Low-carbon and environment-friendly distributed cooling system for engine and heat management method

A low-carbon, environmental-friendly, cooling system technology, applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems of not proposing the best working temperature method, not mentioning the influence of the engine and cooling pipeline, etc., to achieve Enhanced rapid maneuverability, enhanced heat radiation capability, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. However, those skilled in the art should recognize that the following implementations are only exemplary, and are intended to better enable those skilled in the art to understand the patent, and should not be construed as limiting the scope of the patent; as long as Any equivalent changes or modifications based on the spirit disclosed in this patent and similar structures, methods and similar changes thereof all fall within the scope of this patent.

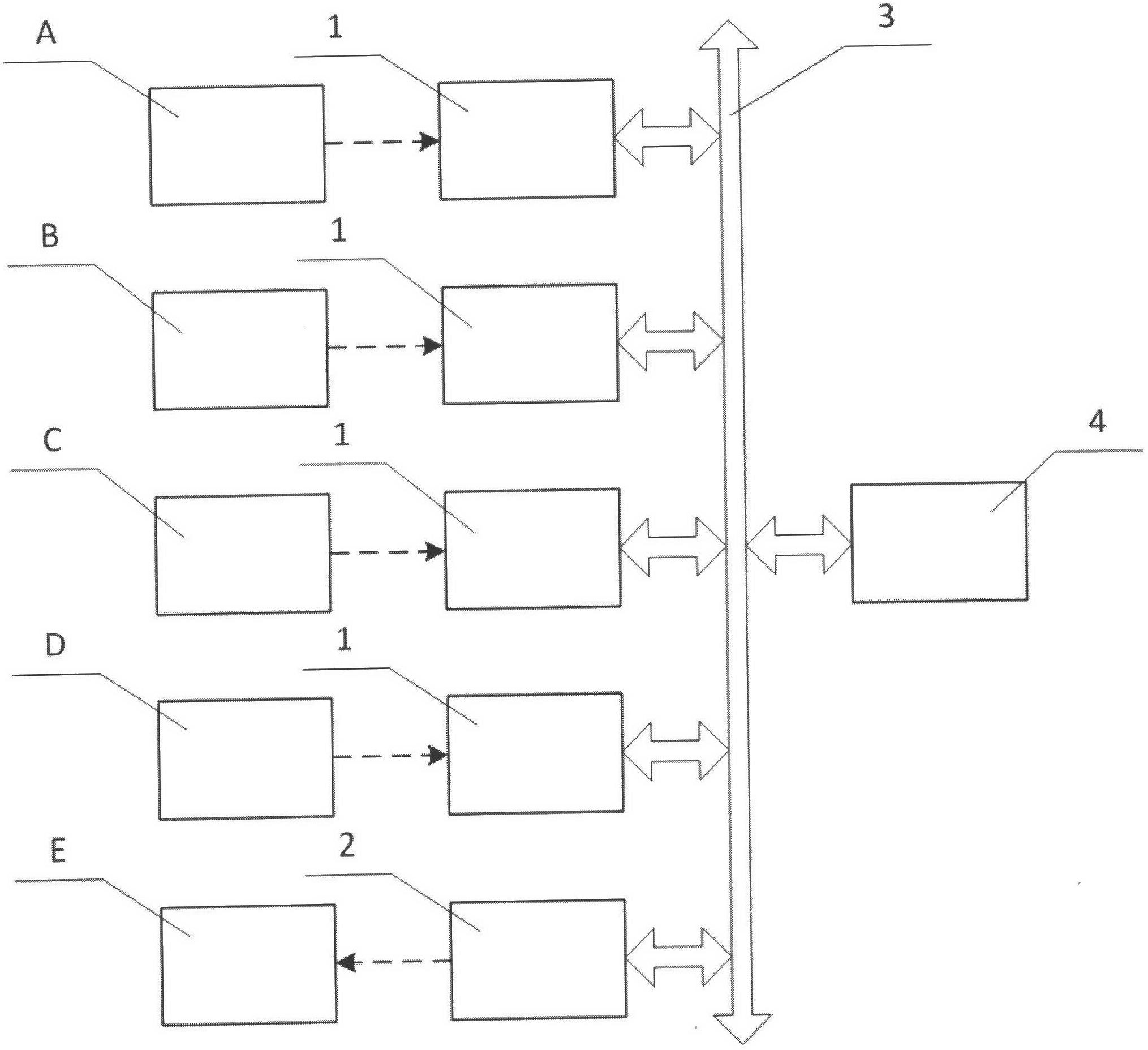

[0030] see figure 1 , the described a kind of low-carbon environment-friendly distributed cooling system for engine is made up of several sets of distributed cooling devices 1, cabin heating device 2, bus 3 and electronic control unit 4, respectively used to cool the cylinder head A of the engine , cylinder block B, pressurized air C and oil pan D, and heating for the compartment E.

