Patents

Literature

279results about "Shaping building parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

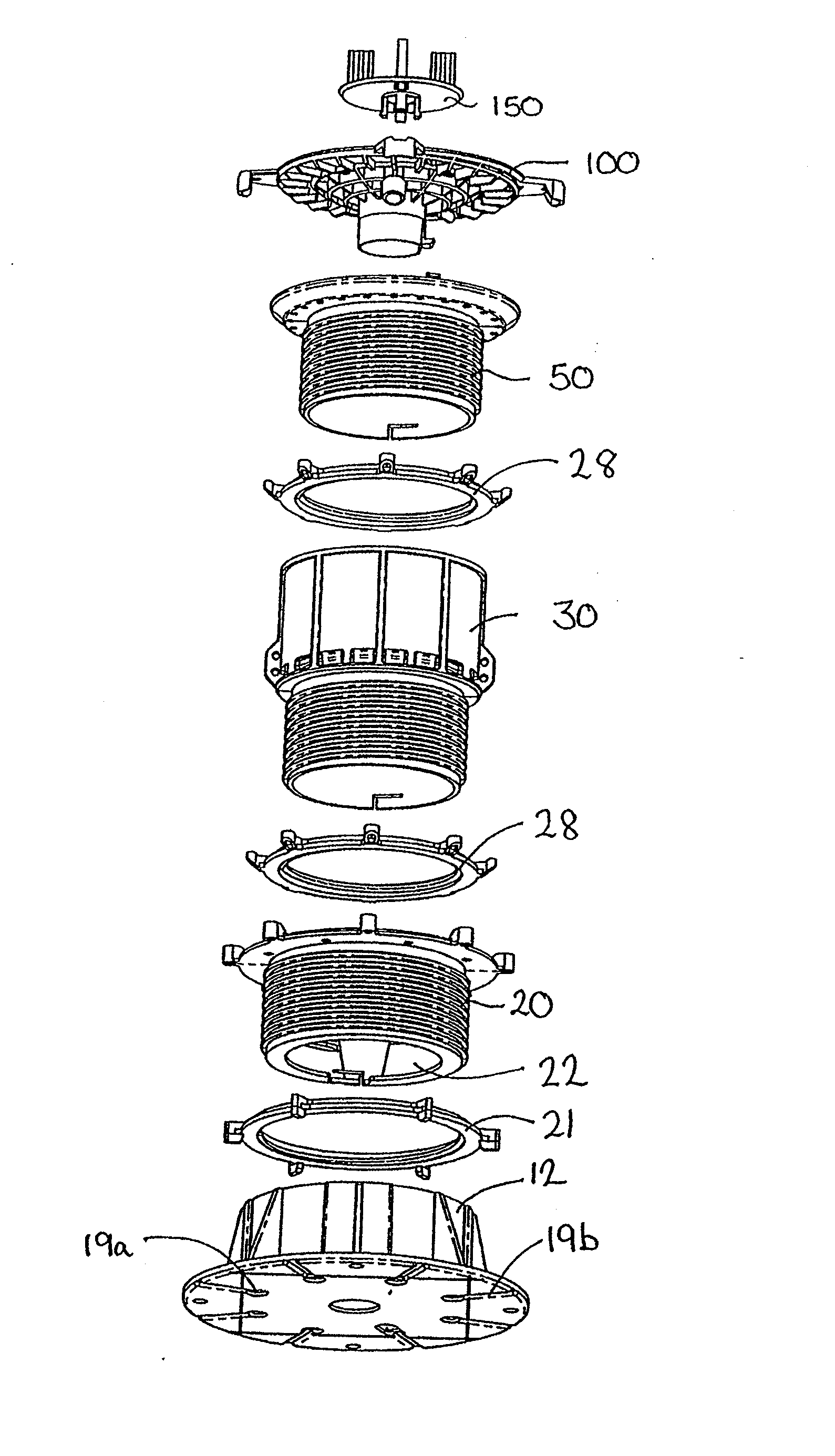

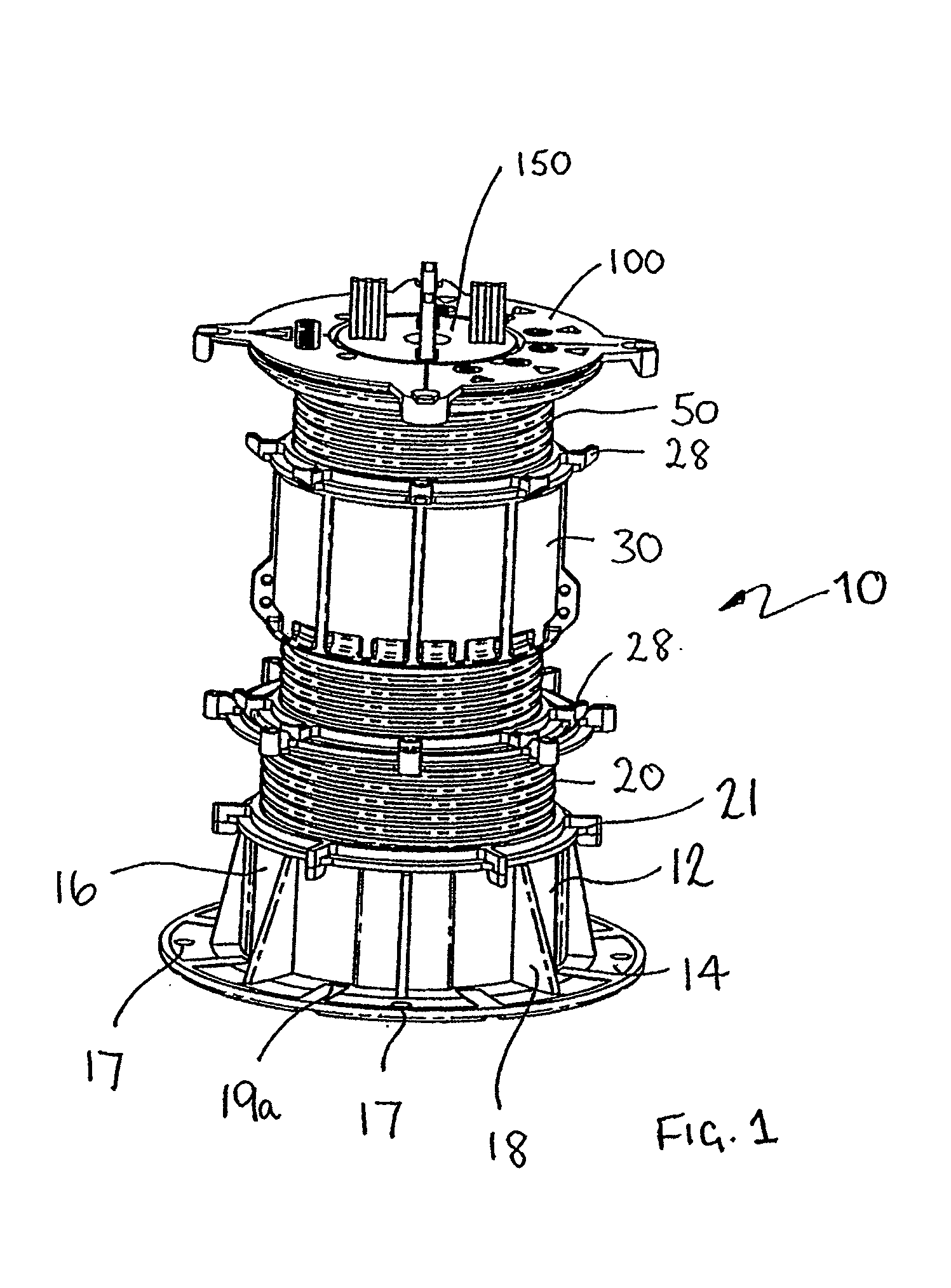

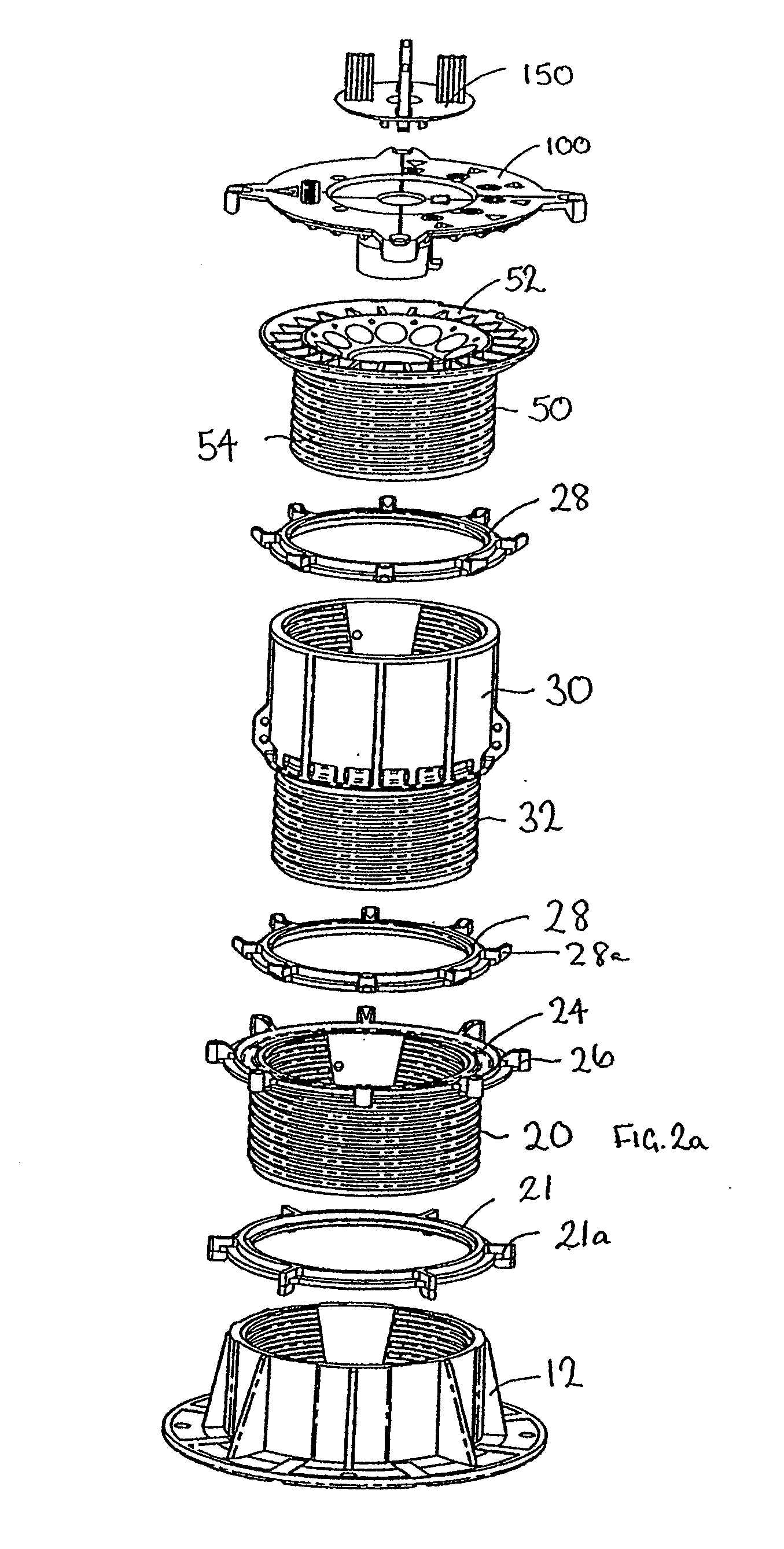

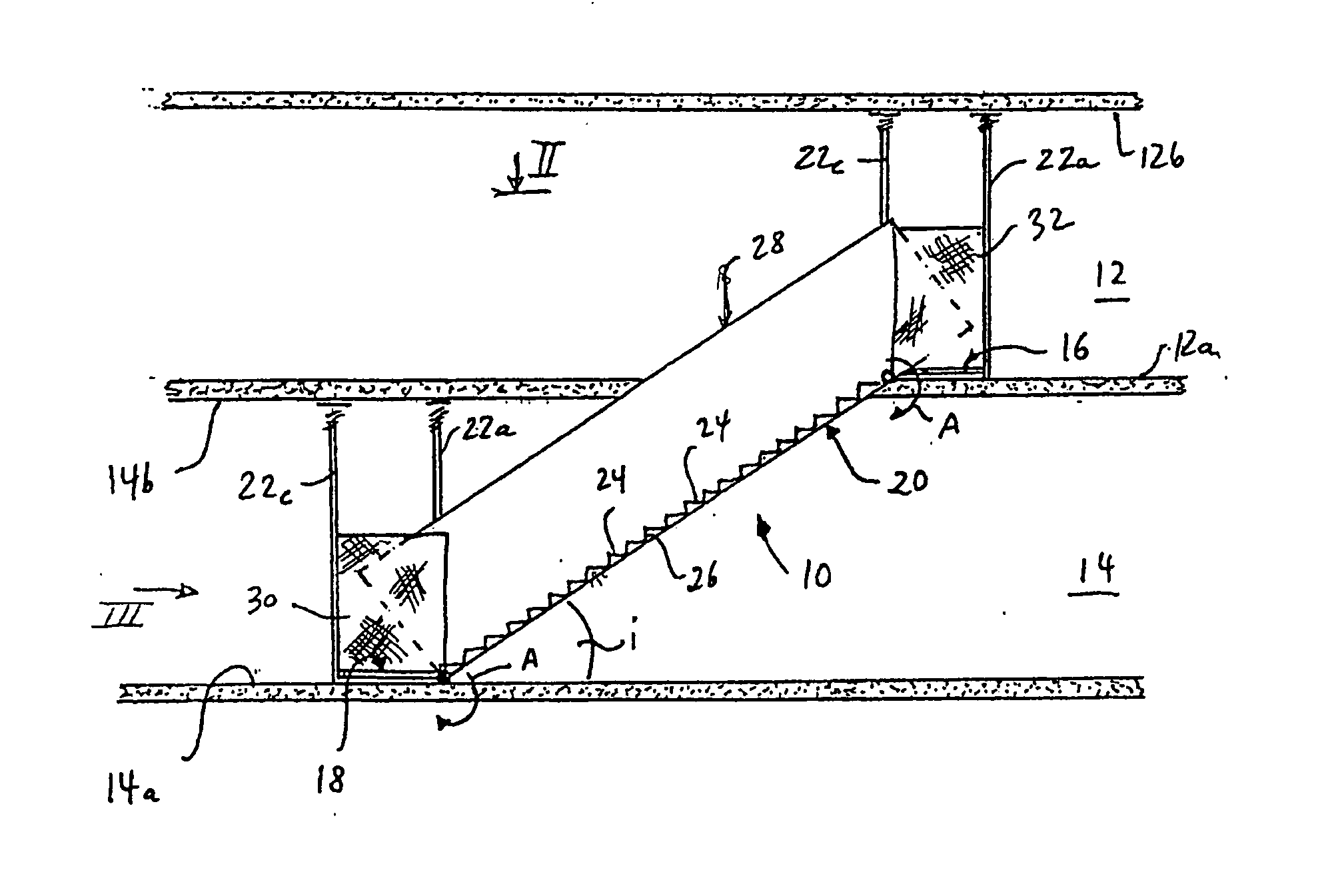

Slope compensator for pedestal for elevated floors

InactiveUS20080222973A1Reduce prevent relative movementImprove stabilityBuilding roofsCeilingsConvex sideEngineering

A slope adjustable head for an adjustable pedestal (10) for supporting beams, panel members, typically pavers, in accurate edge aligned relation, in a level plane is disclosed. The pedestal (10) includes a base block (12) and a series of inter-engaging threaded annular elements (20, 30) which can be rotated relative to each other to adjust the height of the top of the pedestal in a screw jack fashion. A slope compensator is located at the top of the pedestal and comprises a slope compensation plate (100) and a head member (50). The head member (50) defines a concave surface having a defined radius of curvature. The slope compensation plate (100) defines a corresponding convex surface having the same radius of curvature and sits on top of the head member. The pedestal (10) is calibrated to allow adjustment for typically zero to five percent in one percent increments. The top member defines a central aperture (56) and a series of holes (72) arranged in a spiral around the central aperture. The adjustment member defines a depending central cylindrical portion (110) which locates in the central aperture (56) and two diametrically opposed depending pegs (132, 134) spaced either side of the central cylindrical portion which locate in the holes of the top member. Rotation of the slope compensation plate (100) about its centre of curvature causes the angle of the adjustment plate relative to the vertical axis to change thus allowing for compensation for the slope of the surface on which the pedestal is standing.

