Thermal insulation decorative brick and producing method thereof

A production method and technology for facing bricks, which are applied to building materials and other directions, can solve the problems of polystyrene board deformation, hollowing, easy deformation of thermal insulation bodies, etc., and achieve the effects of improving construction speed, simple process procedures, and avoiding wall cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

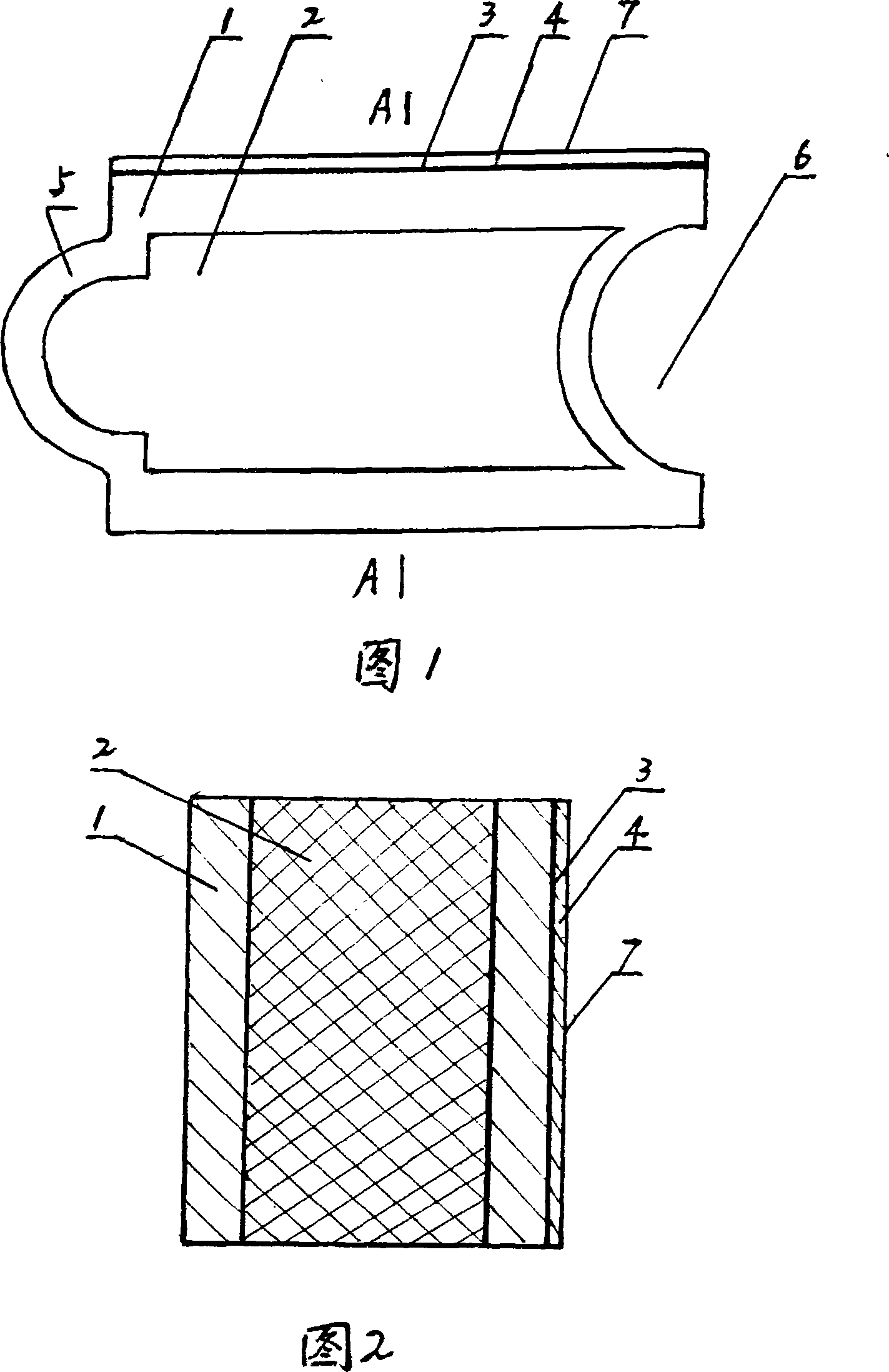

[0010] In the accompanying drawings, the thermal insulation facing brick of the present invention is mainly composed of hollow bricks, thermal insulation body and decorative surface; hollow brick 1 is composed of 14.8% fly ash, 49% magnesium oxide, 15% sawdust, 20% sodium oxide, 1% After mixing the rubber powder and 0.2% curing agent, stir for 10 minutes, put into the mold to vibrate and extrude to form; the hollow brick body made of the above materials is light, sound-proof and heat-insulating; the curing agent is Ethylenediamine or other curing agent suitable for building materials. One side of the left and right sides of the hollow brick 1 is made into a convex head 5 shape, and the other side is made into a groove 6 shape that can be placed in the convex head 5. The insulation material can be made of polystyrene board, polyurethane, polystyrene particles, extruded board, slag wool and other materials; according to the different filling insulation materials, the insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com