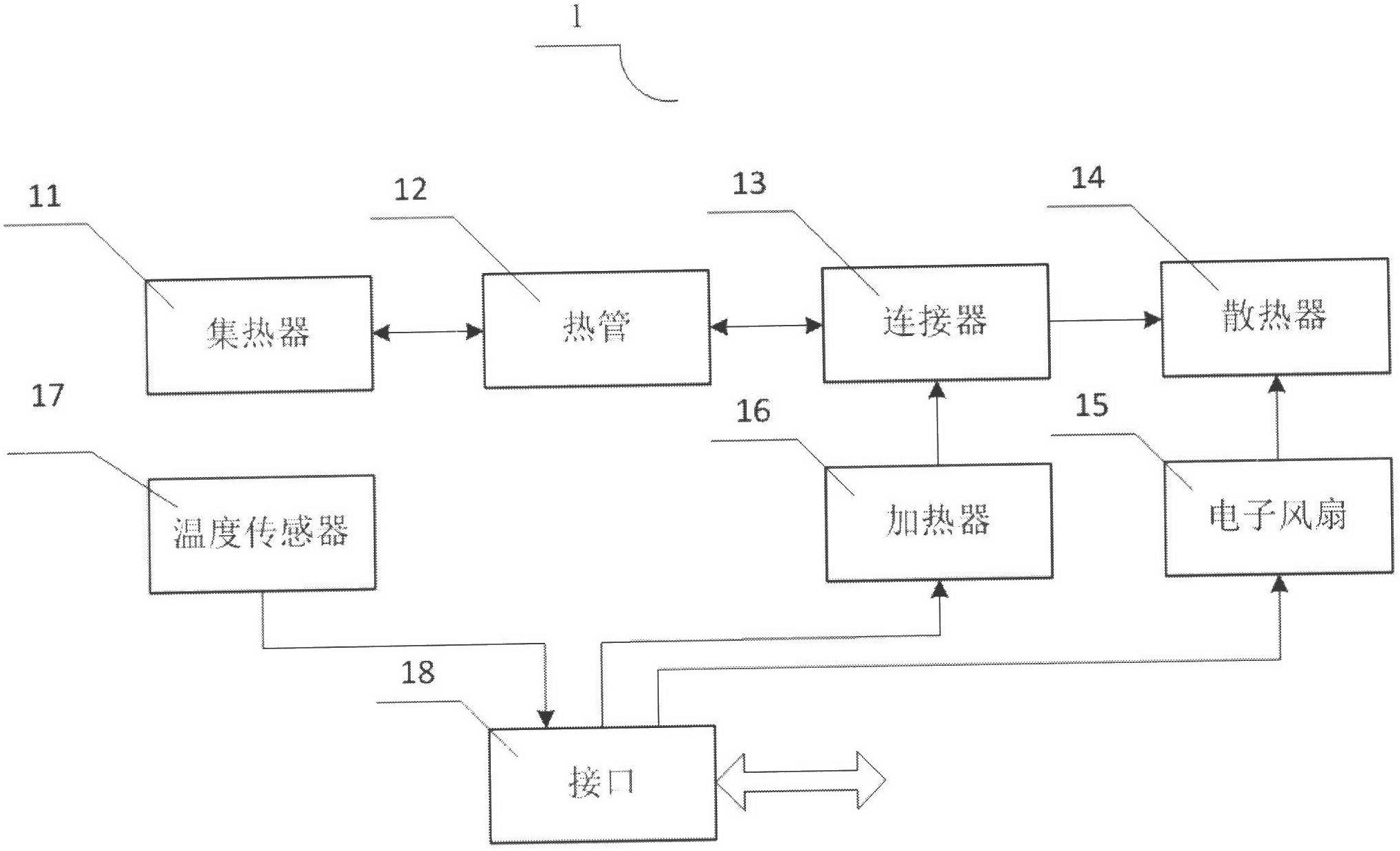

[0031] see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com