Owner:LEE IN OK

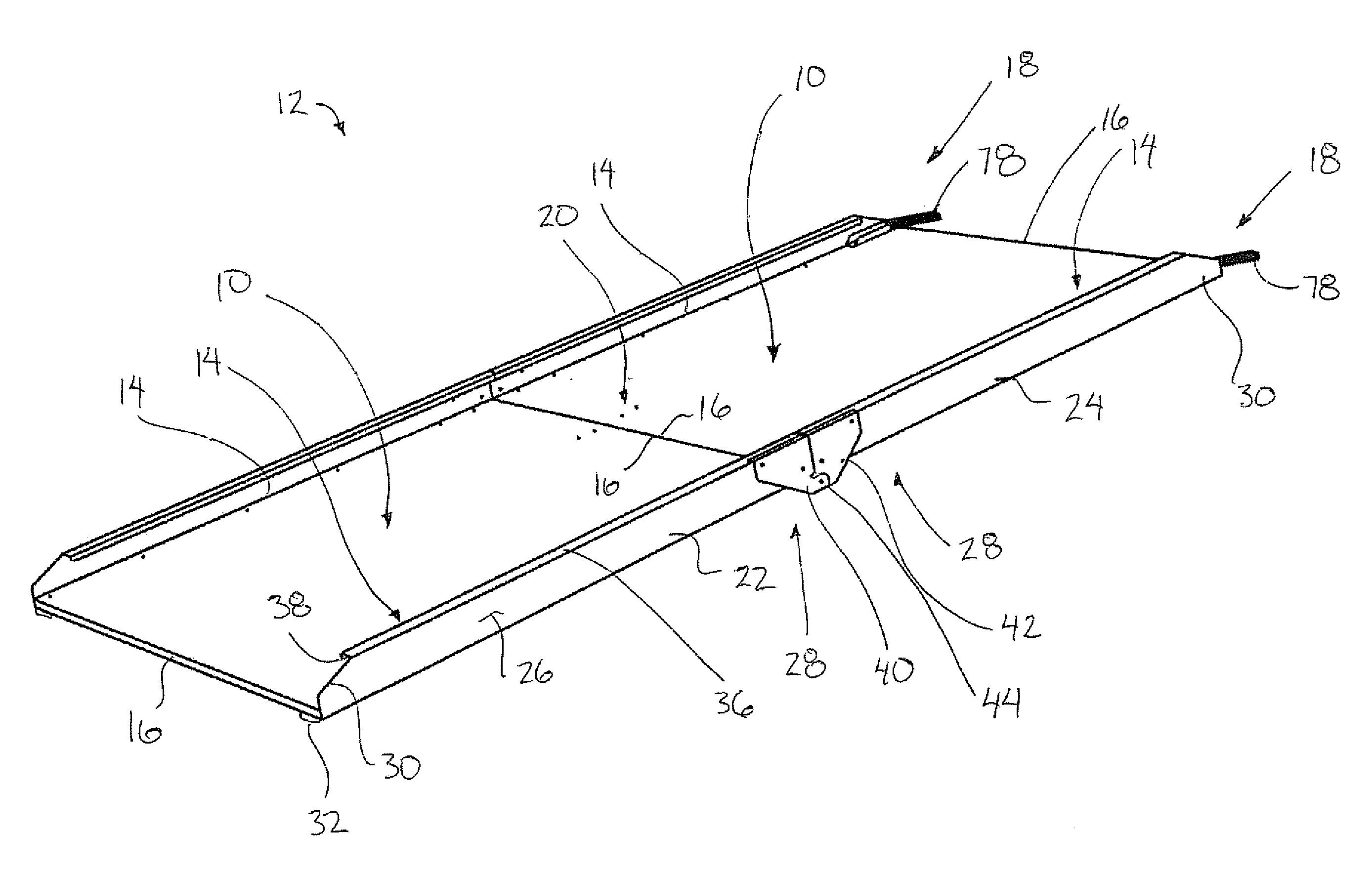

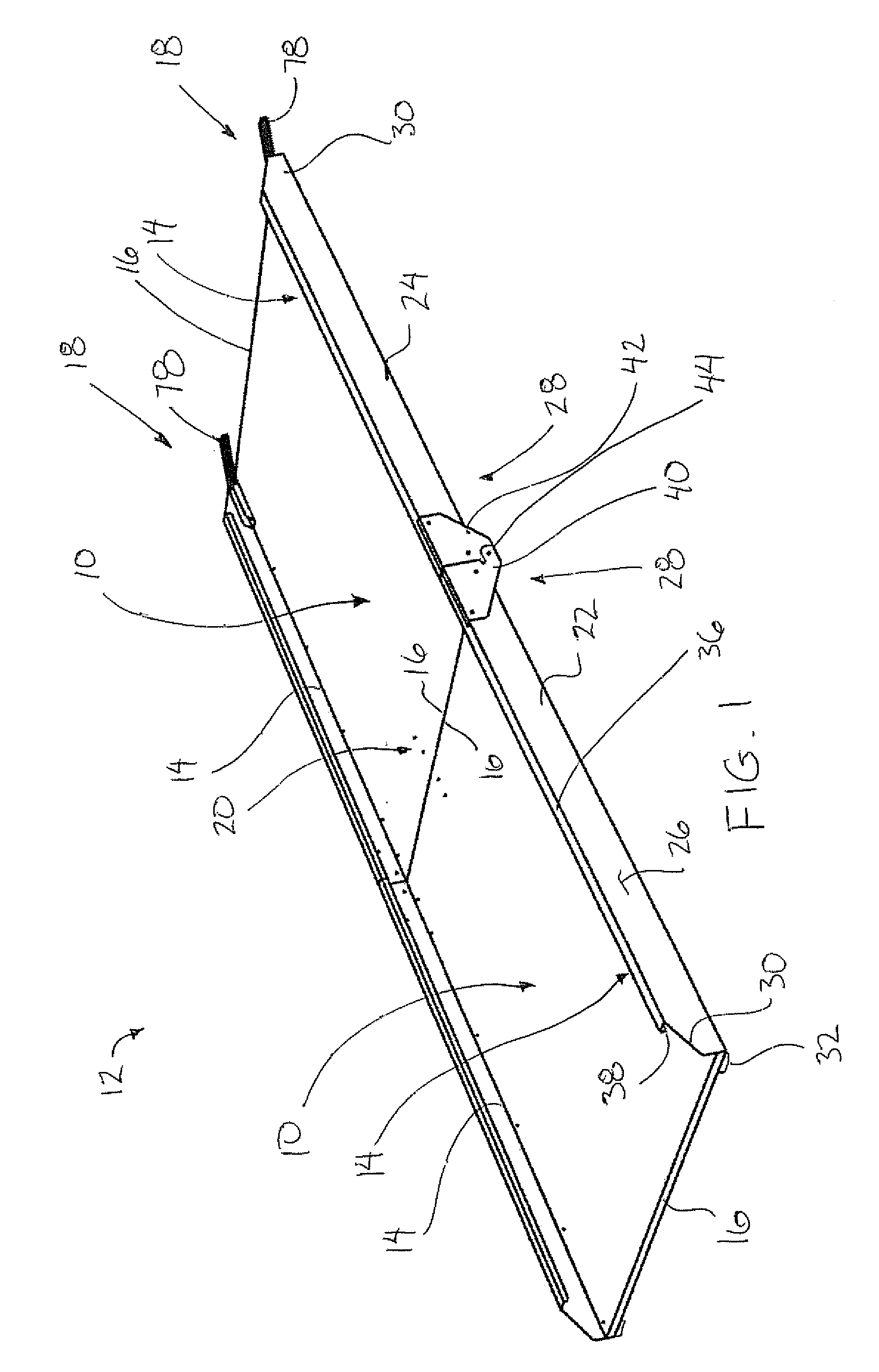

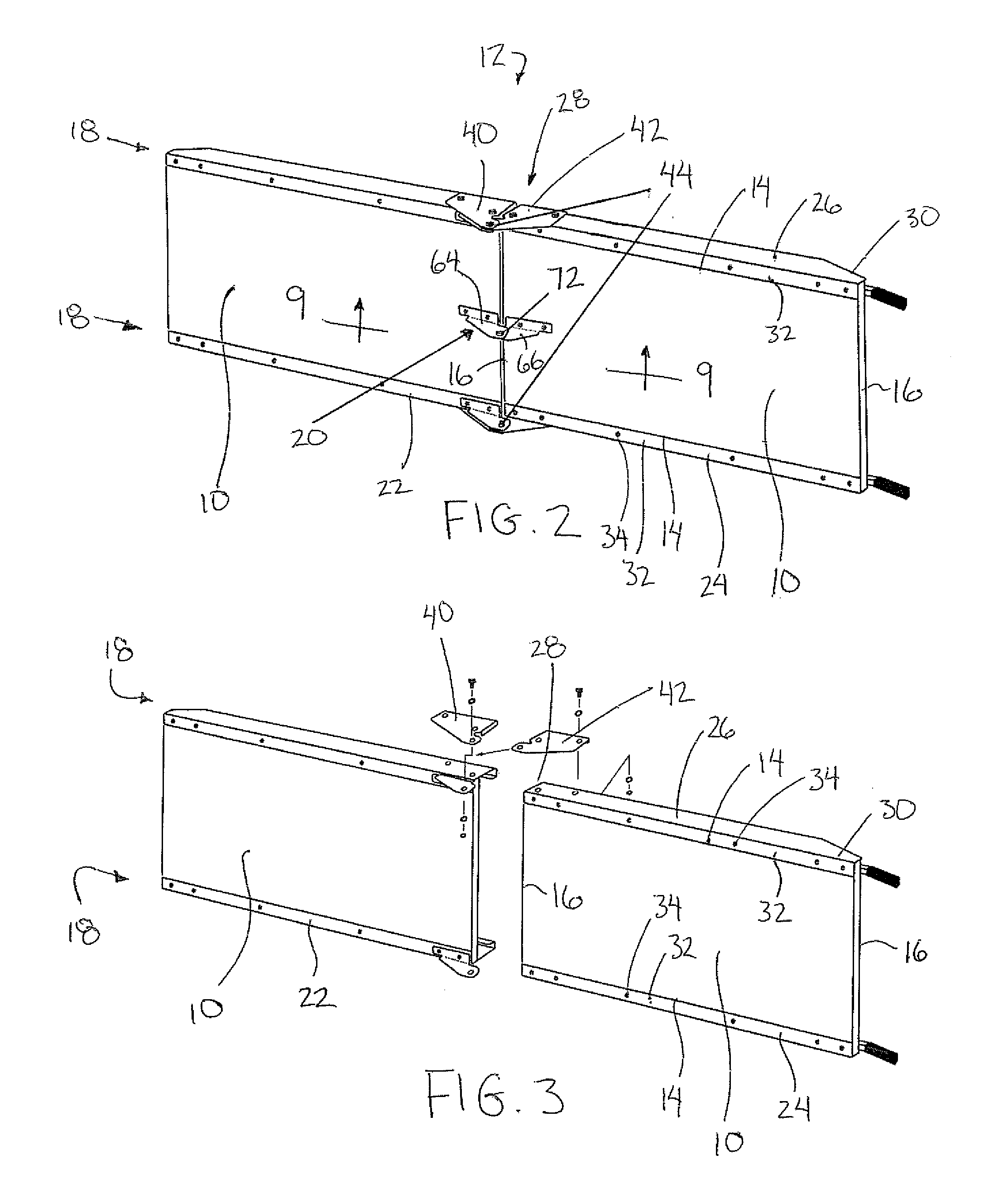

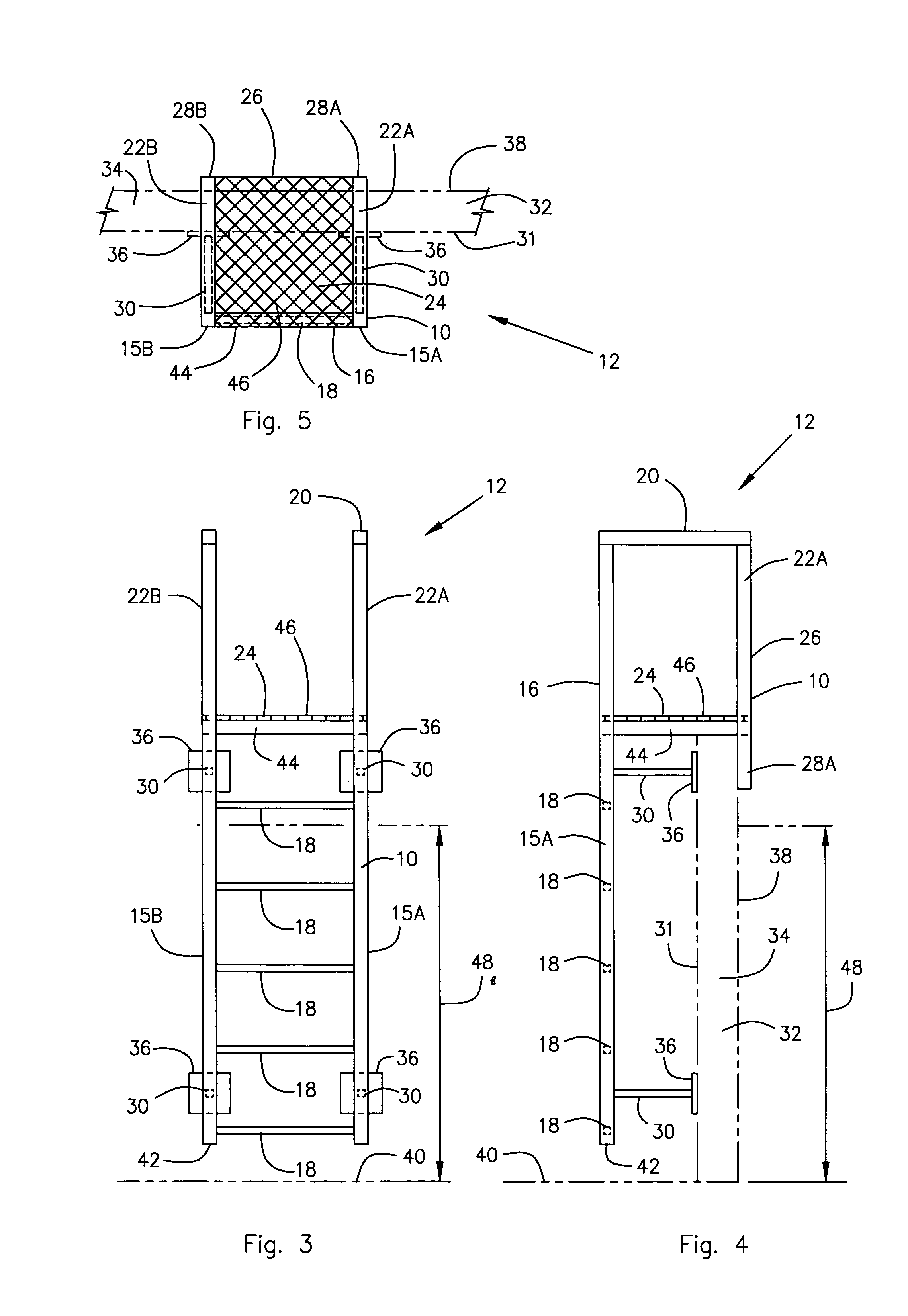

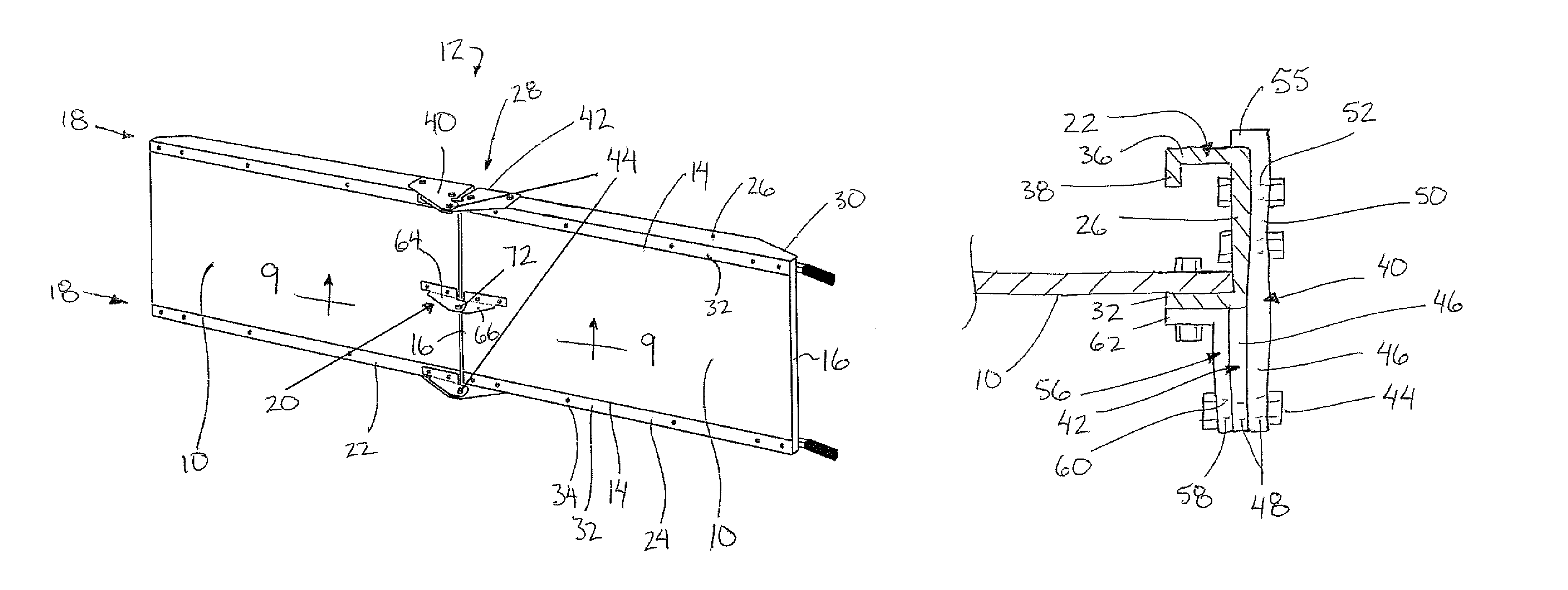

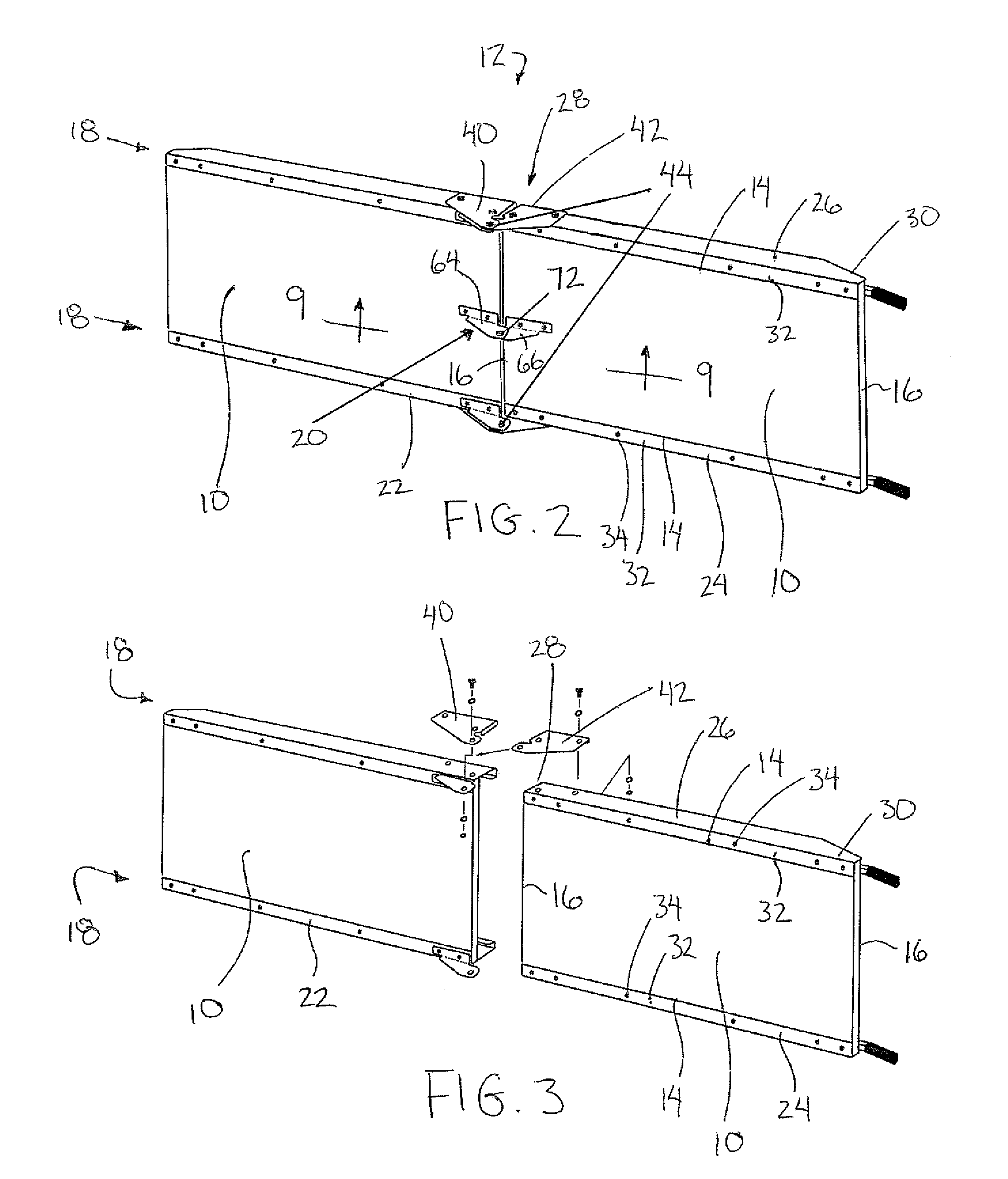

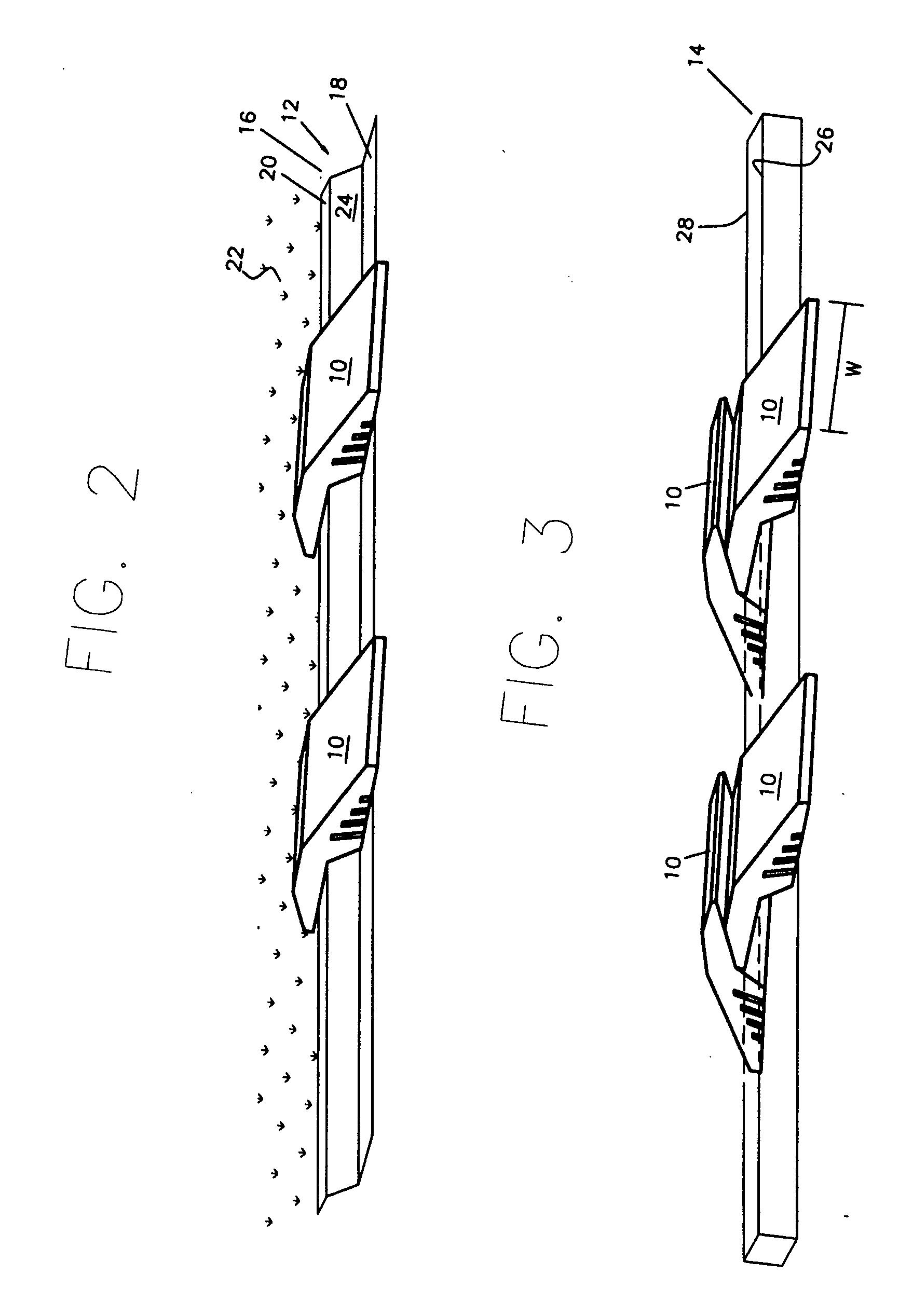

Hinged Ramp Assembly

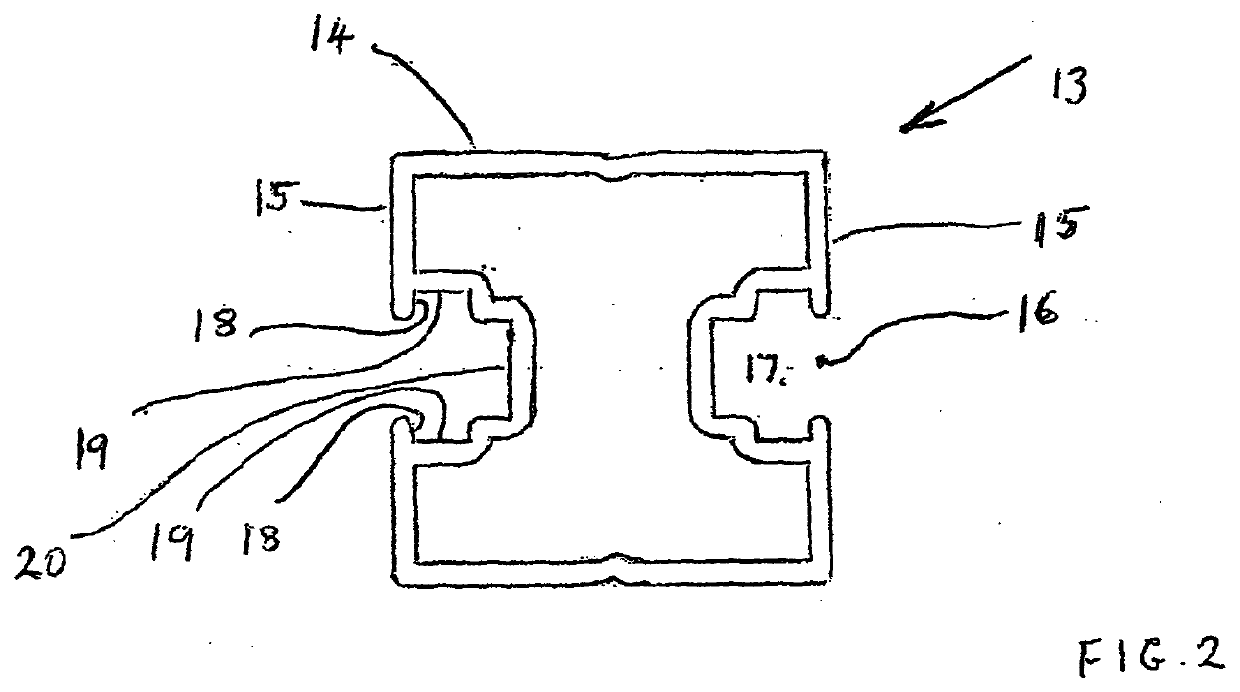

A ramp is assembled from first and second boards such that the first and second boards are foldable relative to one another. Rail assemblies comprising first and second channels are fastened along opposing sides of the boards. First and second hinge members, fastened to the sides of the first and second channels, pivotally couple the channels. Two central hinge members are mounted on the boards respectively to pivotally couple the boards at a central location between the opposing sides of the boards. An auxiliary hinge member is supported on the bottom of the first channels to provided added support to the pivotal coupling between the first and second channels. The auxiliary hinge member and the central hinge members are interchangeable with one another.

