Modular platform, walkway or ramp

a module, platform technology, applied in the direction of ramps, balustrades, building scaffolds, etc., can solve the problems of difficult to transport the components required to form a ramp, the ramp of this us specification has a number of significant limitations, and cannot be usually duplicated for other buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

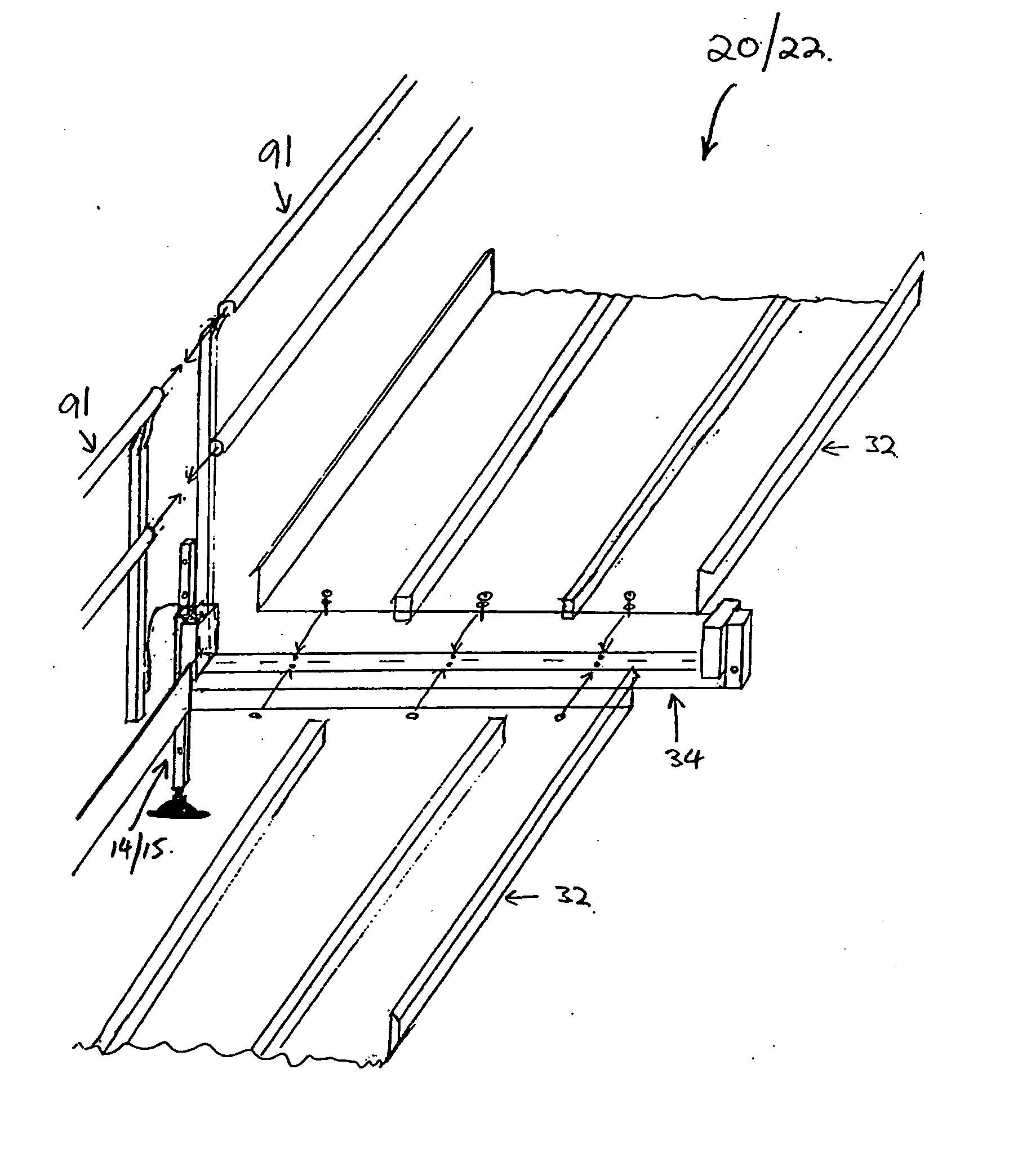

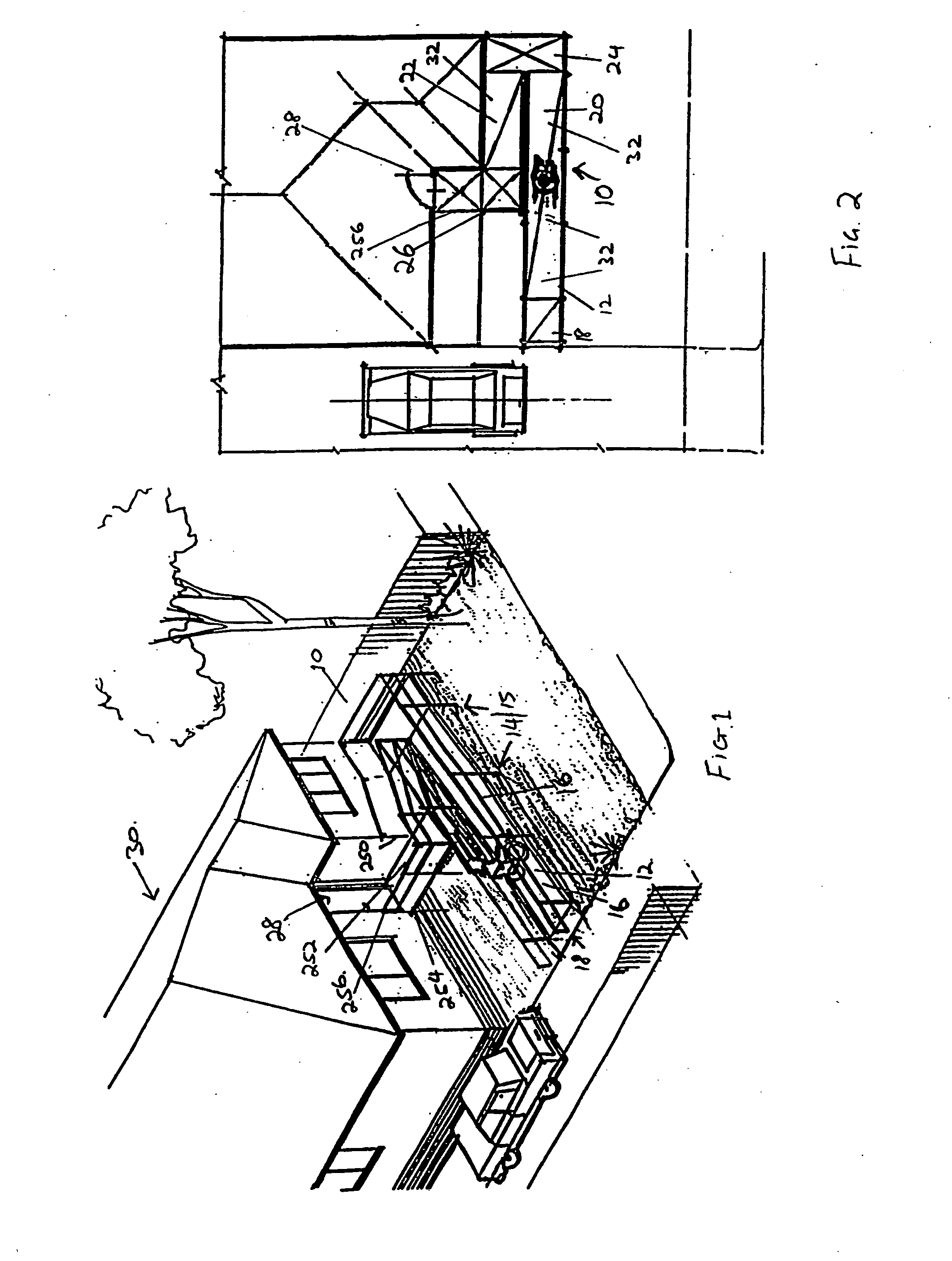

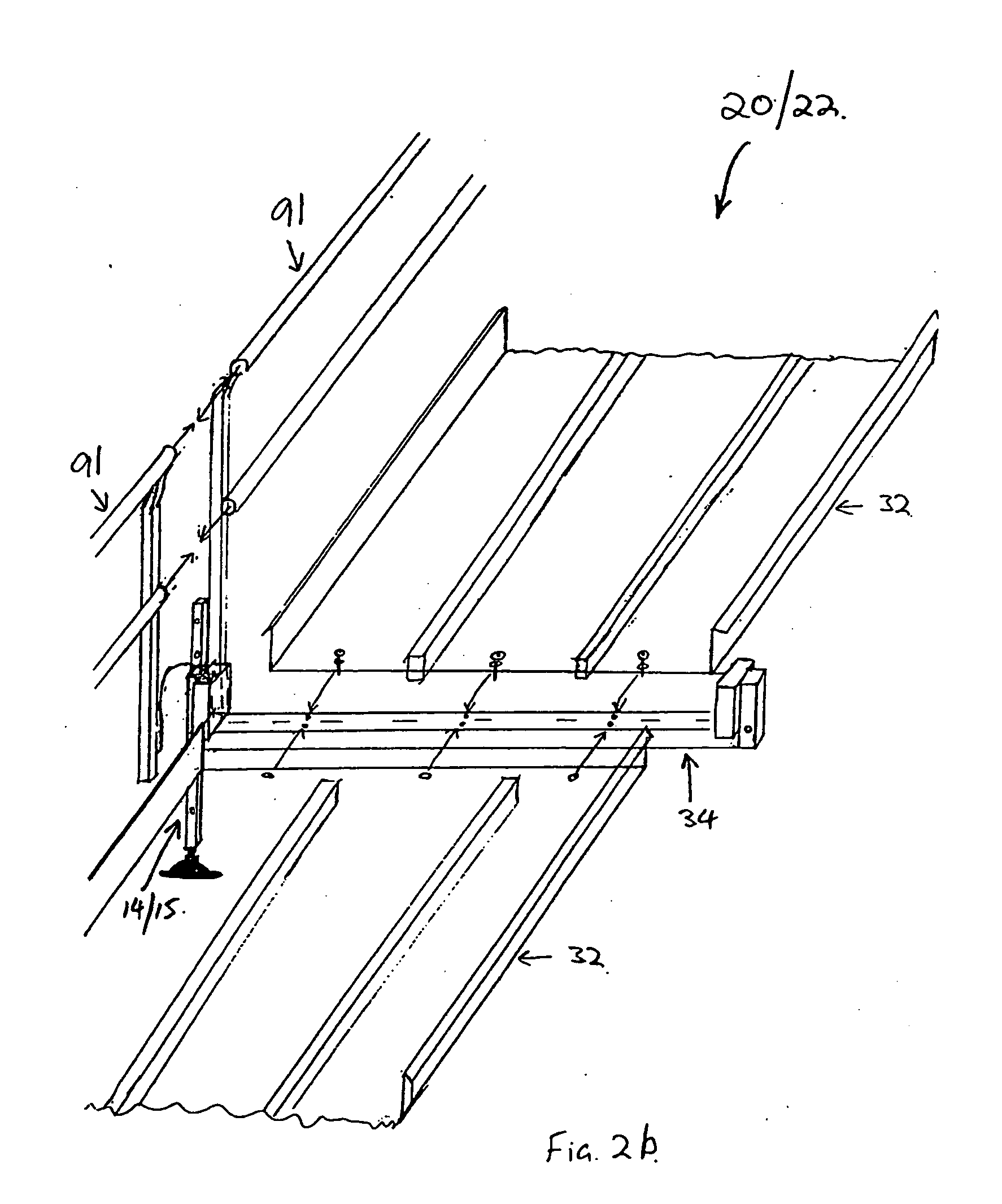

[0082]FIGS. 1 and 2 depict a modular ramp 10 formed of a number of prefabricated components which are described below. As will be clear from the description of the modular ramp 10, it will be readily apparent to a person skilled in the relevant art, that components forming the modular ramp 10 can be used, in a similar manner, to form a platform or walkway. In the case of a walkway, the height of the floor bearers are adjustable so that the floor surface is generally level, rather than inclined. In the case of a platform, the size of the floor components and the length of the floor bearers can be increased.

[0083] Referring to FIGS. 1 and 2, the modular ramp 10 generally comprises a raked floor 12, elongate members in the form of floor pillars 14 and 15, and handrails handrail 16, all formed of prefabricated components. The modular ramp 10 also comprises a number of different regions: an initial incline region 18; incline regions 20 and 22; a double landing 24 and a landing 26. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com