Reinforced backfill earthwork ramp and construction method thereof

A construction method and earthwork technology, which are applied in excavation, foundation structure engineering, building construction, etc., can solve the problems such as the protection technology and construction method of backfill earthwork ramps, which can save labor, have good stability, and reduce engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 In the backfilled earth-rock slope of this embodiment, one side of the slope leans against a stable structure, and the other side is a side slope to be protected.

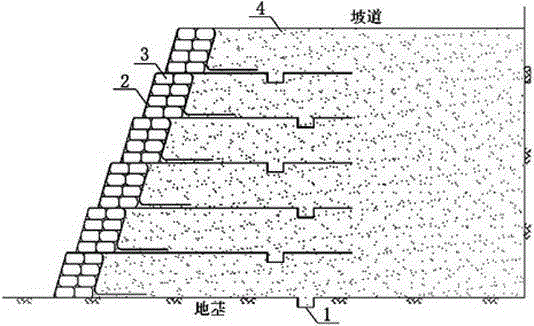

[0029] Such as figure 1 As shown, the slope rate of the ramp in this embodiment should be about 1:0.5. Reinforced backfill earth and stone slopes, including ramps and protective structures; the protective structure is a layered repeating structure; each protective structure includes backfill 4, anchor trench 1, geotextile 2; geotextile 2 is laid on anchor trench 1; The backfill soil 4 is pressed on the geotextile 2; a soil bag 3 is set on one side of the slope, and a certain length is reserved on the outside of the geotextile 2, and the soil bag 3 is turned up and pressed into the backfill soil to form a protective structure.

Embodiment 2

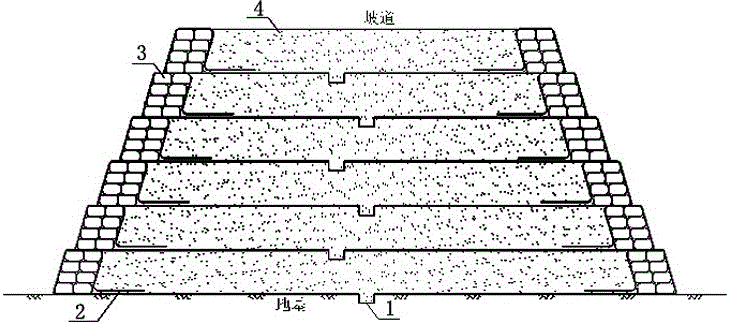

[0030] Embodiment 2 In the backfilled earth and rock slope of this embodiment, both sides of the slope are slopes that need to be protected. Such as figure 2 As shown, the slope rate of the ramp in this embodiment should be about 1:0.5. The structure of the reinforced backfilled earth-rock slope is basically the same as that of Example 1, except that: soil bags 3 are set on both sides of the slope of the slope, a certain length is reserved on both sides of the geotextile 2, and soil bags 3 are turned over Then press into the backfill to form a protective structure.

Embodiment 3

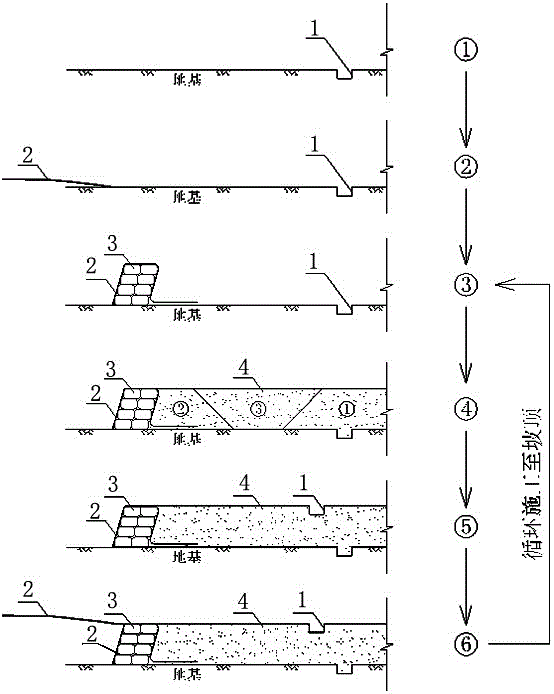

[0031] Example 3 The construction method of the reinforced backfill earth-rock slope of the present invention includes the following steps:

[0032] (1) Clean and level the foundation soil at the bottom of the ramp, and recheck the foundation bearing capacity to meet the requirements; excavate anchor ditch; anchor ditch is a trench excavated parallel to the slope direction, the width of the anchor ditch is generally 50cm, and the depth is generally 25 ~30cm.

[0033] (2) Laying the bottom geotextile, the geotextile needs to reserve about 3.5~4m turn-up length on the outside of the slope slope; the zonal width of the geotextile is 3~6m, and the longitudinal length is greater than 50m; the warp direction is the main force Direction, the longitudinal breaking strength is 20~100kN / m, and the latitudinal breaking strength is 15~70kN / m. Geotextiles should be kept horizontal and laid parallel to each other; the longitudinal direction of the geotextiles should be perpendicular to the dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com