Owner:LUCHT DUANE

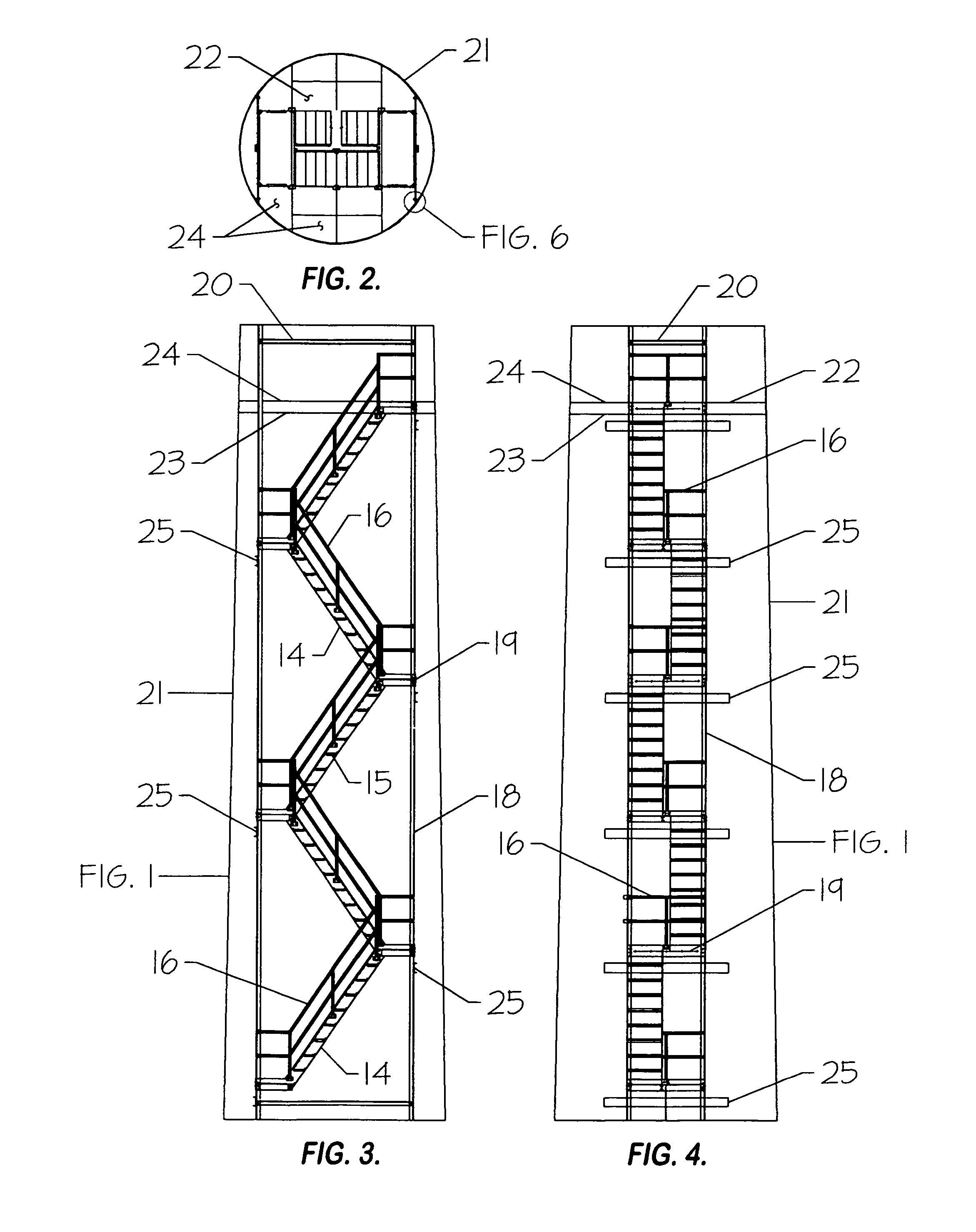

Trench shield ladder

Owner:INC O L S

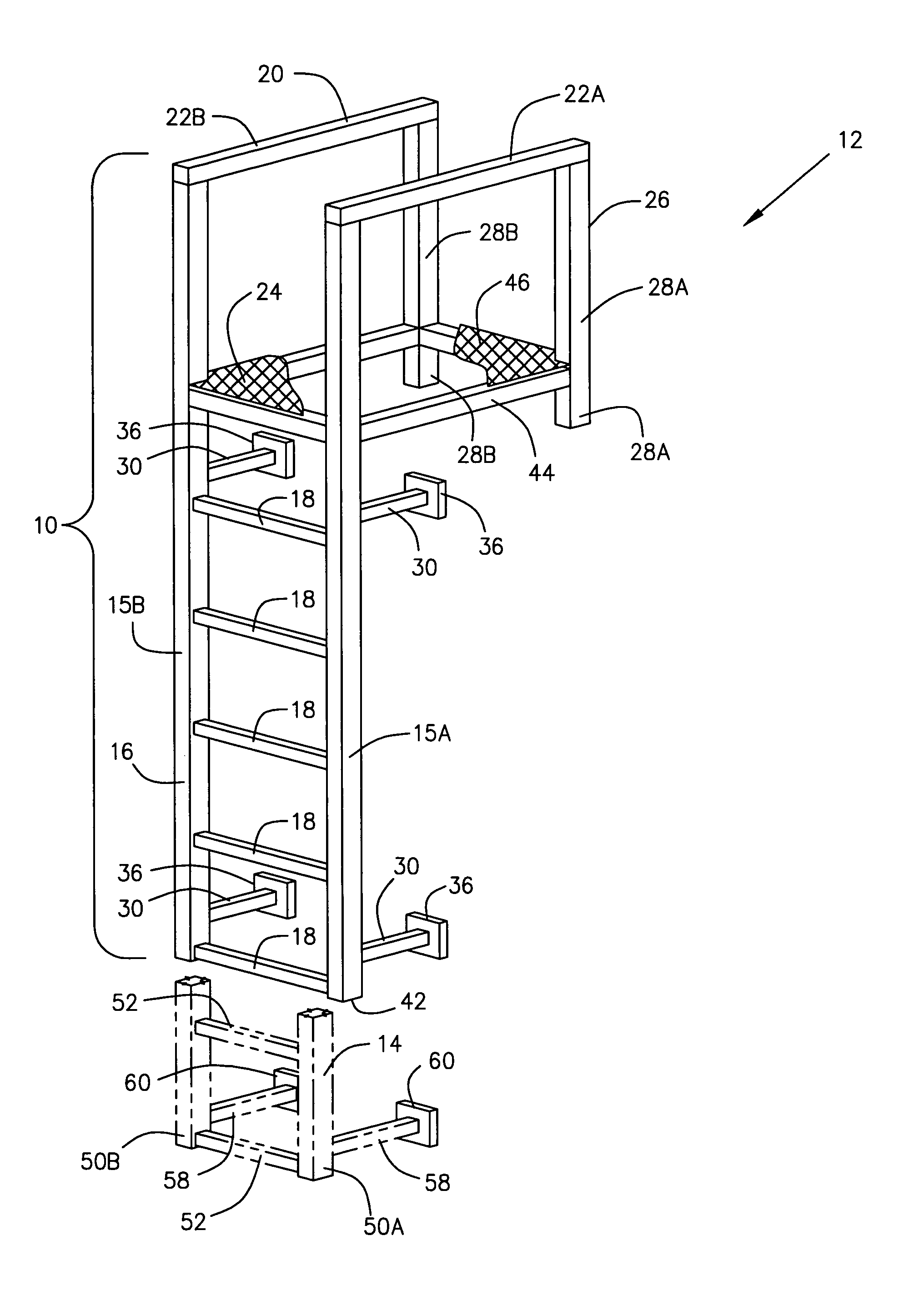

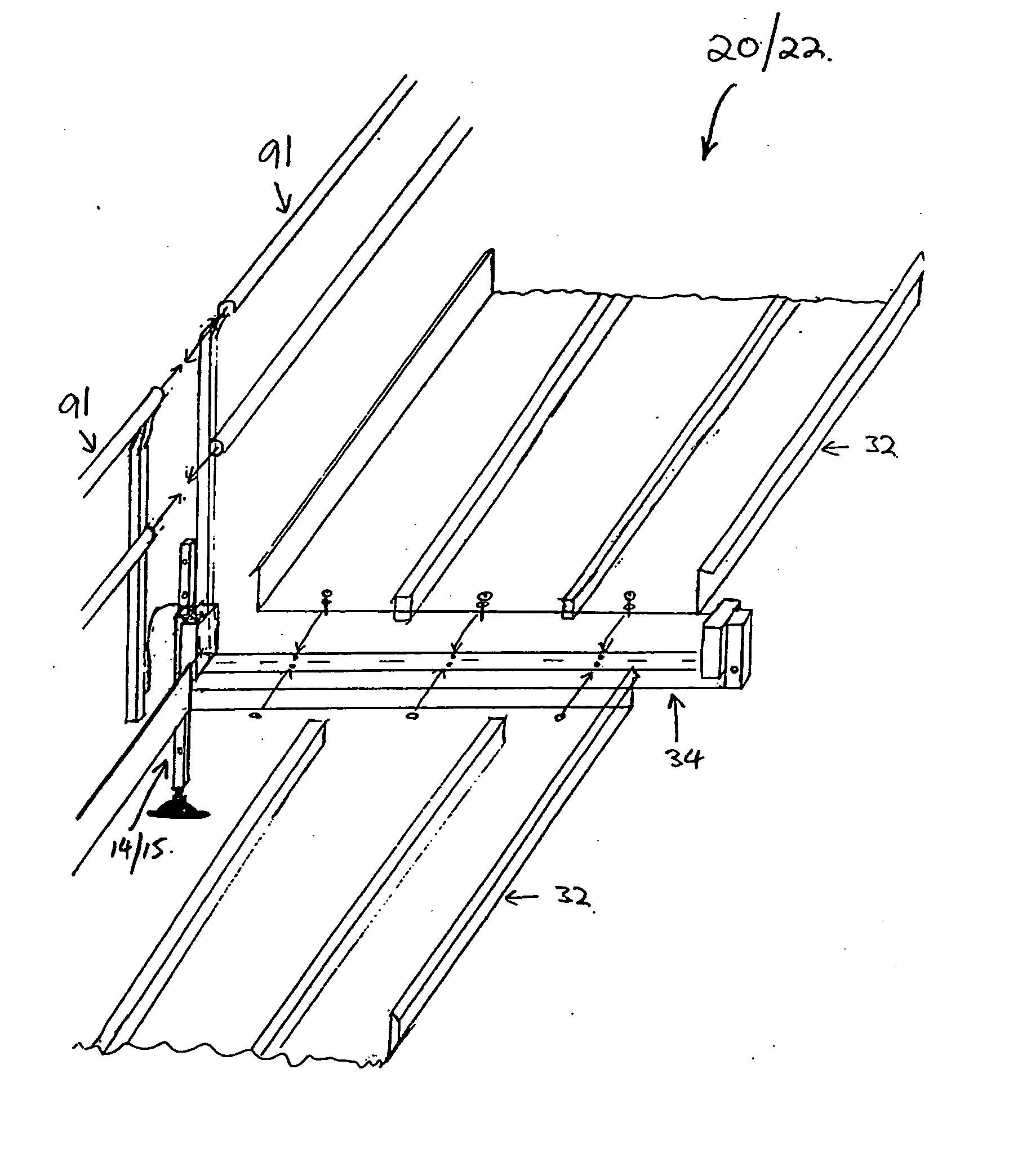

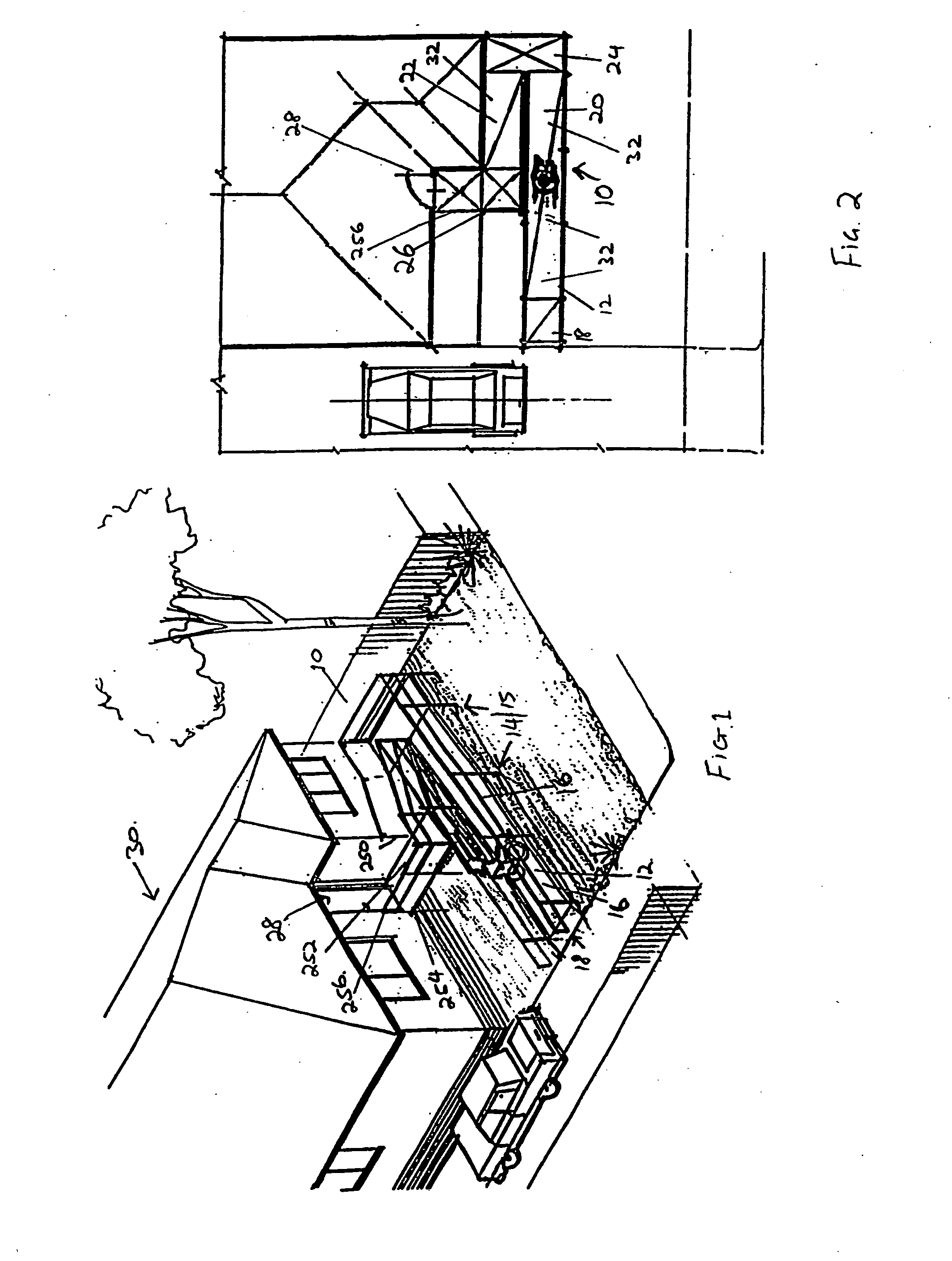

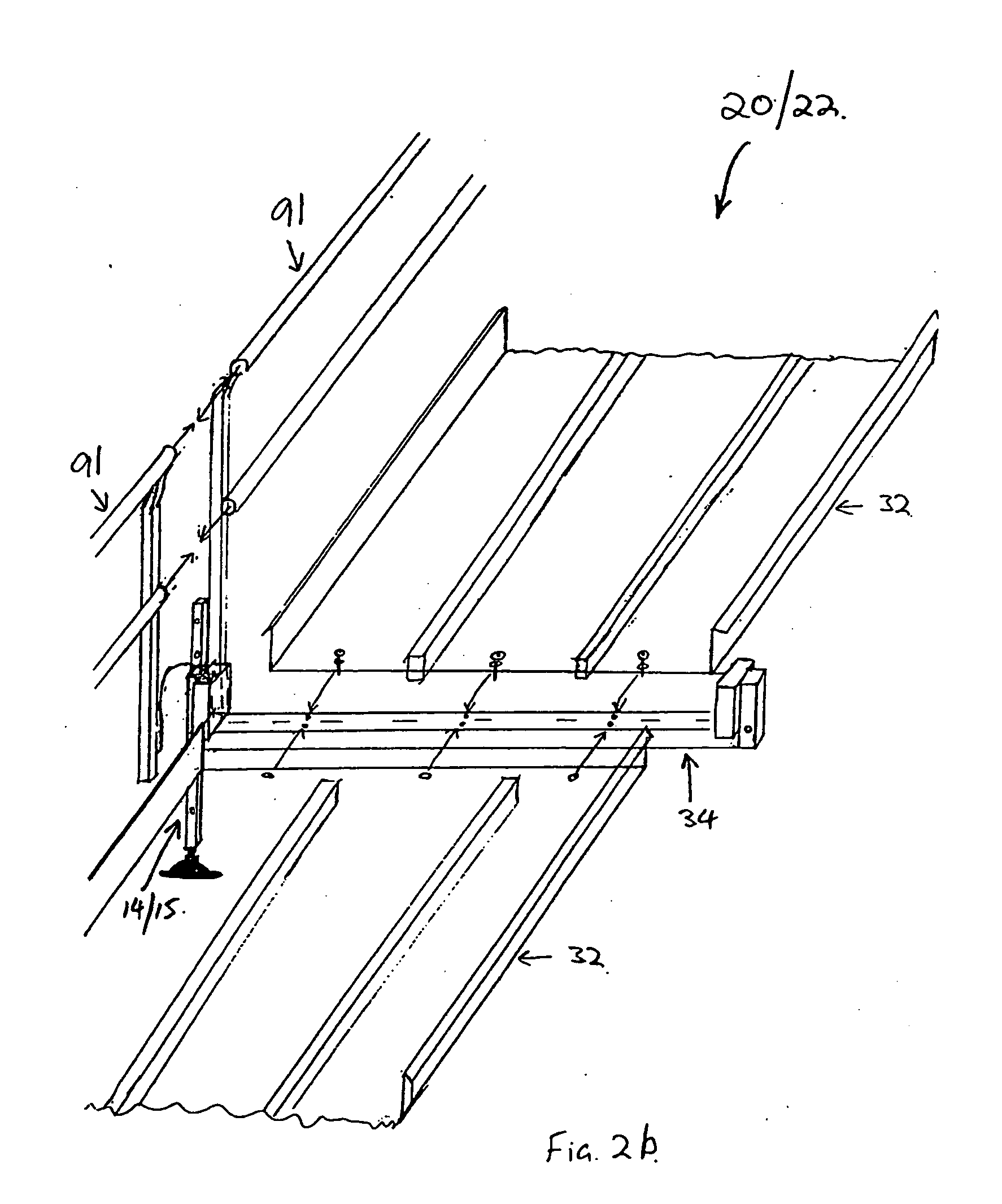

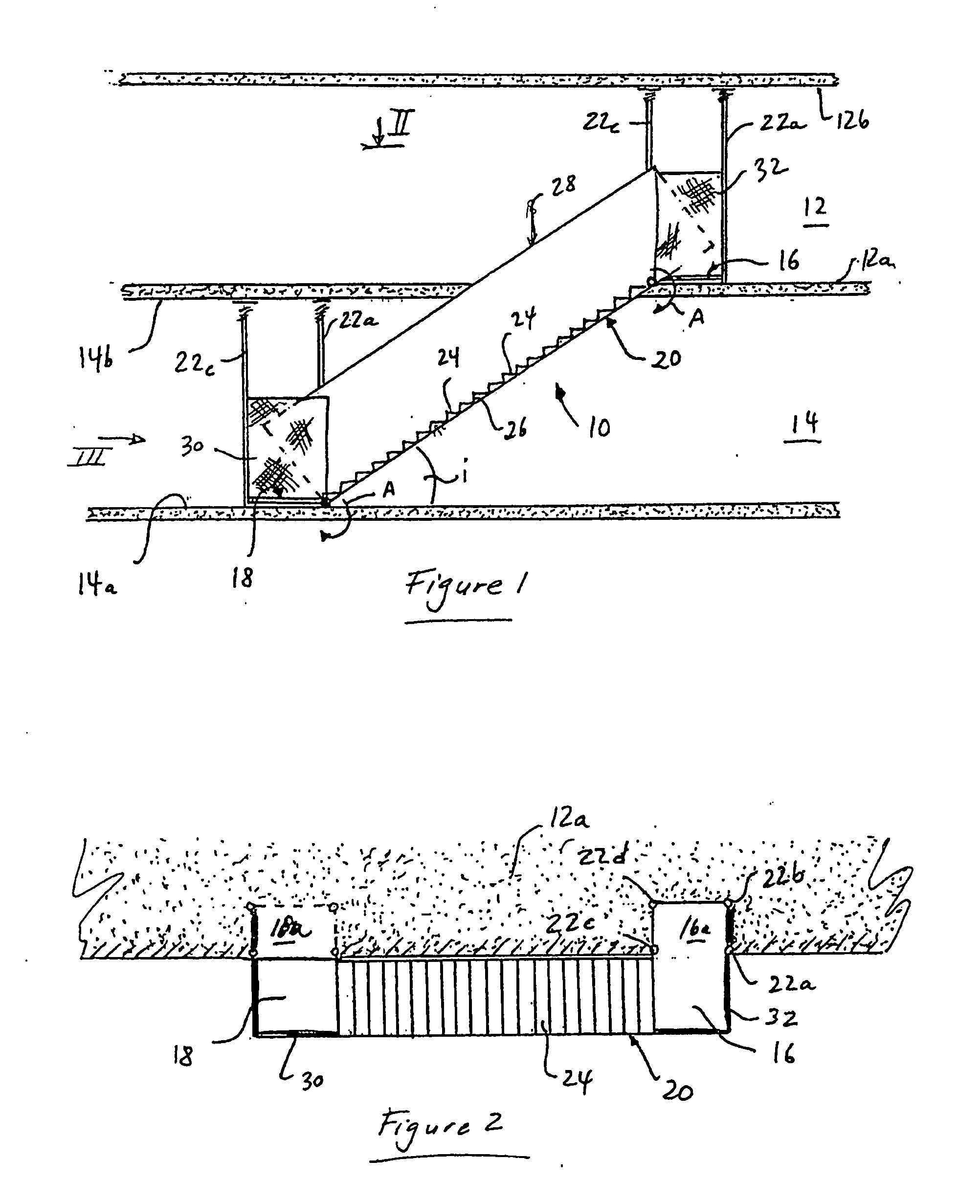

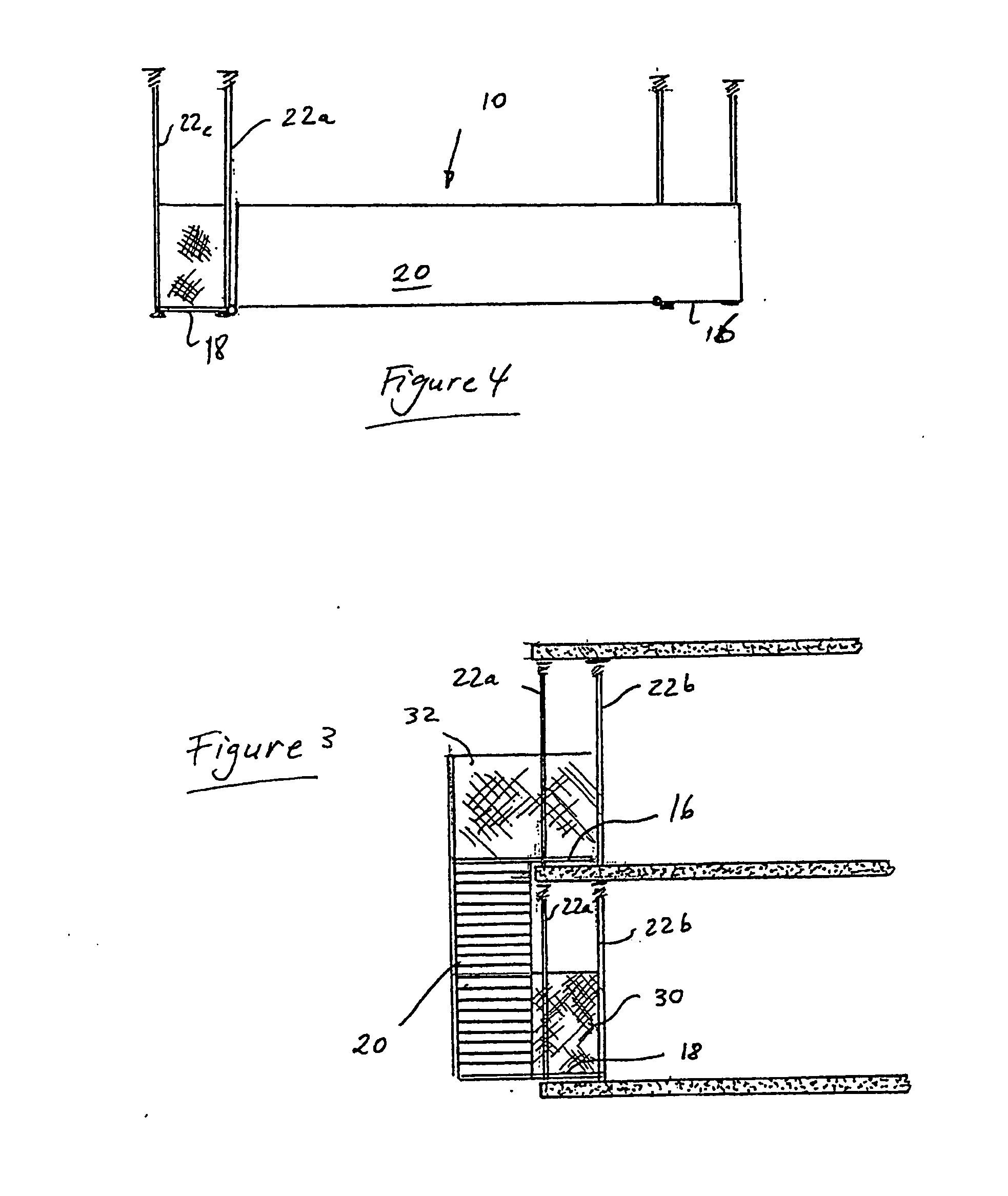

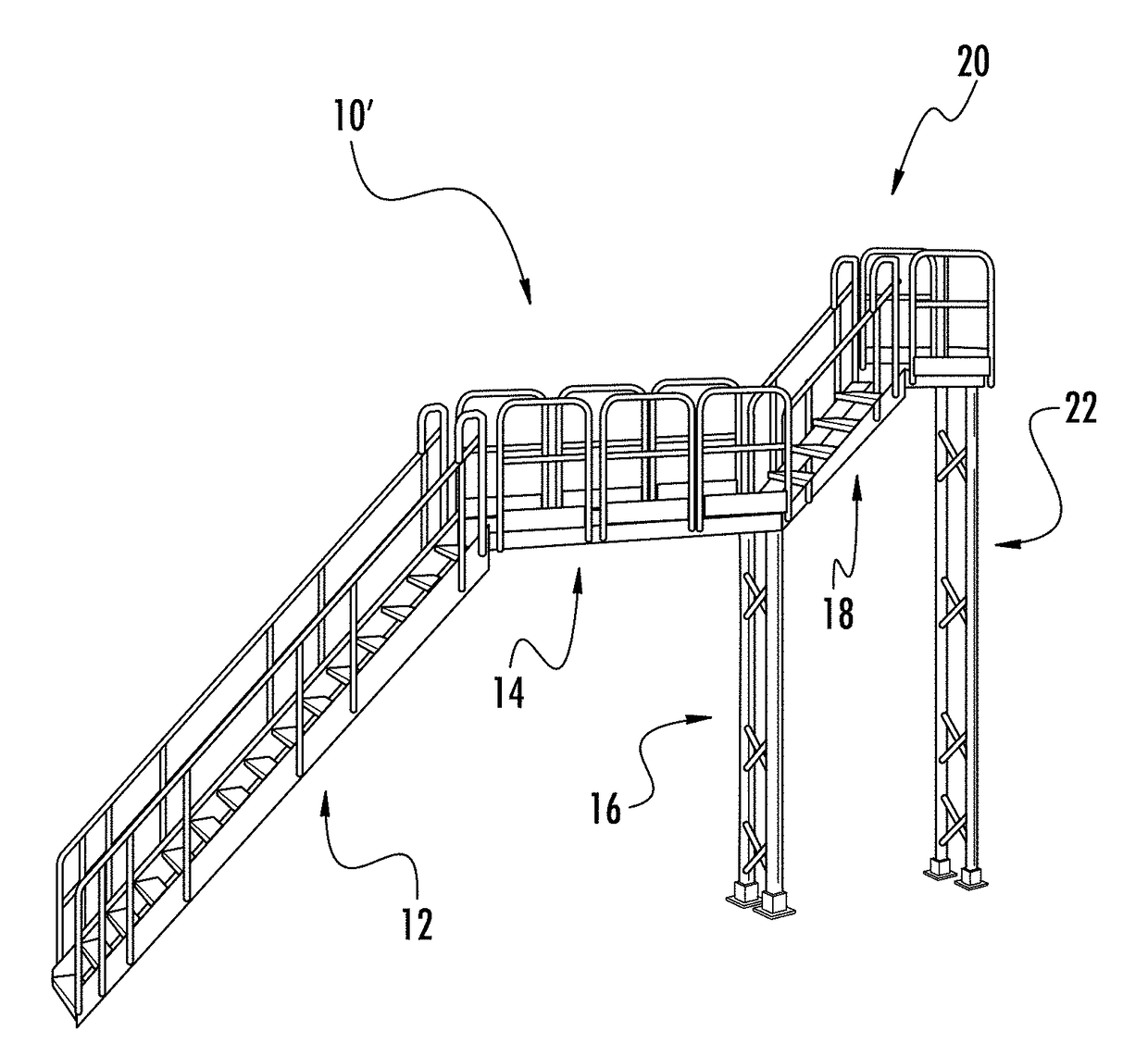

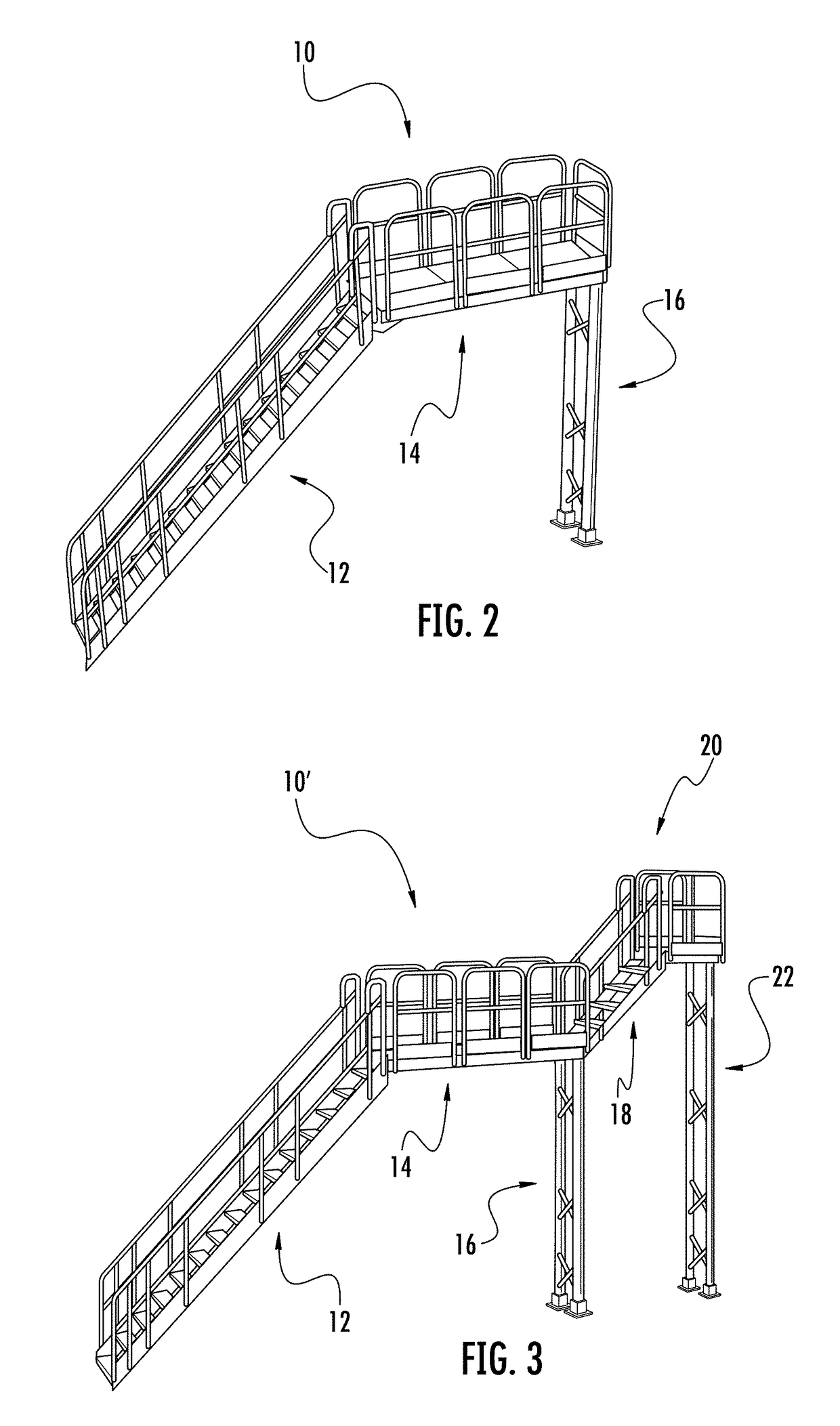

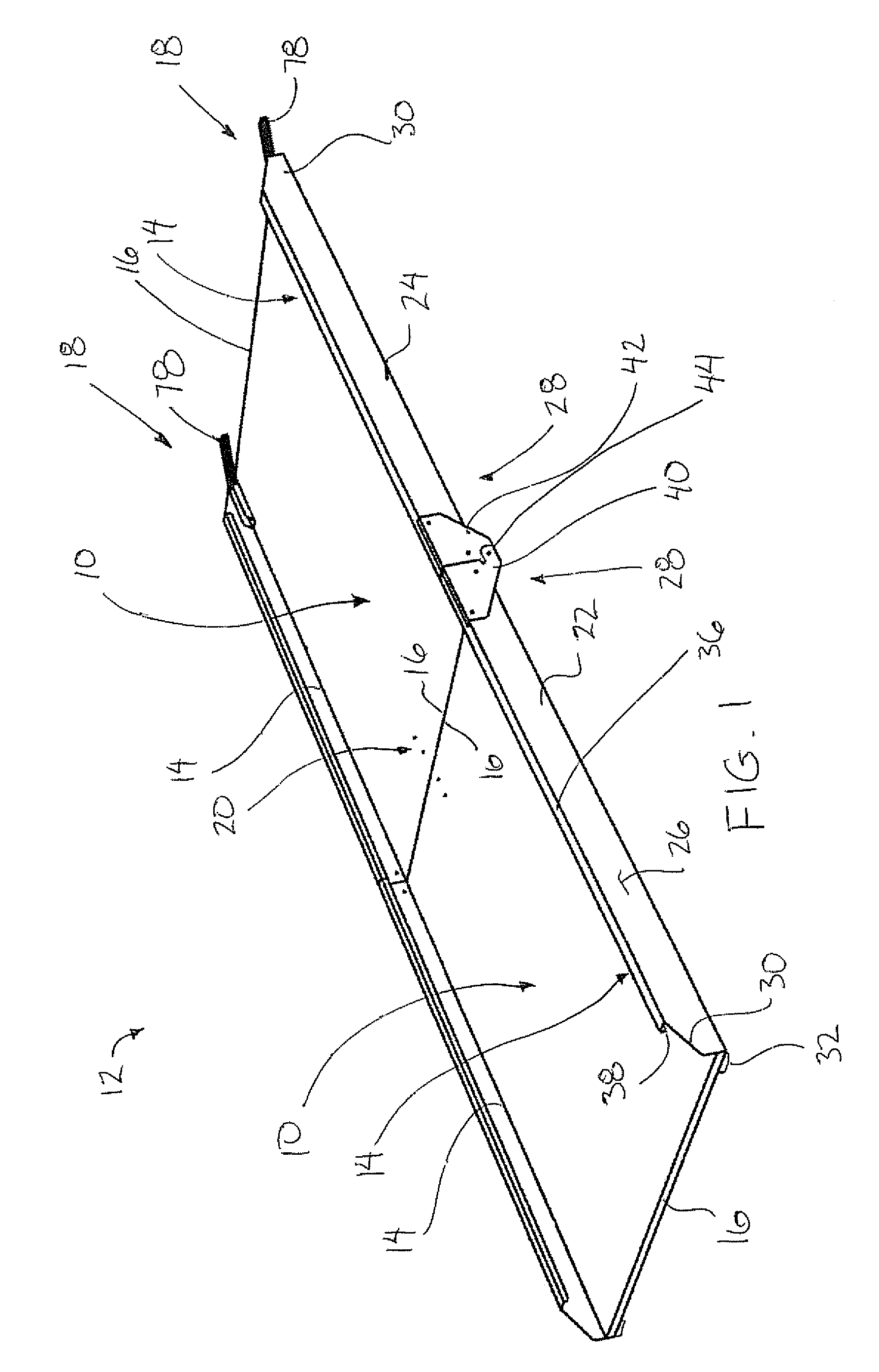

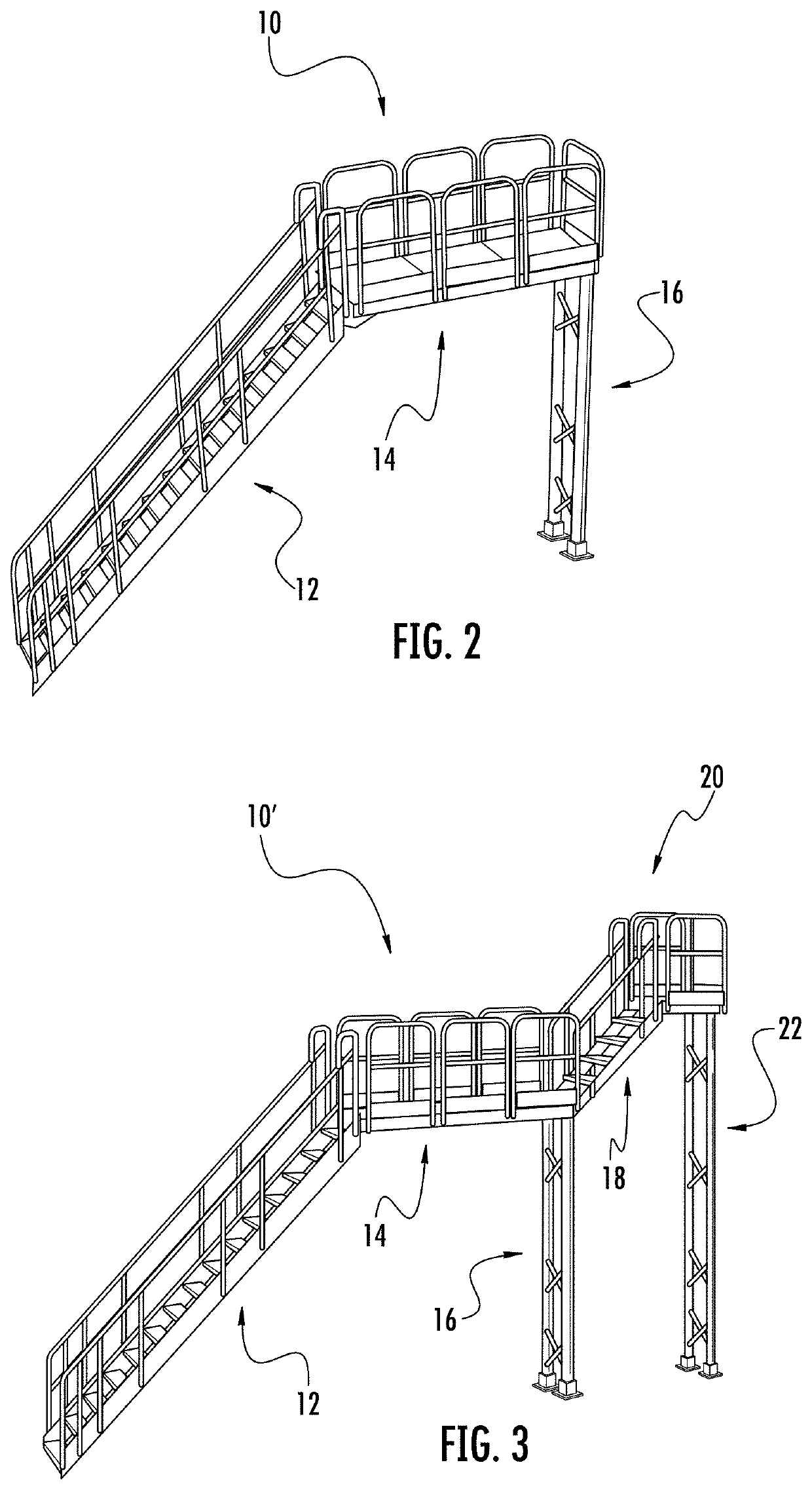

Modular platform, walkway or ramp

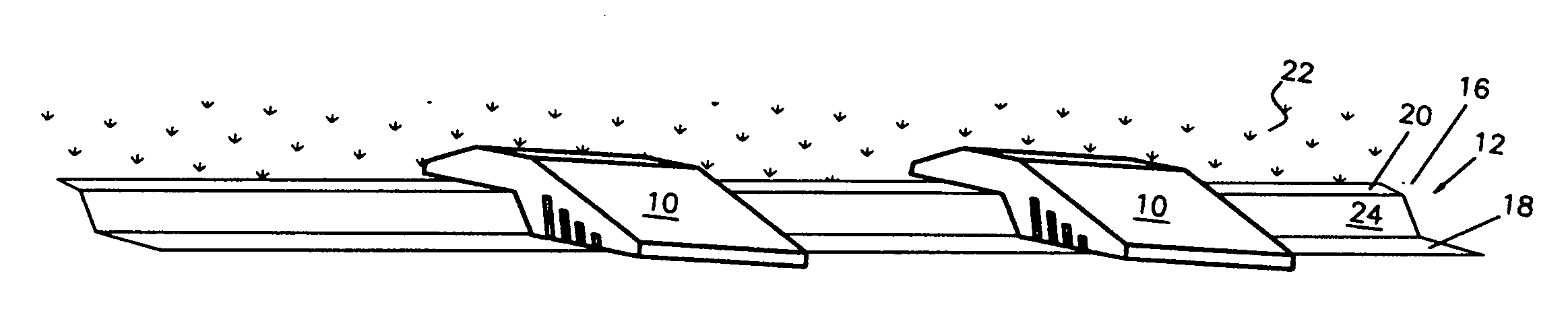

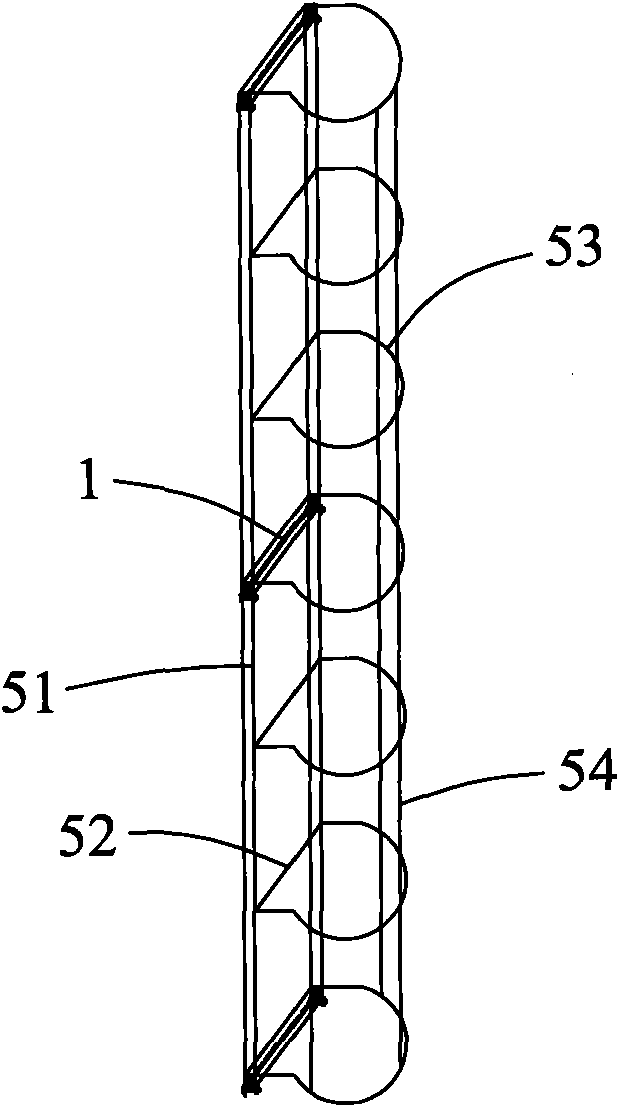

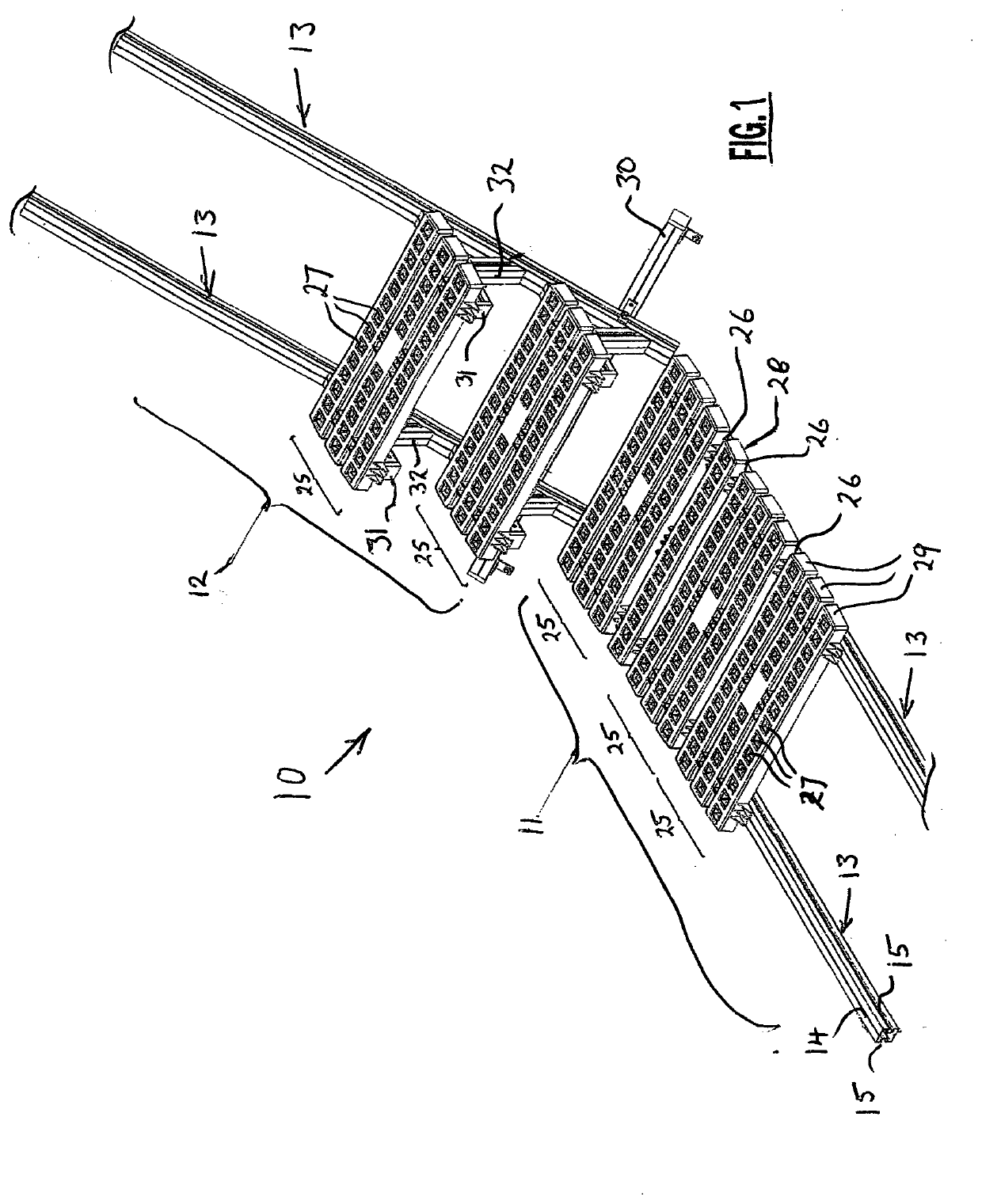

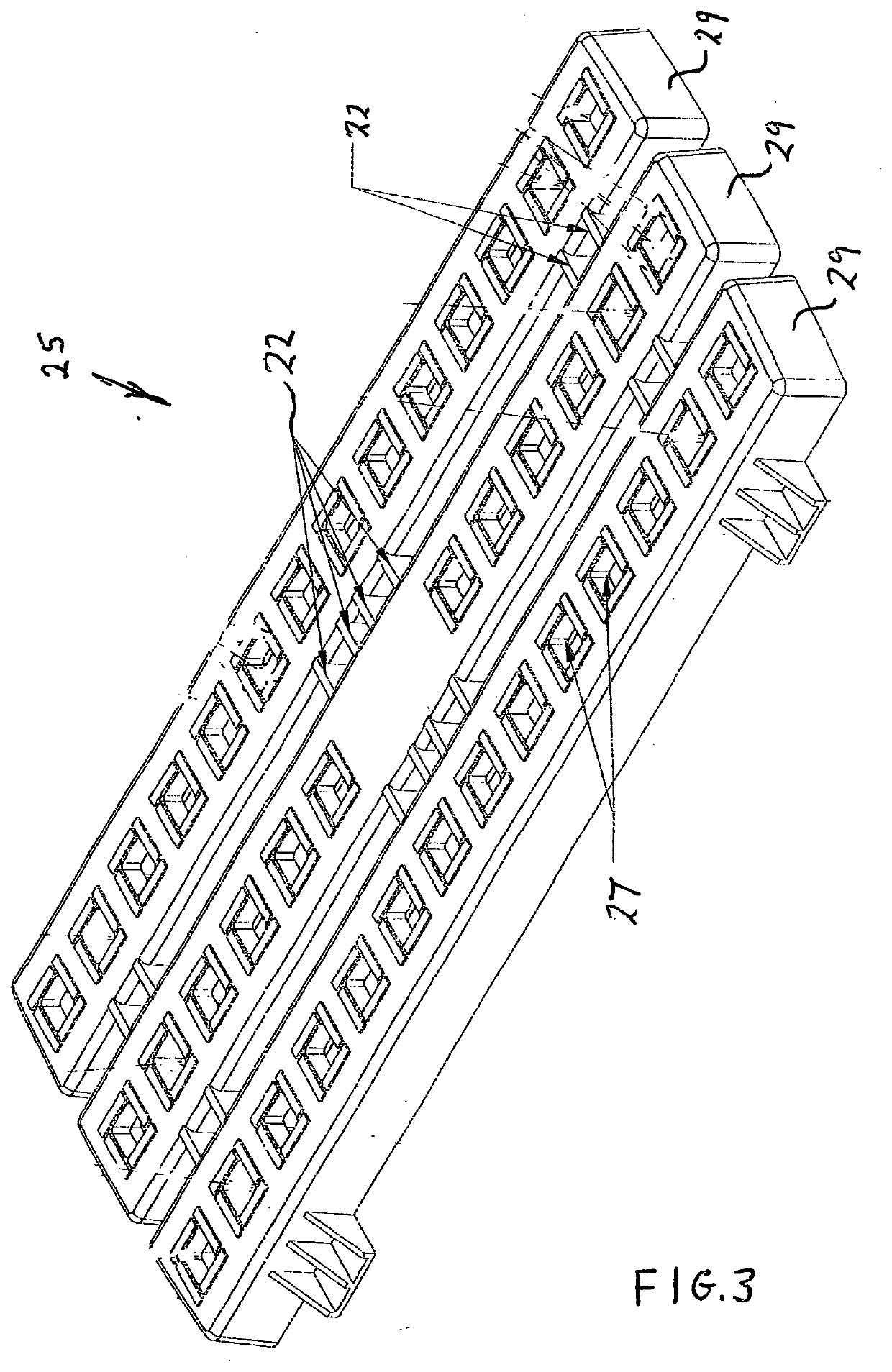

The present invention relates generally to a modular ramp (10) formed of prefabricated components. The modular ramp (10) includes a raked floor (12), elongate members in the form of floor pillars (14) and (15), and hand rails (16). The raked floor (12) is formed of a number prefabricated floor segments, an example of which are prefabricated floor panels (32) which extend between adjacent prefabricated floor bearers (34). The floor bearers (34) are supported by the floor pillars (14) and (15). The prefabricated floor bearers (34) have sleeves (56) and 58 attached at each end for respective receipt of the floor pillars (14) and (15). The pillars (14) and (15) are thus arranged for longitudinal movement relative to the sleeves such as (56) and locating pins (83) retain the pillars (14) or (15) relative to the sleeve (56).

Owner:SUGGATE TREVOR ROSS

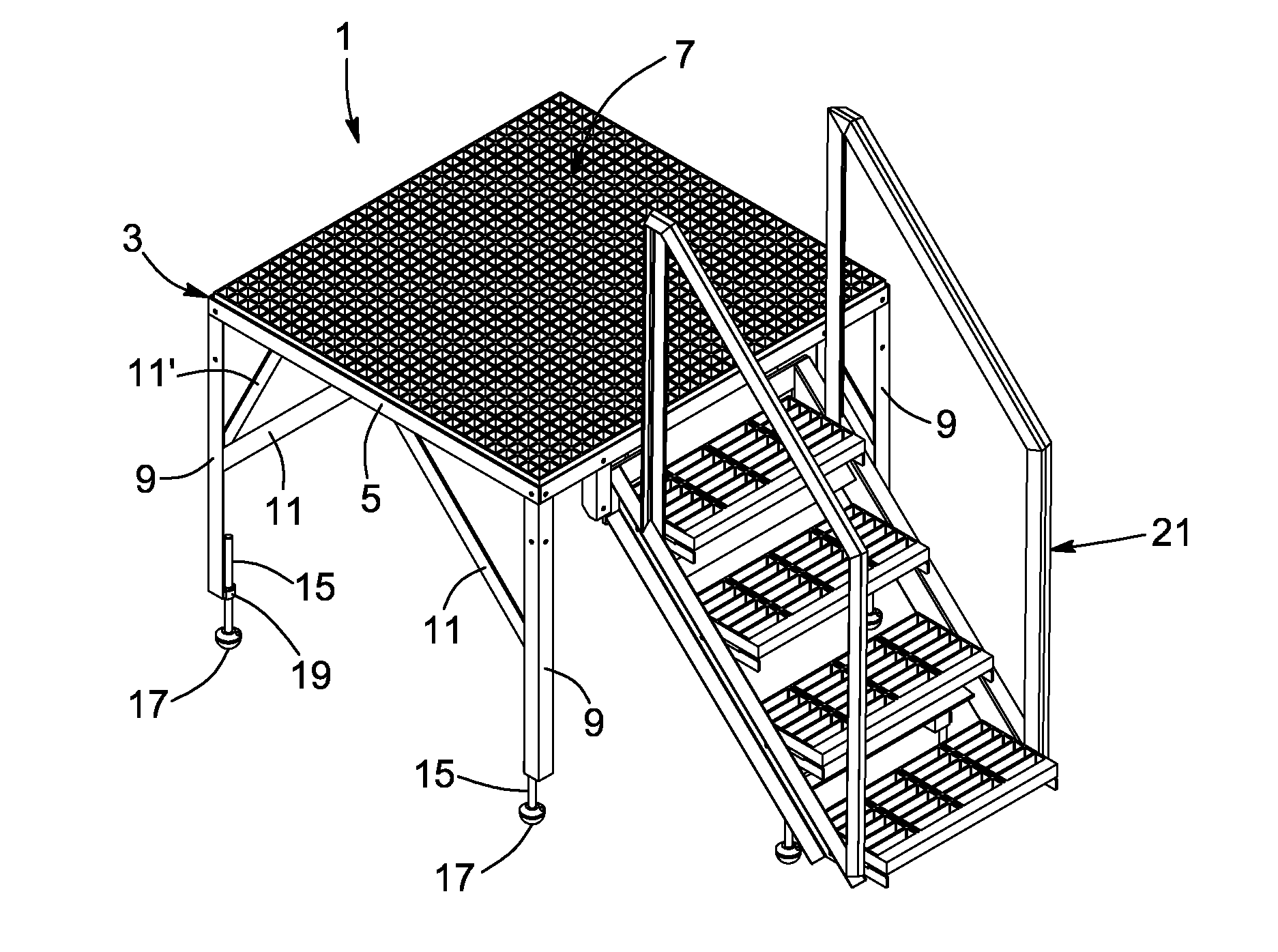

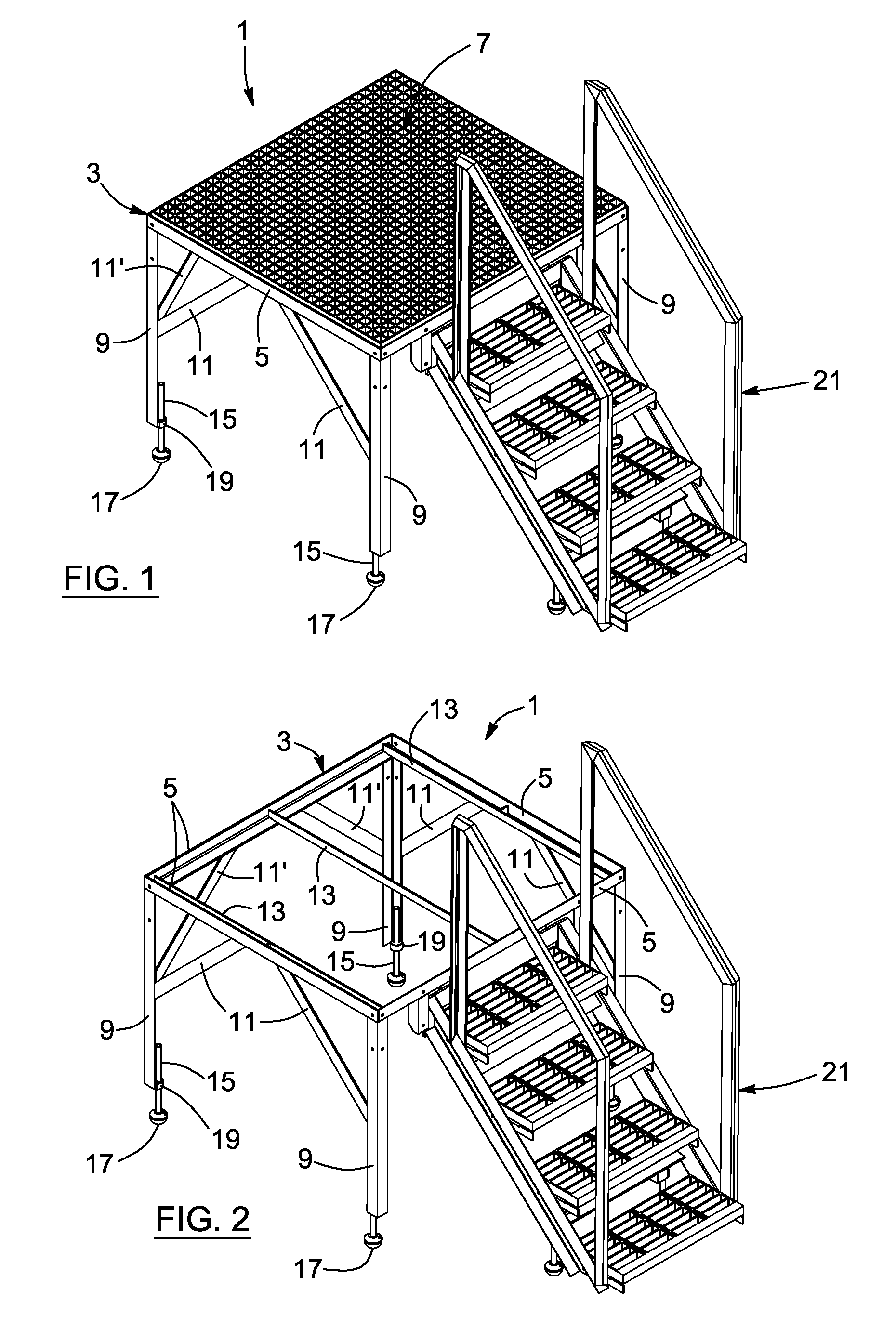

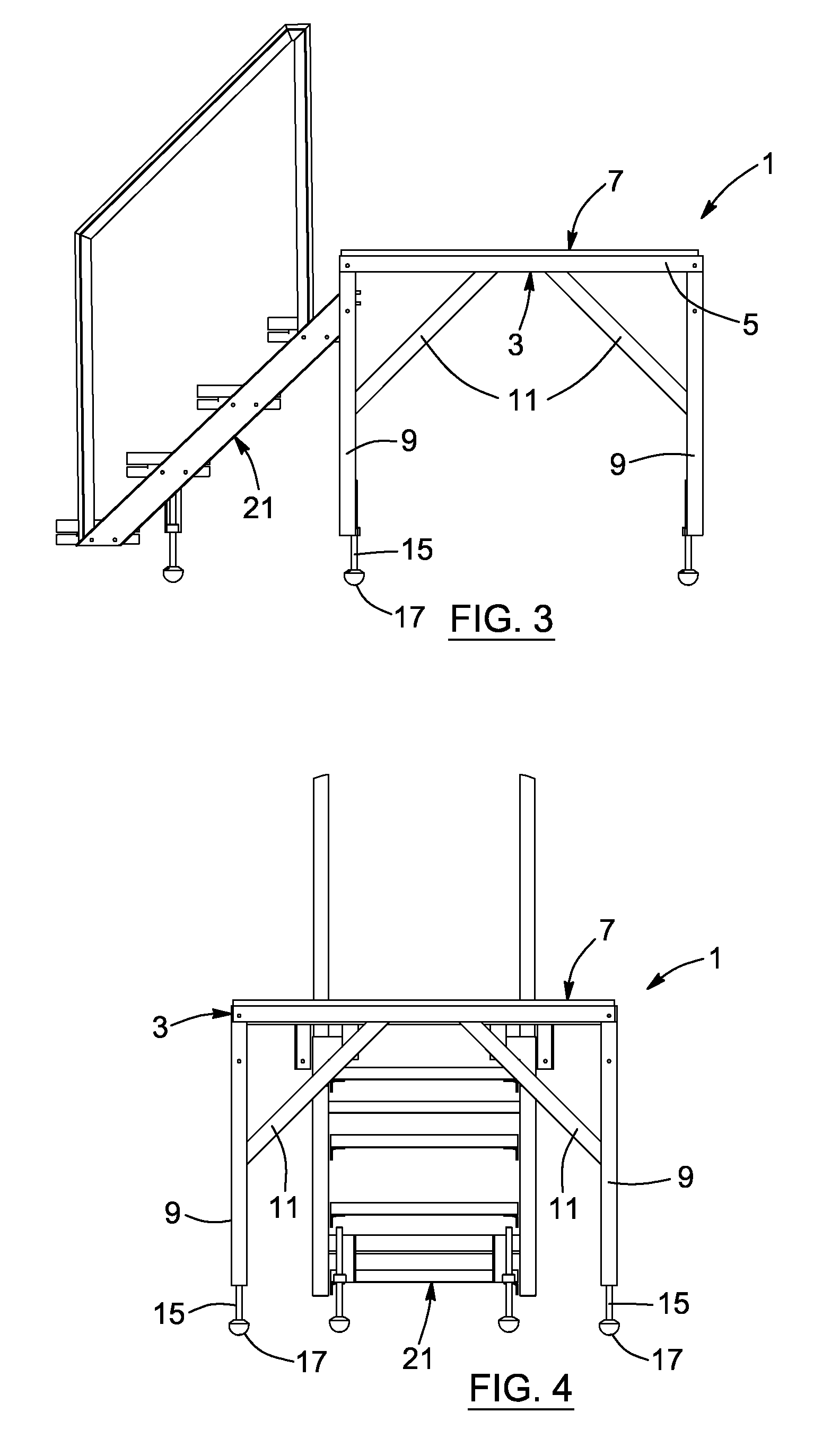

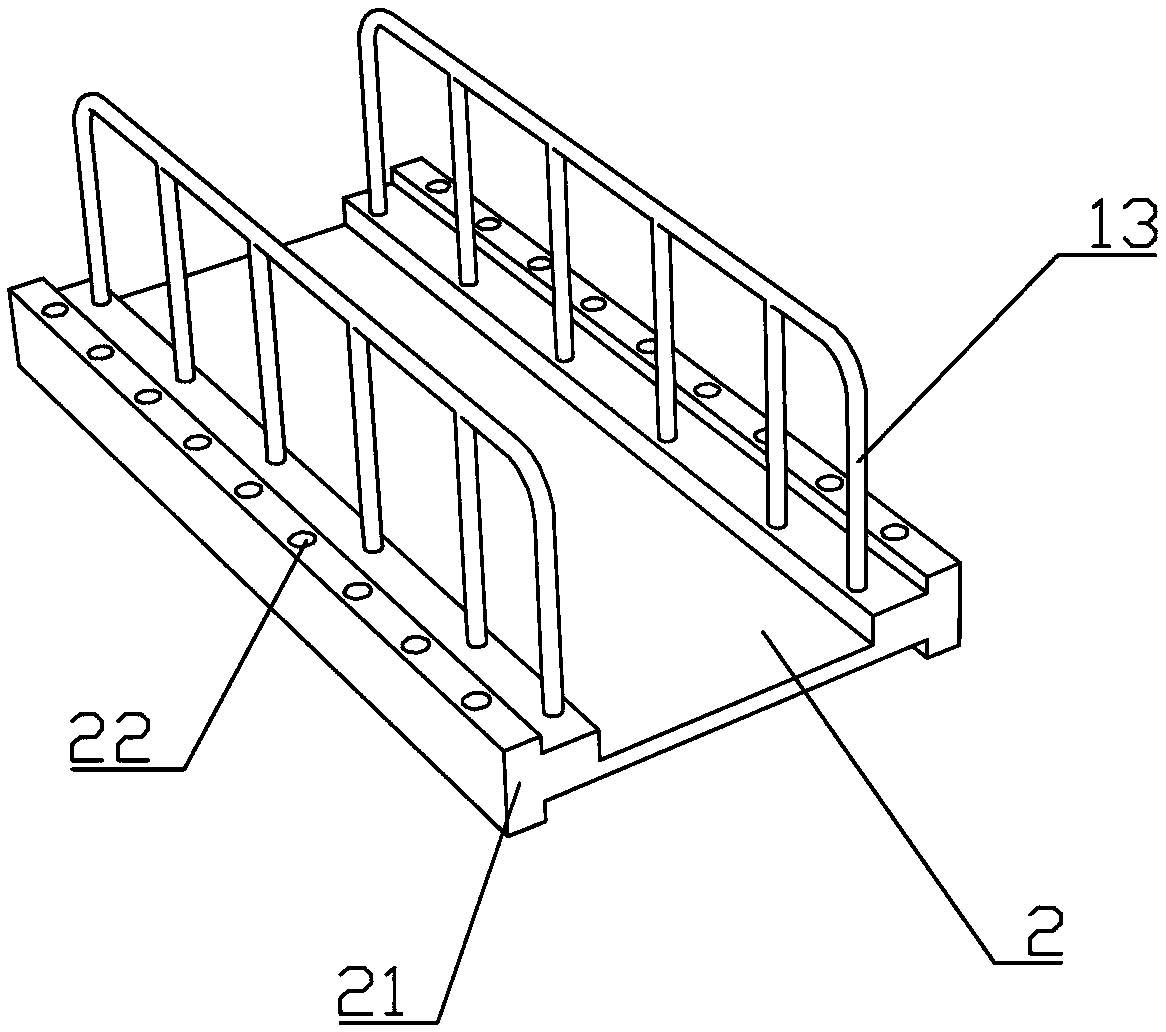

Modular platform

Owner:G E LEBLANC

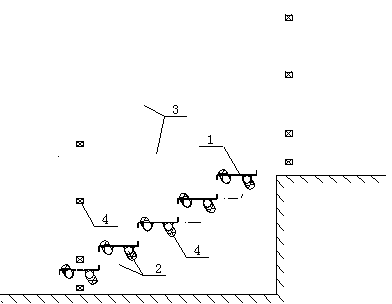

Stairway for Use on Building Sites

InactiveUS20100293875A1Low costAvoid damageGround installationsShaping building partsEngineeringCantilever

