Small-tube-diameter carbon nano-tube purification device and small-tube-diameter carbon nano-tube purification method

A carbon nanotube, purification device technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as reducing production costs, acid mist and waste acid are not recycled, etc. The effect of reducing production costs, avoiding excessive heating temperature, and reducing washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

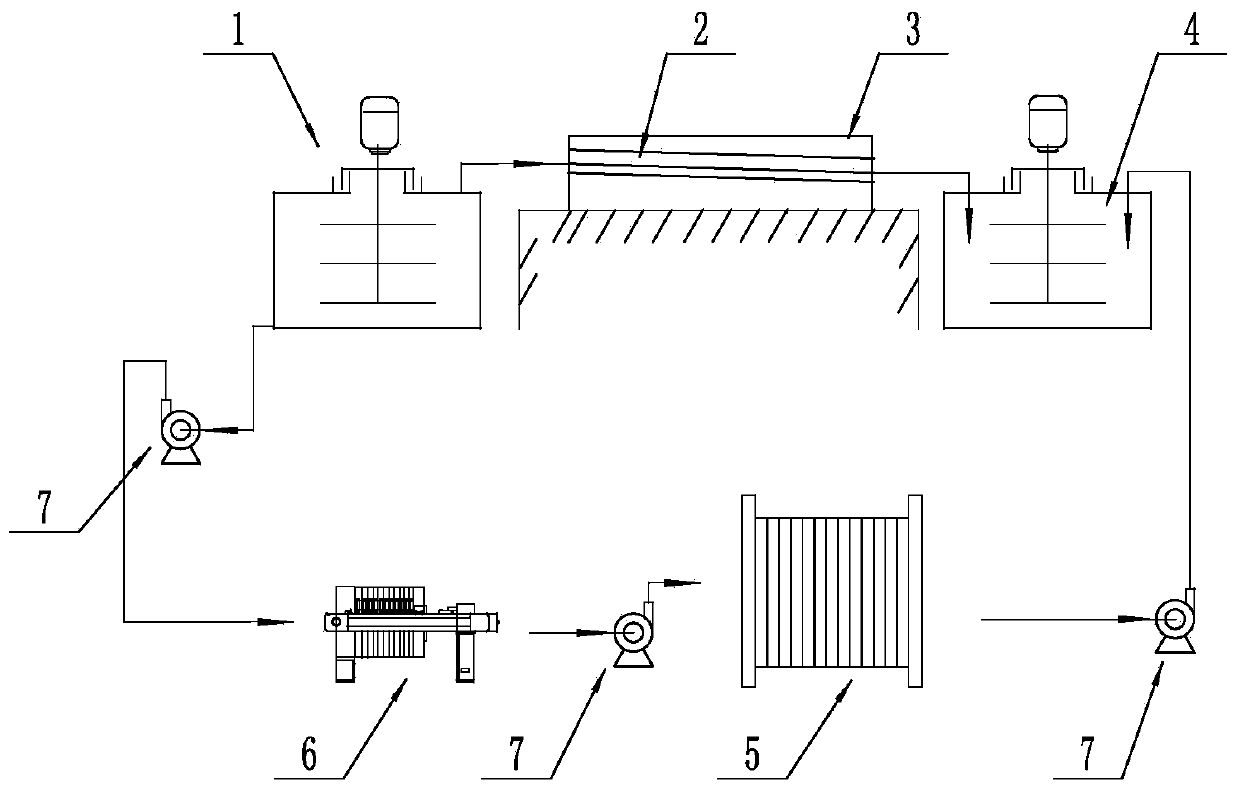

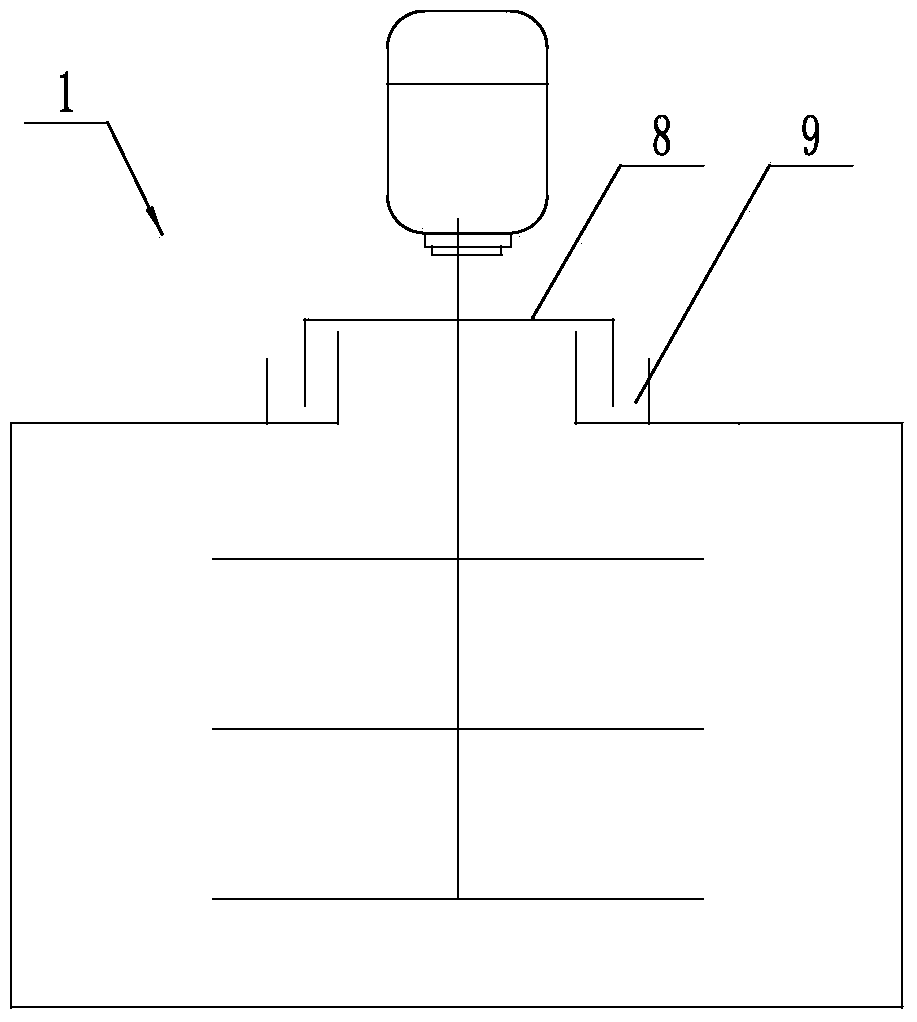

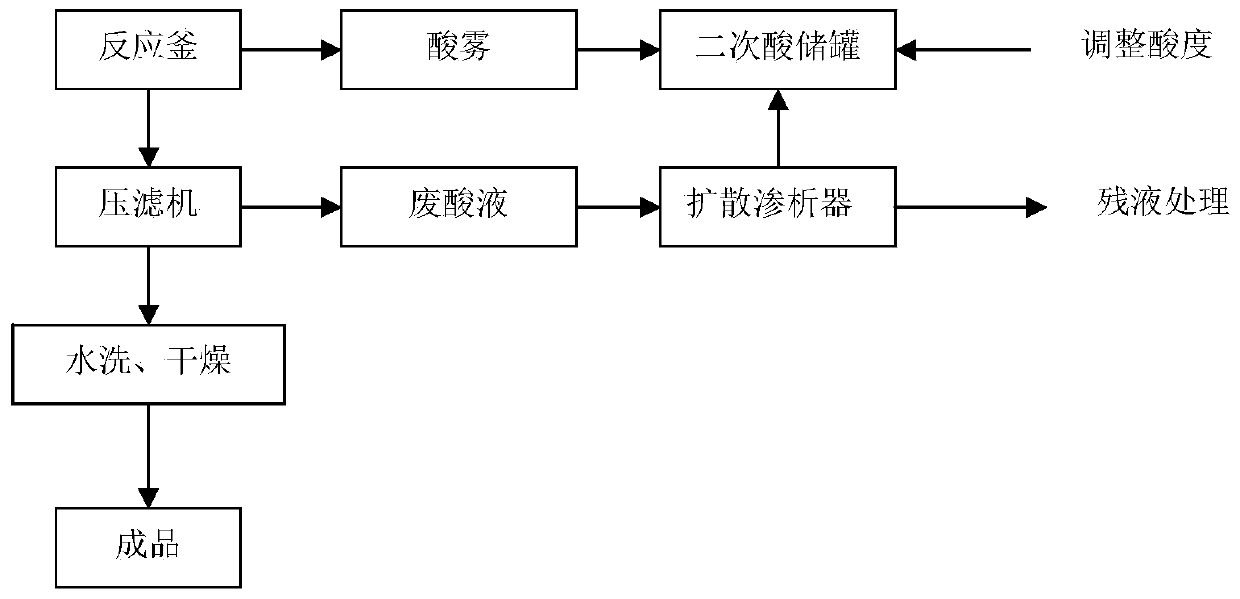

Method used

Image

Examples

Embodiment 1

[0042] The iron catalyst is prepared by a sol-gel method, ethylene is used as a reaction gas, and the cracking temperature is 700°C. The metal content in the prepared small diameter carbon nanotube is about 4%, and the diameter of the carbon nanotube is less than 20nm. A catalyst that does not contain rare earth elements and has no heavy pollution to the environment is prepared by using the sol-gel method, and small-diameter carbon nanotubes with high yield and high conductivity are prepared by using the catalyst.

[0043] A hydrofluoric acid solution with a mass concentration of 5% was prepared to react with the carbon nanotubes, the weight ratio of the solution to the carbon nanotubes was 10:1, the reaction temperature was 80° C., and the reaction time was 20 hours.

[0044] The acid mist generated during the heating process of the reactor is cooled through the horizontal tube heat exchanger in the pure water pool, the cooling temperature is 10-20°C, and the acid liquid obtai...

Embodiment 2

[0050] The iron catalyst is prepared by a sol-gel method, ethylene is used as a reaction gas, the cracking temperature is 700 DEG C, the metal content in the prepared carbon nanotube is about 4%, and the diameter of the carbon nanotube is less than 20nm.

[0051] A hydrochloric acid solution with a mass concentration of 24% was prepared to react with the carbon nanotubes, the weight ratio of the solution to the carbon nanotubes was 10:1, the reaction temperature was 80° C., and the reaction time was 20 hours.

[0052] The acid mist generated during the heating process of the reactor is cooled through the horizontal tube heat exchanger in the purified water pool, the cooling temperature is 10-20°C, and the acid liquid obtained after cooling is introduced into the secondary acid storage tank.

[0053] The carbon nanotube solution after the reaction is press-filtered by a filter press, and the waste acid solution filtered out by the press-filter is purified by a diffusion dialyzer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com