Method and system for controlling load-shedding working condition of supercritical unit

A technology of supercritical unit and control method, which is applied in the direction of control system, lighting and heating equipment, steam generation, etc., which can solve the problems of unit equipment damage, hidden dangers of power grid stable operation, etc., and achieve the effect of preventing stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

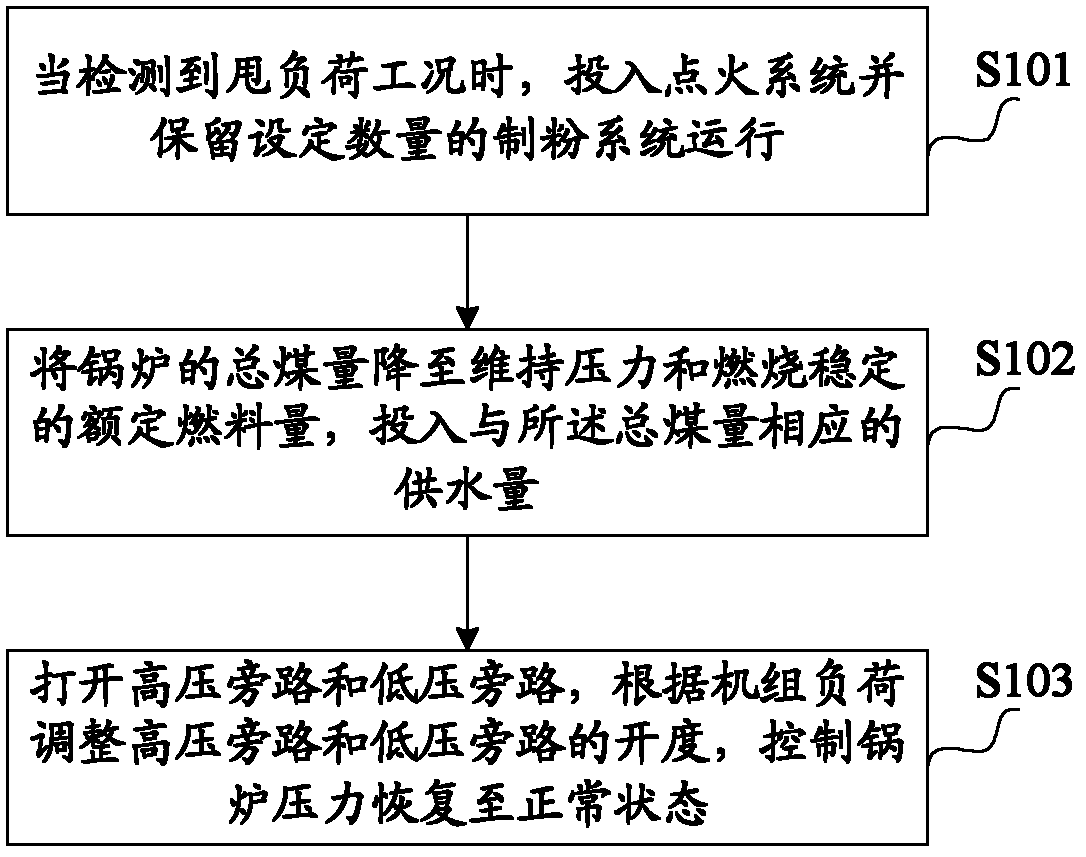

Method used

Image

Examples

example 1

[0045] Example 1. Overview of 50% load shedding control of a 600MW supercritical unit in a power plant:

[0046] A 600MW supercritical unit is controlled by the supercritical unit load rejection control method of the present invention after shedding 50% of the load. The main steam pressure in the boiler is up to 15.84MPa without overpressure; the main steam temperature is stable and the lowest is 551°C , no overheating; the feed water flow rate is stable; the reheat steam pressure and fluctuation range are 2.13-2.07MPa, within a reasonable range, and the steam temperature is stable; other furnace side parameters are normal, the induced draft fan does not jump out of the automatic, and the primary fan does not surge.