Owner:PRESTON JOHN CLEMENT

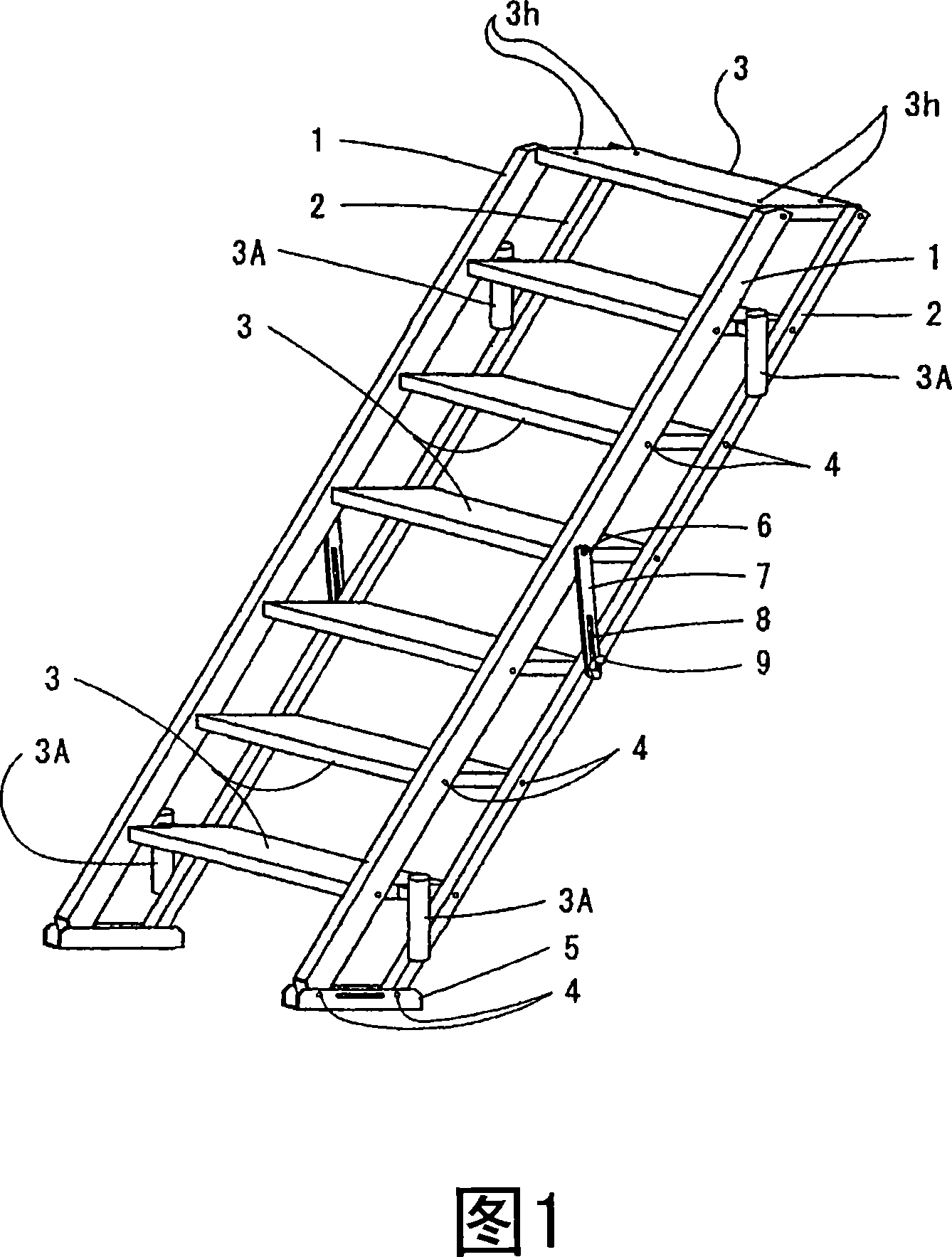

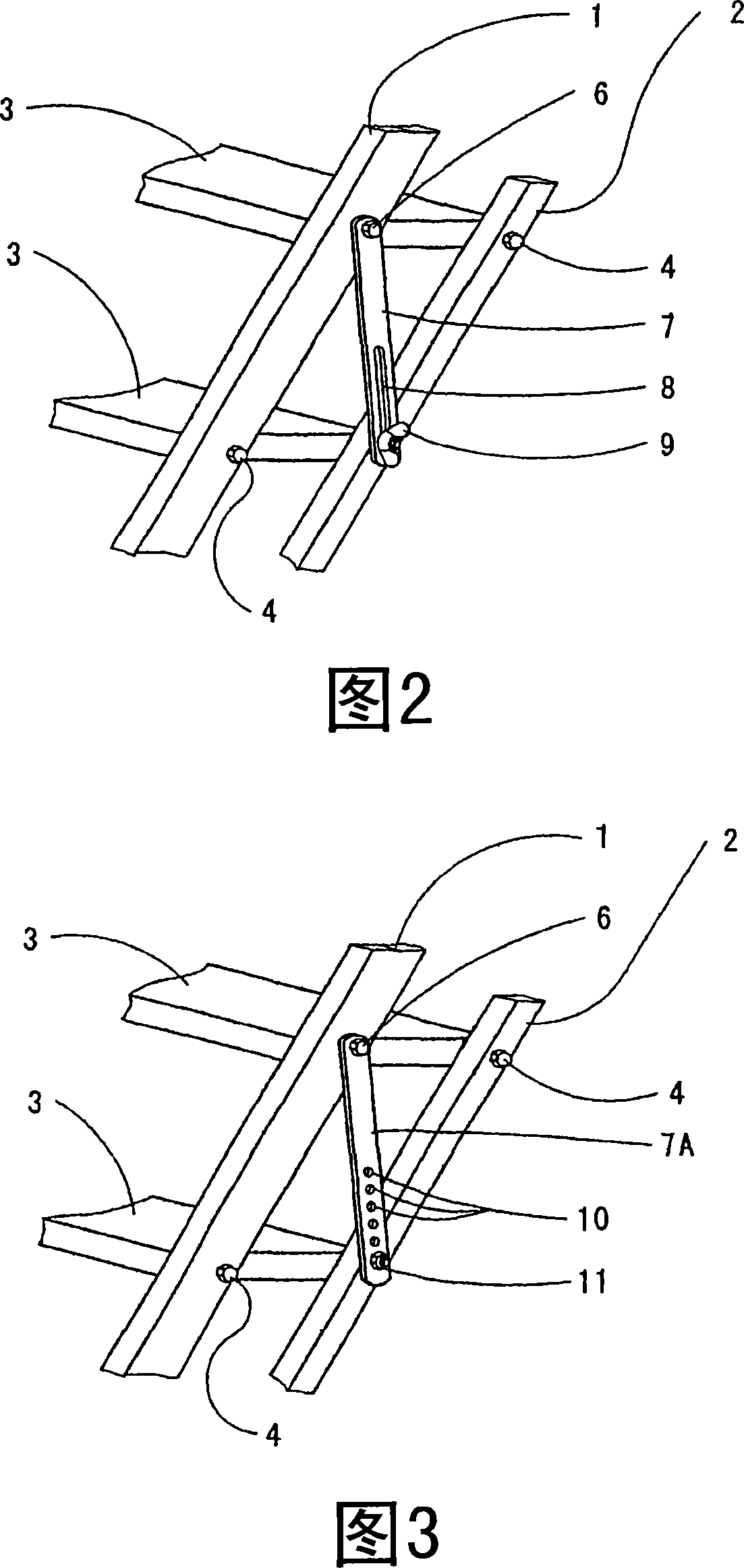

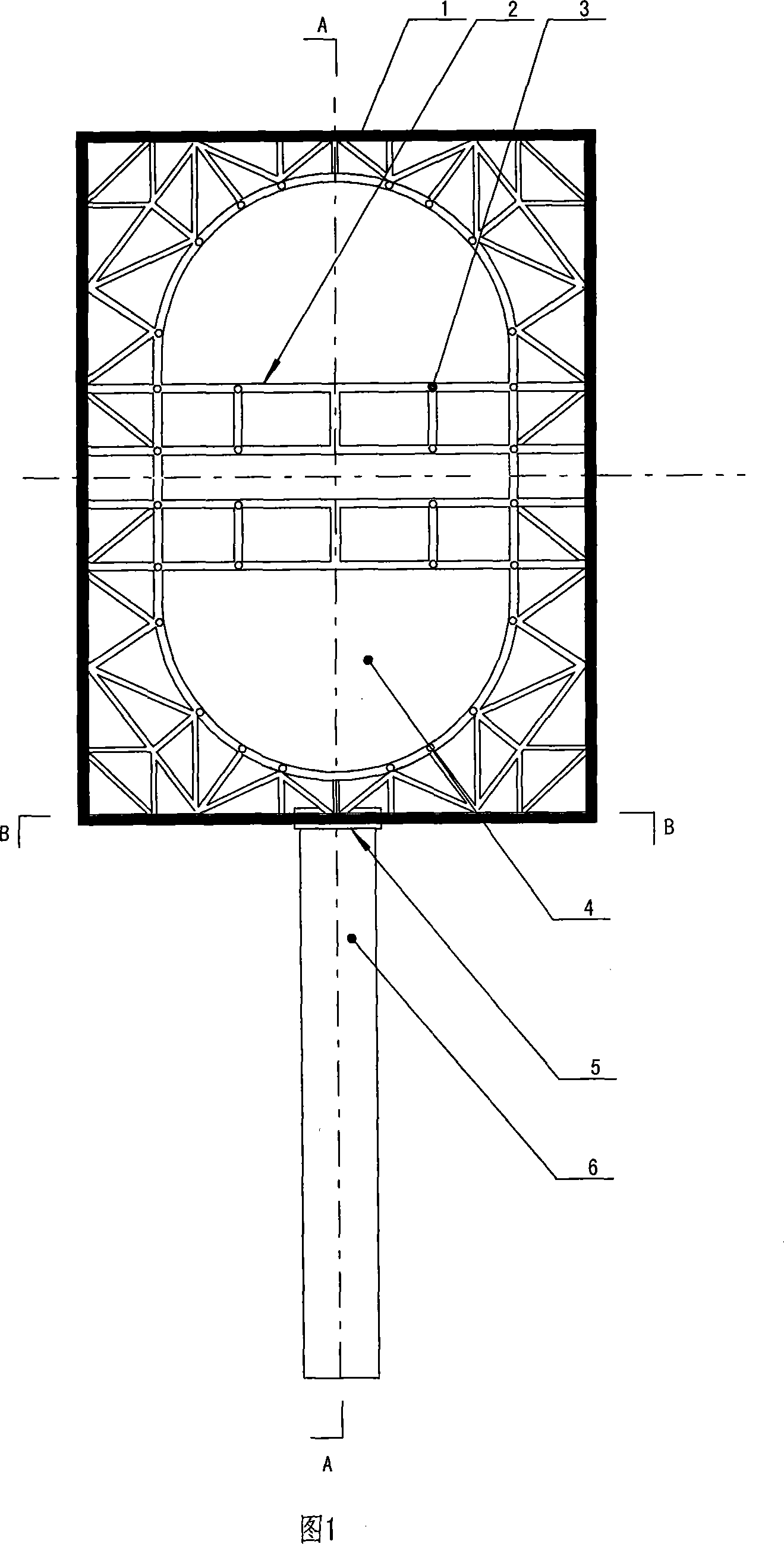

Ramp apparatus

The invention provides a gangway device, which can keep the level of the step from being affected by soil, small stones and dust, always smoothly and stably, and can keep the handrail at a certain height. The two end shafts of these pedals (3) are supported between two sets of trusses composed of upper chord members (1) and lower chord members (2) arranged in parallel, so that multiple pedals (3) are horizontal; these upper chords can be adjusted and maintained One end of the connecting rod for adjusting the distance between the member (1) and the lower chord member (2) is supported on one of the upper chord member (1) and the lower chord member (2), and on the other of the upper chord member and the lower chord member. A position fixing member (9) is provided to fix the other end of the adjustment link at a position of a prescribed length; an armrest socket (3A) is installed perpendicularly to the side end surface of the pedal (3). ; Moreover, the socket (3A) is provided with an anti-loosening mechanism to prevent the support (23) of the armrest (22) from loosening.

Owner:小野 辰雄

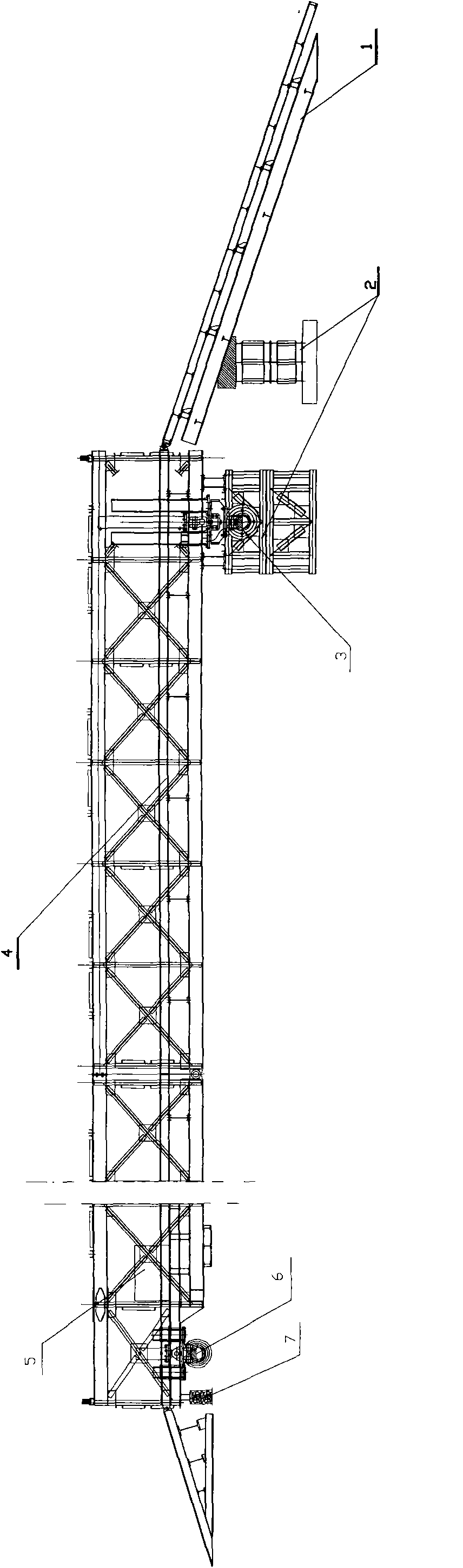

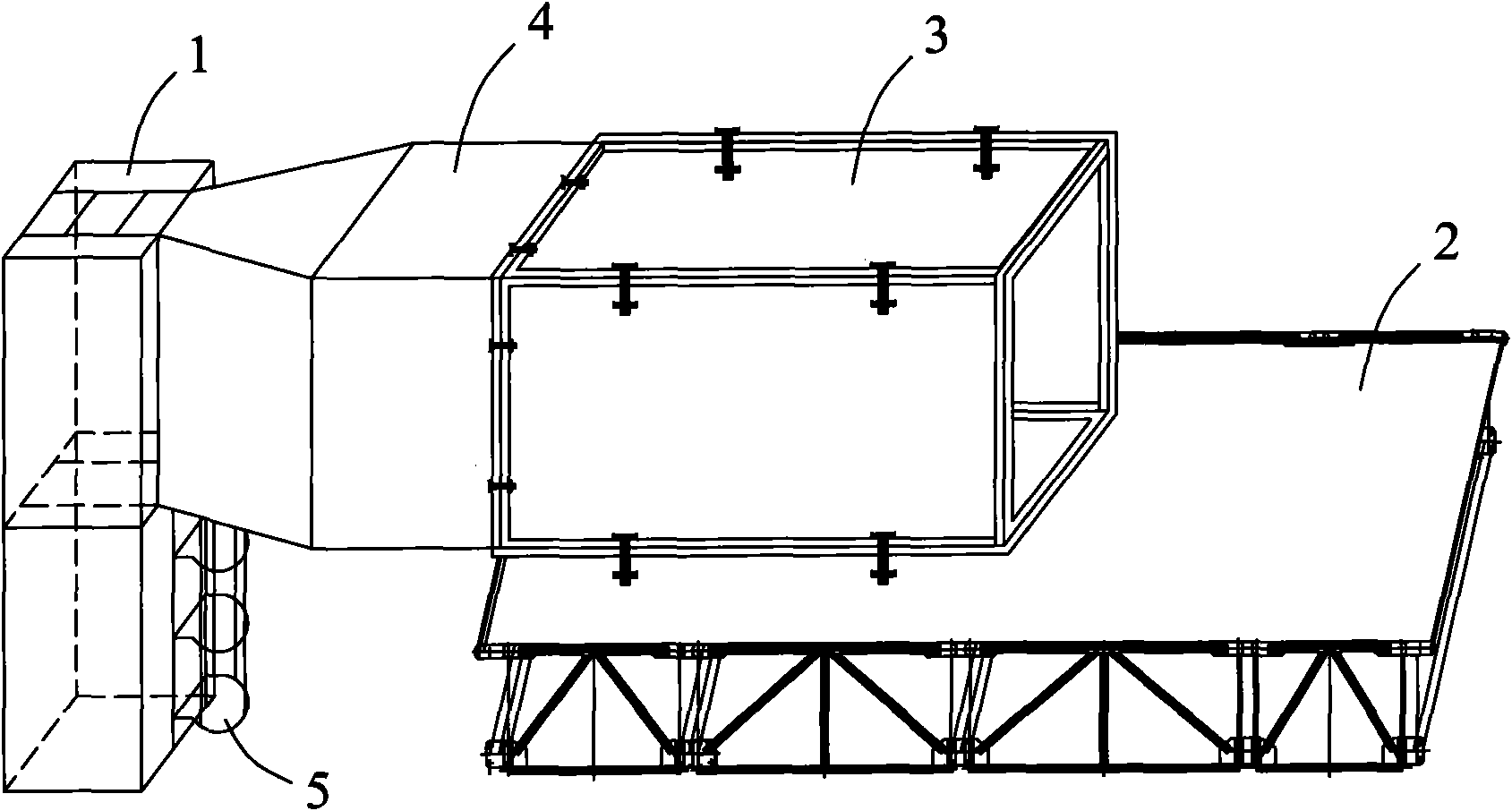

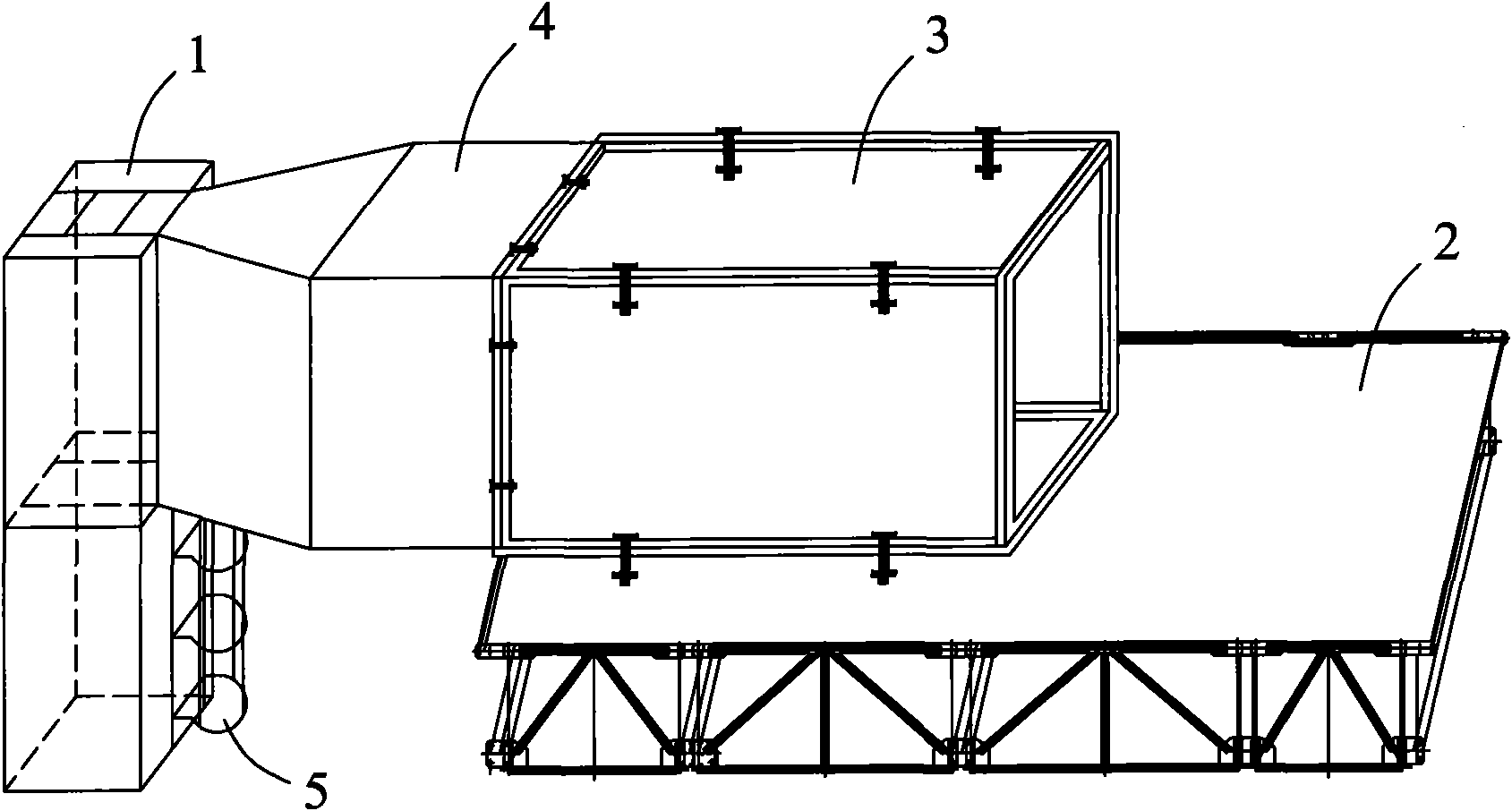

Movable trestle

ActiveCN101550769AGuarantee normal construction workGuaranteed duration requirementsUnderground chambersTunnel liningBridge deckSupport plane

The invention discloses tunnel construction equipment, i.e., a movable trestle comprising a main bridge which is provided with an approach bridge and a support both in the front part and the rear part of the main bridge; the movable trestle is characterized by also comprising a hydraulic system and an electric system as well; both the front end and the rear end of the main bridge are provided with a walking unit; and the main bridge comprises a deformed Bailey truss, a bridge deck and a bridge deck supporting bracket. The invention has the advantages that the research and development of the movable trestle can not only facilitate the hauling-out of slag charge produced by excavation in the cave, but also ensure the normal construction of inverted concrete lining, thereby significantly improving efficiency, shortening construction period, ensuring a construction period and realizing civilized construction as well.

Owner:中国水利水电第七工程局有限公司

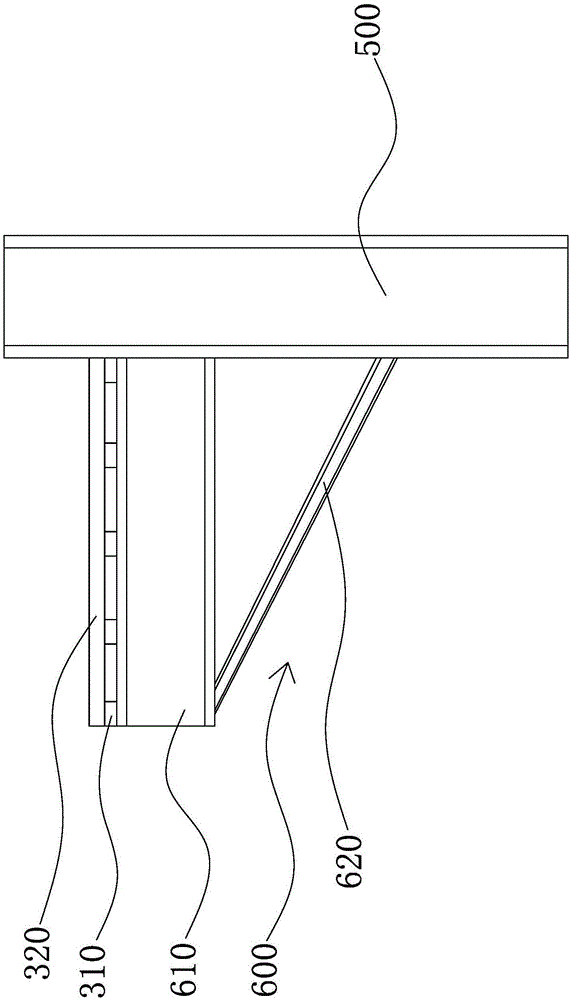

Hanging channel device for foundation pit

PendingCN107939068AEasy to get on and offStrong site applicabilityExcavationsShaping building partsEngineeringStairs

The invention discloses a hanging channel device for a foundation pit. The channel device comprises a concrete foundation platform arranged at the top of the foundation pit, a supporting frame fixed to the platform and a fast-mounted hanging ladder cage fixed to the supporting frame and going deeply into the foundation pit downwards. The fast-mounted hanging ladder cage comprises ladder cage standard sections and Z-shaped staircases, wherein the ladder cage standard sections and the Z-shaped staircases are spliced downwards layer by layer. Each ladder cage standard section comprises at least three ladder cage vertical rods and transverse braces fixed to the corresponding ladder cage vertical rods and defining a closed frame with the corresponding ladder cage vertical rods. The ladder cagevertical rods at the tops of the ladder cage standard sections are fixed to the supporting frame. The reset adjacent corresponding ladder cage vertical rods in the ladder cage standard sections are connected through connecting parts. Each Z-shaped staircase includes a resting platform arranged corresponding to each ladder cage standard section and a step fixed to the vertical adjacent resting platforms. Each resting platform is provided with a clamping groove and is arranged at the corresponding transverse brace of the corresponding ladder cage standard section to be fixed in a clamped mode. The hanging channel device is suitable for going up and down of workers under the condition of constant changing of the excavation depth in the excavation process, the site adaptability is high, assembly and disassembly are convenient and flexible, the structure is safe and reliable, and the hanging channel device can be repeatedly used.

Owner:THE SECOND CONSTR OF CTCE GROUP

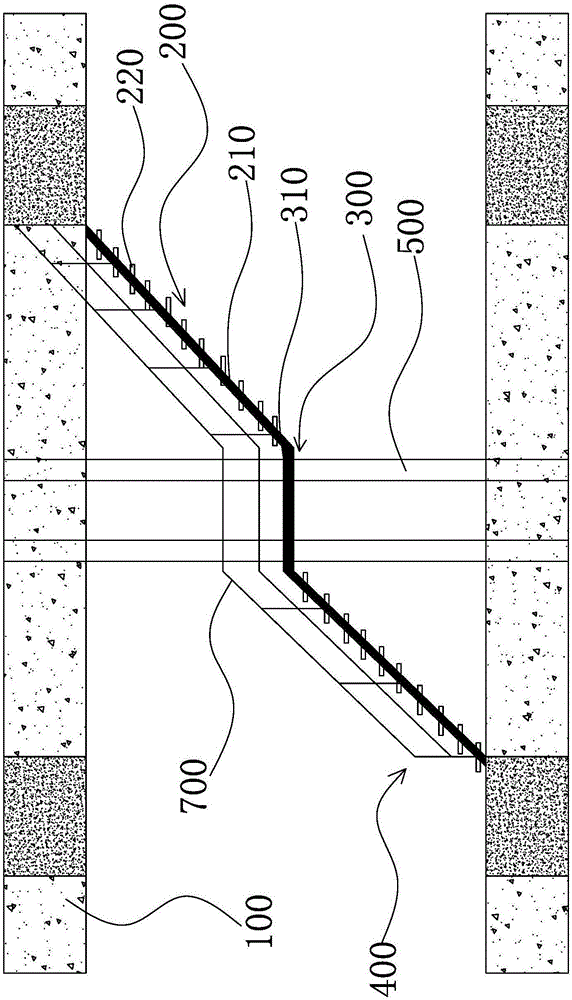

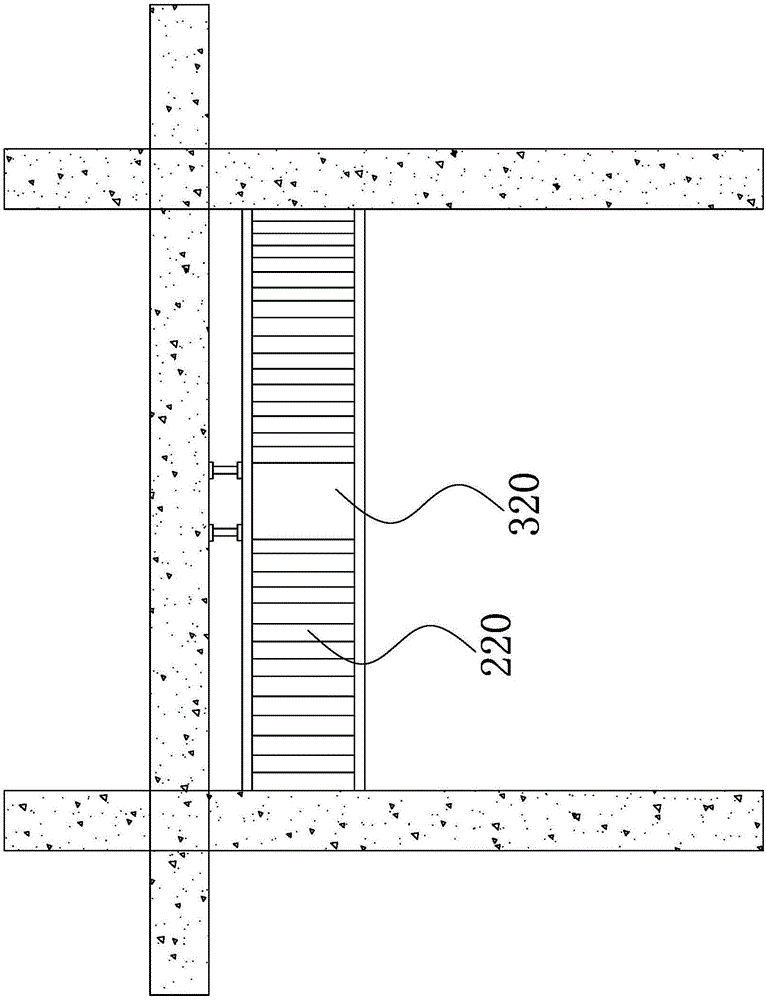

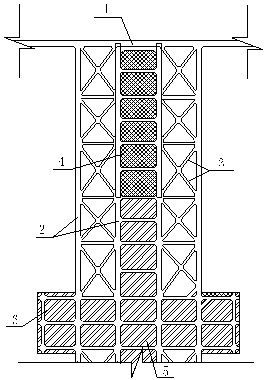

Hanging type construction staircase of deep foundation pit and construction method thereof

InactiveCN106836851ASatisfies the shortcomings of large site changesImprove the installation environmentShaping building partsReinforced concreteRebar

The invention provides a hanging type construction staircase of a deep foundation pit and a construction method thereof. The hanging type construction staircase is located between two reinforced concrete horizontal supports and comprises a first step section, a second step section and a third step section, wherein the first step section, the second step section and the third step section are connected in a head-to-tail mode to be a Z-shaped structure. According to the hanging type construction staircase of the deep foundation pit, the reinforced concrete horizontal supports in the deep foundation pit engineering are utilized, the staircase is suspended on the supports, the mounting environment of the construction staircase can be greatly expanded, and the use performance is improved; and in addition, the staircase can be lengthened or removed by sections according to the engineering progress, the shortcoming that the site change is large during construction of the deep foundation pit is overcome, and good adaptability is achieved.

