Automatic welding auxiliary device for in-hole pressure steel pipe pile joints

An automatic welding and auxiliary device technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding accessories, etc., can solve the problems of large amount of installation work, uneven quality of manual welding, slow progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

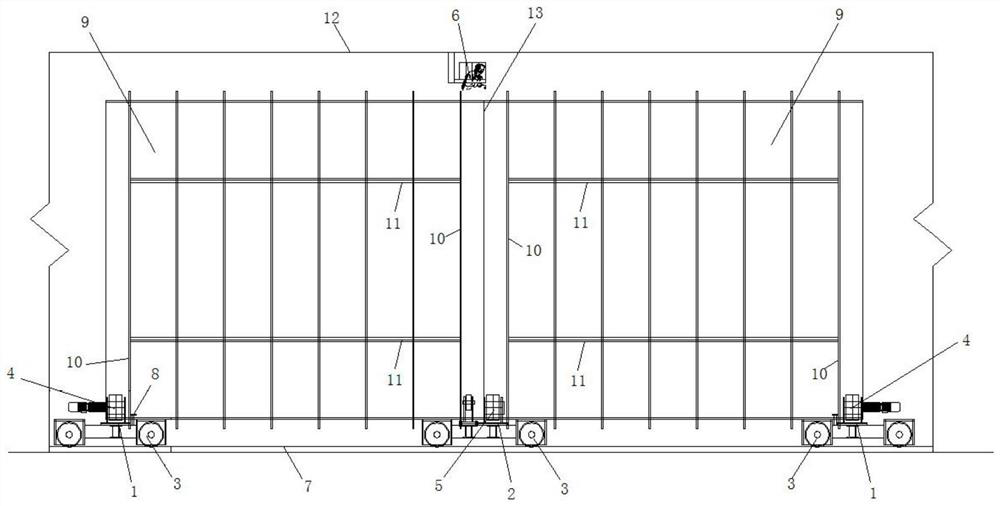

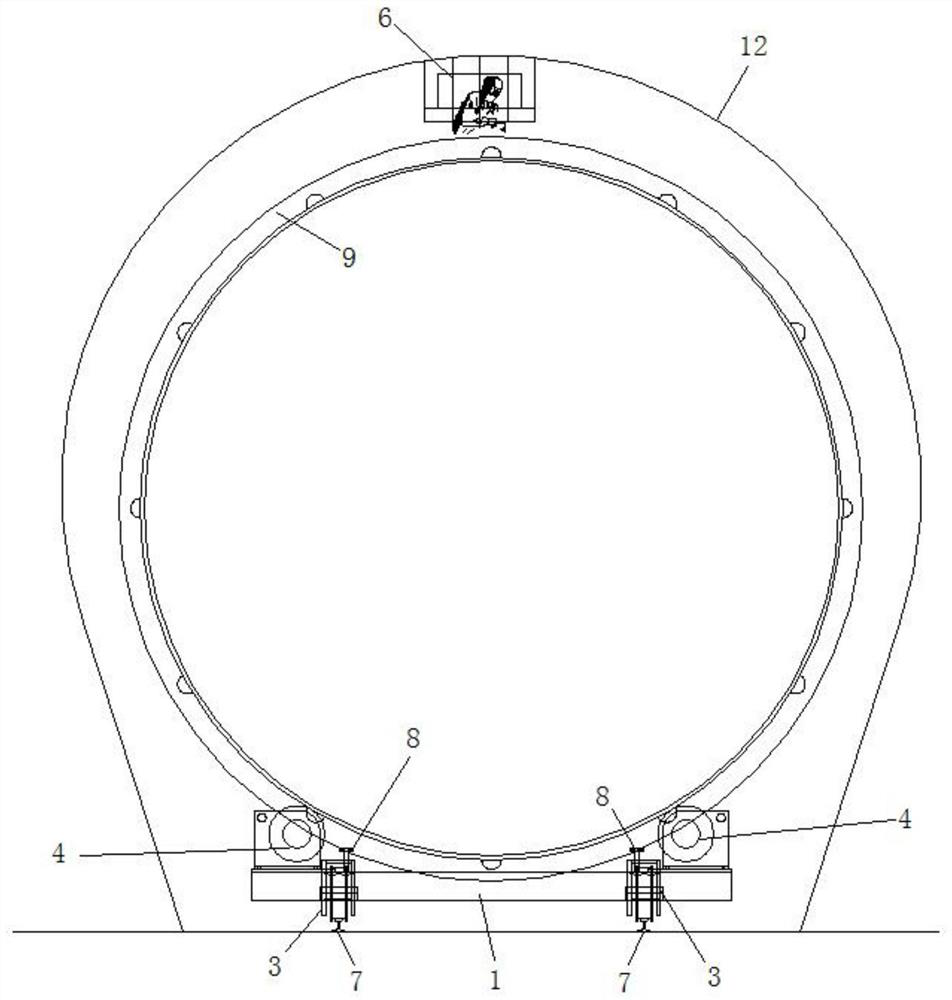

[0027] see figure 1 , figure 2 , an automatic welding auxiliary device for stacking joints of pressure steel pipes in a cave provided by an embodiment of the present invention, such as figure 1 , figure 2 As shown, the device may include:

[0028] The trolley group is used to carry the two pressure steel pipes 9 after the ring seam group is completed and to drive the two penstocks 9 to perform circular motion; the trolley group includes two first trolleys 1 and a second A trolley 2, the first trolley 1 is equipped with a road wheel 3 and a rolling drive assembly 4, and the second trolley 2 is equipped with a road wheel 3 and a rolling driven assembly 5;

[0029] The welding assembly 6 is used for welding the inner seams and / or outer seams of the two pressure steel pipes 9 on the trolley group.

[0030] Further, the device provided in the embodiment of the present application can also be used to carry the pressure steel pipe to the corresponding welding position or instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com