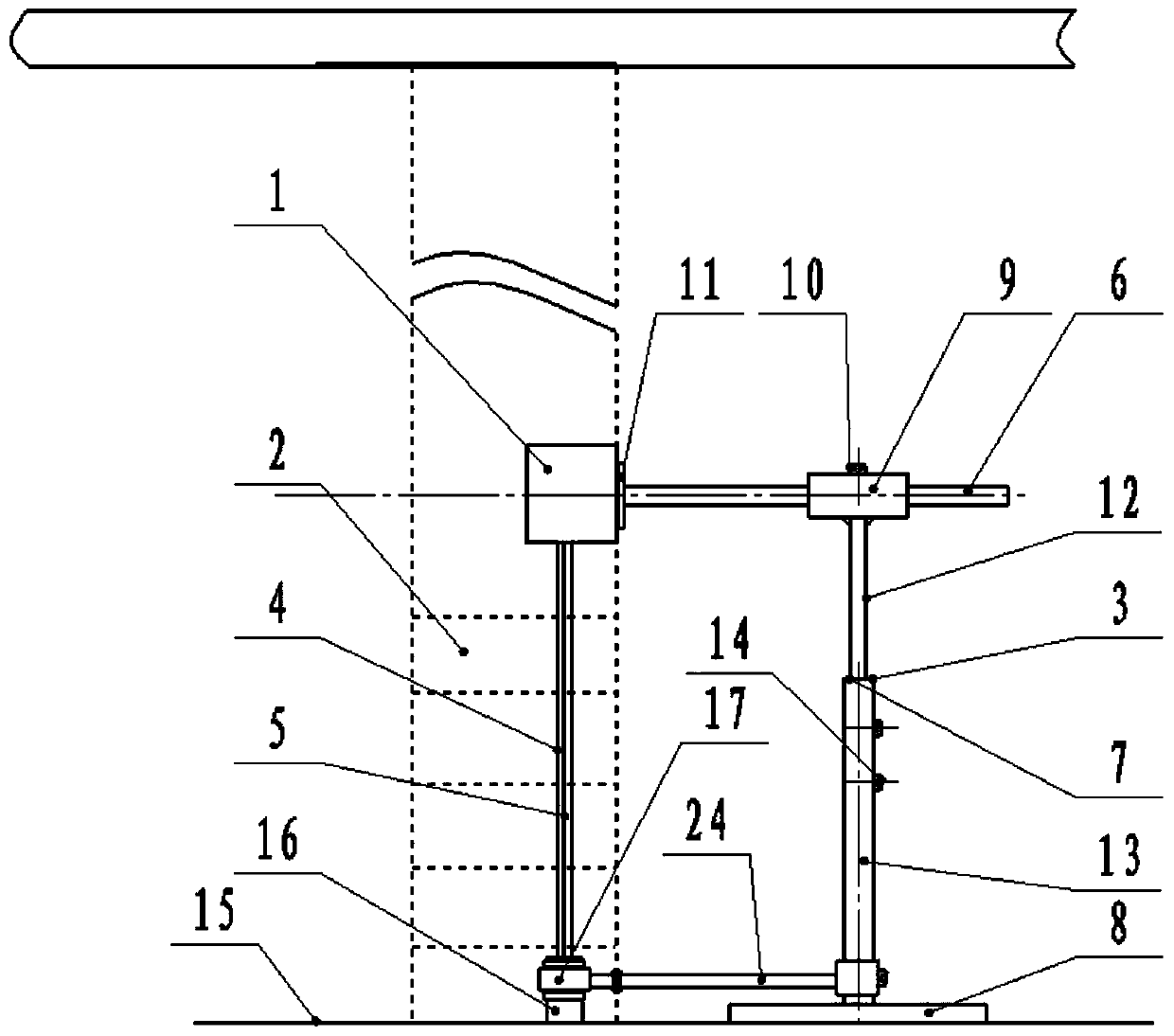

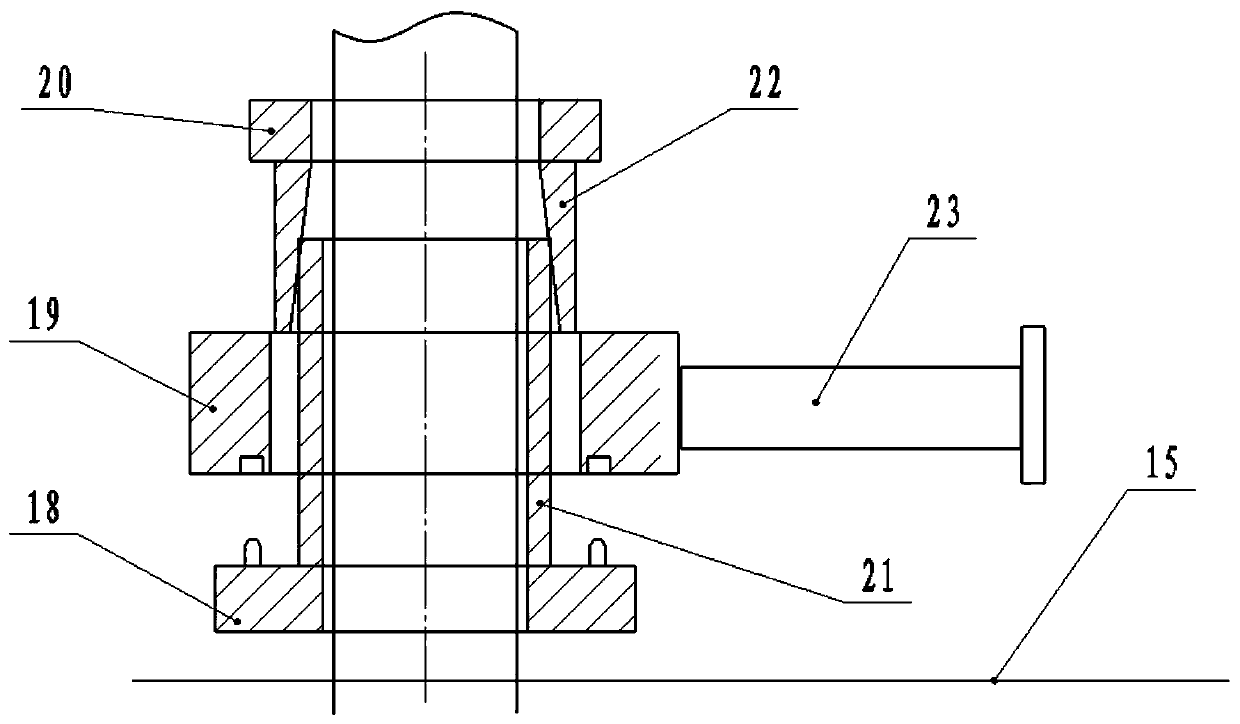

[0041] Such as Figure 1-2 As shown, a wire box installation point construction method includes steps:

[0042] Step 1. Sleeve the support frame connector 17 on the wire pipe head 16 reserved on the floor 15; the wire pipe head 16 reserved on the floor 15 is a wiring joint reserved when building a house;

[0043] Step 2, determine the spatial position of the wire box 1 on the pre-built wall 2;

[0044] Step 3, install the wire box support frame 3 according to the spatial position of the wire box 1, the wire box support frame 3 is connected to the support frame connector 17 and positioned; the panel part of the wire box 1 is fixedly installed on the wire box support frame 3;

[0045] Step 4, intercepting the line pipe 4 of matching length, the lower end of the line pipe 4 is connected with the line pipe head 16, and the wire 5 connector in the line pipe 4 is connected with the wire box 1;

[0046] Step 5. Build the wall according to the position of the pre-built wall 2, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com