Owner:浙江二十冶建设有限公司

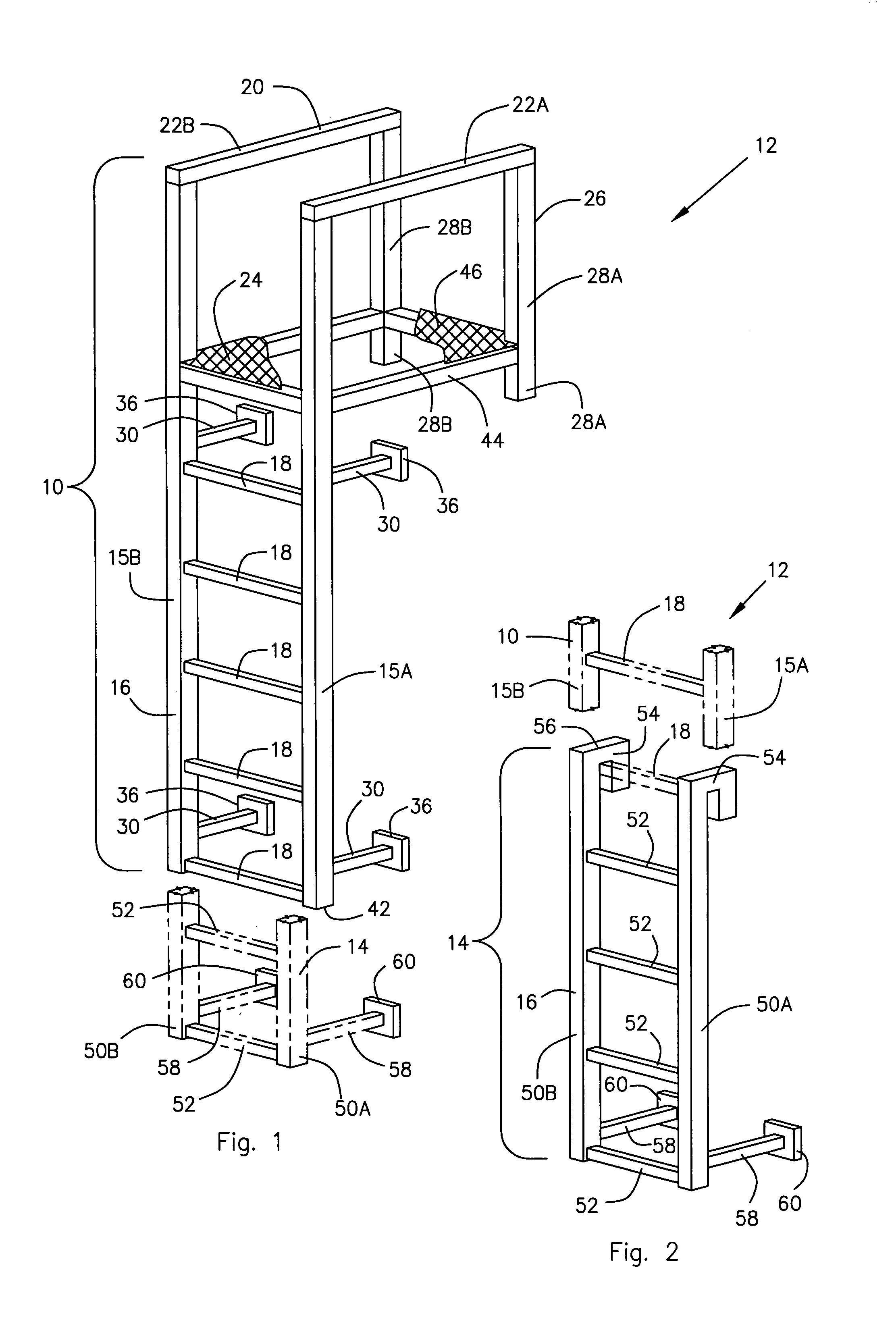

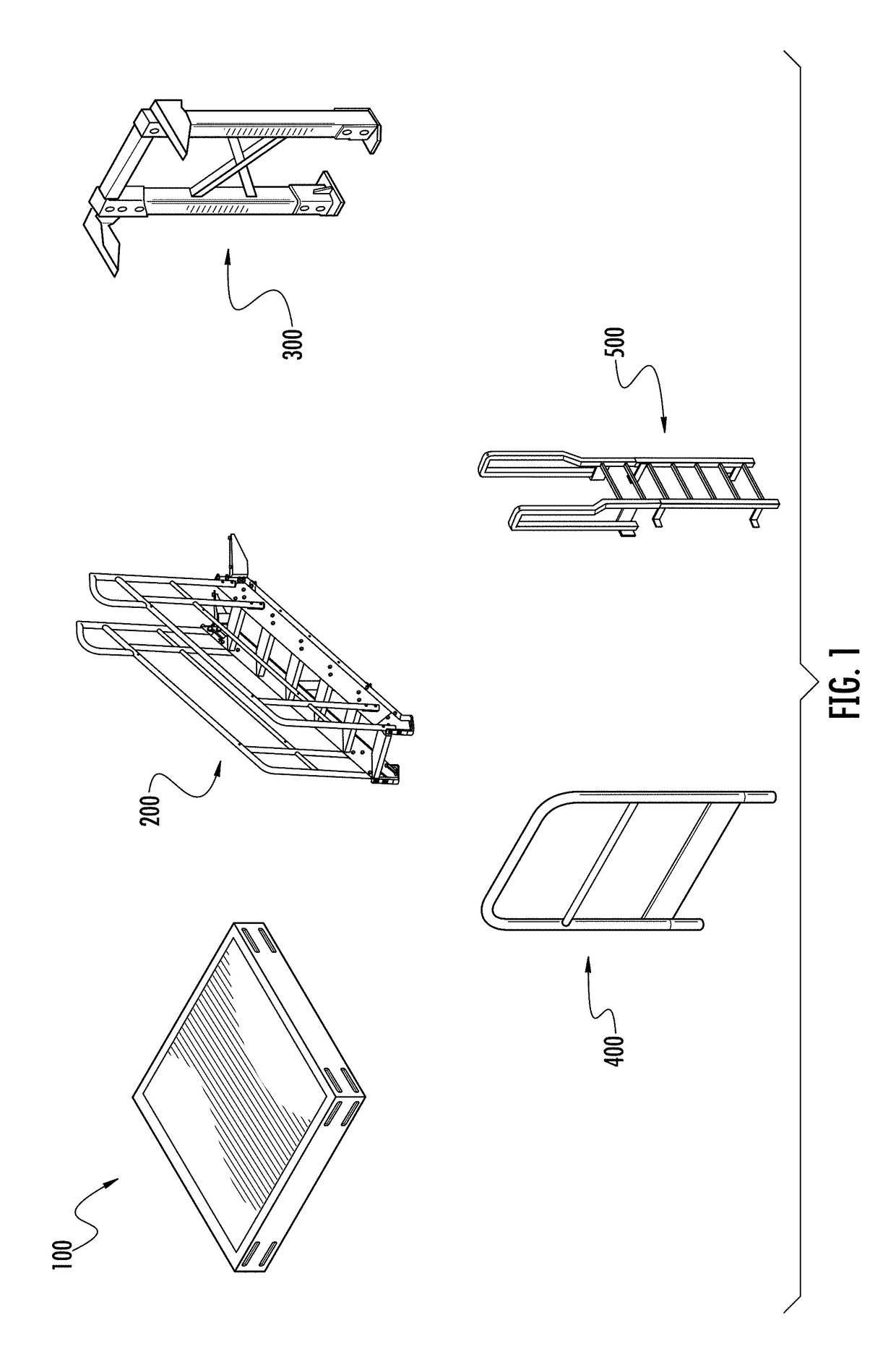

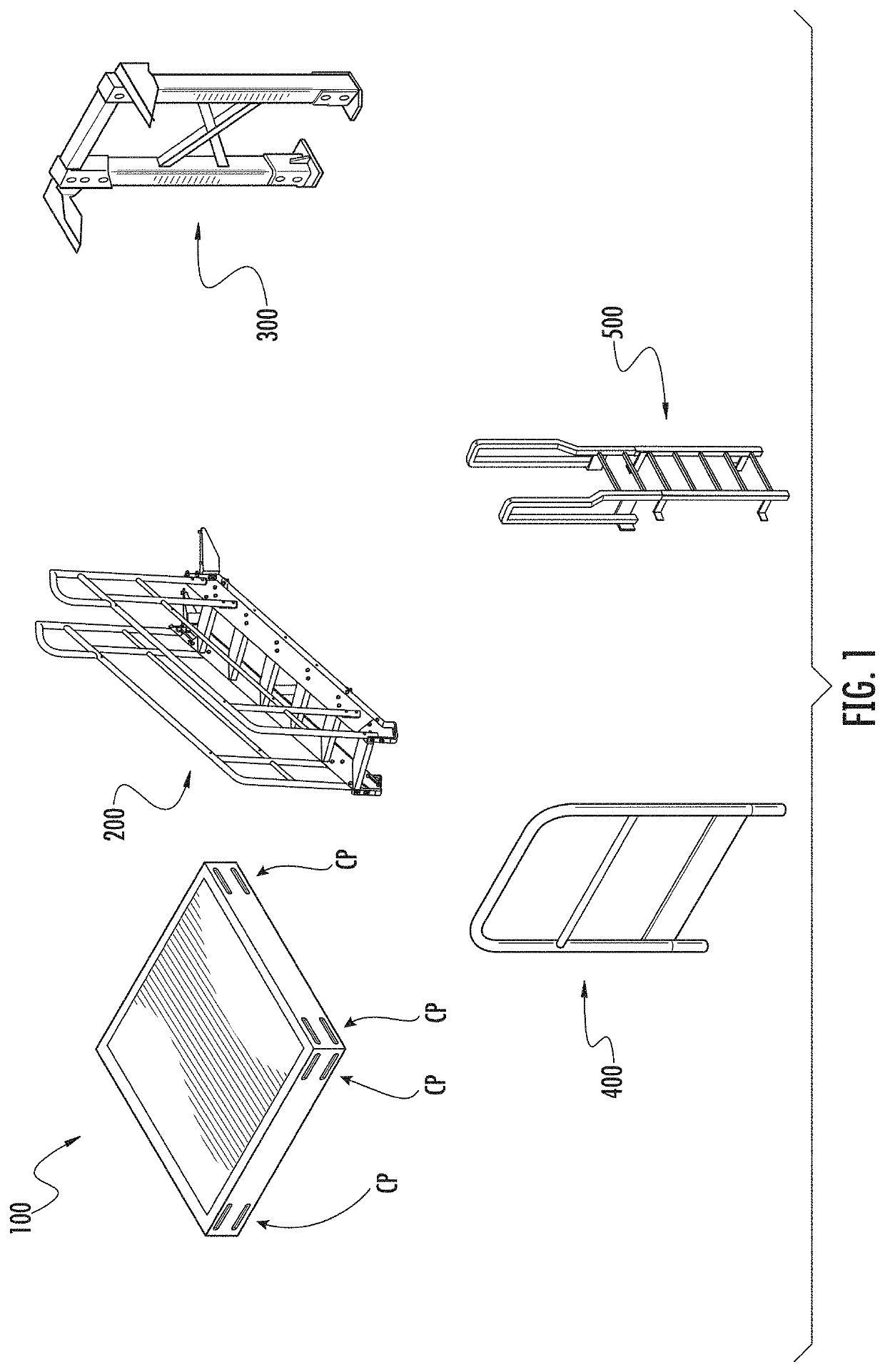

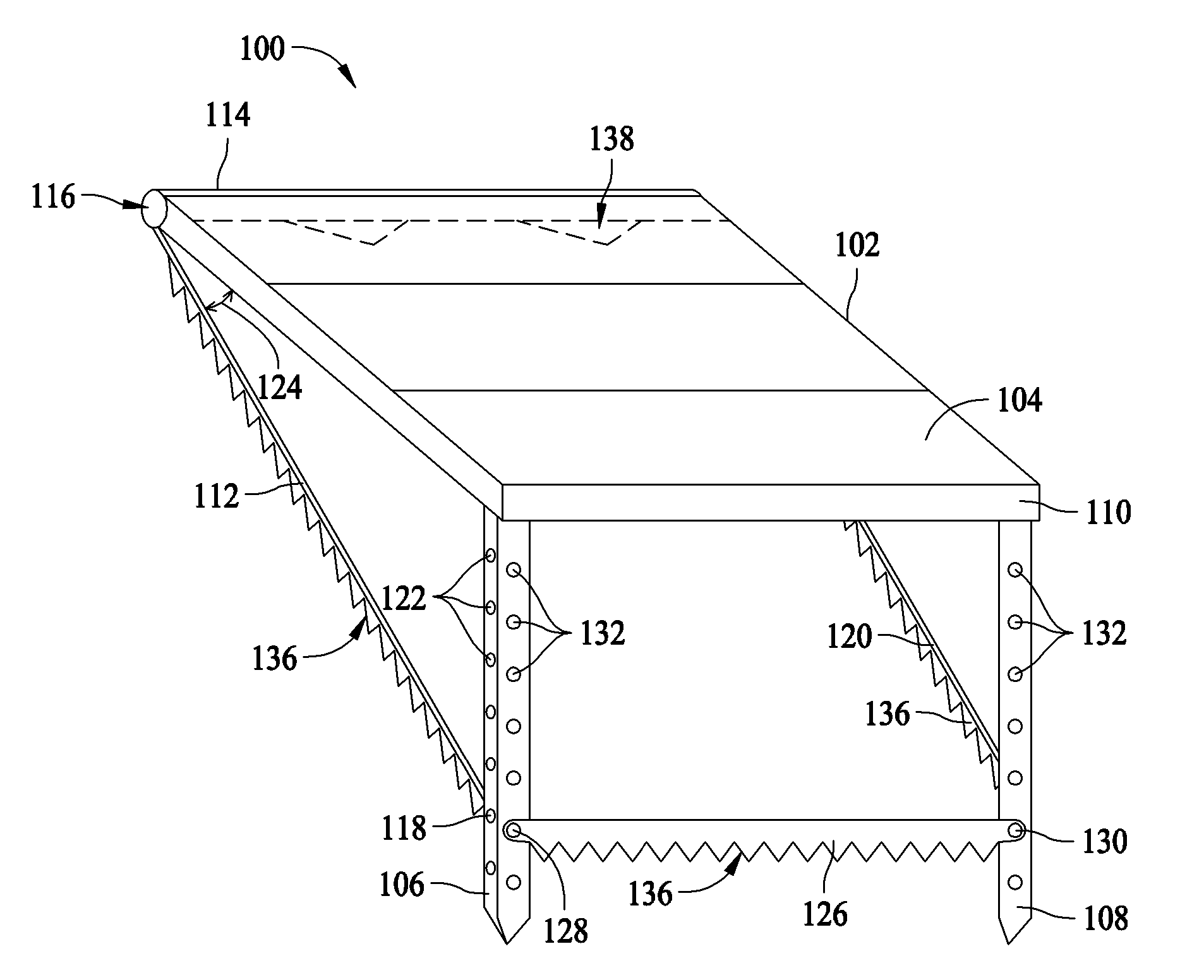

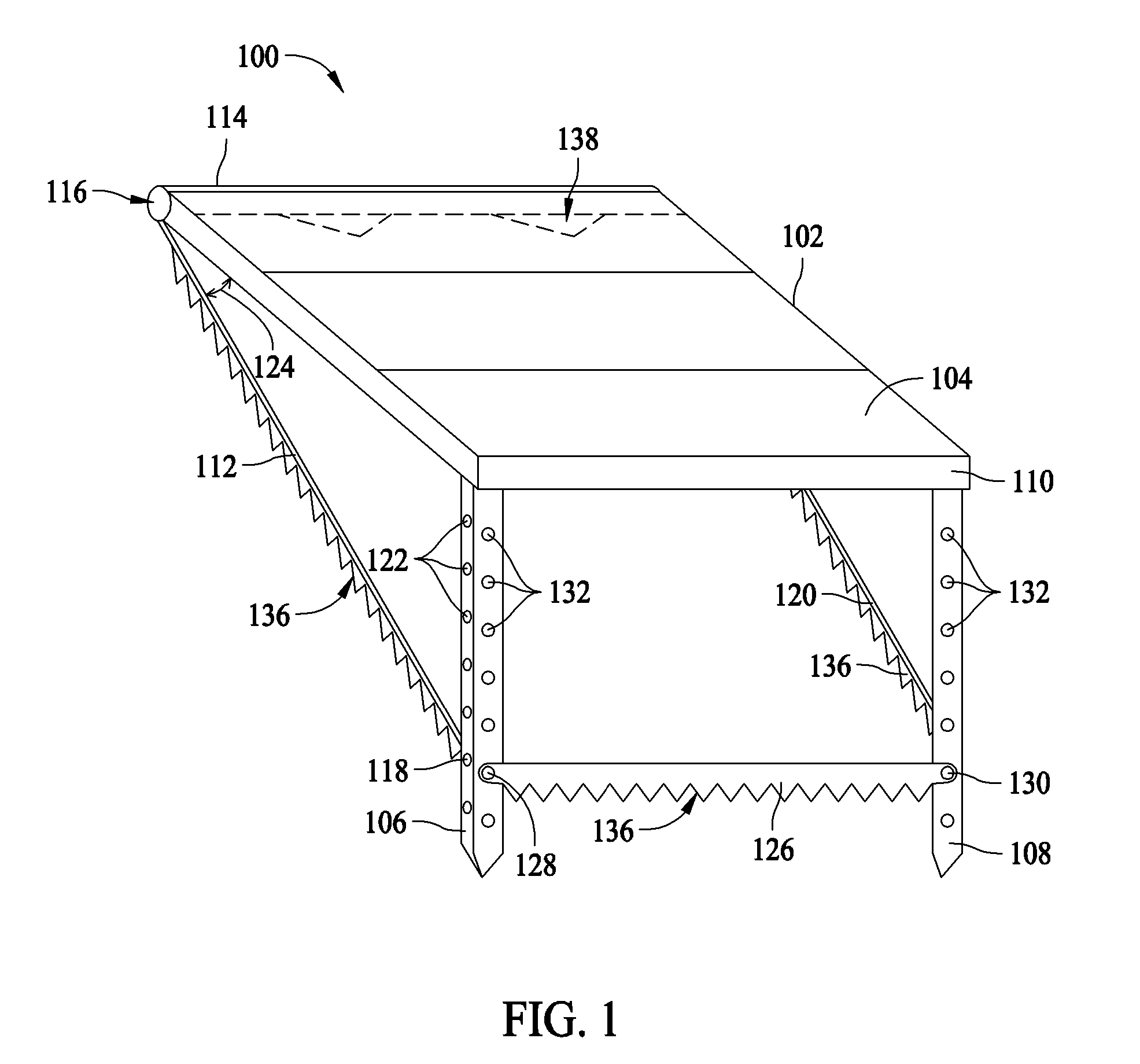

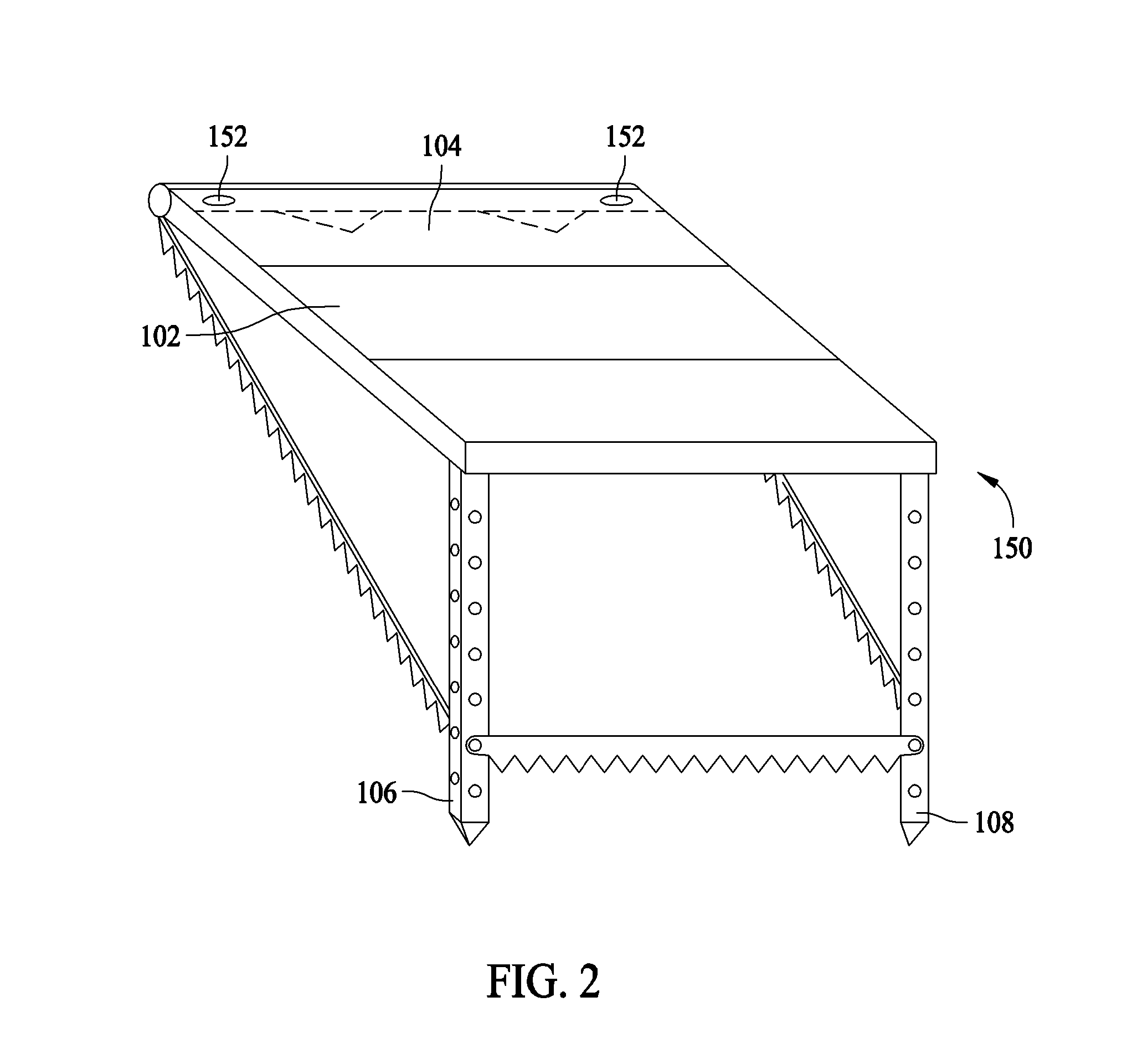

Platform system

A platform system comprising a platform structure having at least one modular platform unit with platform connection features on a side surface thereof to which other components can be connected, the other components including at least two of the following: another modular platform unit, a stair unit, a tower unit, a handrail unit, and a ladder unit. A stair assembly is connected to the platform structure via said connection features, the stair assembly comprising a plurality of stair units connected together to provide a number of steps equal to the sum of steps of the stair units.

Owner:SAFERACK

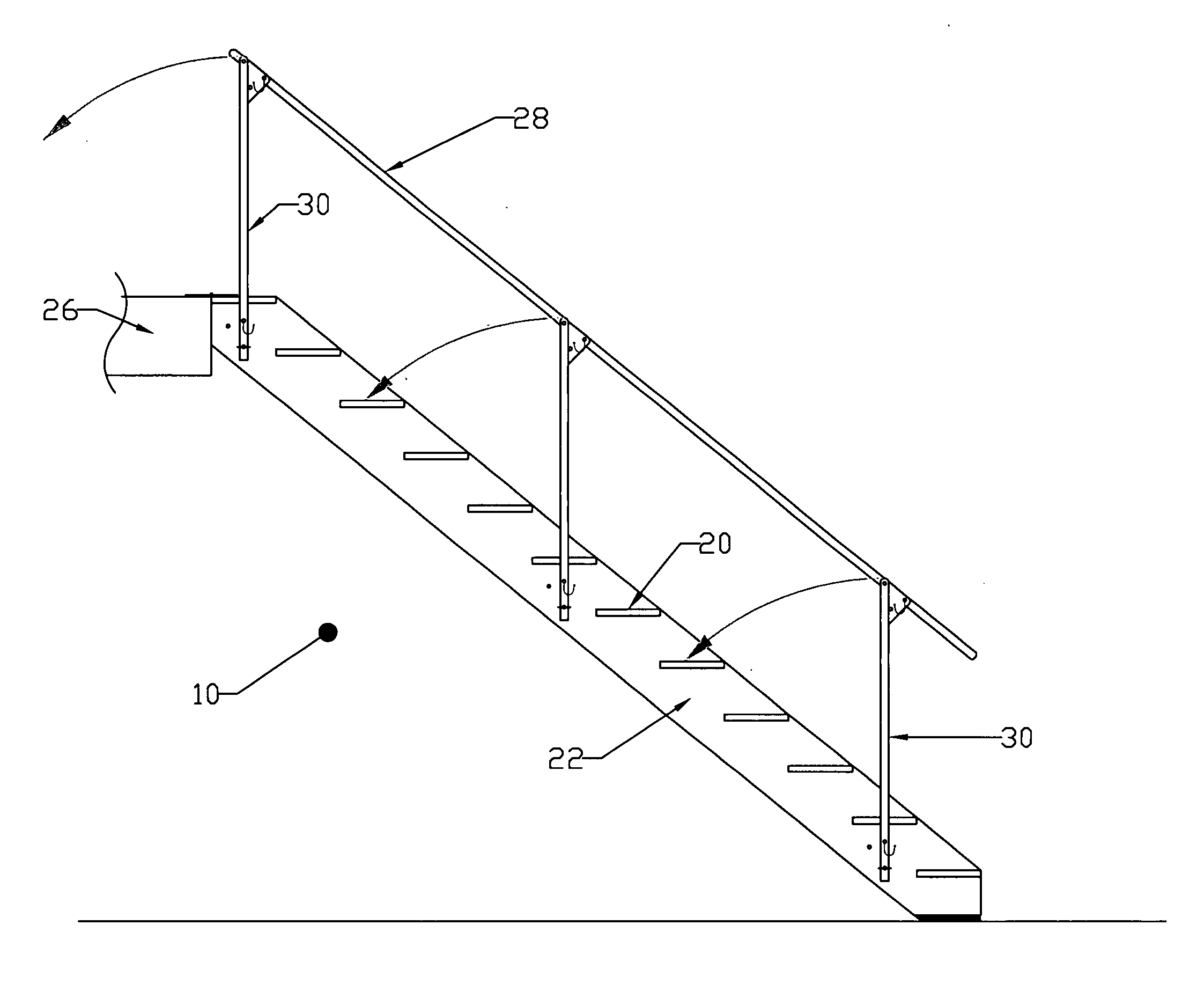

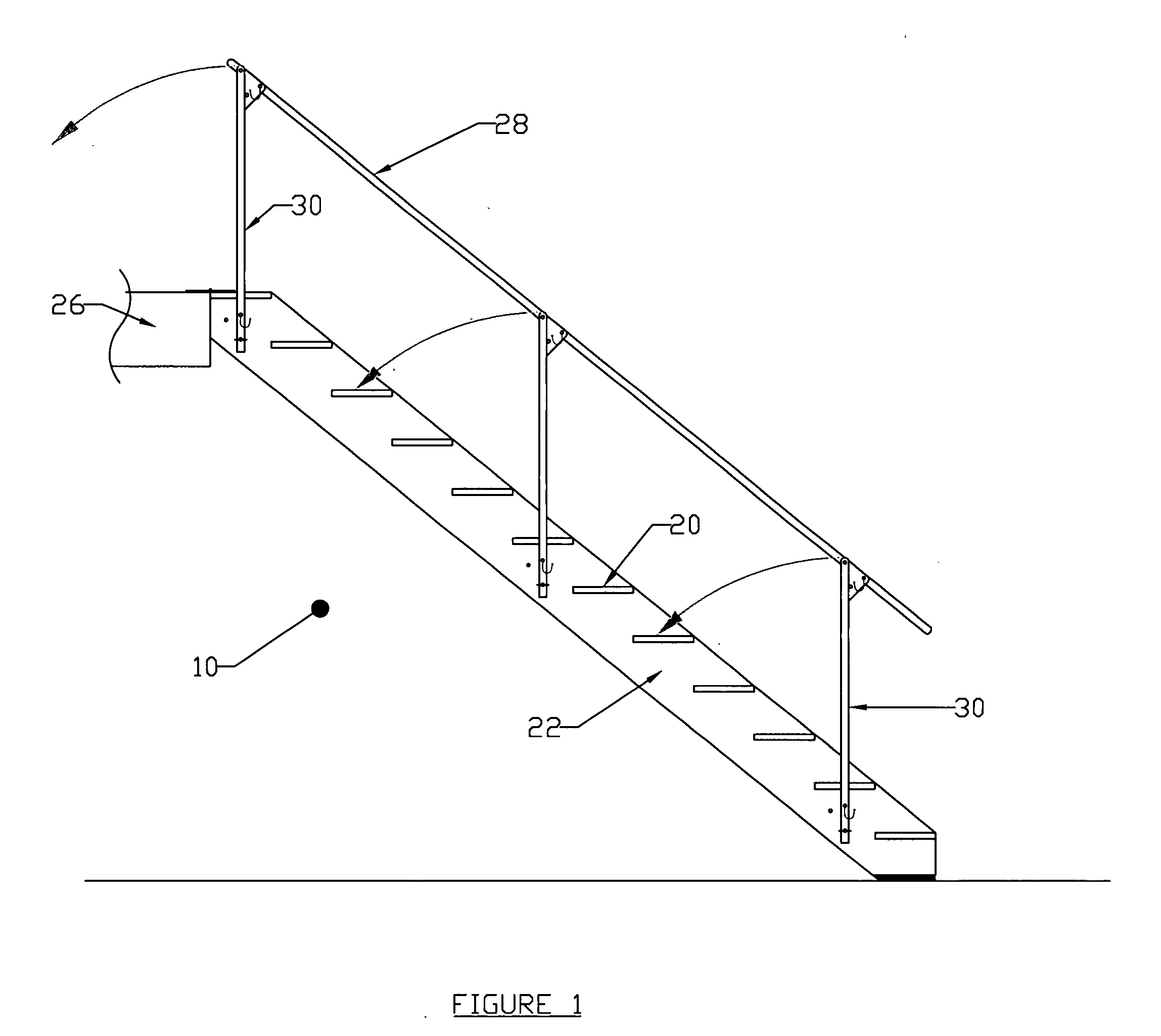

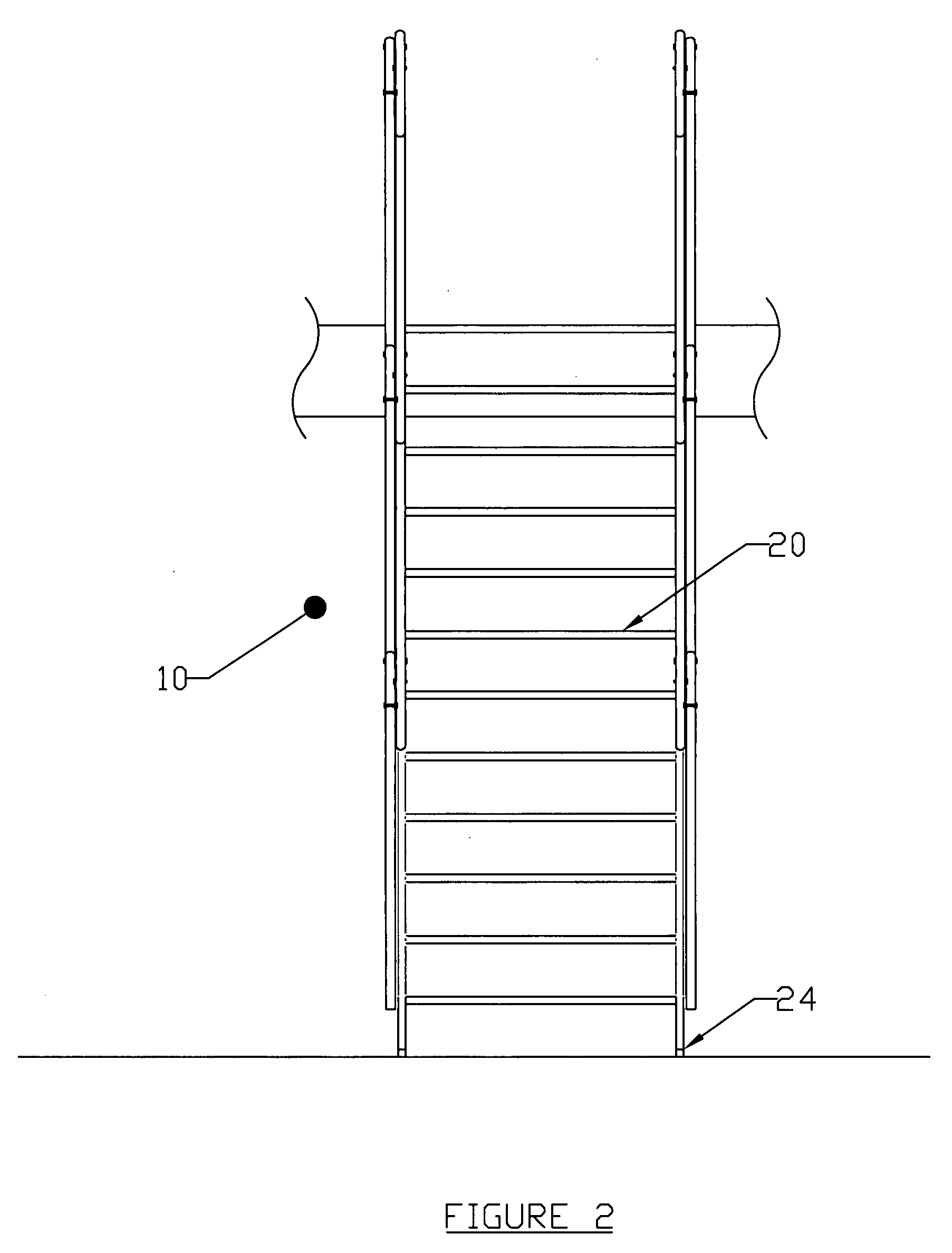

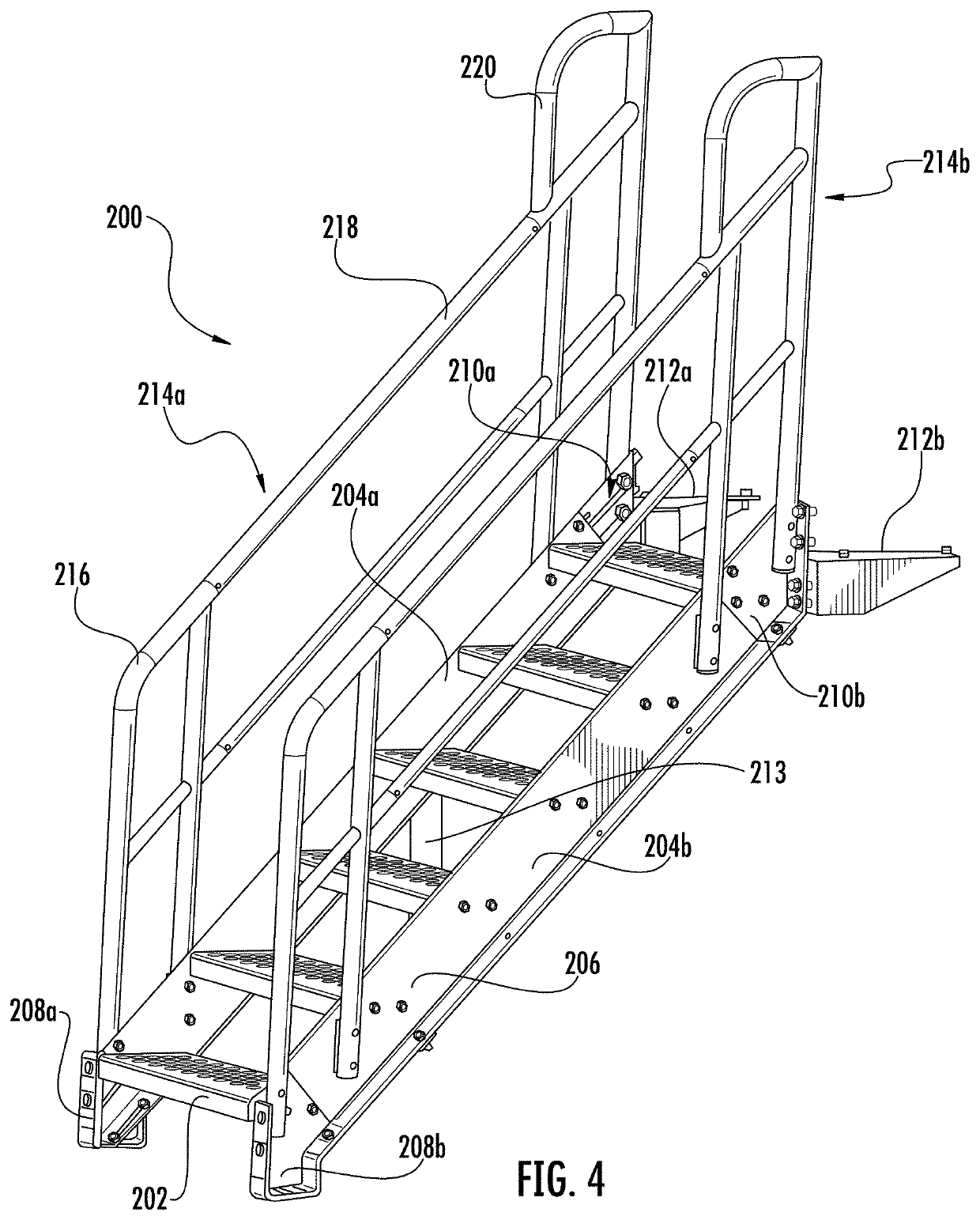

Portable construction staircase

InactiveUS20080190049A1Easy to transportShaping building partsStairway-like structuresEngineeringBaluster

A portable staircase for use at construction sites that comprises fold-down railings to facilitate transport from one construction site to the next. The portable staircase includes a plurality of horizontal treads supported by stringers. Handrails are provided which pivotally connect to the stringer utilizing a plurality of handrail support posts. A permanent pivot pin pivotally connects the handrail to each of the handrail support posts. Another permanent pivot pin pivotally connects each of the handrail support posts to the stringer. The handrail can be locked into one of two pre-selected positions: a first folded-down position to facilitate transportation and a second upright position for use at construction sites. Two removable pins may be employed to lock the handrail in position: a first removable pin to lock the handrail support post to the stringer and a second removable pin to lock the handrail support post to the handrail in the up and usable position.

Owner:MUTI DAVID

Hinged ramp assembly

Owner:LUCHT DUANE

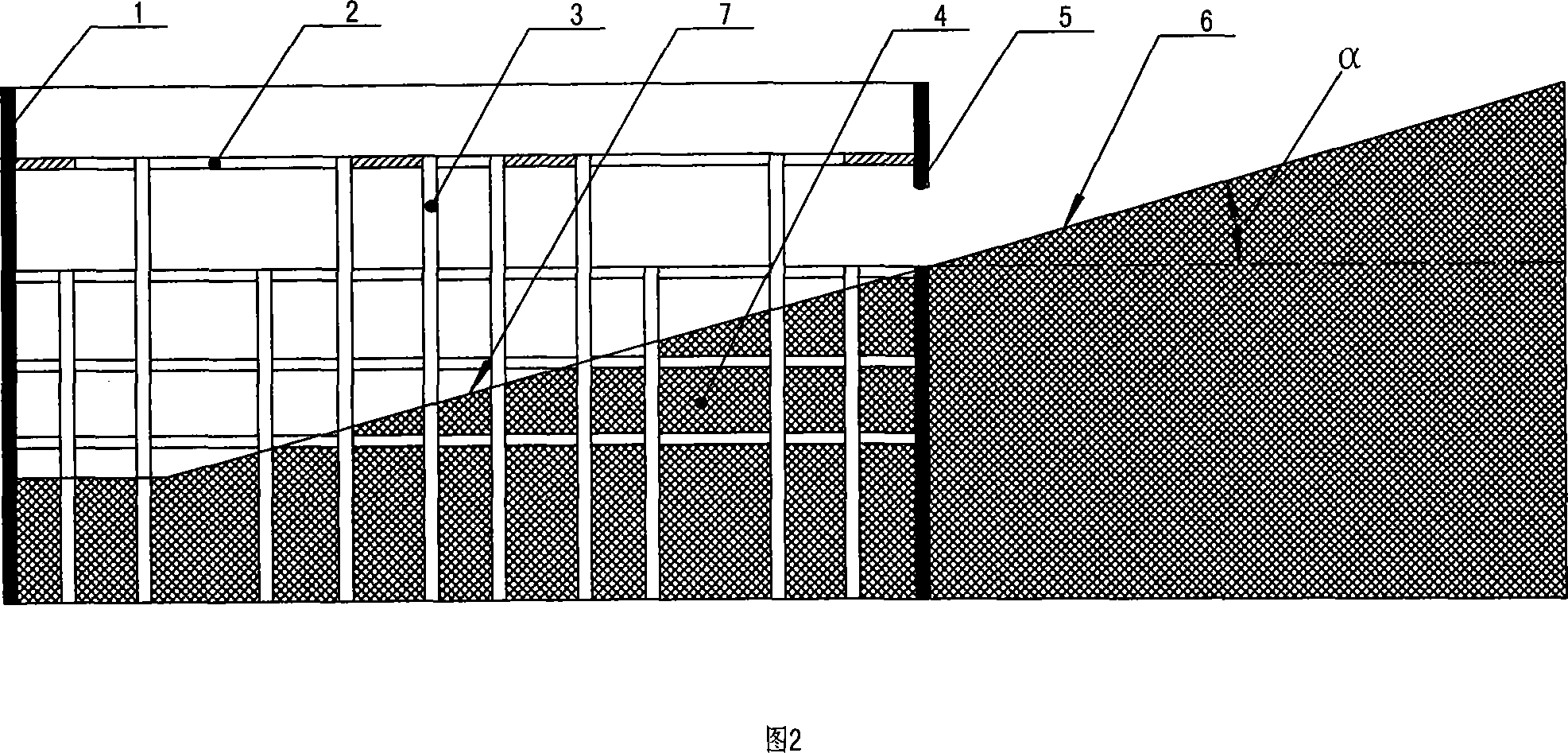

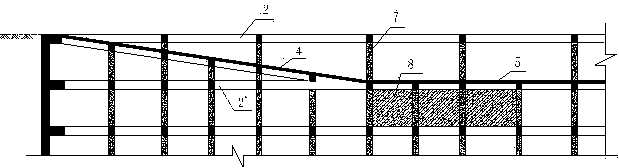

Deep foundation pits rampway structure

InactiveCN101067300AFixed issue where long ramps could not be builtEasy to digExcavationsShaping building partsSupport planeBuilding construction

The present invention relates to building engineering technology, and is especially one kind of deep foundation pit ramp structure. The deep foundation pit ramp structure consists of a deep foundation pit, a vertical enclosing structure around the deep foundation pit, a horizontal holding frame inside the enclosing structure, and a vertical holding frame fixed below the horizontal holding frame. Technologically, the present invention features that the enclosing structure is provided with one ramp door opening connecting one outer ramp outside the enclosing structure and one inner ramp inside the deep foundation pit. By means of combining the outer ramp and the inner ramp, the present invention makes it possible to construct long ramp in limited site. The deep foundation pit ramp structure facilitates the deep foundation pit construction.

