Environmentally-friendly coating

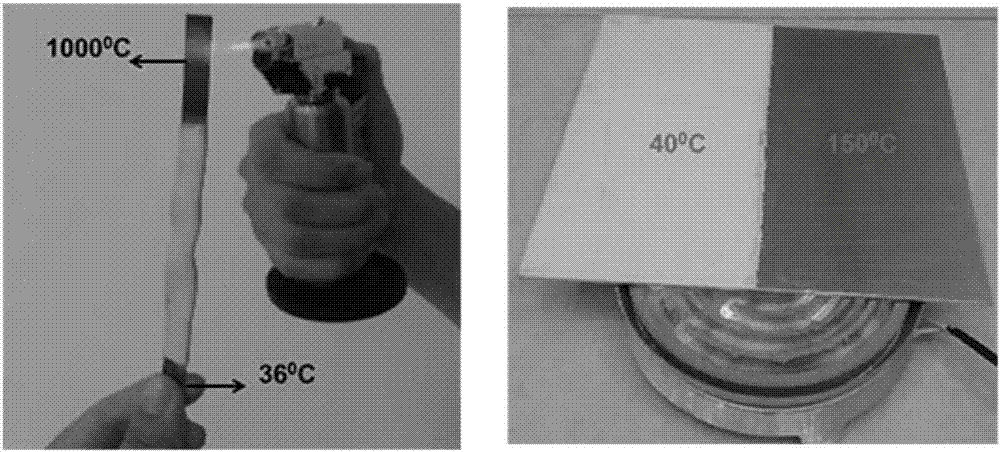

A technology of environmentally friendly coatings and environmentally friendly materials, applied in epoxy resin coatings, reflective/signal coatings, antifouling/underwater coatings, etc., can solve the problems of environmental and human hazards, large-scale industrial production, and high raw material costs. Reduce hazards, increase the ability to reflect sunlight and heat radiation, and ensure the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

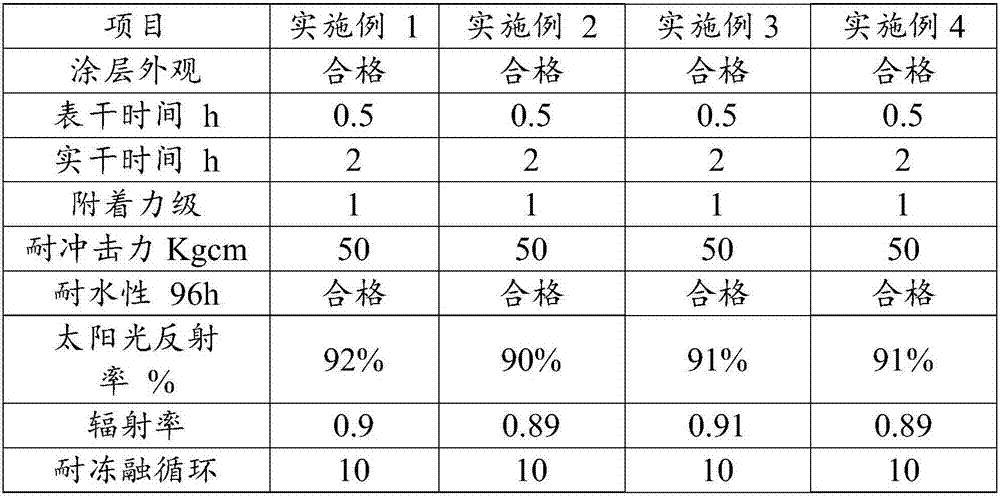

[0020] An environmentally friendly coating, comprising the following components in parts by weight: 15 parts of resin emulsion, 18 parts of nano ceramics, 15 parts of filler, 13 parts of pigment, 3 parts of auxiliary agent, 9 parts of auxiliary heat insulating material, and 2 parts of lotus leaf hydrophobic agent , 25 parts of deionized water.

