Deep foundation pits rampway structure

A technology for deep foundation pits and ramps, which is applied in the fields of infrastructure engineering, building construction, and on-site preparation of building components, can solve problems such as increasing the difficulty of excavating foundation pits, increasing construction costs, and prolonging construction period, and achieves shortening The effect of construction period, improving efficiency and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

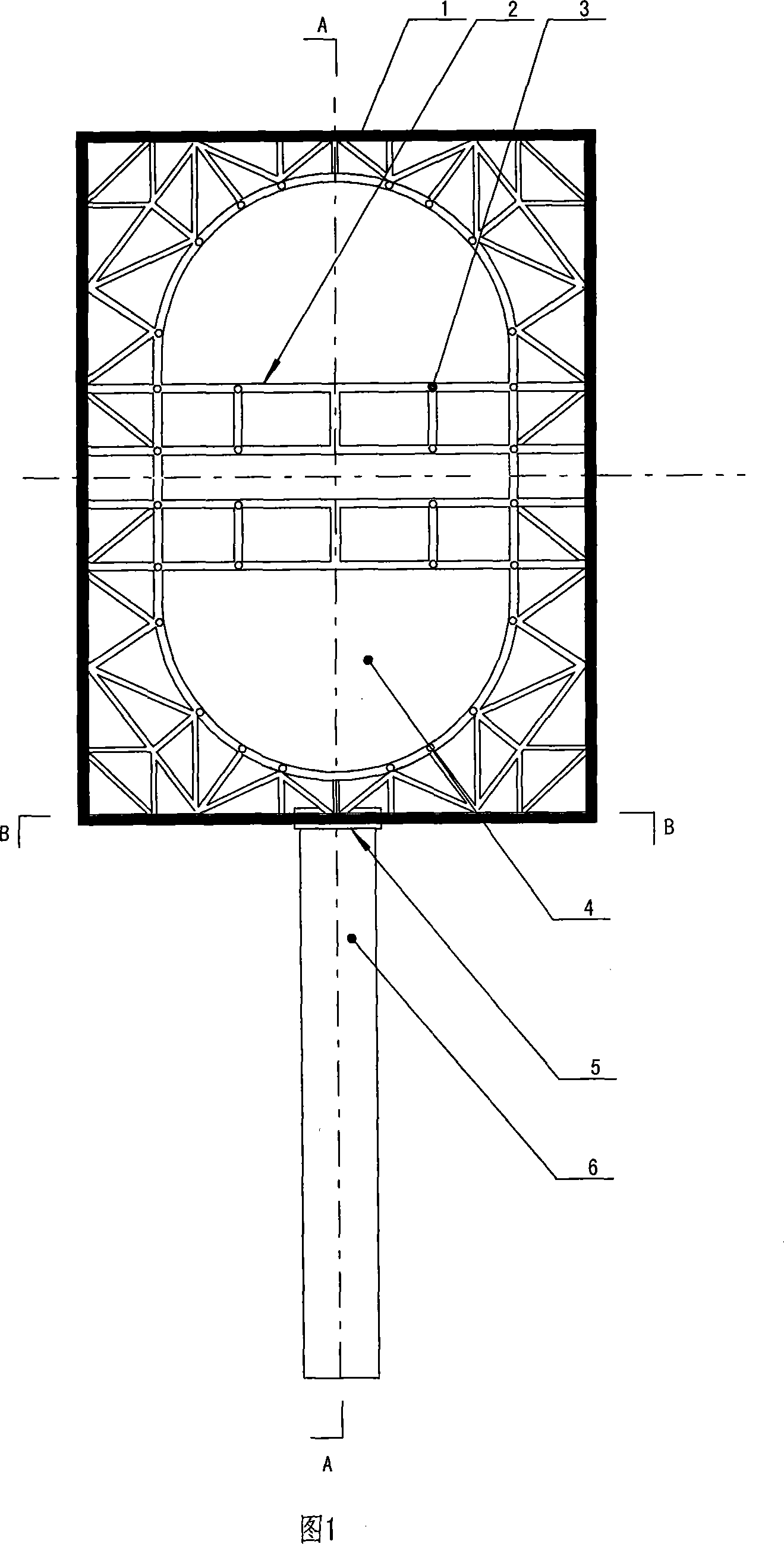

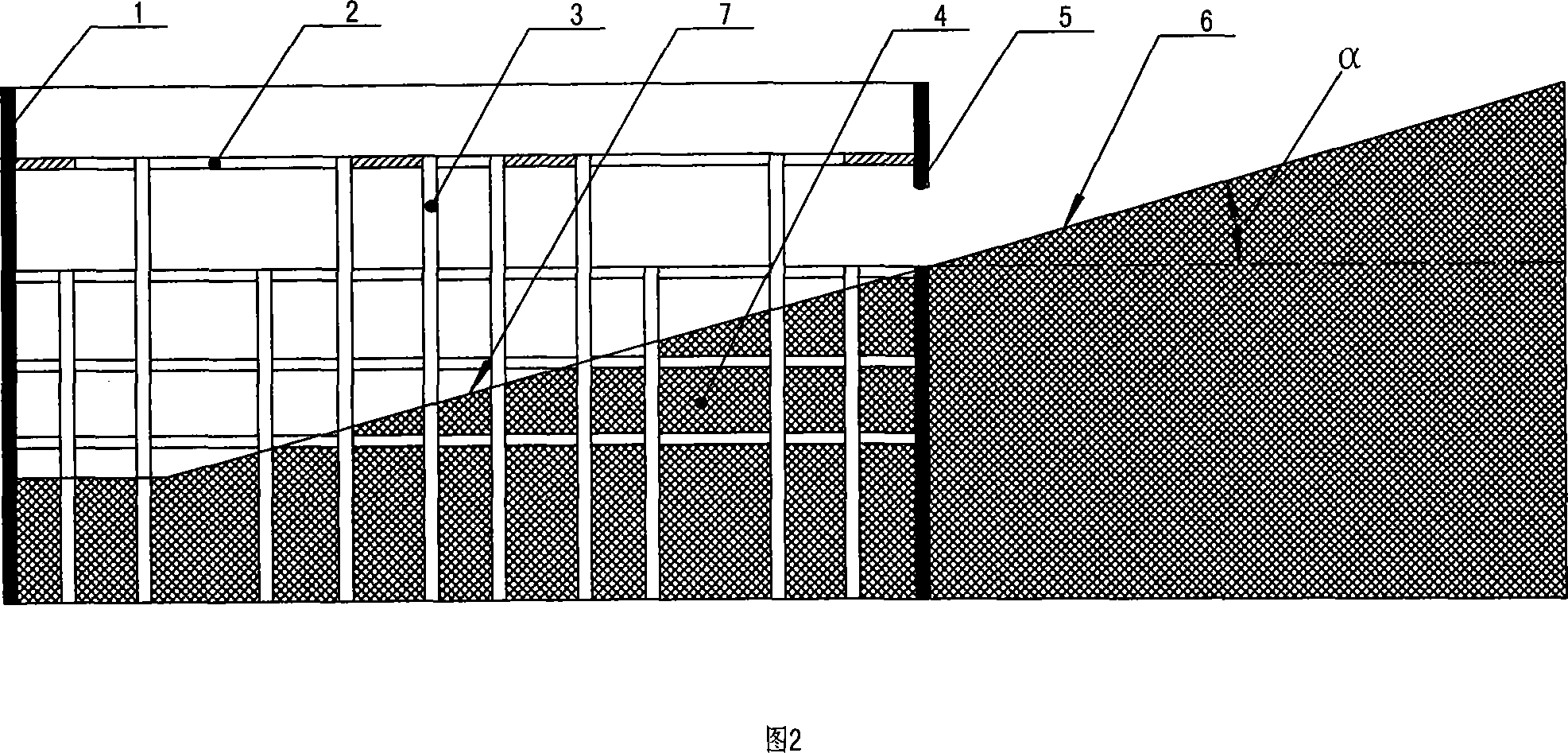

[0024] As shown in Figure 1, Figure 2 and Figure 4, the ramp structure of the deep foundation pit is composed of a deep foundation pit 4, an enclosure structure 1, a horizontal support frame 2 and a vertical support frame 3, and a vertical support structure is built around the deep foundation pit Enclosure structure, the enclosure structure includes the peripheral underground diaphragm wall (not shown in the figure) and the temporary partition enclosure (not shown in the figure) inside the deep foundation pit, and the temporary partition enclosure inside the deep foundation pit adopts Drilling and grouting piles combined with a single row of rotary grouting piles for water-stop curtains; 3 to 6 horizontal support frames can be fixed vertically at the inner end of the enclosure structure. The horizontal support frames in this embodiment have four horizontal support frames. From top to bottom are the first horizontal support frame, the second horizontal support frame, the third h...