Owner:天津一建建筑工程有限公司

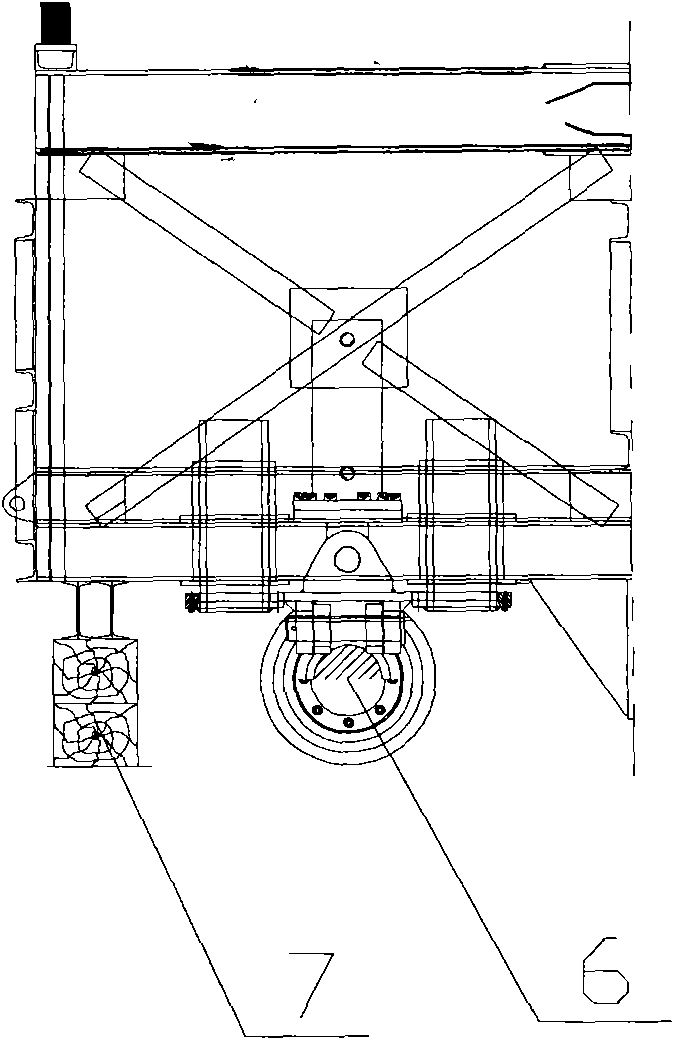

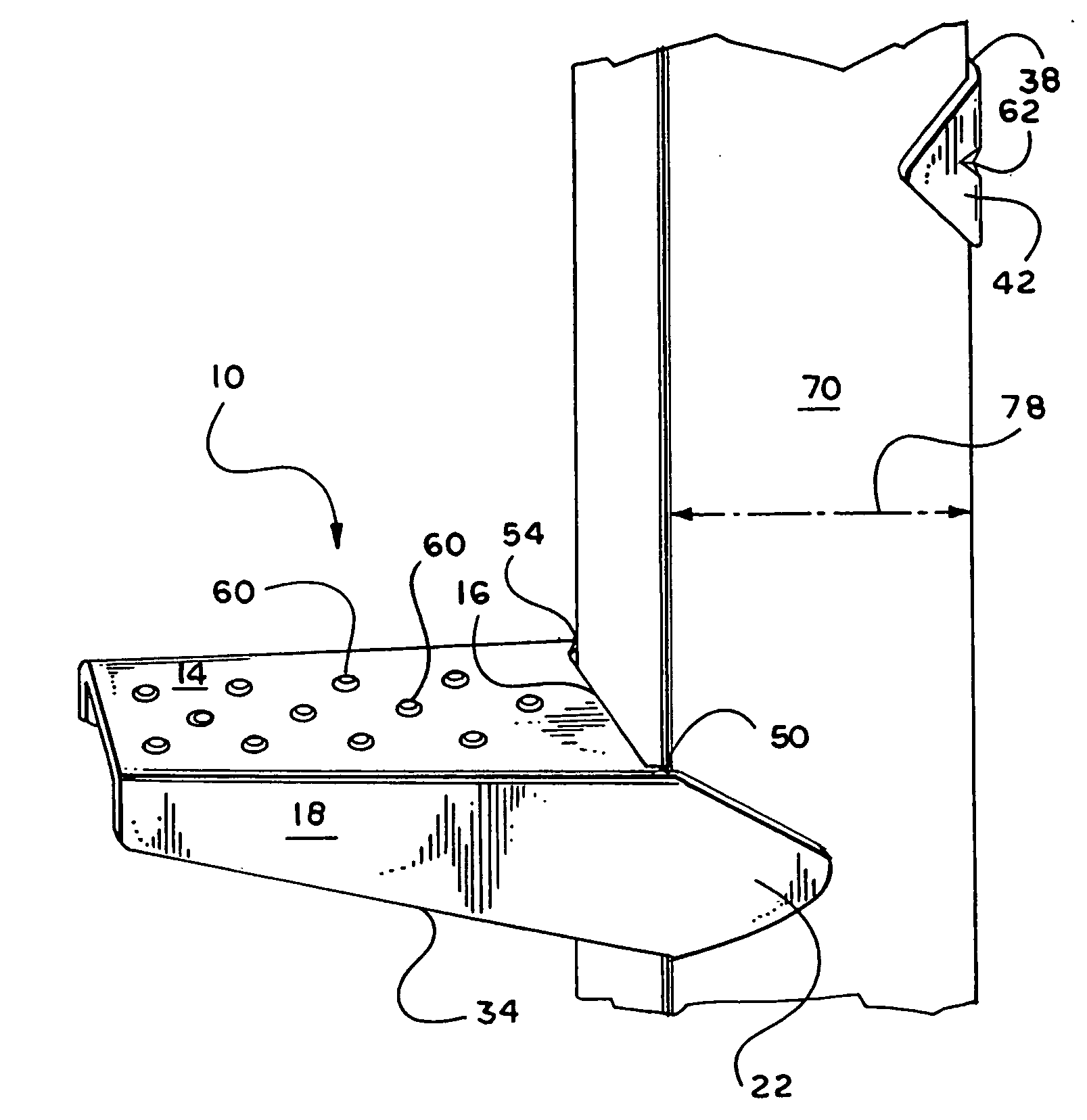

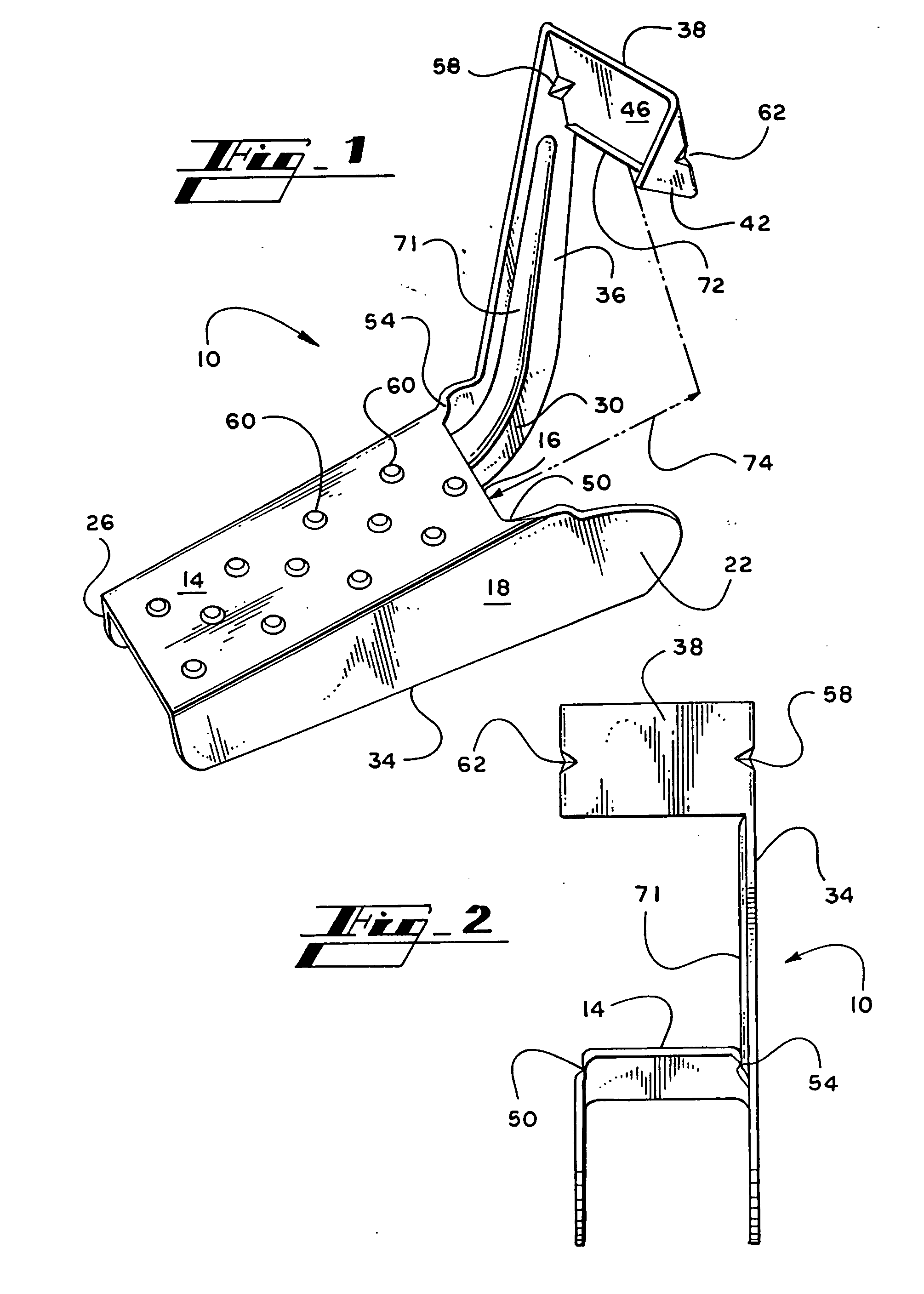

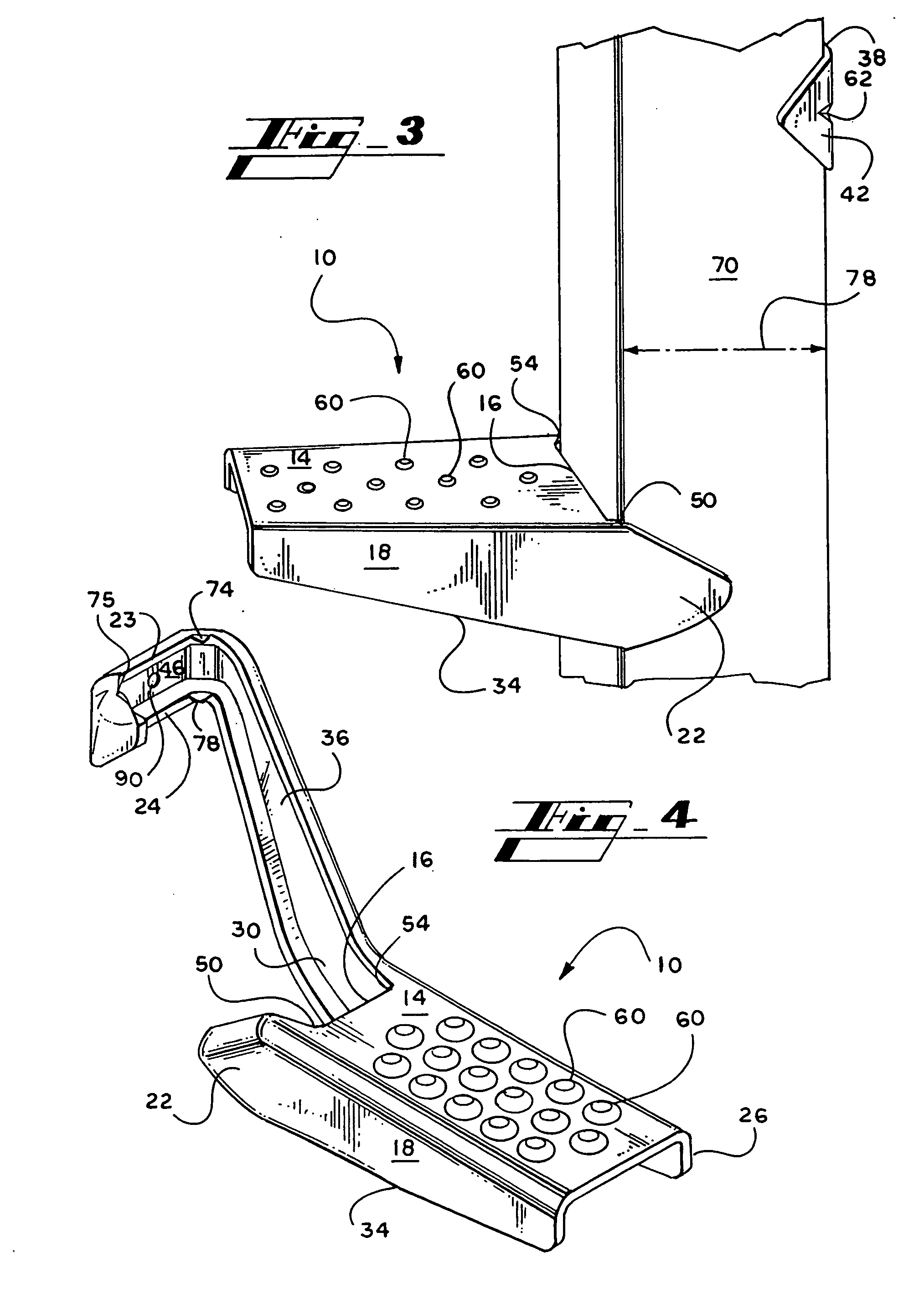

Locking and removable step

InactiveUS20050006174A1Easy to useConvenient and stableTreadsBuilding material handlingEngineeringShaft collar

The present invention is an easy to use device that attaches to a beam. The device may be used as a step for a user to stand on and attain elevation. The device may be used in combination to form a scaffold or a platform. The device is a tool having an upper surface with tapered ribs located on the back edge of the upper surface, a vertical member, and a collar. When the tool is placed around a beam and downward force applied to the tool, the ribs engage a first side of the beam and the collar engages the opposite side of the beam forming a lever. The tool is locked in place and the user is free to stand on it for support and elevation.

Owner:TERZINI ROBERT

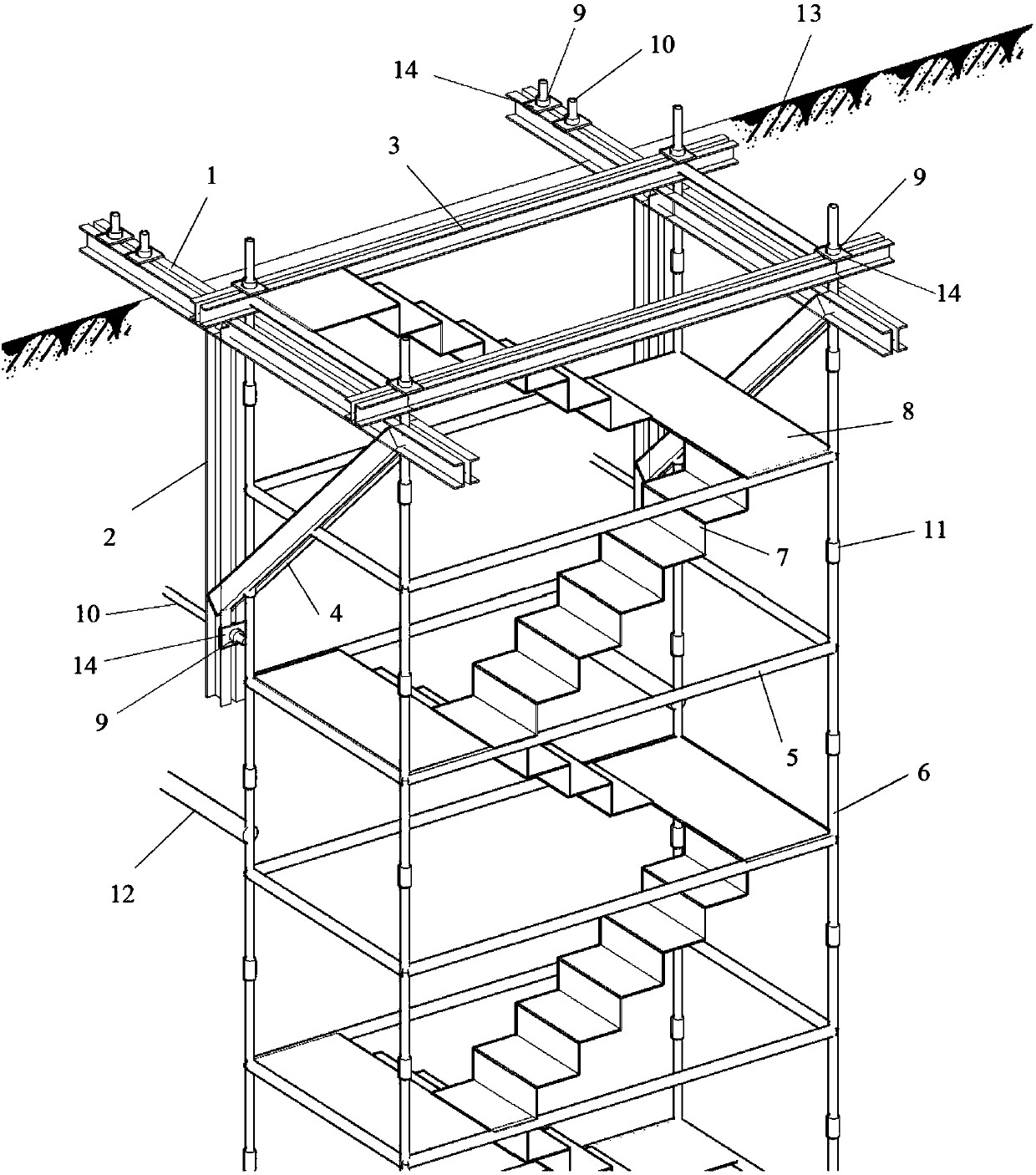

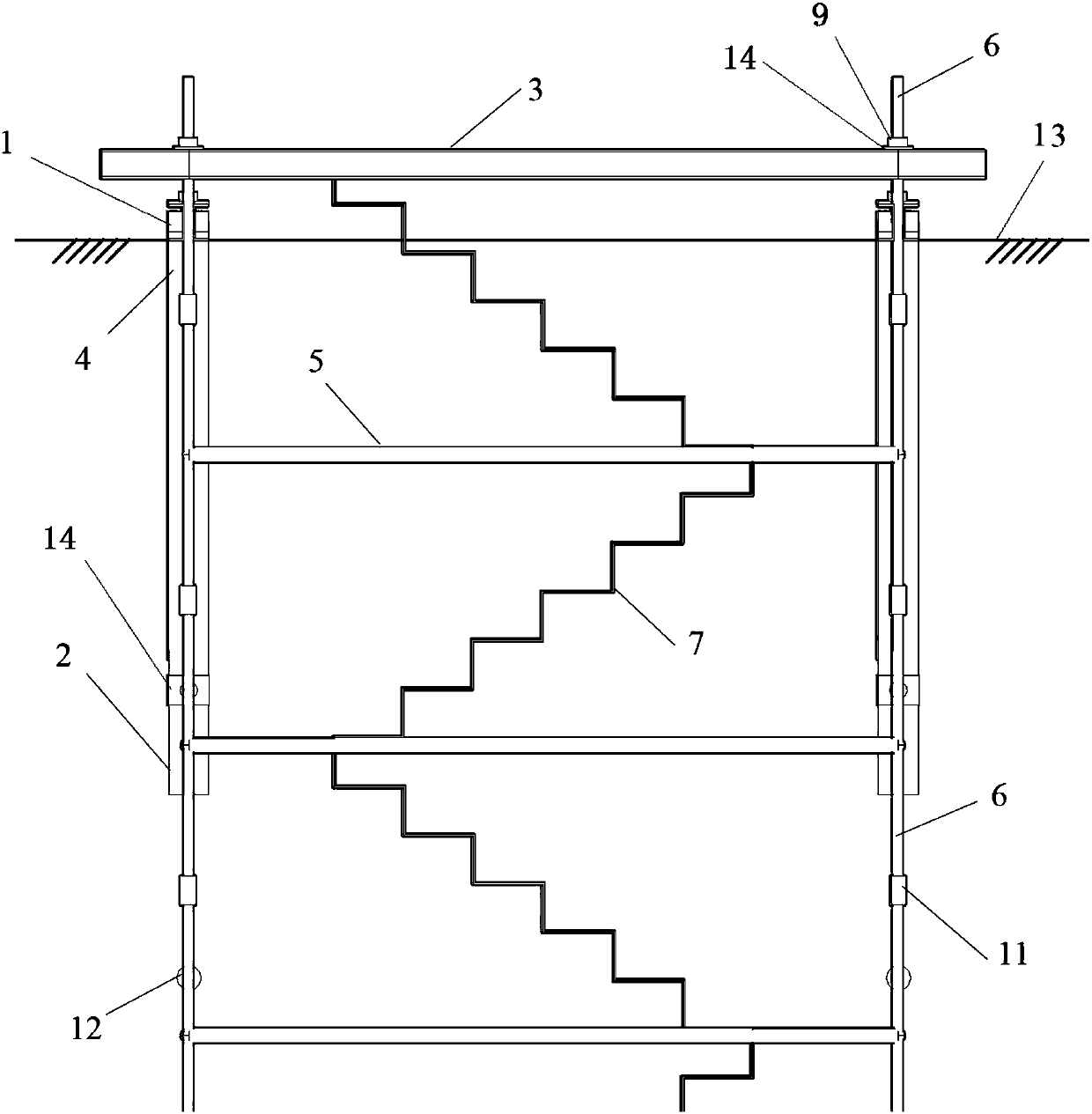

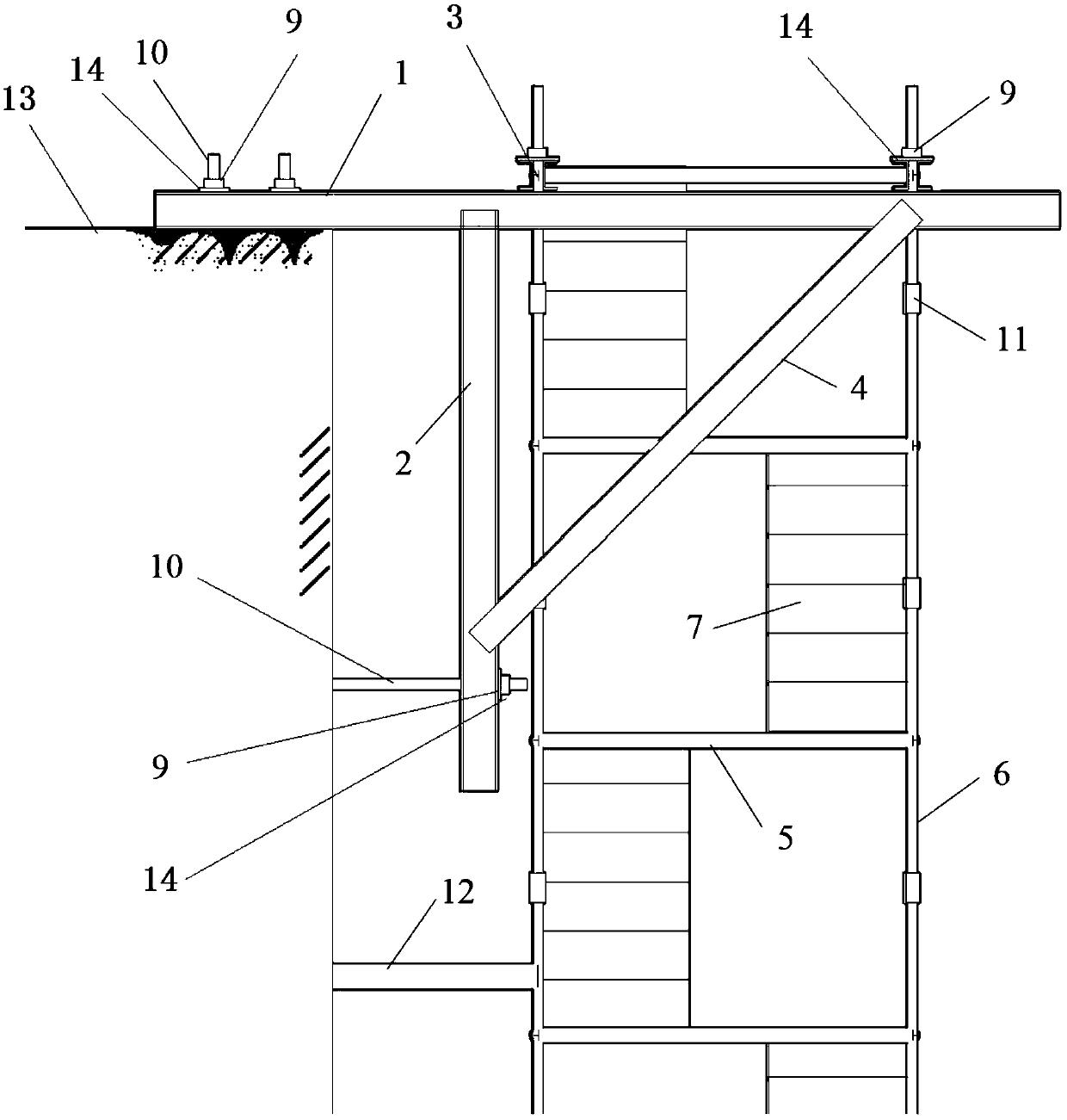

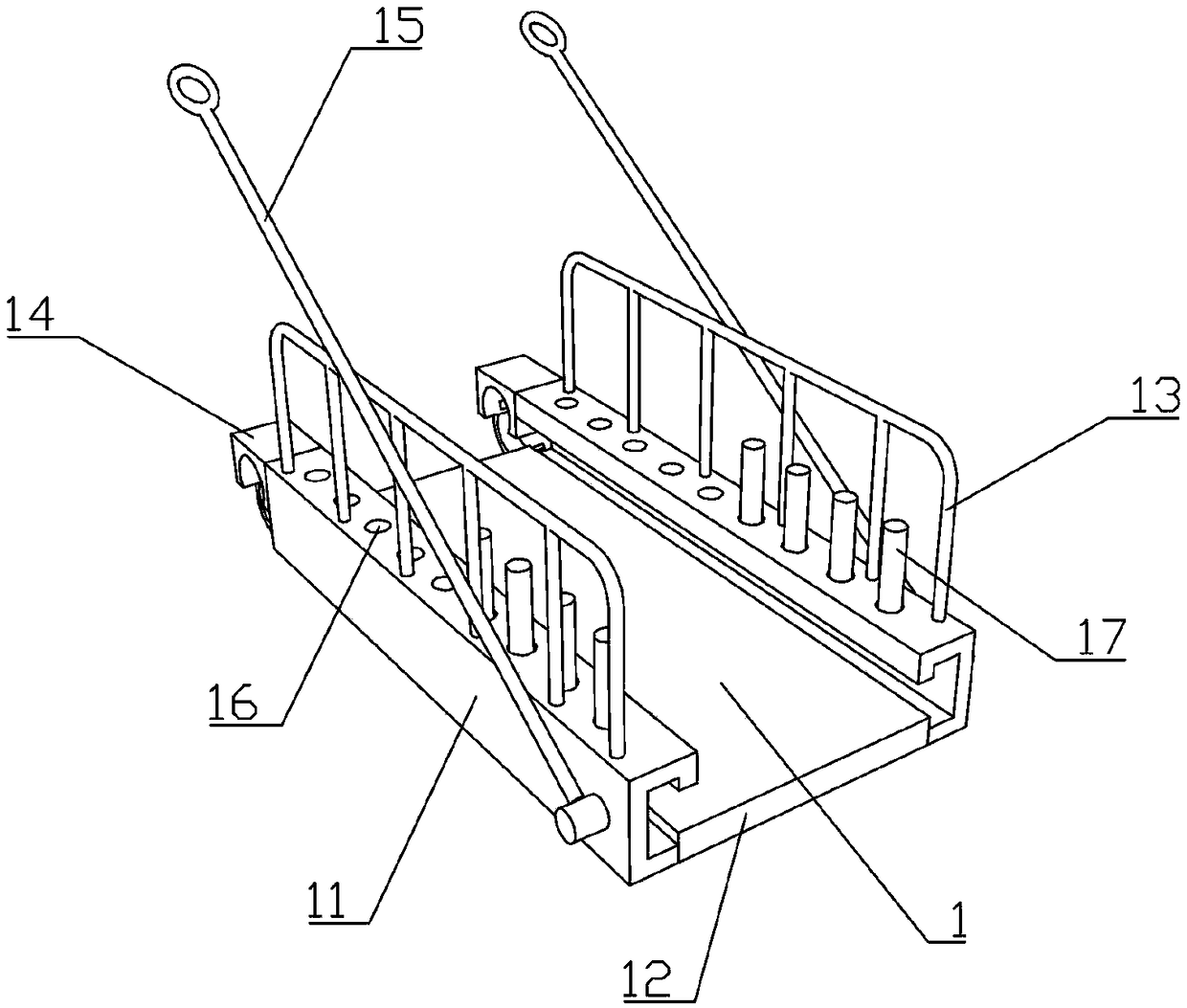

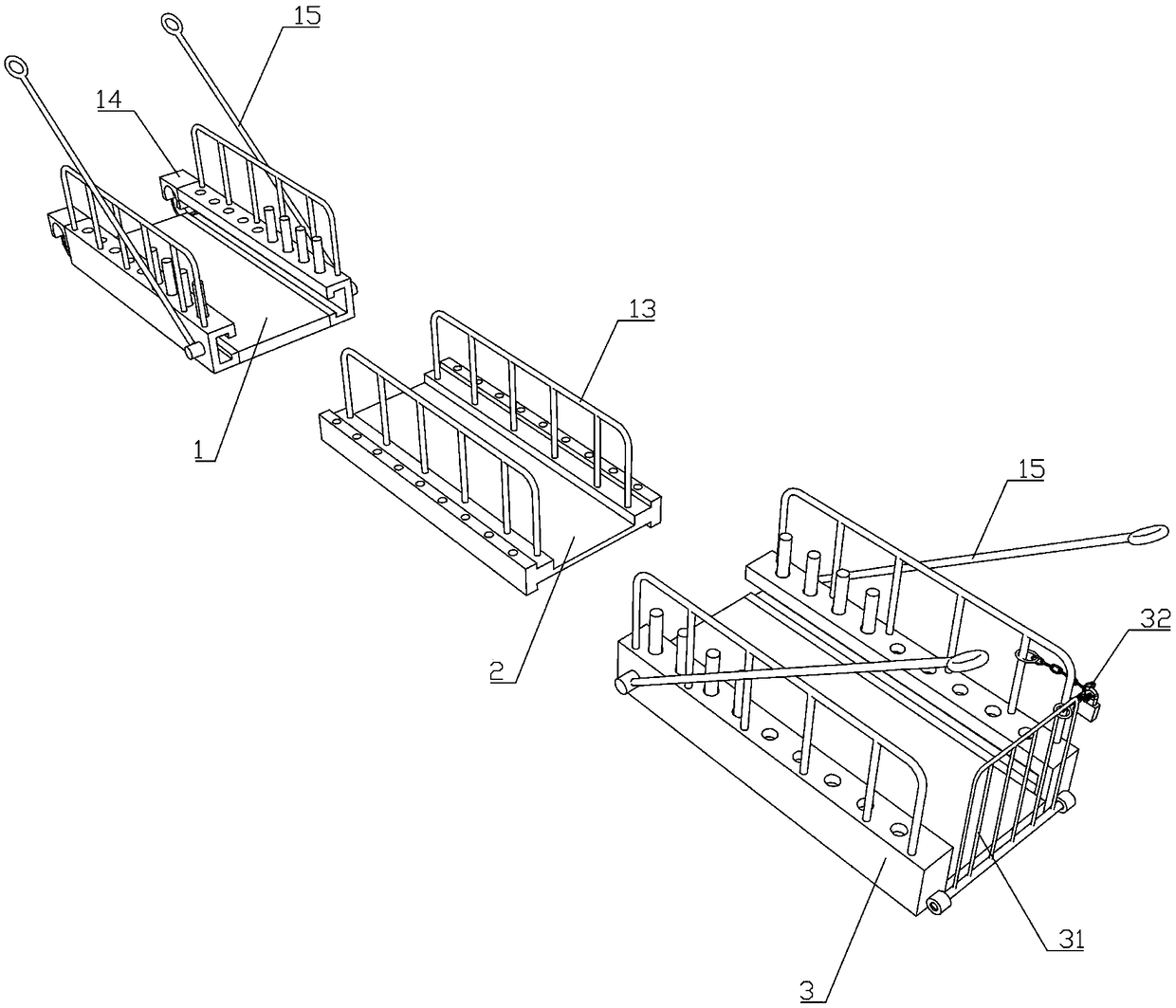

Tool type hanging stairs for deep foundation pit

InactiveCN104234447BAchieve sustainable developmentMeet traffic needsShaping building partsEngineeringBuilding construction

The invention discloses a tool-type suspension staircase for a deep foundation pit. The tool-type suspension staircase comprises a ladder assembly, a ladder assembly supporting seat and a staircase body, wherein the ladder assembly consists of two groups of ladder assembly units, a gap for installing the staircase body is arranged between the two groups of ladder assembly units, each group of ladder assembly unit comprises four stand columns, the cross section of each ladder assembly unit is in a rectangular shape, the upper end of each stand column is perpendicularly and fixedly connected with a steel beam above the stand column, and the lower end of each stand column perpendicularly stretches to the bottom surface of the foundation pit; the ladder assembly supporting seat is fixedly connected with a foundation pit enclosure, the ladder assembly supporting seat comprises two or four steel beams, and the steel beams are fixed on the upper surface of a crown beam of the enclosure structure; the staircase body is installed between the two groups of ladder assembly units from top to bottom in sequence, a corner between two adjacent staircase bodies is provided with a resting platform, and the resting platform is fixed in the internal space of the ladder assembly units. The staircase has a suspension characteristic and is installed from top to bottom, so that the staircase can be tightly combined with the procedure of the foundation pit project; the staircase is convenient for construction personnel to pass, high is safety, high in disassembling and installation speed and high in circulation rate.

Owner:BCEG CIVIL ENG

Platform system

A platform system comprising a platform structure having at least one modular platform unit with platform connection features on a side surface thereof to which other components can be connected, the other components including at least two of the following: another modular platform unit, a stair unit, a tower unit, a handrail unit, and a ladder unit. A stair assembly is connected to the platform structure via said connection features, the stair assembly comprising a plurality of stair units connected together to provide a number of steps equal to the sum of steps of the stair units.

Owner:SAFERACK

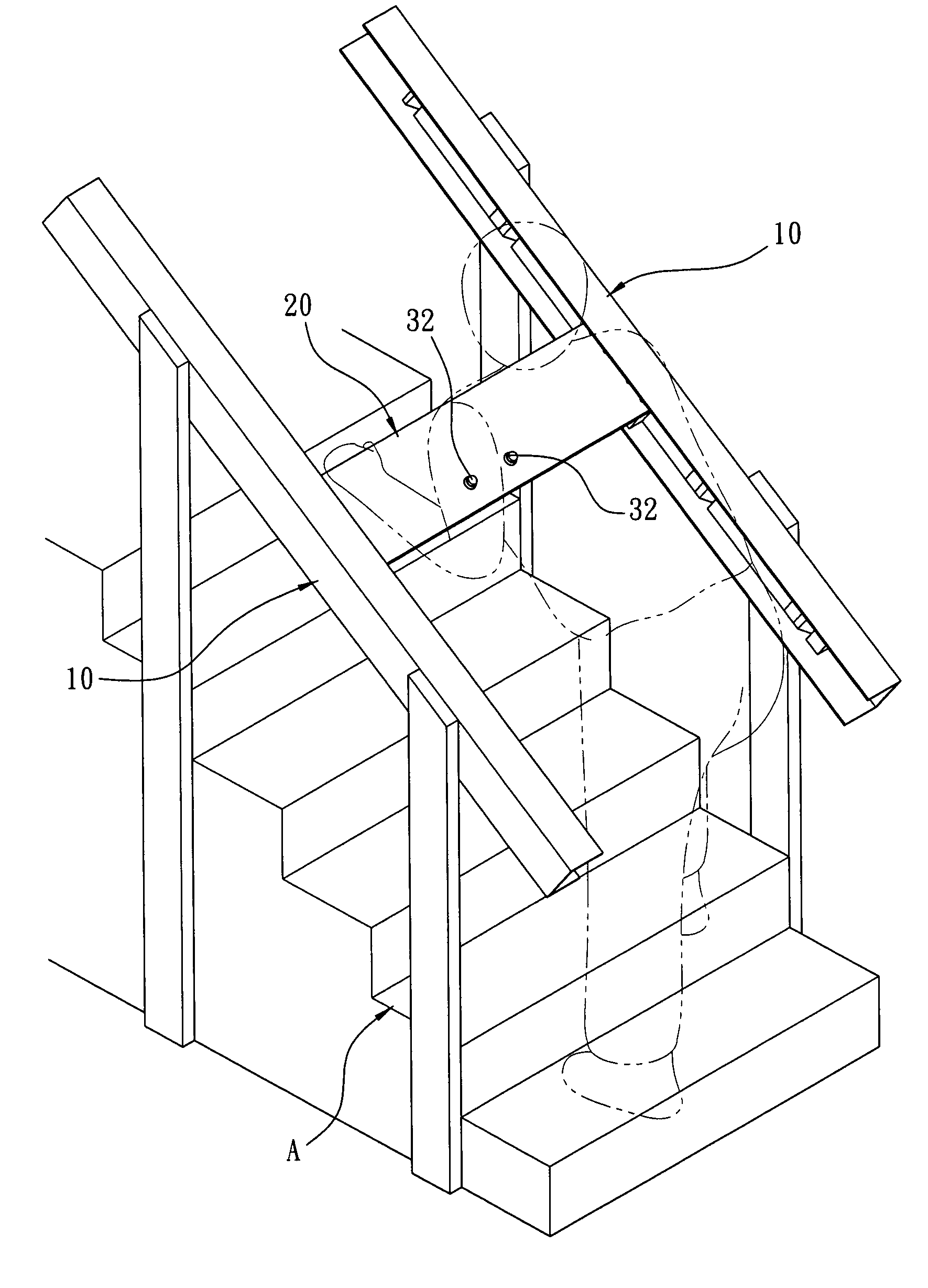

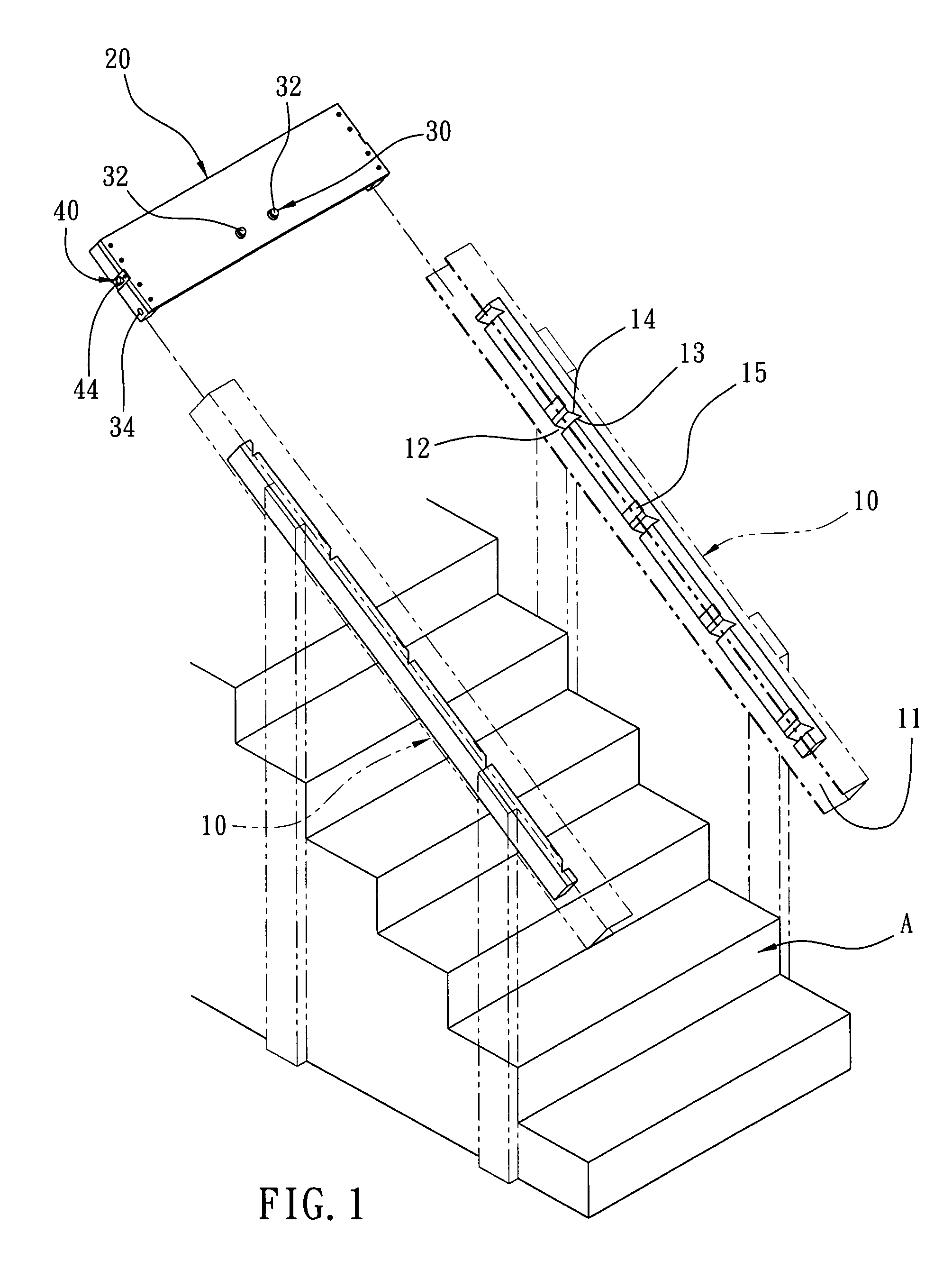

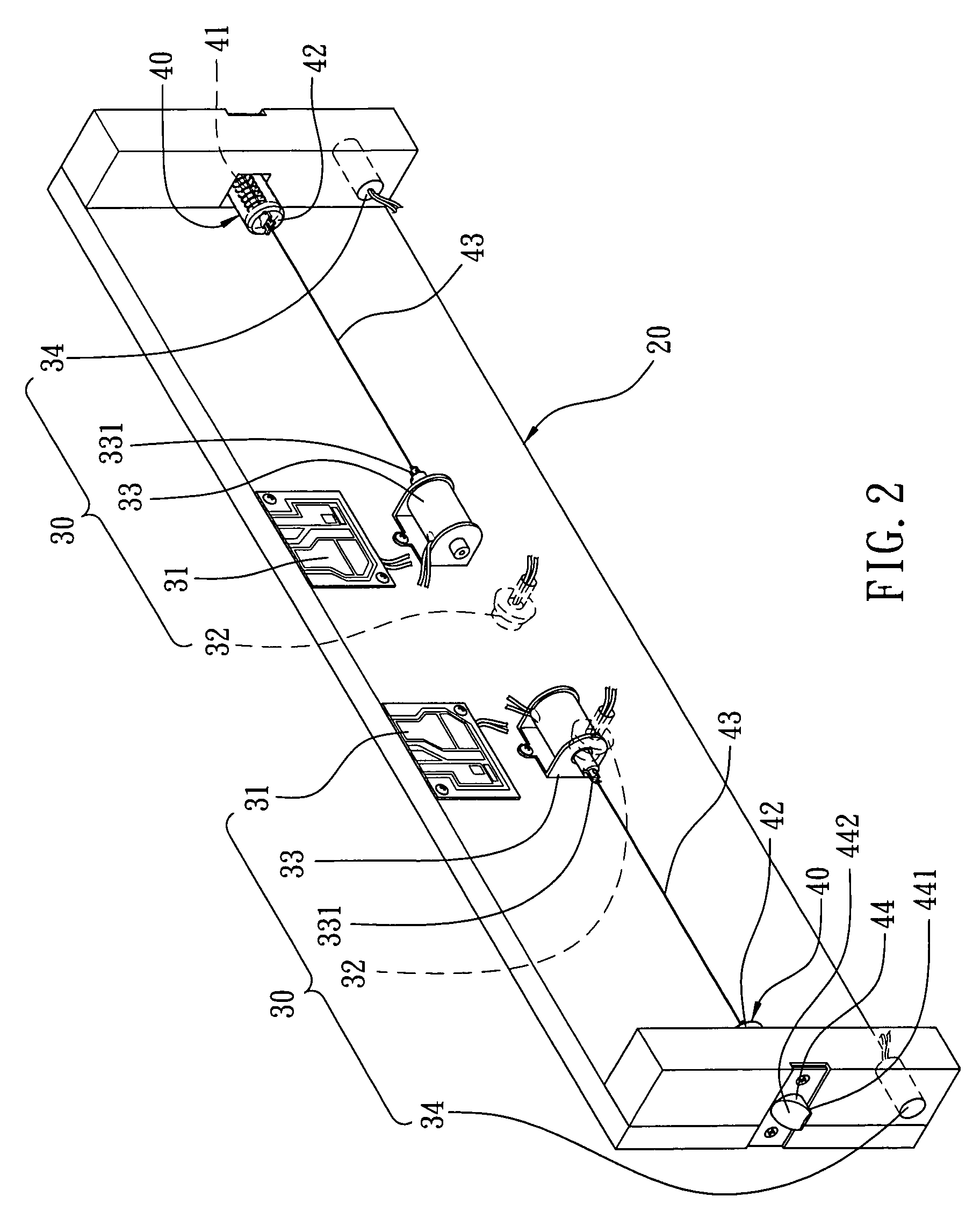

Stair climbing aid

InactiveUS7950498B2Affordable for any familySmall spacingWalking sticksScaffold connectionsEngineeringPositioning system

A stair climbing aid comprises two slide rails, an assist member, a control mechanism and two positioning assemblies. The slide rails and the assist member are assembled to handrails at both sides of the stairs. The control mechanism is disposed on the assist member to be controlled by the user. The positioning assemblies are disposed at both sides of the assist member, each positioning assembly is provided with an engaging portion to be engaged in the respective positioning portions of the slide rail. Thereby, an anti-slide effect is produced, so as to prevent the user from falling down the stairs and to help the user move from step to step safely.

