Three-axis acceleration sensor

A shaft acceleration and acceleration sensing technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of low natural frequency, poor packaging reliability, cover plate depression, etc., to improve sensitivity and prevent mechanical damage. , the effect of reducing the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

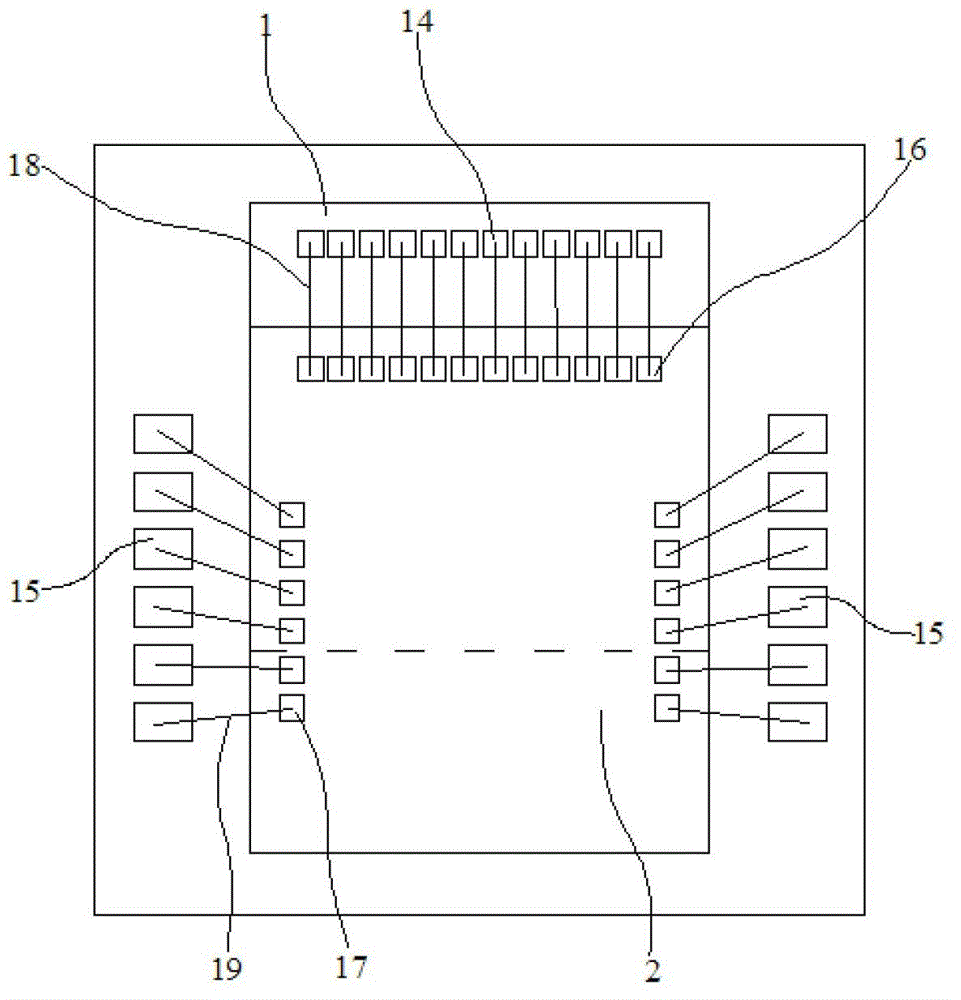

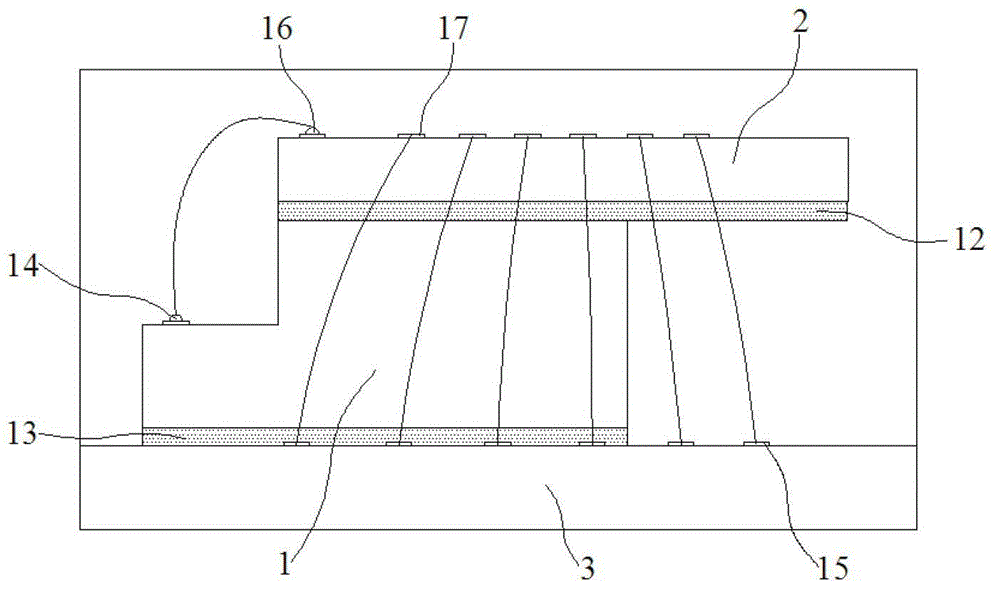

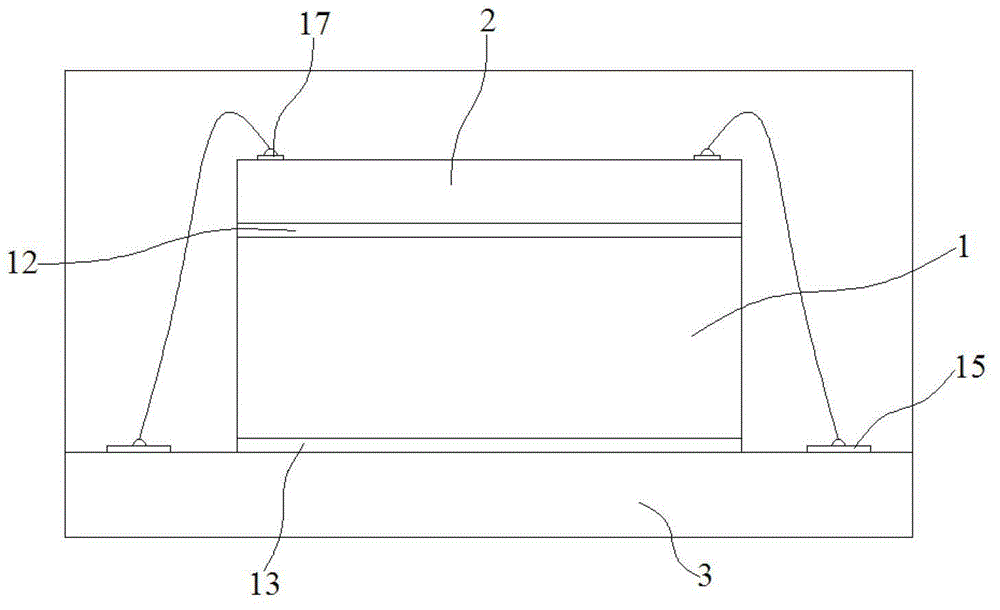

[0032] Embodiment: a kind of three-axis acceleration sensor, comprises MEMS acceleration chip 1, is used for filtering the signal processing chip 2 of interference signal and processing induction signal and substrate 3, and described MEMS acceleration chip 1 is made up of cover body 4, micromechanical system 5 and A circuit substrate 6 for generating induction signals. The micromechanical system 5 is composed of an X-axis acceleration sensing area 7, a Y-axis acceleration sensing area 8, and a Z-axis acceleration sensing area 9 for sensing external Z-axis motion. The cover Body 4 and circuit substrate 6 are bonded by a sealant layer 10 to form a sealed cavity 11. The micromechanical system 5 is located in the sealed cavity 11 and on the upper surface of the circuit substrate 6. The height of the sealed cavity 11 is 45~55μm;

[0033]The X-axis acceleration sensing area 7 includes an X-direction "H"-shaped moving piece 71 with two through holes, two X-direction moving electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com