ORC system starting grid-connected system and method

A start-up and organic technology, applied in the direction of mechanical equipment, steam engine devices, engine components, etc., can solve problems such as various system configurations, difficult operation and maintenance, and complex control, so as to reduce complexity, reduce equipment configuration, and speed up start-up The effect of grid connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

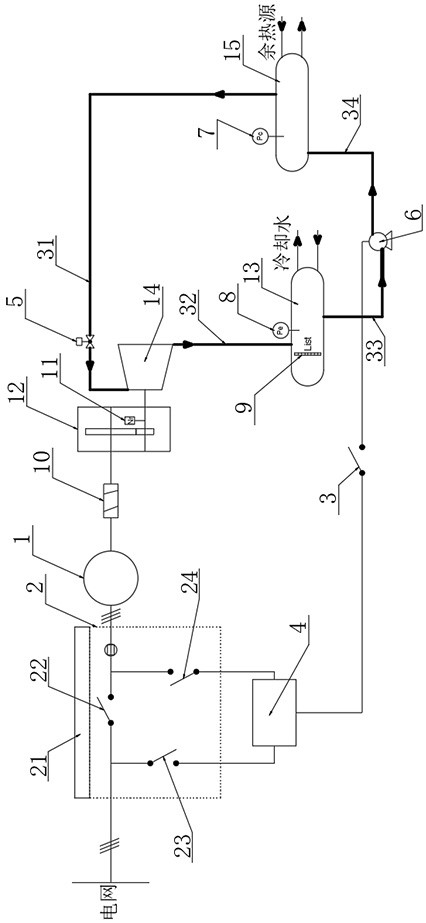

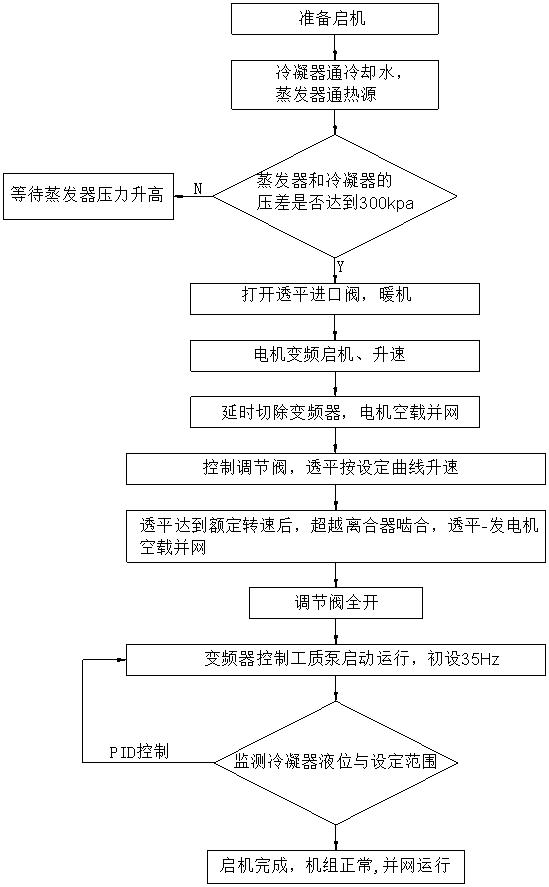

[0034] see figure 1 As shown, an ORC system startup and grid-connected system includes an organic Rankine cycle unit and a grid-connected switch cabinet 2. The organic Rankine cycle unit includes a two-pole induction motor 1, a working fluid pump variable frequency control switch 3, and a low-speed inverter 4. , working fluid pump 6, overrunning clutch 10, reduction box 12, condenser 13, turbine 14 and evaporator 15;

[0035] One end of the two-pole induction motor 1 is connected with one end of the reduction box 12 through the overrunning clutch 10, and the other end of the reduction box 12 is connected with the power input end of the turbine 14; a turbine speed sensor 11 is installed in the reduction box 12; the turbine speed sensor 11 is used to detect the rotational speed data of the turbine 14;

[0036] The evaporator 15 is connected to the inlet of the turbine 14 through a pipeline 31, and the outlet of the turbine 14 is connected to one end of the condenser 13 through ...

Embodiment 2

[0073] If the overrunning clutch 10 is changed to the SSS clutch, the turbine will not rotate during the starting process of the two-pole induction motor 1;

[0074] At this point the process is:

[0075] The power grid gradually starts the two-pole induction motor 1 to achieve the grid synchronous speed and no-load operation; reduce the starting current through the low-speed frequency converter 4;

[0076] The low-speed inverter 4 is cut off, and it is pulled in with the variable frequency control switch of the working fluid pump;

[0077] The opening of the turbine inlet electric regulating valve 5 should not exceed 30% to warm up the machine. The warm-up time is about 10 minutes. Then set the turbine inlet electric regulating valve 5 according to the speed-up curve to slowly increase the opening. The turbine starts to increase speed, exceeding the synchronous speed of the grid. After the SSS clutch is automatically engaged, it starts to output power and turns to grid-conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com