Owner:NAN KAI COLLEGE

Curb cushion

The cushion according to one embodiment is a deformable resilient apparatus with a surface for allowing various vehicles to transverse from a first surface to a second surface that are separated by an obstacle without damaging the obstacle. The cushion deforms to fit the space between the vehicle and the obstacle, thereby preventing concentration of stress on the obstacle. The cushion is constructed such that it does not slide out of place when engaged by tracks or wheels of a vehicle. The cushion is constructed to deform and distribute the force applied by the vehicle onto the object more uniformly.

Owner:GUNNARSON DWIGHT R +1

Methods and apparatus for a step mounting system

Owner:SCHWEITZER KATHLEEN M

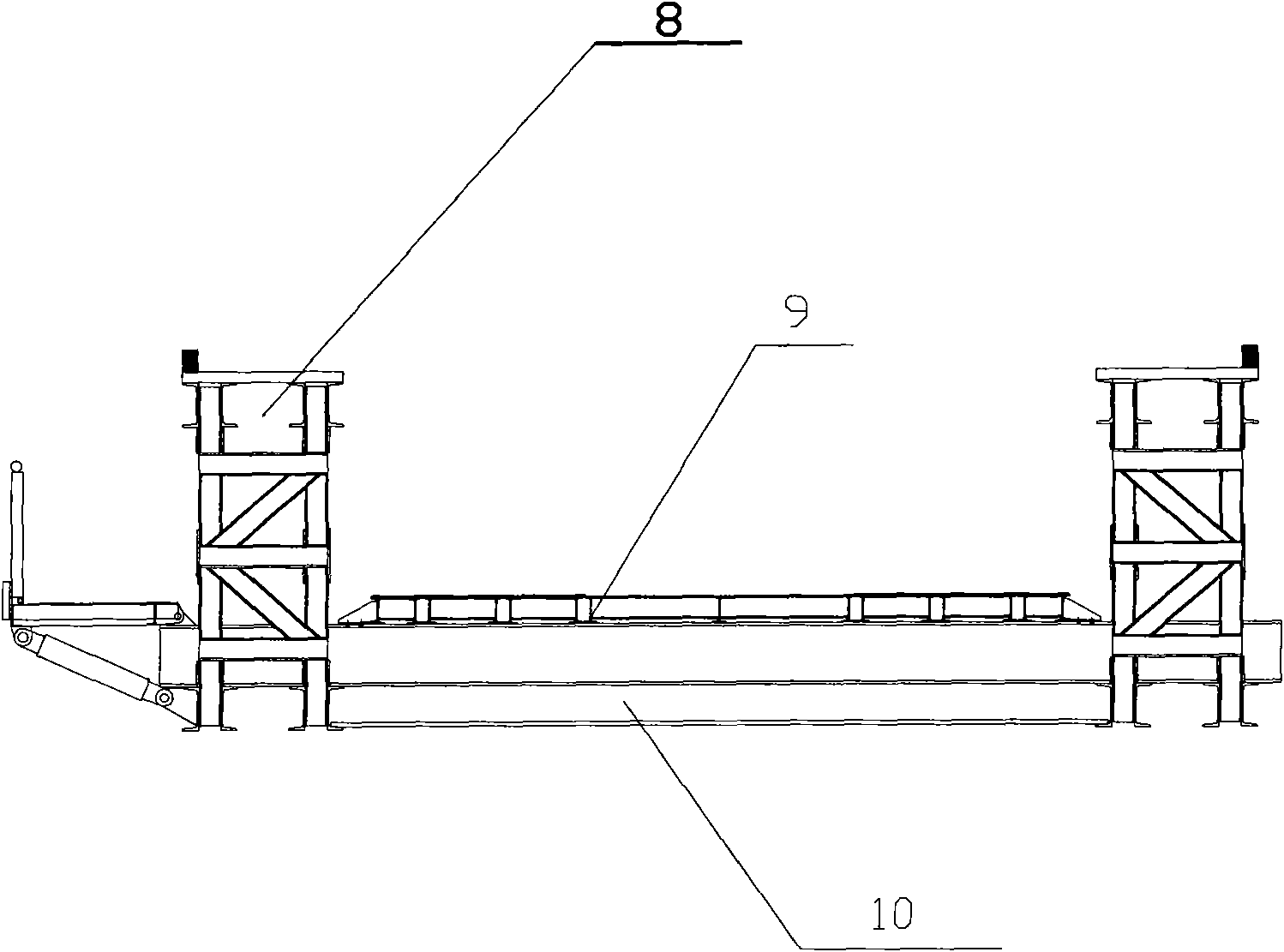

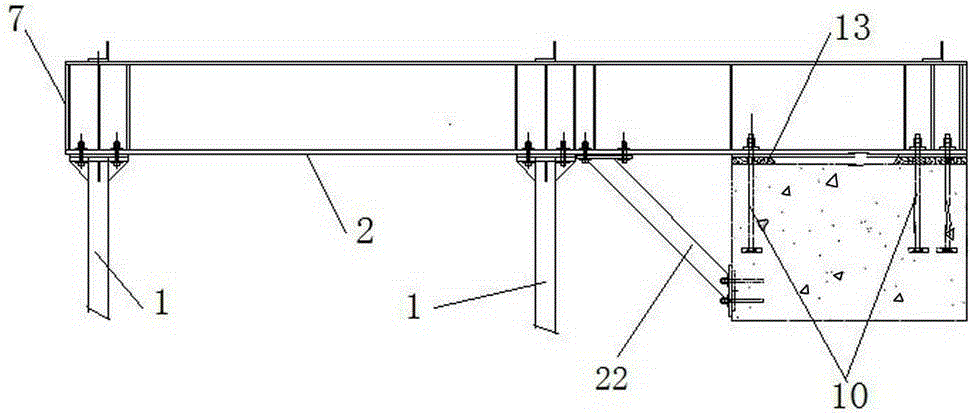

Steel bridge capable of being used as supporting and reinforcing structure

ActiveCN102936897APlay the role of support and reinforcementSave materialExcavationsShaping building partsStructural engineeringSteel columns

The invention discloses a steel bridge capable of being used as a supporting and reinforcing structure, comprising an inclined bridge body and steel columns for supporting the bridge body, wherein a bridge head is supported on a crown beam at the top of a supporting structure of a foundation pit; bridge feet are supported at the bottom of the foundation pit; the bottom face of the bridge head is fixedly connected with a force transmission cross beam which extends along the width direction of the bridge body; the front side face of the force transmission cross beam is mutually adhered to the side face of the crown beam; an inclined supporting rod is arranged between the force transmission cross beam and the bottom of the foundation pit; the upper end of the inclined supporting rod is fixedly connected with the force transmission cross beam; and the lower end of the inclined supporting rod is fixedly connected with the foundation pit. According to the steel bridge, the supporting structure of the bridge head can be effectively supported and reinforced, and an independent reinforcing structure or supporting structure does not need to be arranged, so that the engineering cost is greatly reduced.

Owner:GUANGZHOU CONSTR ENG +1

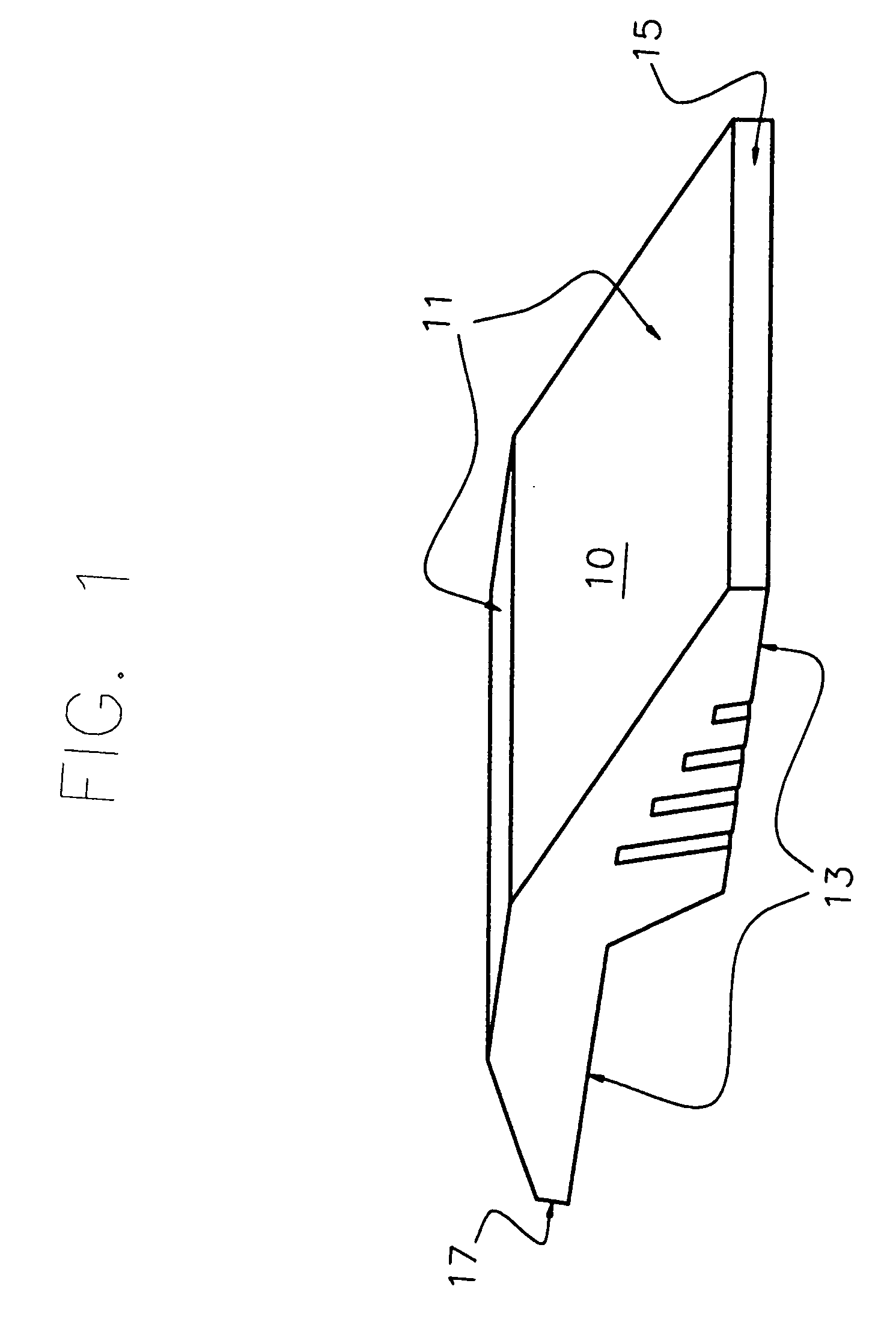

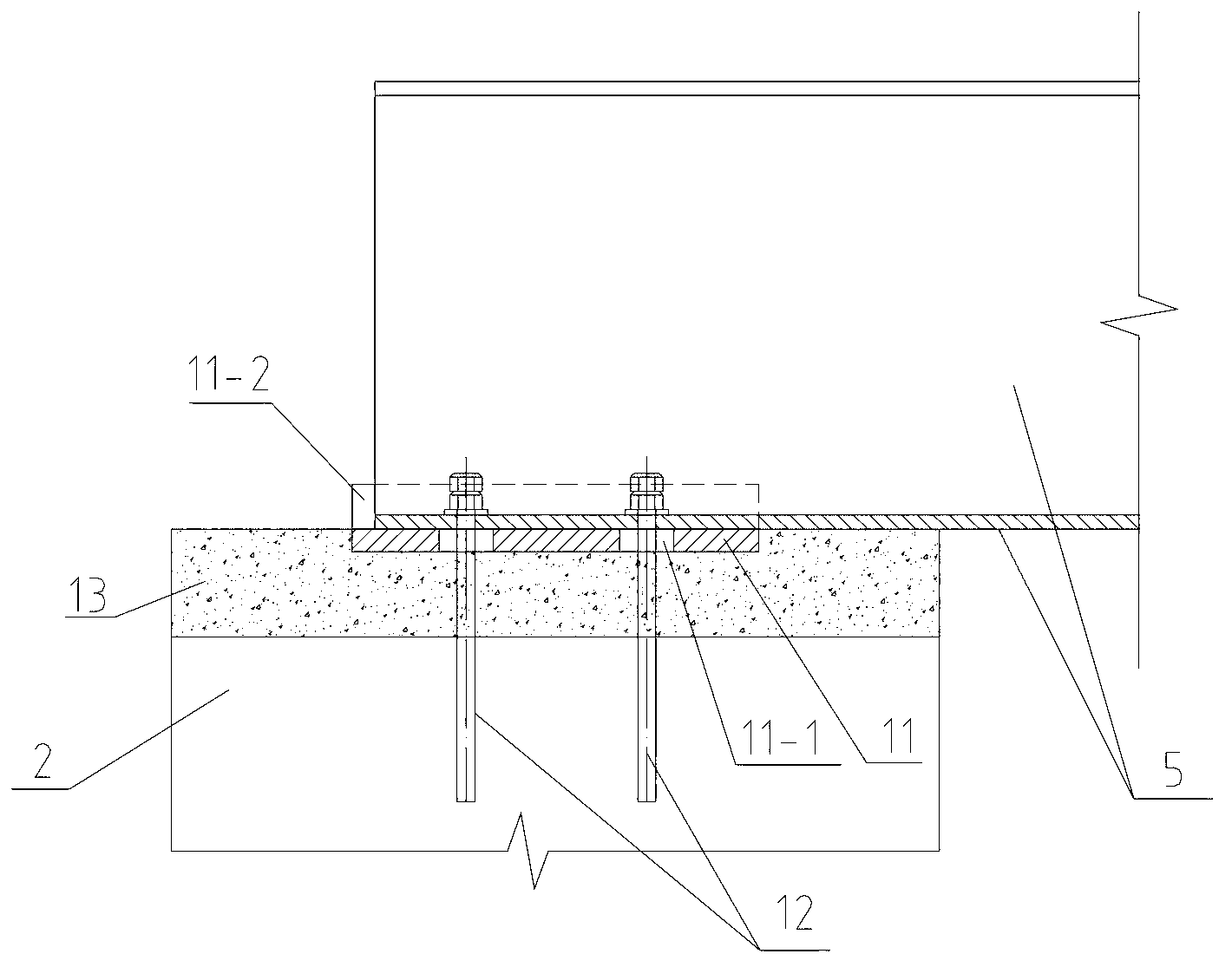

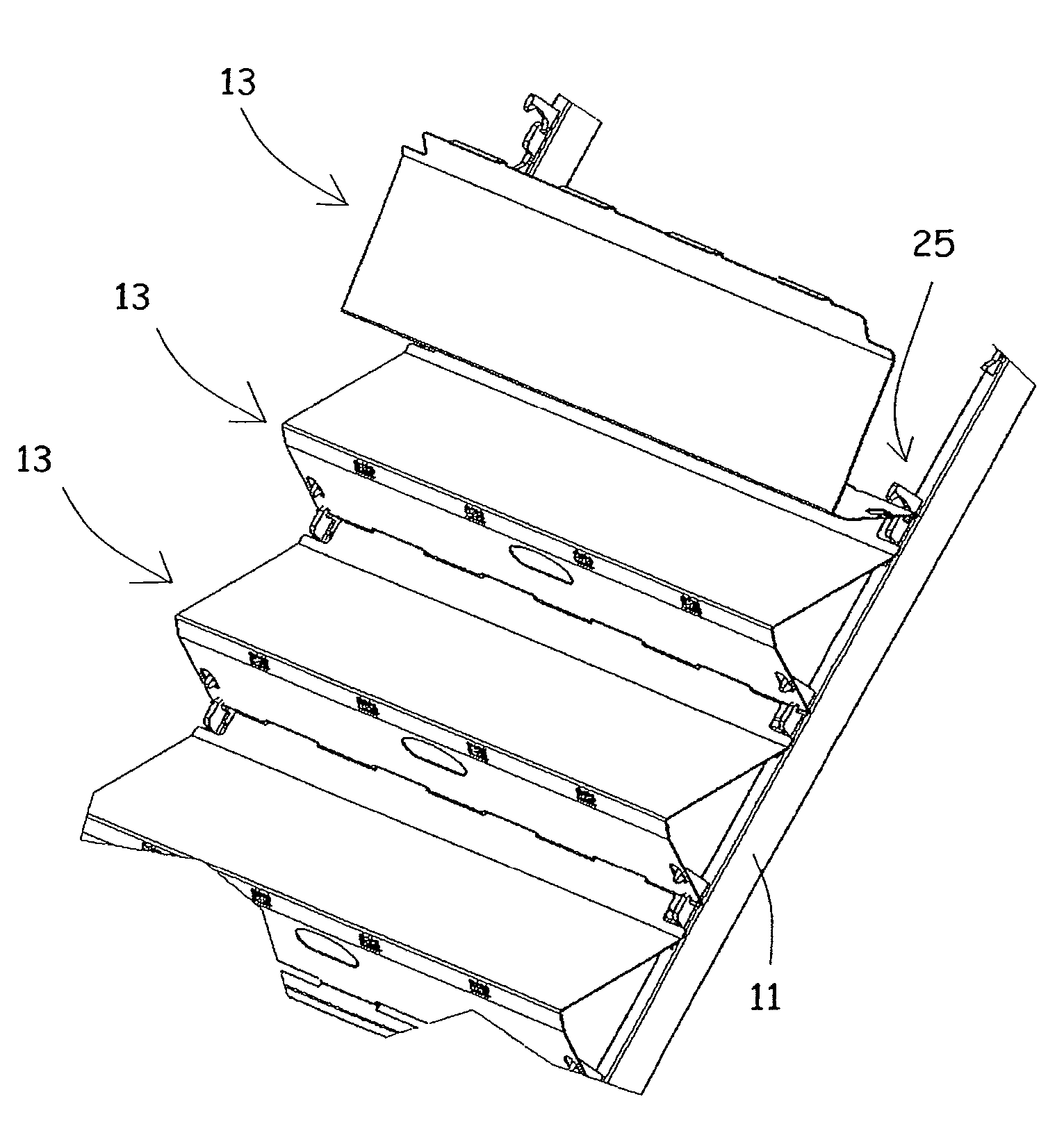

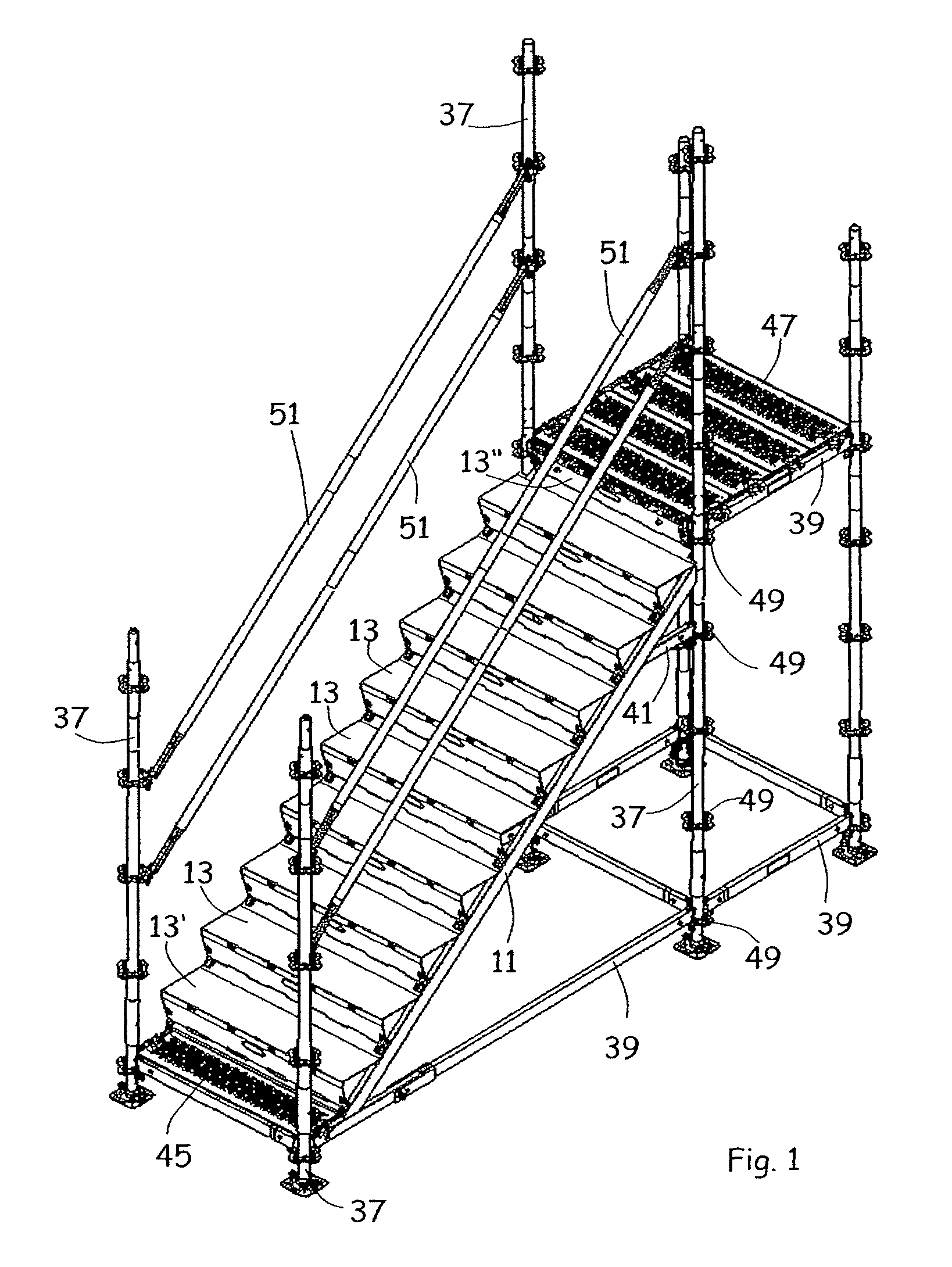

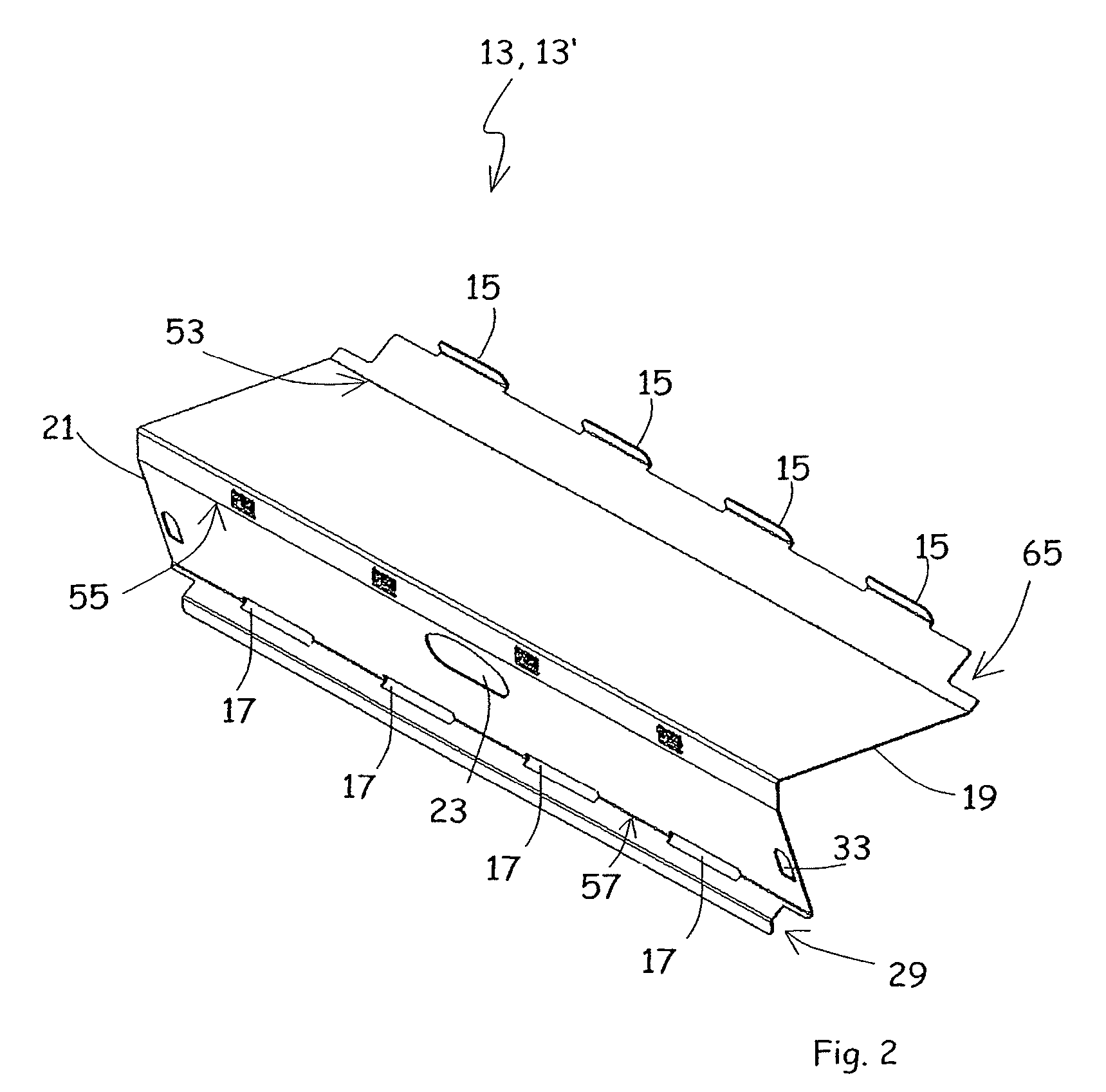

Scaffold steps

The invention relates to scaffold steps, with two separate side pieces (11) and a plurality of separate step elements (13, 13′, 13″), which can be detachably coupled to each other and to the side pieces.

Owner:PERI GMBH

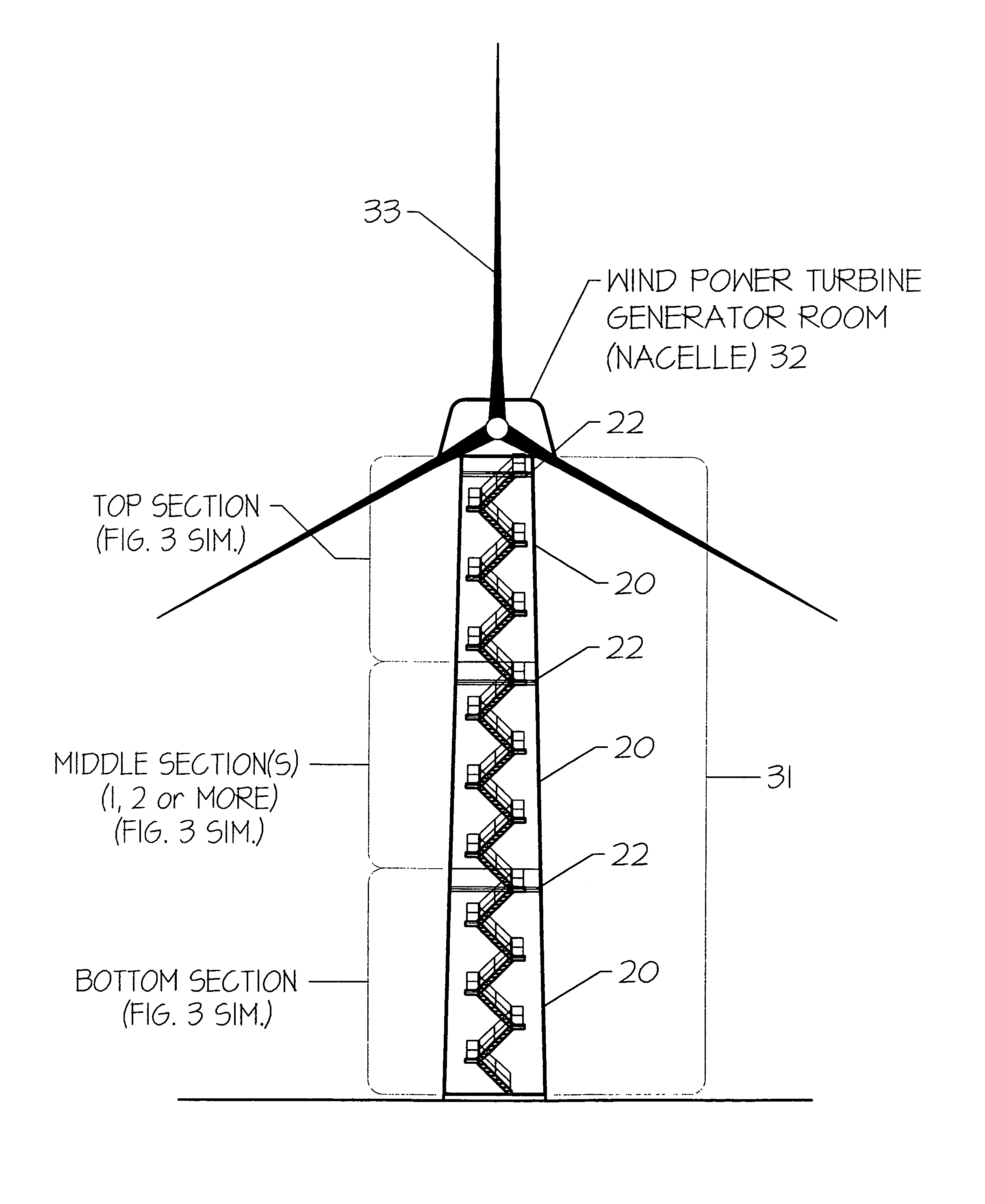

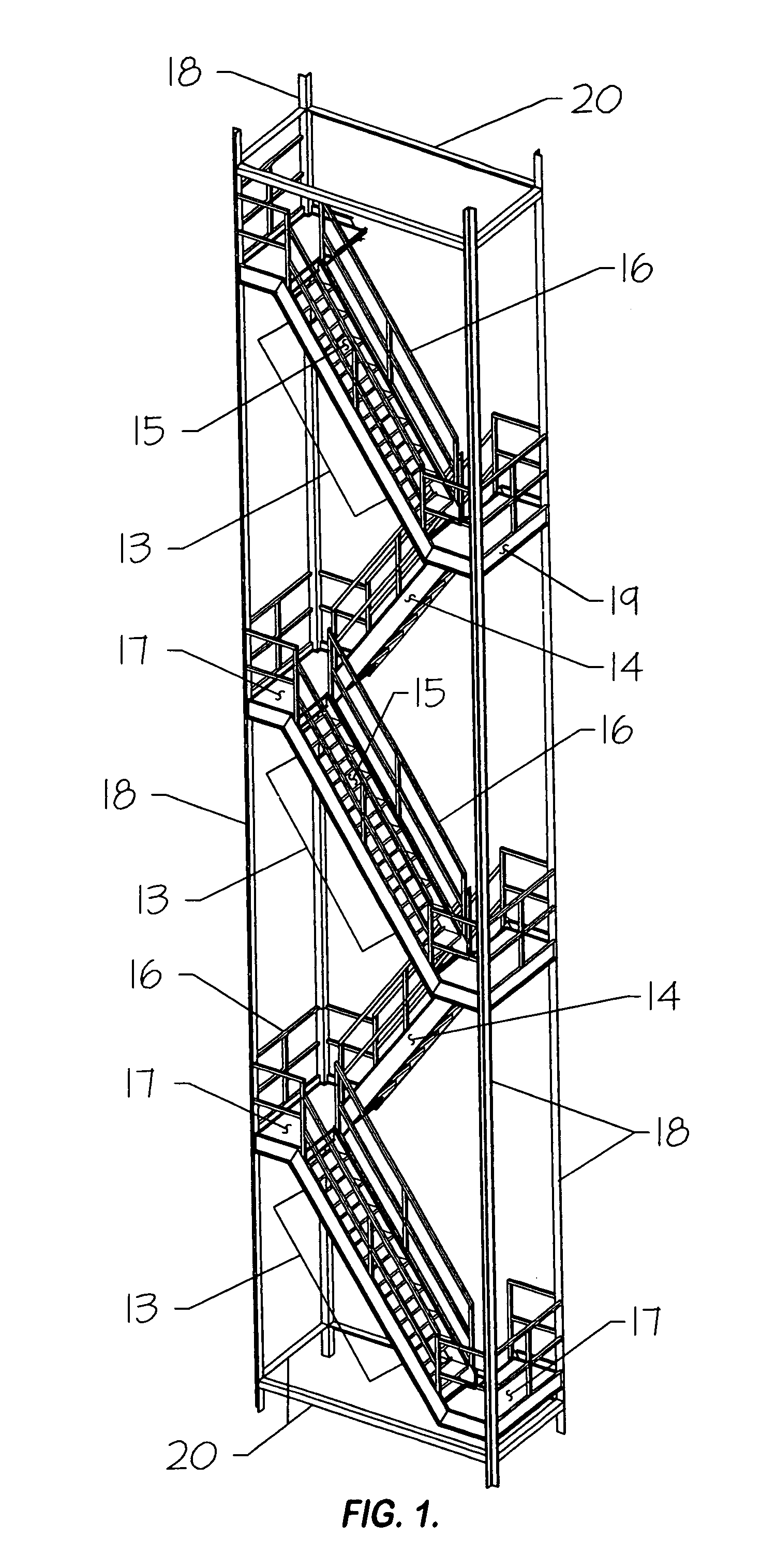

Stair tower module

ActiveUS8771544B2Minimal numberIncrease labor costOther chemical processesWind motor assemblyLand basedOffshore wind power

Owner:HOPPER LARRY JAMES

Supertall building core tube construction safety fire protection system and device

ActiveCN101876209ASolve the technical problems of safe escapeSecurity Fire ControlBuilding material handlingShaping building partsFire protectionArchitectural engineering

The invention discloses supertall building core tube construction safety fire protection system and device, comprising a construction elevator standard section and a core tube inner platform, wherein the construction elevator standard section is connected with a crawling ladder and is connected with a safety fire protection channel framework at the same side with the crawling ladder, the safety fire protection channel framework is fixedly connected to the core tube inner platform, the upper side, the lower side, the left side and the right side of the safety fire protection channel framework are provided with checkered steel plates in which fire-resistance plates are arranged, and the construction elevator standard section is connected with the safety fire protecton channel framework through an engaged channel. The invention effectively solves the technical problem of safety escape of constructors on a work layer when breaking out a fire during supertall building core tube construction and ensures the life safety of the constructors; meanwhile, the invention can realize the effective control on safety fire protection in the supertall building core tube construction, ensure the safety management of the supertall building core tube construction, and improve the safety management level and the integrated benefits of the supertall building core tube construction.