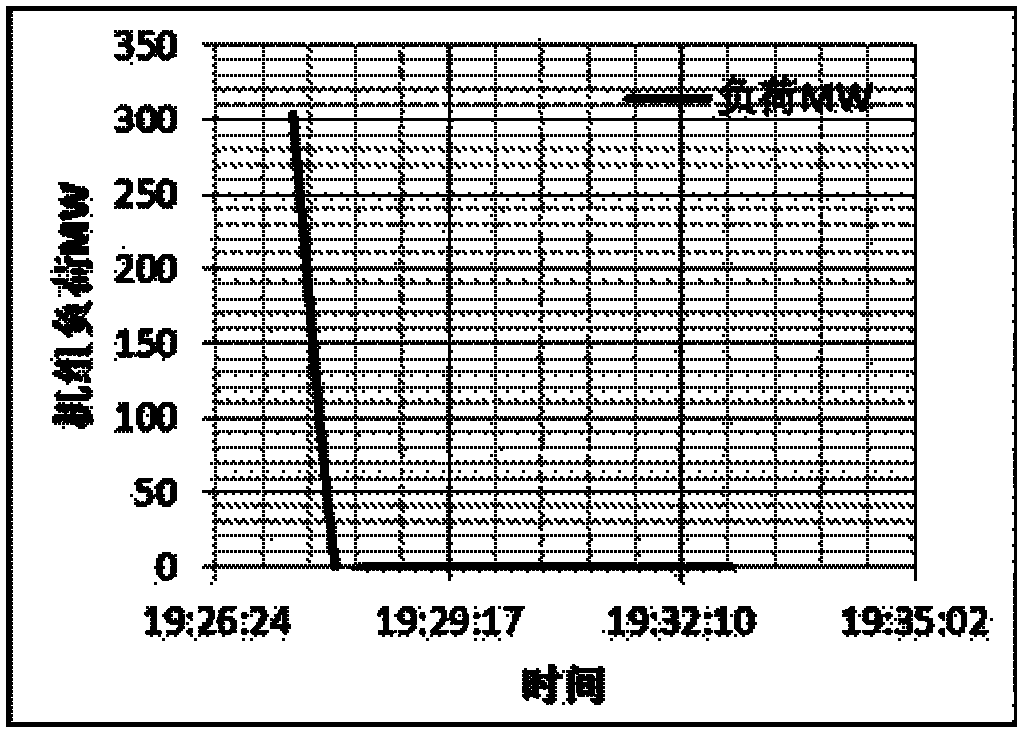

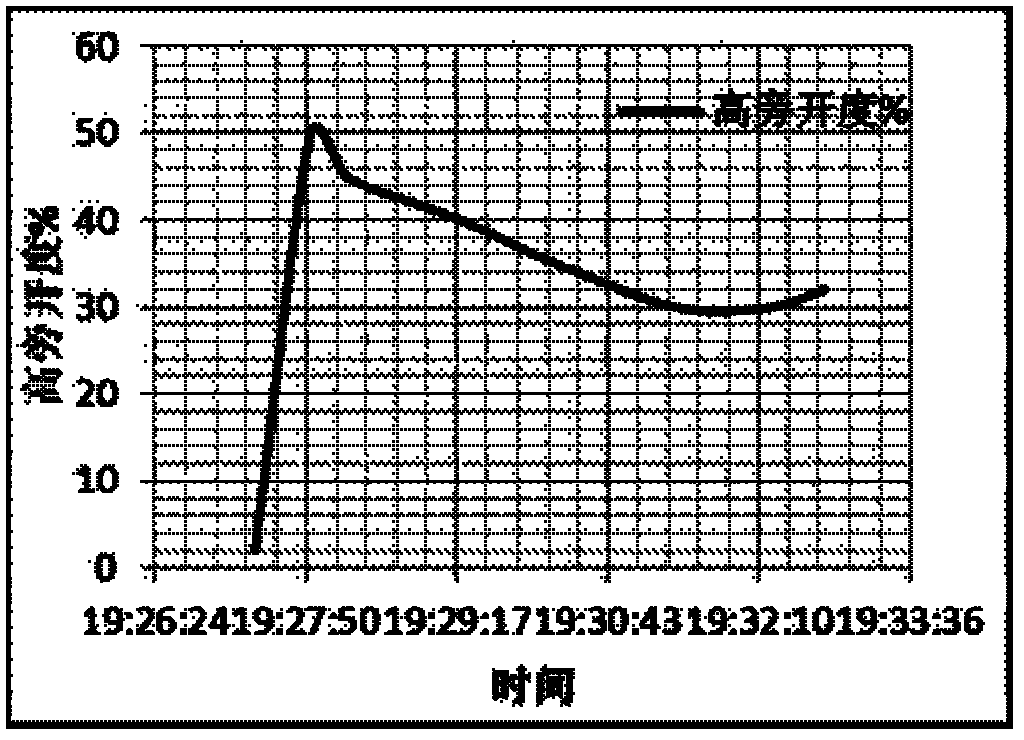

[0047] Figure 2 to Figure 5 Shows the data change status in the control process.

[0048] figure 2 It is a schematic diagram of the load change curve with time after the unit sheds 50% of the load. From 19:27:15 to 19:27:50, the unit load changes from 300MW t...

example 2

[0052] Example 2. Overview of 100% load shedding control of a 600MW supercritical unit in a power plant

[0053] A 600MW supercritical unit, after 100% load rejection, is controlled by the supercritical unit load rejection control method of the present invention, the main steam pressure in the boiler is up to 25.64MPa, no overpressure; the main steam temperature is stable and the lowest is 543°C , not over-temperature; feed water flow rate is stable; reheat steam pressure and steam temperature are stable; other furnace side parameters are normal, the induced draft fan does not jump out of automatic, and the primary fan does not surge.

[0054] Figure 6 ~ Figure 9 Shows the data change status in the control process.

[0055] Image 6 It is a schematic diagram of the load change curve with time after the unit sheds 100% load. From 21:32:50 to 21:33:07, the unit load changes from 600MW to 0MW, 100% load shedding, and then maintains.

[0056] Figure 7 It is a schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com