Quick-response leakproof high-temperature thermocouple

A fast-response, thermocouple technology, used in thermometers, measuring heat, using electrical devices, etc., can solve the problems of high damage rate of internal temperature measuring components, increase the risk of thermocouples, and difficulty in achieving rapid induction, and achieve the effect of enhancing heat conduction. , Measuring the effect of short response time and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

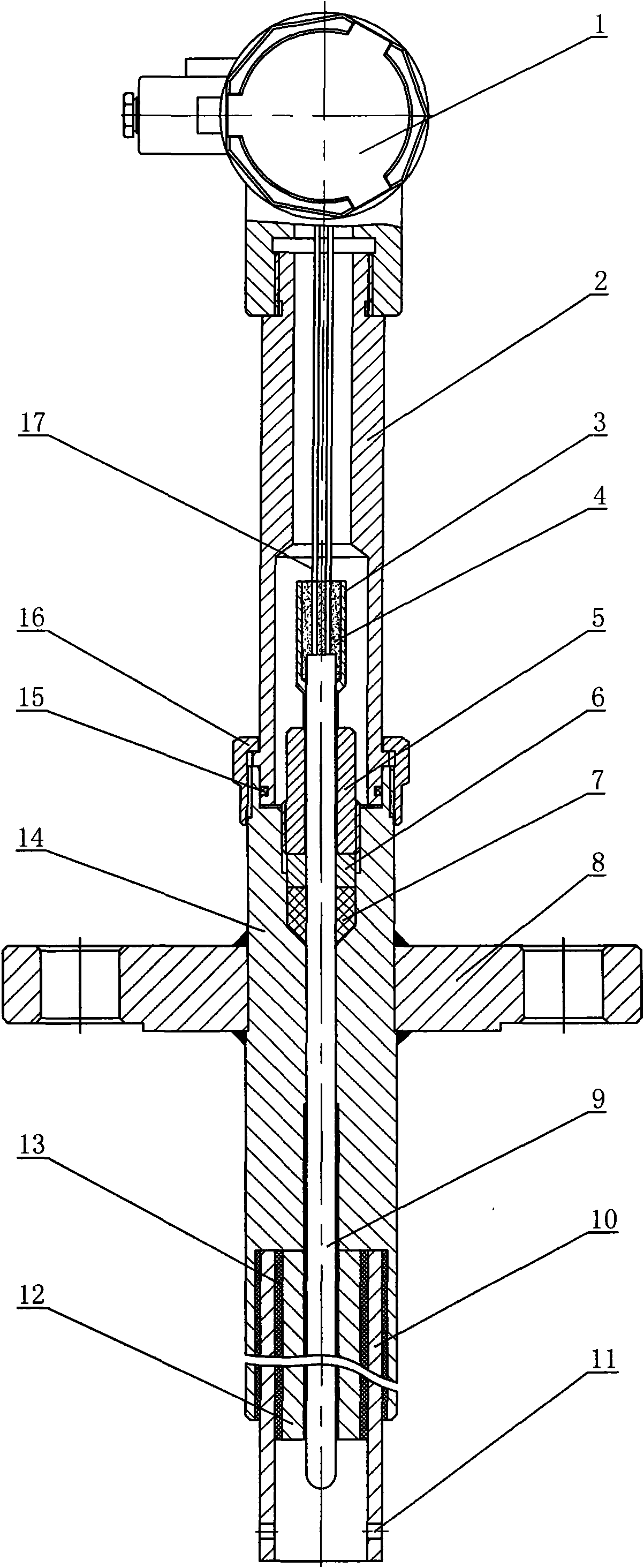

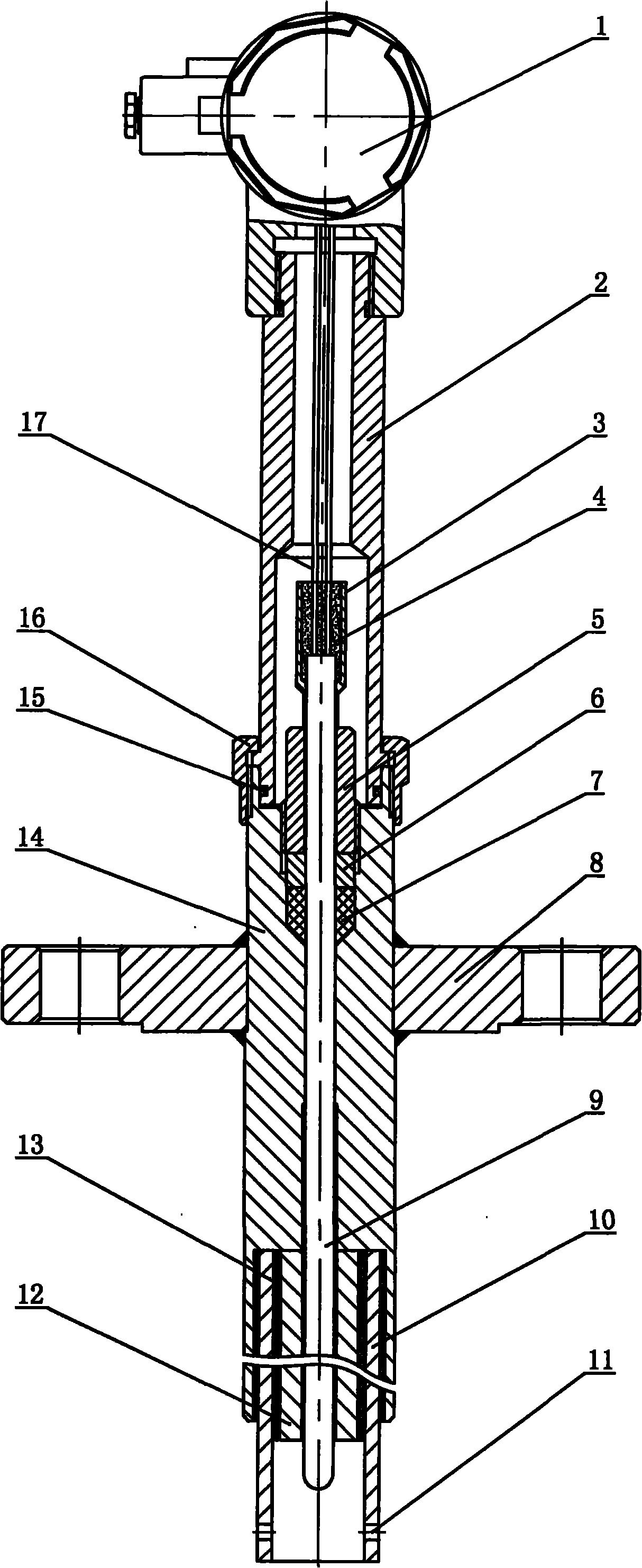

[0020] A fast-response leak-proof high-temperature thermocouple, consisting of a junction box 1, a protective sleeve and a temperature measuring element 9, the outer wall of the protective sleeve can be connected to a flange 8, and the protective sleeve consists of an upper protective sleeve 2 and a lower protective sleeve 14 The upper and lower coaxial installations are formed. The upper protective sleeve is fixedly installed with the lower protective sleeve through the active lock nut 16. A sealing ring 15 is installed between the upper protective sleeve and the lower protective sleeve. The upper end of the upper protective sleeve Fixed on the junction box, the temperature measuring element is fixed on the junction box through the soft wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com