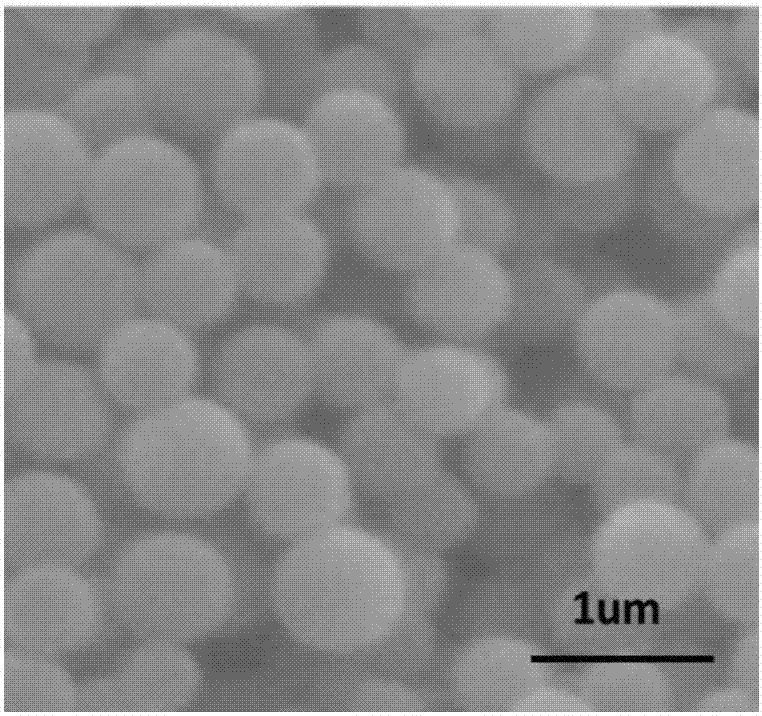

[0021] The resin emulsion is an epoxy resin emulsion, the filler is quartz sand, the pigment is titanium dioxide, and the auxiliary agent includes the following components in parts by weight: 0.8 parts of 2,2,4-trimethyl-1, carboxyl liquid butyl 0.3 parts of nitrile rubber, 0.3 parts of calcium stearate, 0.9 parts of butadiene resin film-forming agent, 0.3 parts of casein and 0.4 parts of benzimidazole ester, the auxiliary heat insulation material is hollow inorganic fiber, and the lotus leaf hydrophobic agent contains nano Barium sulfate; the fineness of nano-ceramics is 1.6-13 μm, and the fineness of fillers and pigments is 2.2-4.4 μ...

Embodiment 2

[0023] An environmentally friendly coating, comprising the following components in parts by weight: 22 parts of resin emulsion, 21 parts of nano ceramics, 12 parts of filler, 16 parts of pigment, 2 parts of auxiliary agent, 10 parts of auxiliary heat insulating material, and 1 part of lotus leaf hydrophobic agent , 16 parts of deionized water.

[0024] The resin emulsion is a phenolic resin emulsion, the filler is bentonite, the pigment is iron oxide red, and the auxiliary agent includes the following components in parts by weight: 0.2 parts of N-phenyl-α-aniline, 0.2 parts of polysulfide rubber, hard 0.6 part of zinc fatty acid, 0.2 part of nitrocellulose film-forming agent, 0.3 part of sodium bentonite and 0.5 part of sodium benzoate, the auxiliary heat insulation material is hollow glass microspheres, and the lotus leaf hydrophobic agent contains nano-silica; the fineness of nano-ceramic The size is 1.6-13 μm, and the fineness of fillers and pigments is 2.2-4.4 μm.

Embodiment 3

[0026] An environmentally friendly coating, comprising the following components in parts by weight: 30 parts of resin emulsion, 14 parts of nano-ceramic, 18 parts of filler, 8 parts of pigment, 2 parts of auxiliary agent, 16 parts of auxiliary heat insulating material, and 0.8 part of lotus leaf hydrophobic agent , 11.2 parts of deionized water.

[0027] Described resin emulsion is phenolic resin emulsion and acrylic resin emulsion, and phenolic resin emulsion and acrylic resin emulsion powder are respectively 18 parts and 12 parts; Filler is bentonite and kaolin, and bentonite and kaolin are respectively 8 parts and 10 parts; Pigment is Iron oxide red and titanium dioxide, iron oxide red and titanium dioxide are 3 parts and 5 parts respectively; the auxiliary agent contains the following components in parts by weight: 0.2 parts of 2,2,4-trimethyl-1, polysulfone 0.5 parts, 0.4 parts of liquid paraffin, 0.5 parts of polyurethane film former, 0.1 parts of hydroxypropyl methylcel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com