Stairway for Use on Building Sites

a technology for building sites and stairs, applied in the field of stairs, can solve the problems of increased travel time for accessing stairs, increased inconvenience, and increased construction costs, and achieve the effect of significant cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

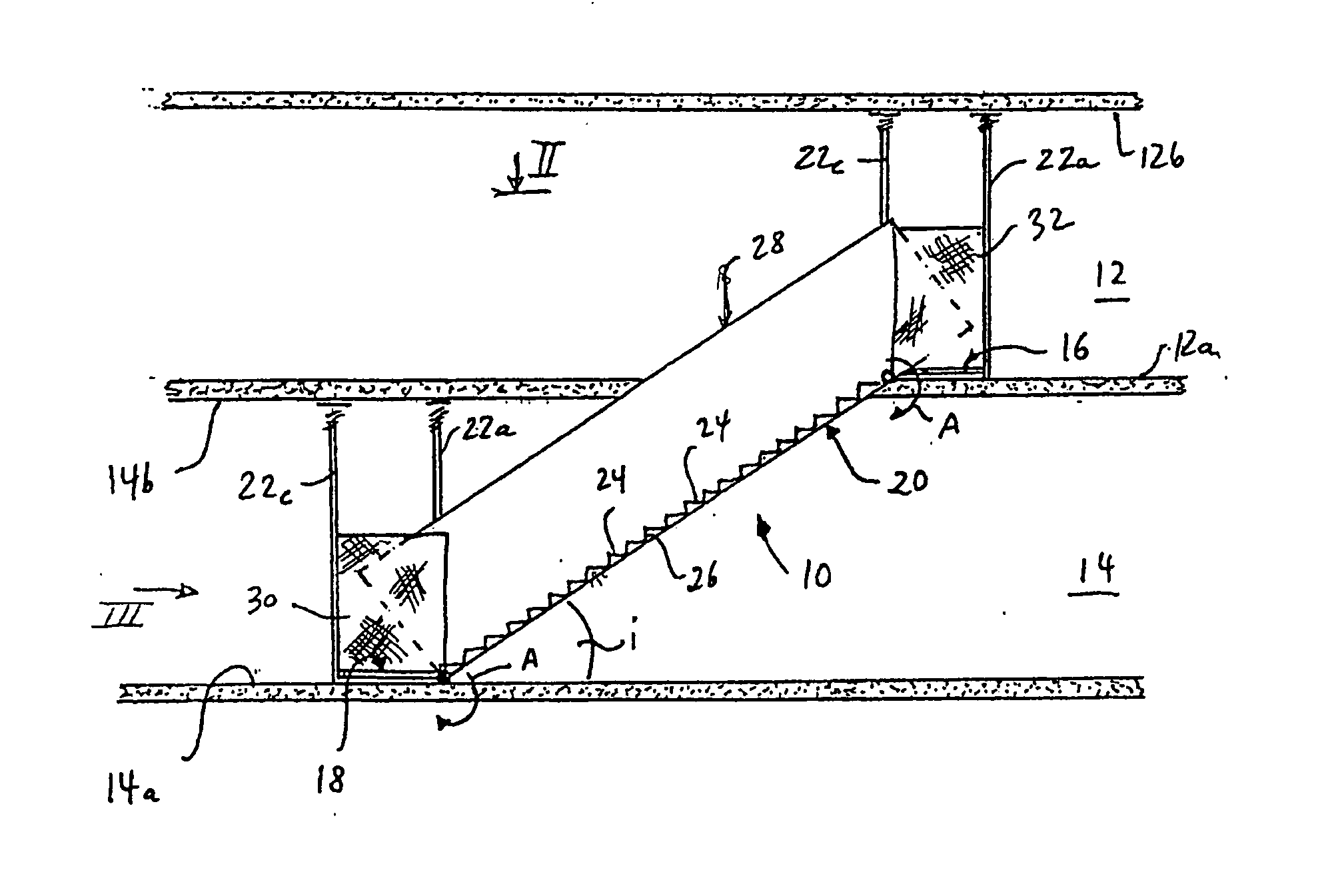

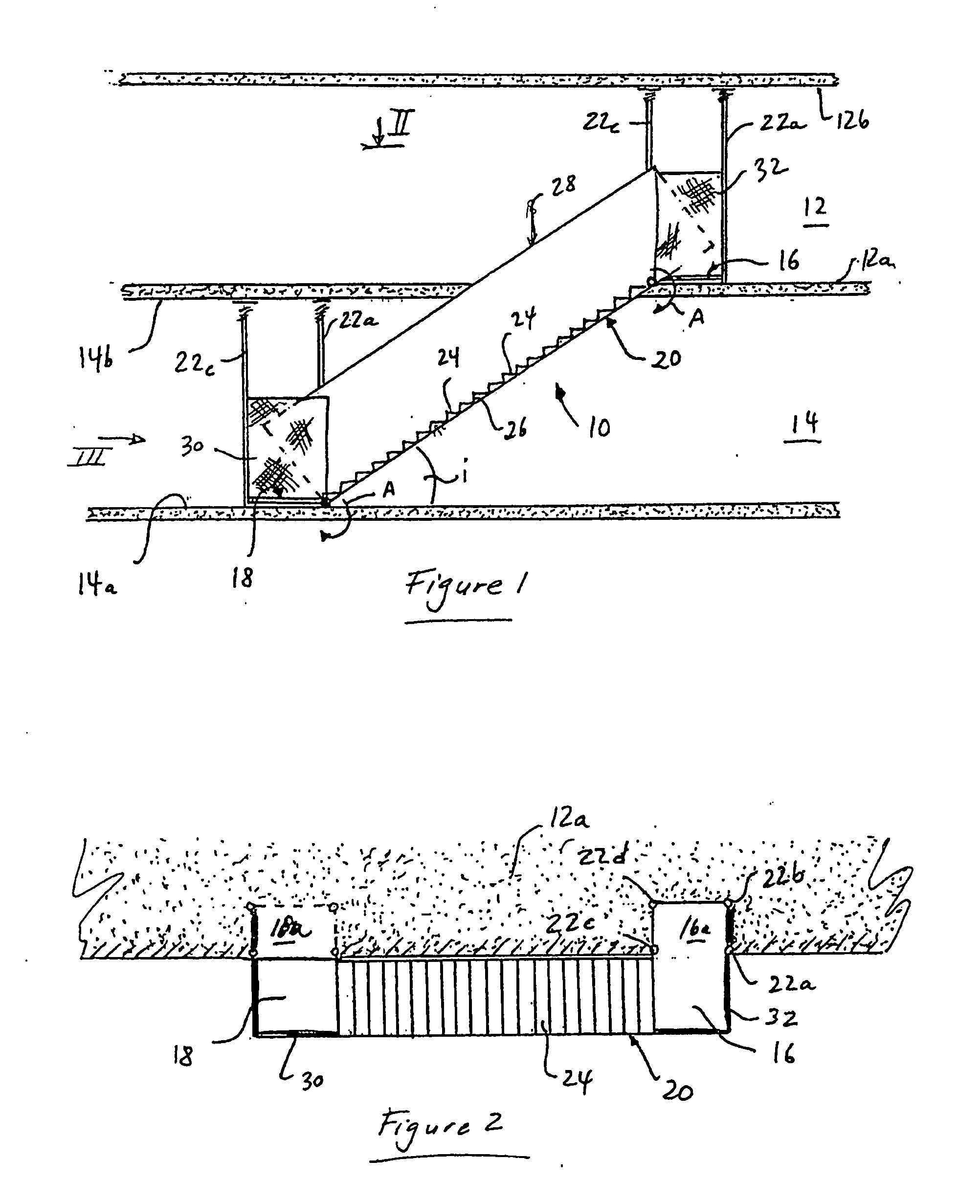

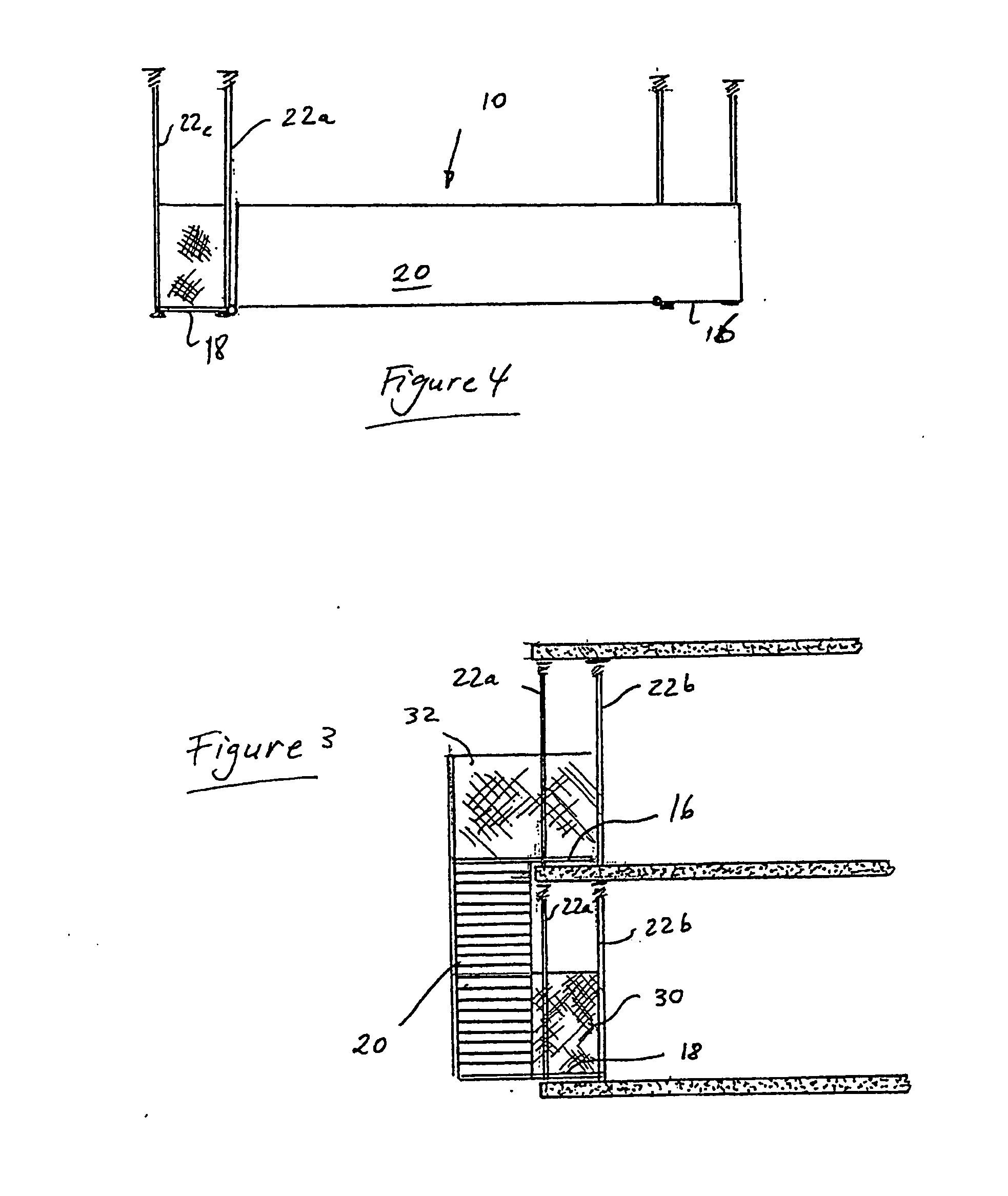

[0029]FIG. 1 shows a modular stairway unit 10 in position at the external face and between an upper storey 12 and a lower storey 14 of a building. The modular stairway unit 10 consists of an upper landing 16, a lower landing 18, a stair run section 20 extending between and connected to the landings 16, 18 and four anchoring members 22a to 22d per landing as described in more detail below.

[0030]The stair run section 20 essentially includes a plurality of individual treads 24 in the form of boards, with optional risers 26 extending therebetween. The treads 24 are suitably secured and supported at their widthward ends at opposed, tread support bar panels (not shown) in a known manner, for example, that described in U.S. Pat. No. 3,788,028. Alternatively, a tread-rise adjustable stair run assembly can be employed, such as that described in U.S. Pat. No. 3,593,821 or U.S. Pat. No. 4,768,617, allowing, of course, for the necessary modifications required for incorporation of such type of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com