Embodiment 2

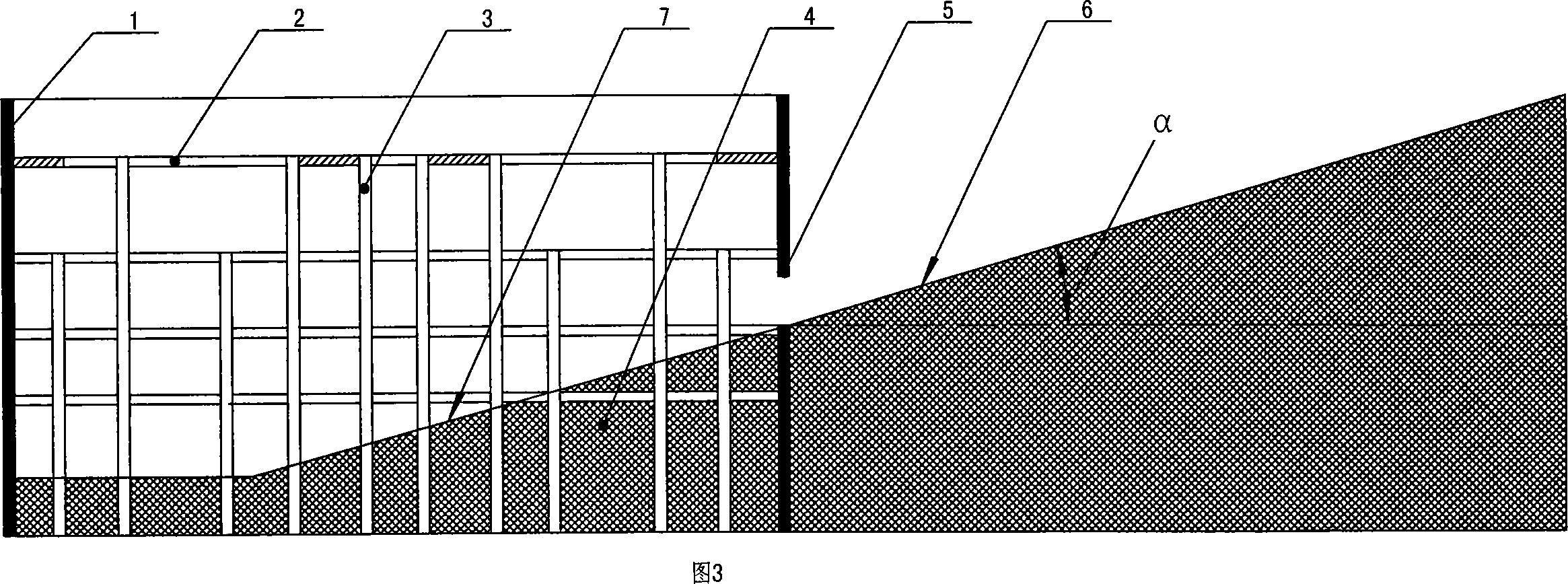

[0026] As shown in FIG. 3 , in this embodiment, the door opening of the ramp is set on the enclosure structure between the second horizontal support frame and the third horizontal support frame, and other structures are completely the same as those in Embodiment 1. Compared with Embodiment 1 in this way, the ramp doorway is located at the third horizontal support frame. Since the position of the ramp doorway is lower than that of the ramp doorway in Embodiment 1, the ramp outside the pit The length is longer than the ramp outside the pit in embodiment 1, and the length of the ramp in the pit is shorter, this mode is suitable for the situation that there is plenty of space outside the deep foundation pit and the length of the deep foundation pit is limited.

Embodiment 3

[0028] As shown in FIG. 5 , in this embodiment, the ramp 6 outside the pit is a curved ramp structure, and other structures are exactly the same as those in Embodiment 1. This method has a certain amount of space in front of and on both sides of the ramp door opening, but each direction cannot fully meet the needs of the ramp length, so the form of this curved ramp can be used to solve the problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com