Foundation beam-slab construction method

A construction method and foundation beam technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problem that the backfill compactness of the earthwork around the brick membrane cannot be guaranteed, the construction is greatly affected by the weather, and the thermal insulation and energy saving effect is poor. and other issues, to achieve the effect of facilitating quality control, reducing the amount of manpower input, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

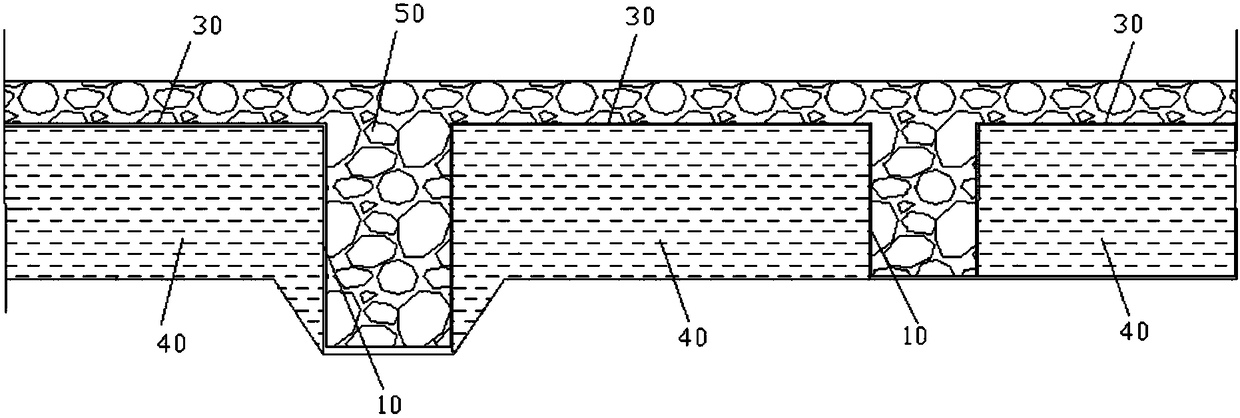

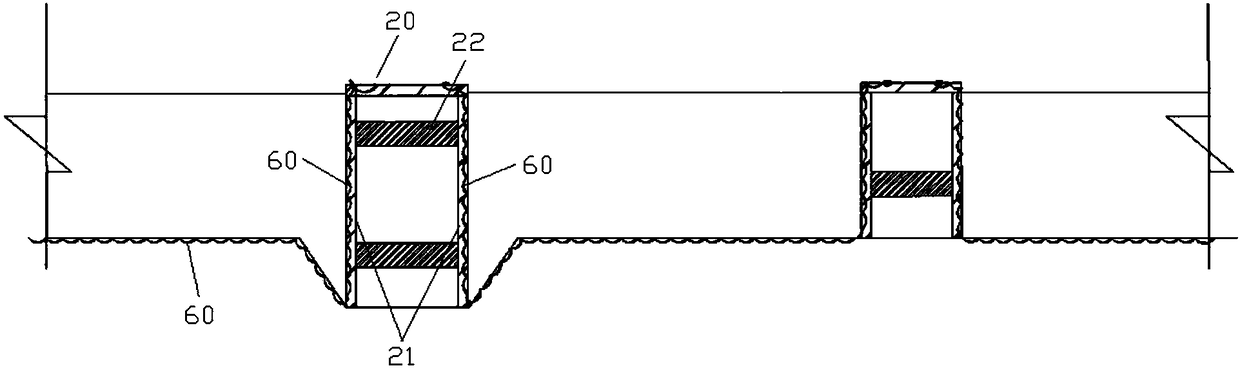

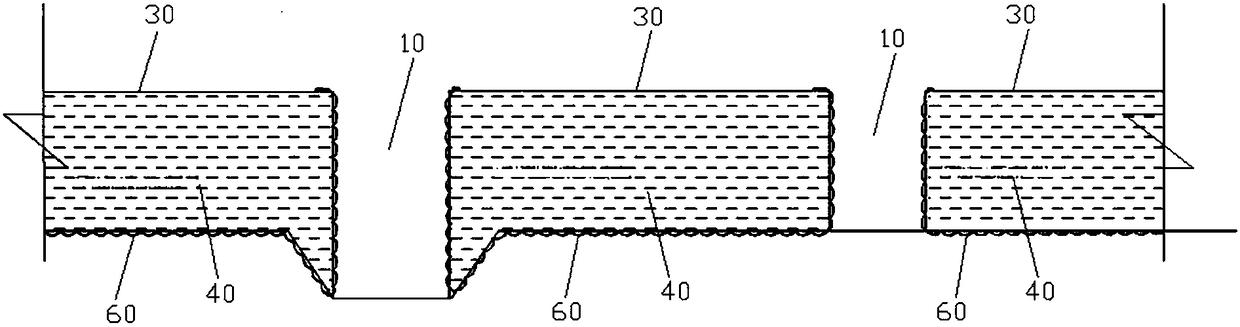

[0031] refer to Figure 1 to Figure 3 , a preferred embodiment of the present invention provides a foundation beam slab construction method, comprising the following steps:

[0032] Use plain soil backfill method or base surface excavation method to construct to the design elevation to obtain the foundation soil layer;

[0033] Construct the cushion layer on the base soil layer and level it;

[0034] Construct a waterproof layer on the leveled cushion;

[0035] On the waterproof layer where the foundation beam needs to be constructed, construct multiple criss-cross waterproof protective layers extending along the direction of the foundation beam;

[0036] On each waterproof protective layer, a beam mold molding strip group 20 extending along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com