Slanting construction trestle combined with internal supporting system

A support system and trestle technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of limited excavation depth, large construction machinery loss, and low excavation efficiency, so as to improve lateral stability High efficiency, saving engineering costs, and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples, but not as any limitation to the present invention.

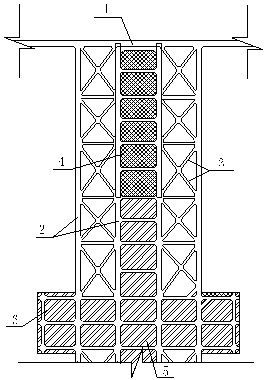

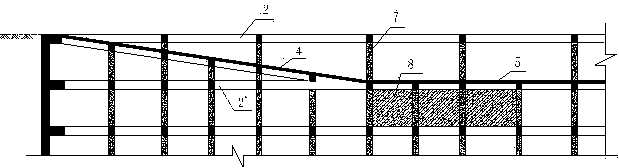

[0012] Such as figure 1 , figure 2 As shown, the present invention is a kind of oblique construction trestle 4 combined with the internal support system, which is arranged between the upper support 2 and the lower support 2', and at the same time, the trestle wharf 6 is set in the middle of the lower support 2'. It is characterized in that the oblique construction trestle 4 is combined with the internal support system, and the column 7 is used as vertical and horizontal support, and a shear wall 8 is set between the support and the trestle to strengthen the connection between the oblique construction trestle 4 and the support 2 Wholeness.

[0013] The inclined construction trestle 4 is a reinforced concrete trestle.

[0014] Since the oblique construction trestle 4 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com