Owner:ZHONGTIAN CONSTR GROUP

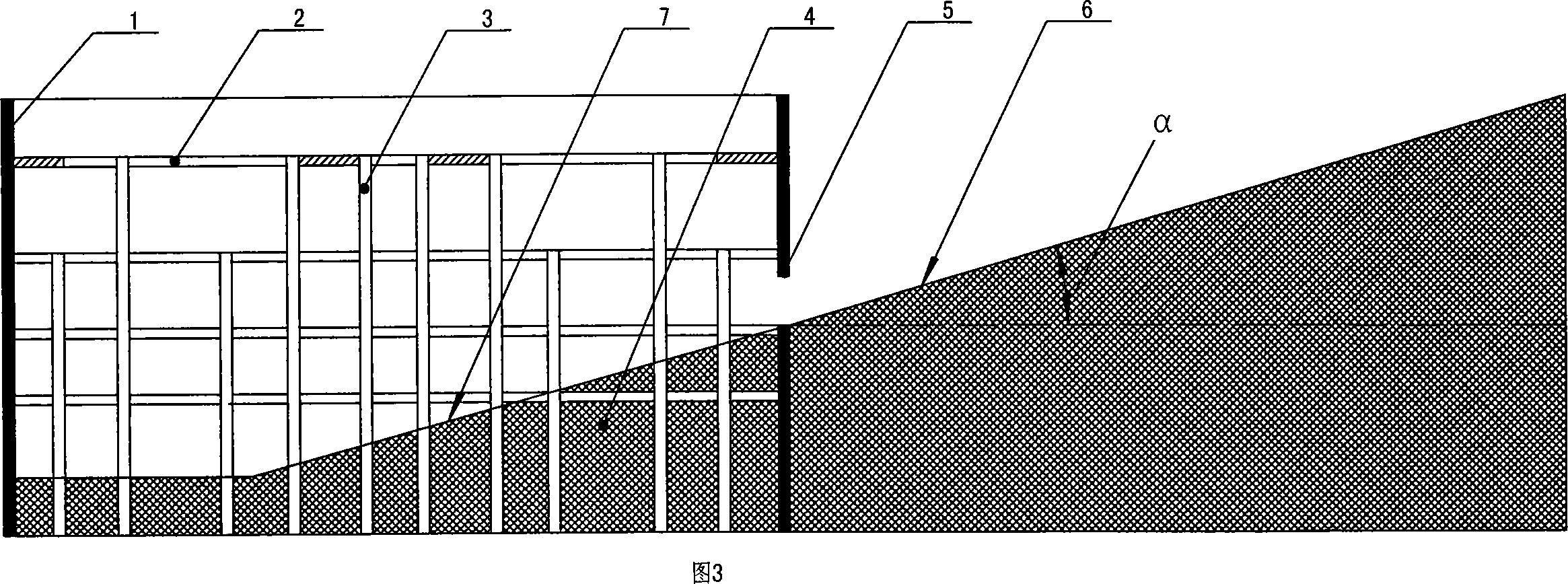

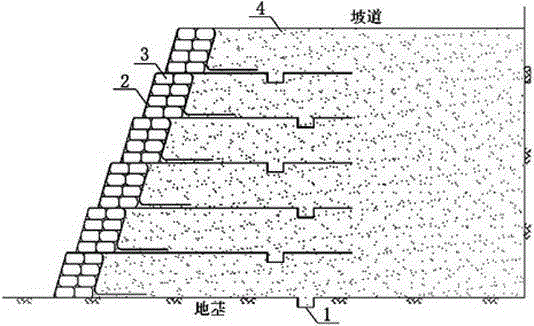

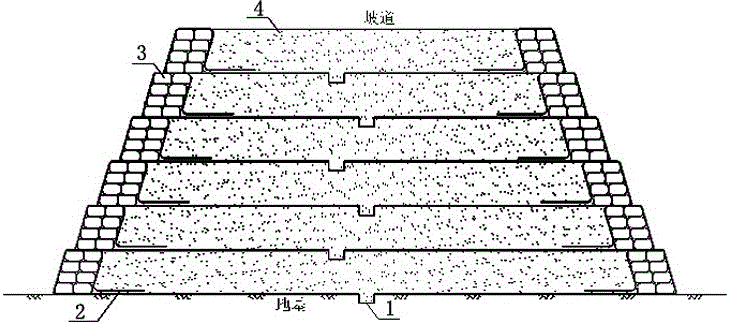

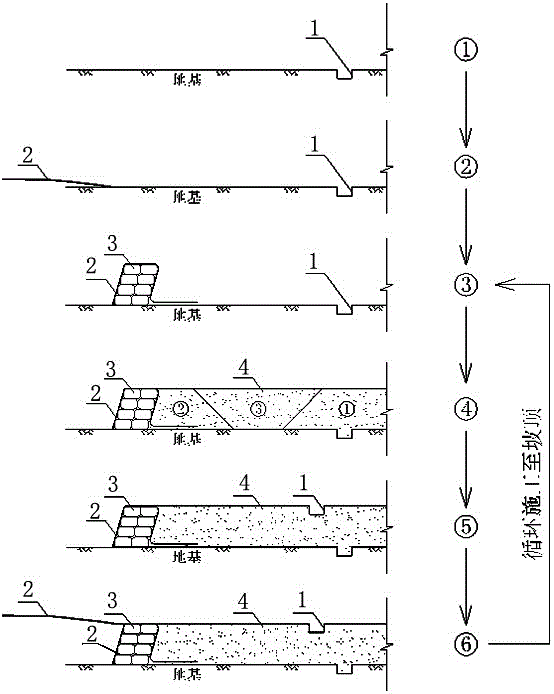

Reinforced backfill earthwork ramp and construction method thereof

InactiveCN104988927AImprove stabilityEnsure safetyExcavationsShaping building partsSlope stabilityGeotextile

The invention belongs to the field of building technology, and particularly to a reinforced backfill earthwork ramp and a construction method thereof. A reinforced backfill earthwork ramp comprises a ramp and a protective structure, and the protective structure has multilayer repetitive structures. Each protective structure has backfill, an anchoring trench, earthwork cloth and earth bags. The earthwork cloth is laid in the anchoring trench, and the backfill presses on the earthwork cloth. The earth bags are arranged at one side of a side slope of a ramp, a portion of at the outside of the earthwork cloth is reserved, and the reserved portion reversely wraps the earth bags and then is pressed in the backfill, to form the protective structure. The construction method of the reinforced backfill earthwork ramp comprises back filling in layers, excavating the anchoring trenches, laying the earthwork cloth in the backfill in layers, arranging the earth bags at one side of a side slope of a ramp, reserving a portion of at the outside of the earthwork cloth, reversely wrapping the earth bags and pressing the reserved portion in the backfill to form the protective structure. By adopting the reinforced backfill earthwork ramp and the construction method thereof, the side slope of the ramp is good in stability, the side slope of the ramp can be ensured safe, and the reinforced backfill earthwork ramp is simple in construction and low in cost.

Owner:QINGDAO INST OF SURVEYING & MAPPING SURVEY

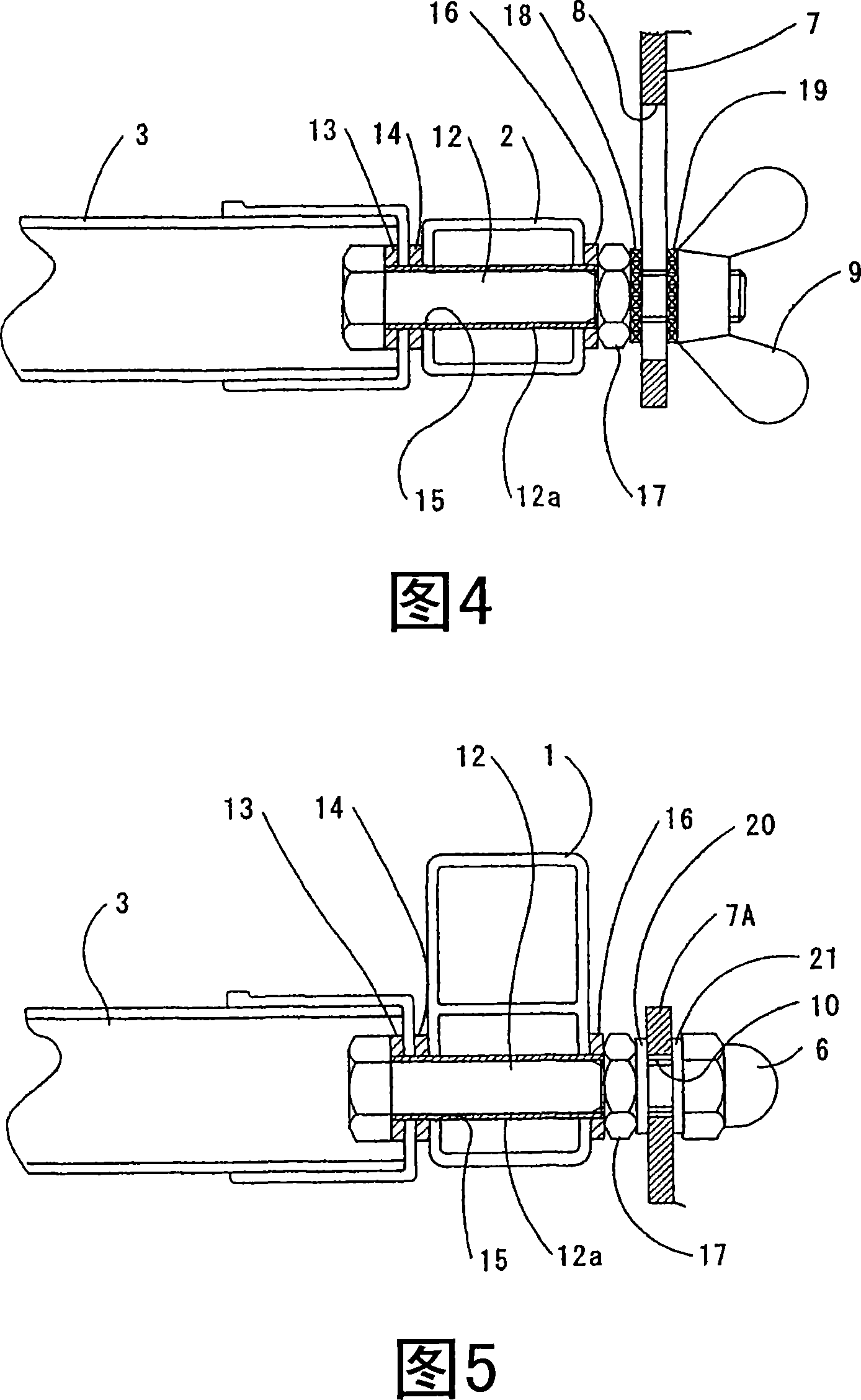

Walkway installation having a handrail connector

ActiveUS20210293028A1Better able to resist sideways deflectionReduced torsional stiffnessRod connectionsSnow trapsFootpathHandrail

A walkway installation includes a walkway assembly which includes at least one tread module supported by a pair of spaced apart elongate supports which extend in the direction of the length of the walkway installation, the walkway installation additionally including a handrail assembly including a handrail which extends in the direction of the length of the walkway assembly and a plurality of spaced apart posts which each secure the handrail relative to the walkway assembly, the handrail assembly additionally including a first connector which secures a post to one side of the walkway assembly and the first connector having secured thereto a substantially inflexible transverse link which extends across the walkway assembly in a direction perpendicular to the length of the walkway installation, the transverse link extending to a second connector secured to the other side of the walkway.

Owner:KEE KLAMP LTD

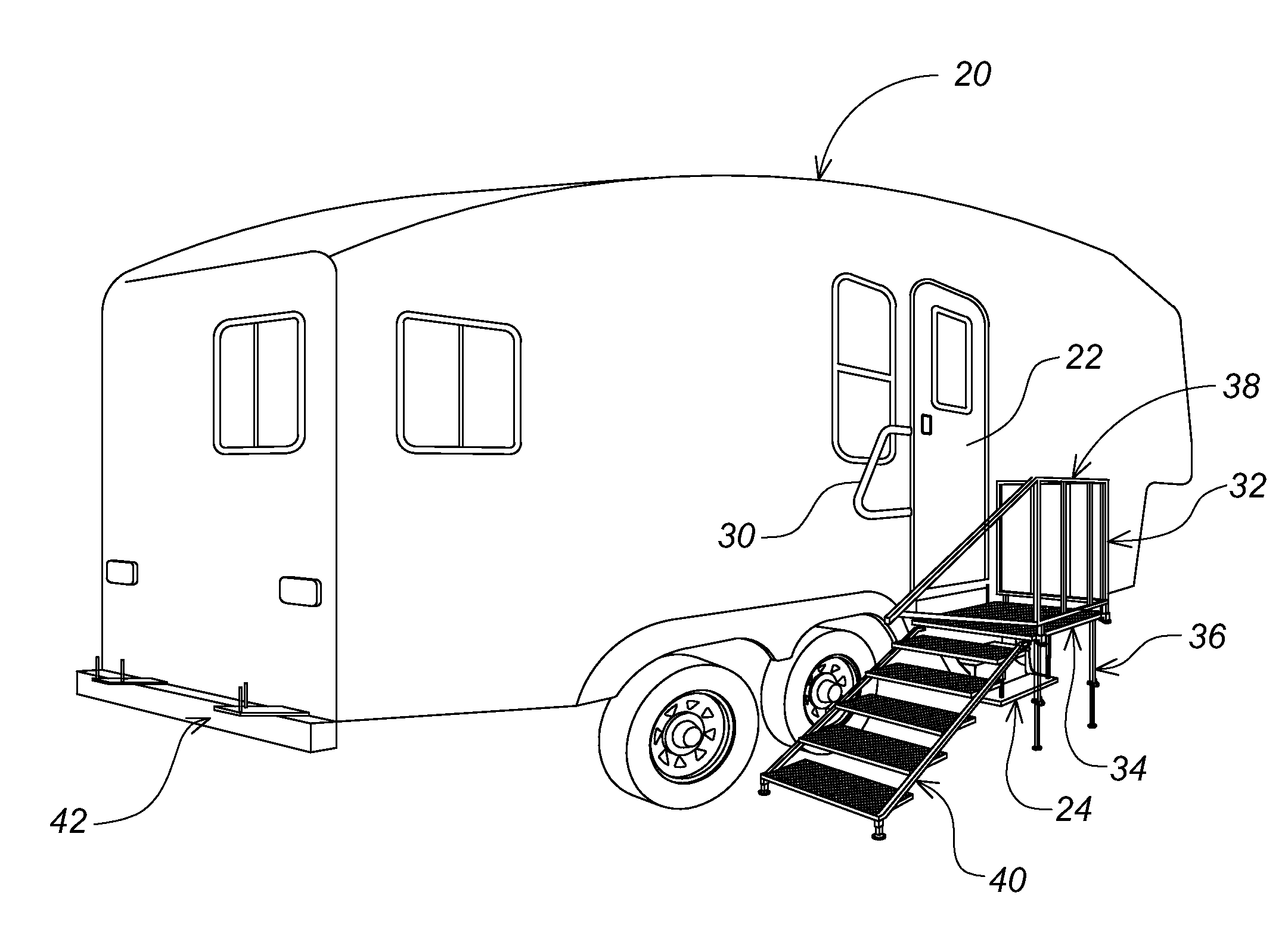

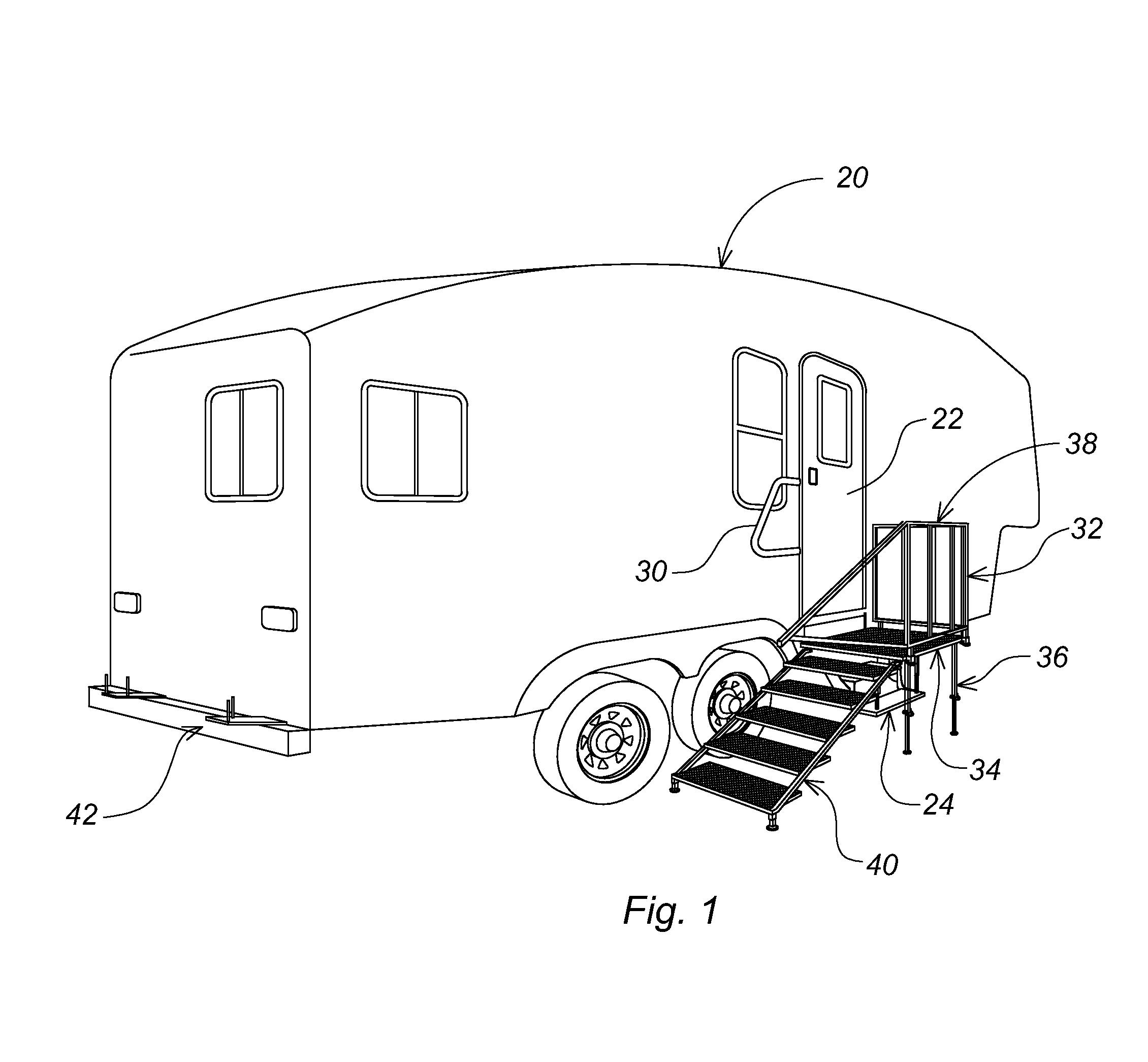

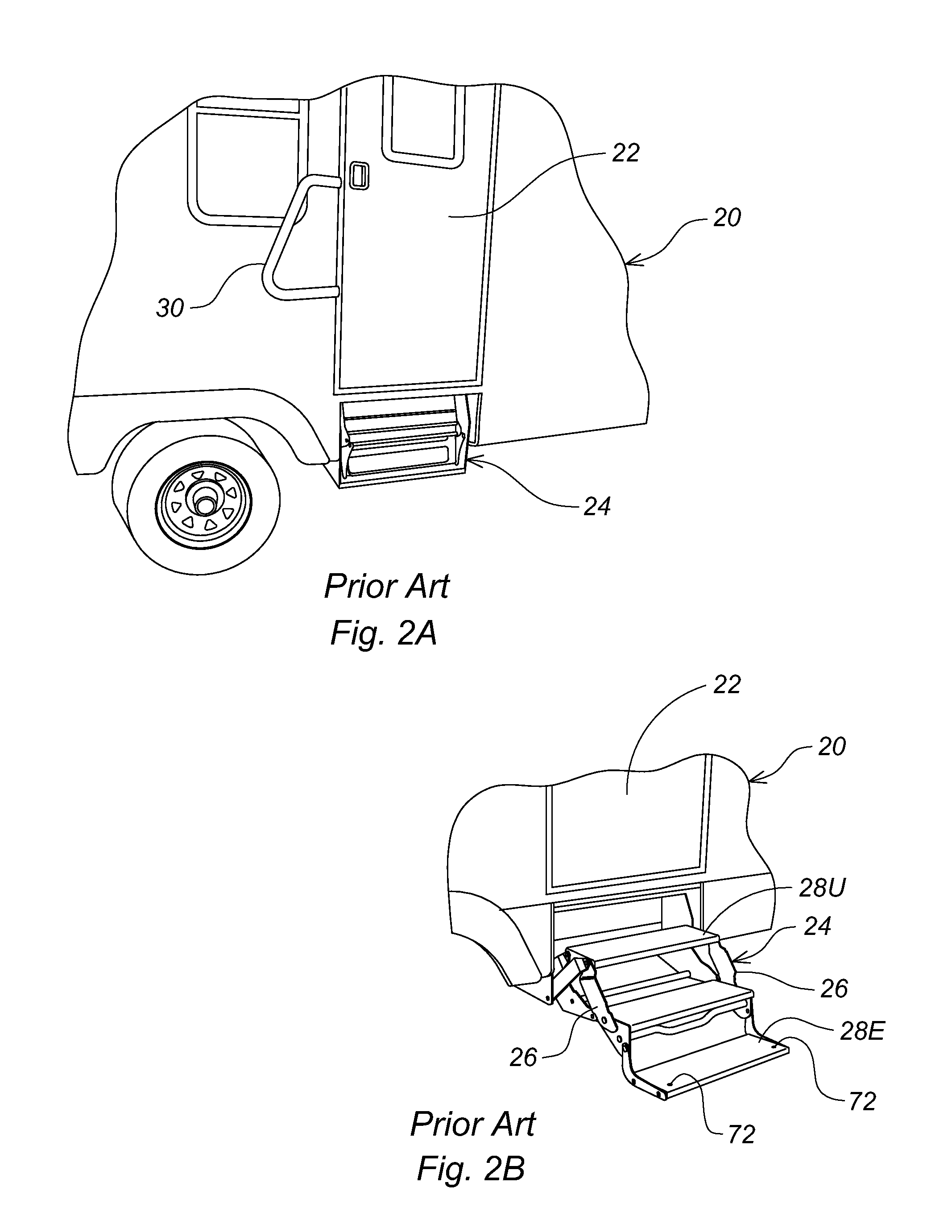

Portable porch with integral stairs

A portable porch configured to at least partially attach to a recreational vehicle (RV) by integrating with a retractable step assembly associated with the vehicle for accessing a doorway in the vehicles's sidewall. The portable porch includes a platform, a plurality of adjustable legs, at least one railing, and a porch stairway for additional functionality and stability. The platform couples to an upper step of the retractable step assembly and at least one of the adjustable legs couples to a lower step in the retractable step assembly. Other features include support rods on the platform for attachment of the porch stairway.

Owner:OWENS JR JAMES W

Safe and practical tread board for realizing simple and convenient disassembly and assembly of temporary staircase in construction site

InactiveCN102995916AOvercome the shortcomings of poor anti-skid force of stepping, which can easily cause safety accidentsEasy to set upShaping building partsSteel tubeTread

The invention relates to a safe and practical tread board for realizing the simple and convenient disassembly and assembly of a temporary staircase in a construction site, comprising a tread steel board and steel tube rings, wherein the outer side of the tread steel board is turned downwards, the inner side of the tread steel board is turned upwards, and one steel tube ring used for penetrating in a tread steel tube is welded at each of the both sides of the back surface of the tread steel board respectively. The tread steel board is a steel board with patterns which are 3 mm thick, as well as is 900 mm long and 250 mm wide. The inner side and the outer side of the tread steel board are turned upwards by 30 mm and turned downwards by 30 mm respectively. The two steel tube rings on the back surface of the steel board have a diameter of 50 mm. According to the invention, the tread steel board which is convenient to disassemble and assemble is additionally arranged on the basis of the original temporary staircase which is erected by all-steel tubes, thus overcoming the defect that the original tread steel board composed of double steel tubes is bad in anti-slide force and extremely easy to cause safety accidents. Except the tread steel board, the whole temporary staircase structure can be formed by standard scaffold steel tubes and fasteners, and is simple and convenient to erect.

Owner:SHANGHAI NO 4 CONSTR

Tower crane temporary passage and mounting method thereof

InactiveCN108750970ASolve problems such as complicated constructionEliminate potential safety hazardsCranesShaping building partsArchitectural engineeringEngineering

The invention relates to the technical field of building safety construction, in particular to a tower crane temporary passage and a mounting method thereof. The tower crane temporary passage comprises a fixing joint, a middle joint and a telescopic joint. The fixing joint is fixedly connected with a tower crane standard joint. One end of the telescopic joint is arranged on a building floor plate.The middle joint is inserted between the fixing joint and the telescopic joint and matched with the telescopic joint for adjusting the length of the channel. The mode that the fixing joint, the middle joint and the telescopic joint are spliced is adopted, and the length can be adjusted at will to reach the required construction distance; and the tower crane temporary passage is simple in structure, convenient to dismount and mount and reusable and does not need to be repeatedly erected, the problems that existing super high tower crane passages are tedious to construct in the erection and dismounting processes and the like are solved, the turnover frequency is increased, lots of labor is saved, potential safety hazards during mounting and dismounting are eliminated, safety of a tower crane driver during crane getting-on is effectively improved, and the tower crane temporary passage is scientific and reasonable in design and suitable for application and popularization for building construction.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

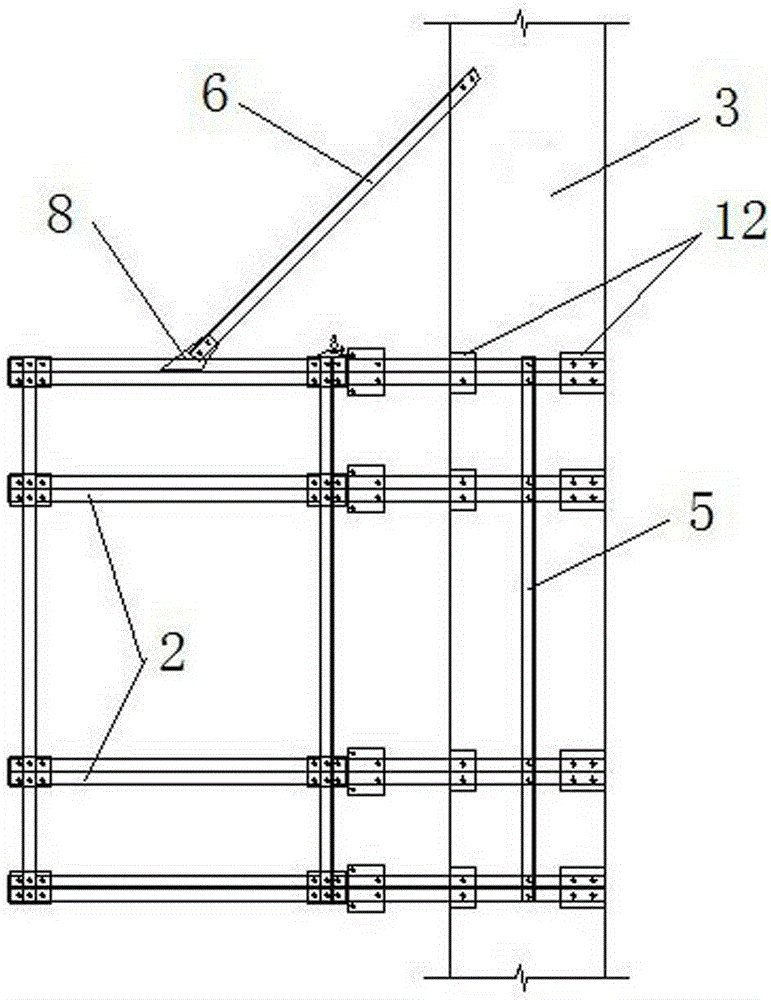

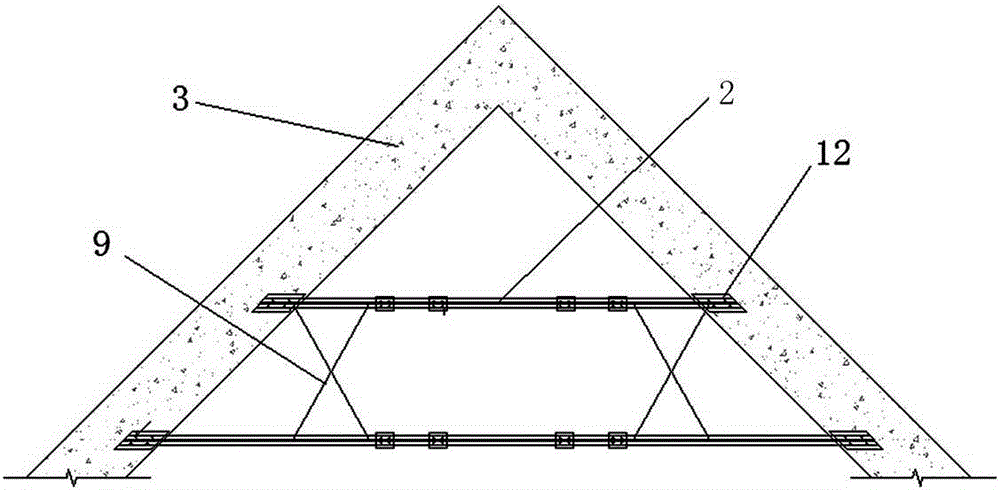

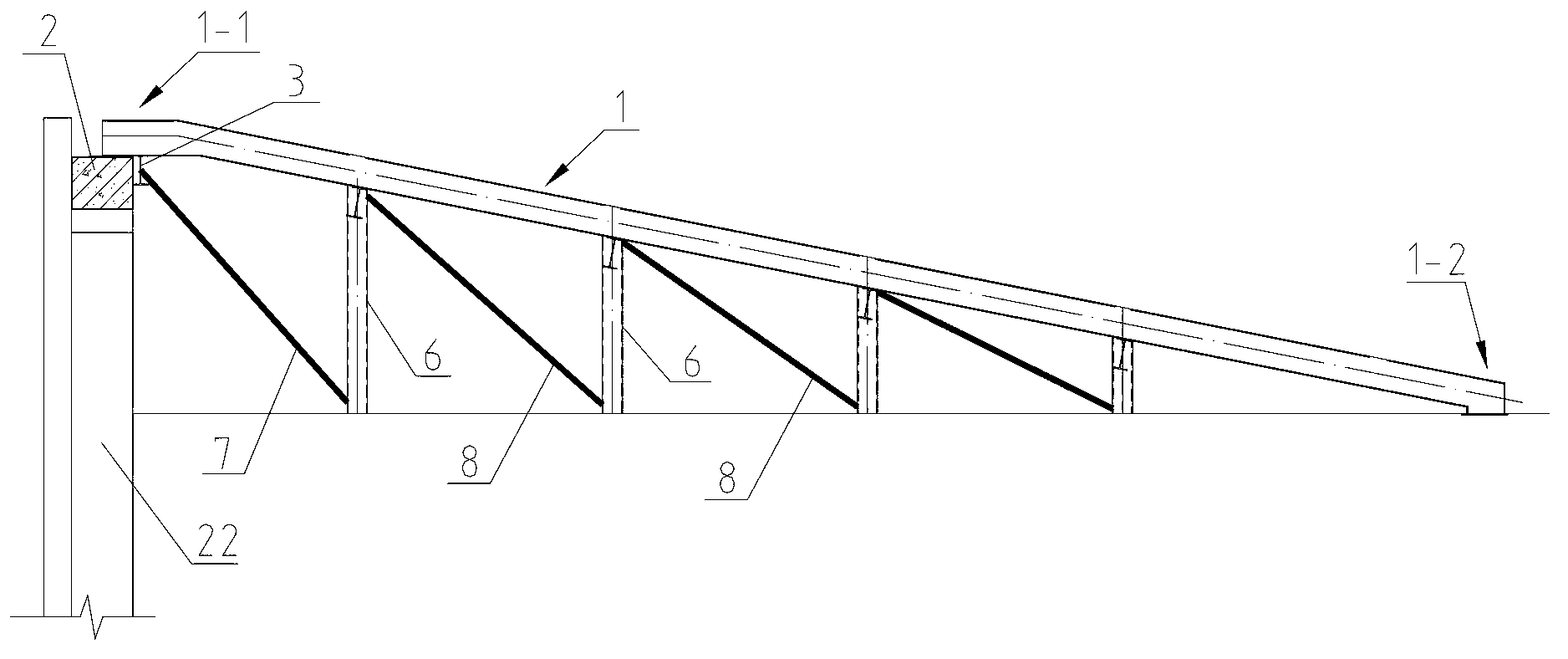

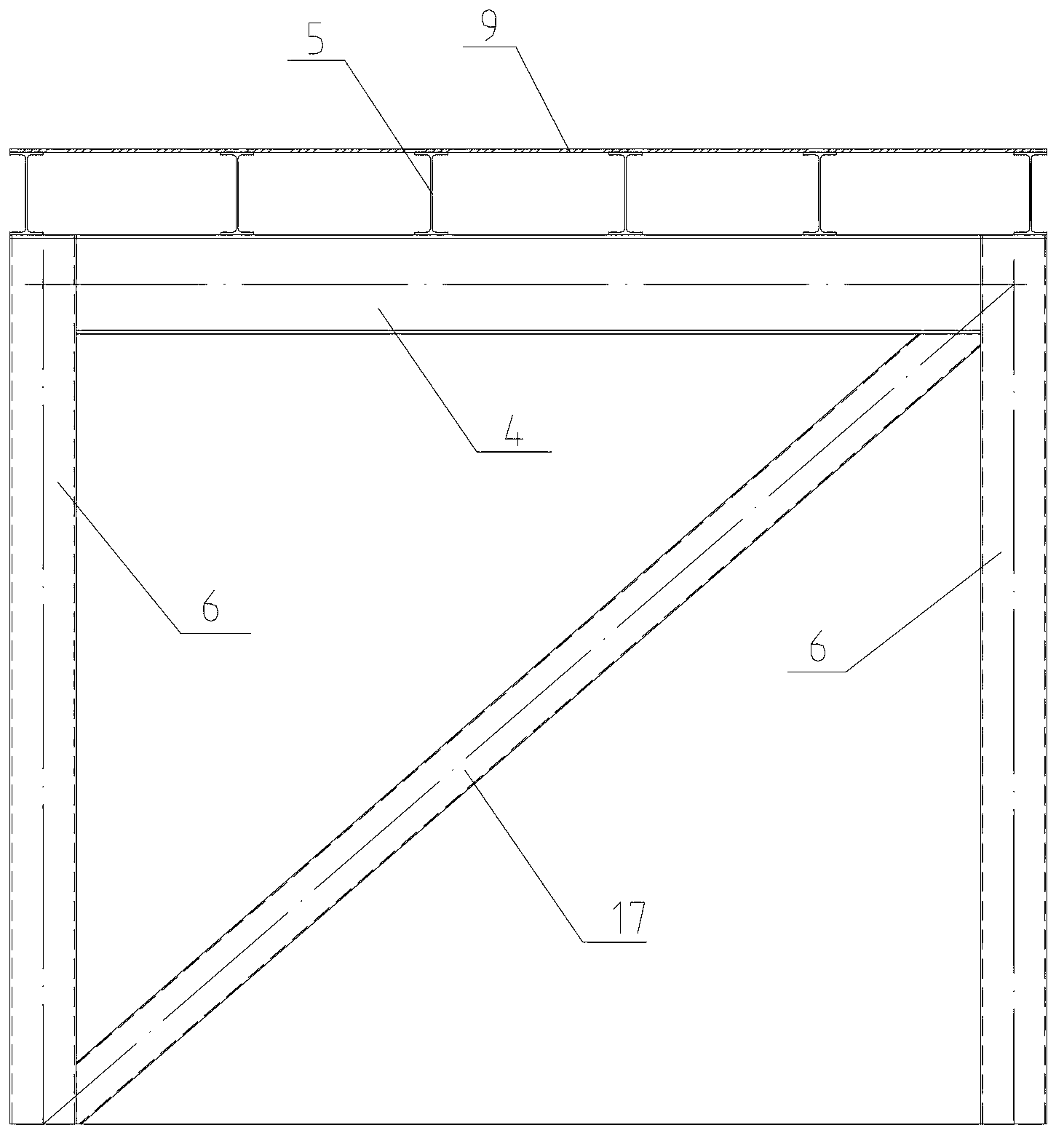

Slanting construction trestle combined with internal supporting system

InactiveCN104005571AImprove lateral stabilityImprove digging efficiencyShaping building partsSupporting systemSupport system

The invention discloses a slanting construction trestle combined with an internal supporting system of a foundation pit. The slanting construction trestle is arranged between an upper support and a lower support, and a trestle wharf is arranged in the middle of the lower support at the same time. The slanting construction trestle is combined with the internal supporting system, column piles are used for vertical supporting and horizontal supporting, and shear walls or trusses are arranged between the supports and the trestle to reinforce the integrity of the trestle and the supports. By means of the slanting construction trestle, a construction channel from the ground to the inside of the foundation pit is established, an earth cutting machine can directly descend into the pit for earth cutting construction and transportation operation without limitation of the cutting depth of the foundation pit, and therefore the earth cutting efficiency is improved to a great extent; since the slanting construction trestle is combined with the internal supporting system, the lateral stability of the trestle is improved; moreover, the column piles of the supporting system are used for supporting the trestle vertically and horizontally, a supporting beam is used as a frame beam of the trestle, and therefore a large amount of engineering cost can be saved.

Owner:浙江华展工程研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com