Light assembling structure for optical fiber gyro-space application

A fiber optic gyroscope and combined structure technology, applied in Sagnac effect gyroscopes and other directions, can solve the problems of low reliability, difficult to maintain volume, etc., and achieve the effects of high reliability, firm and stable instruments, and increased heat conduction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

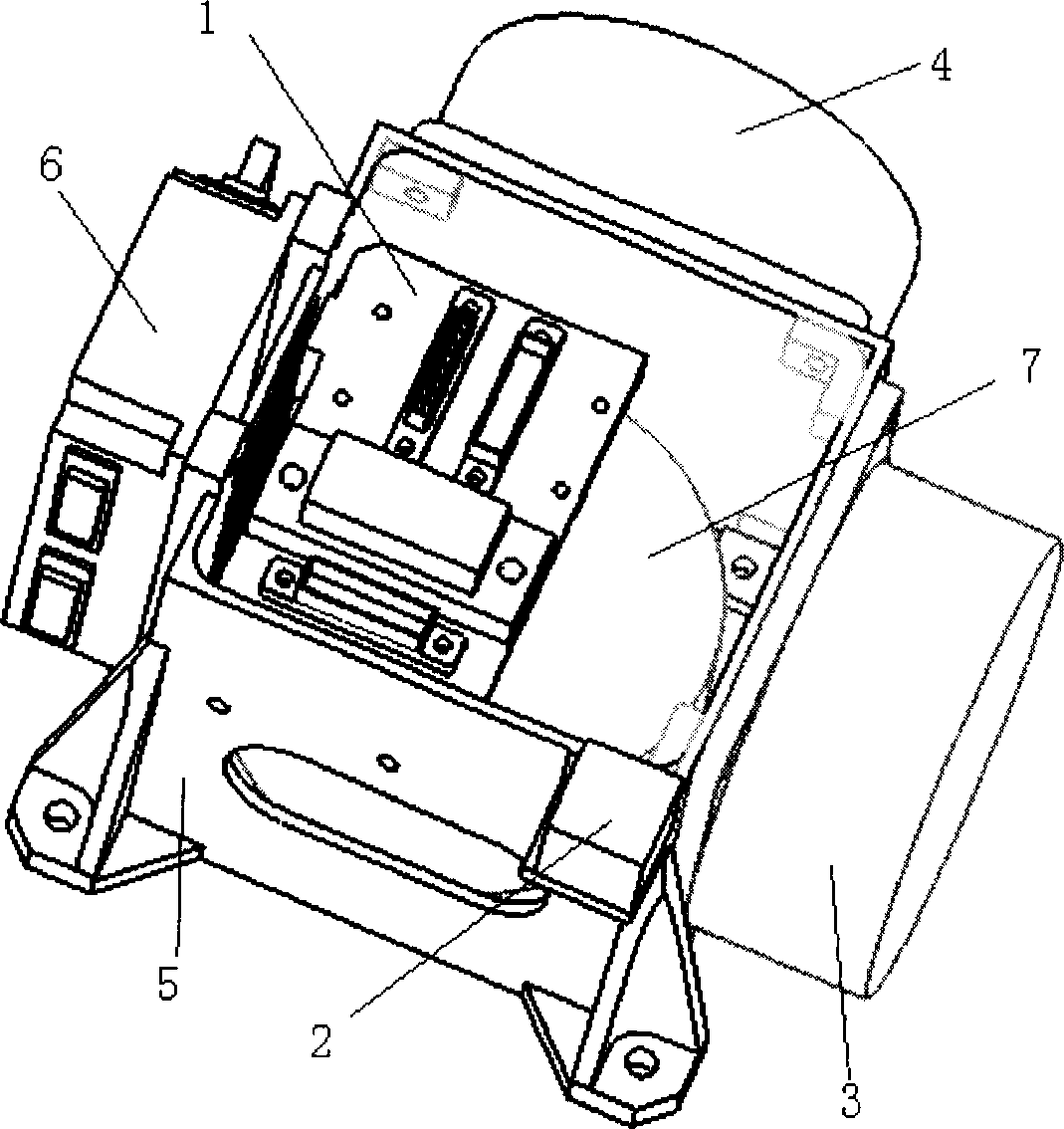

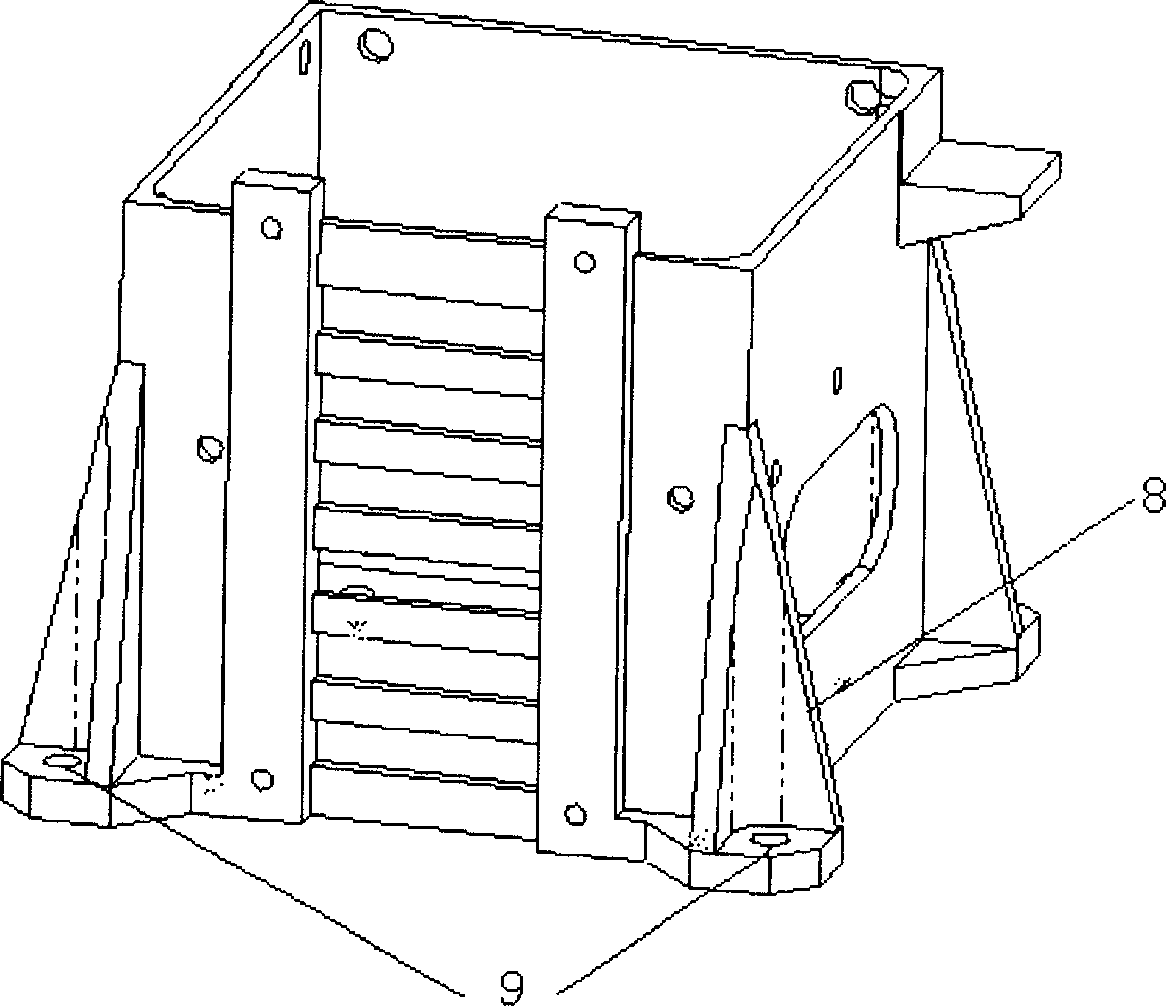

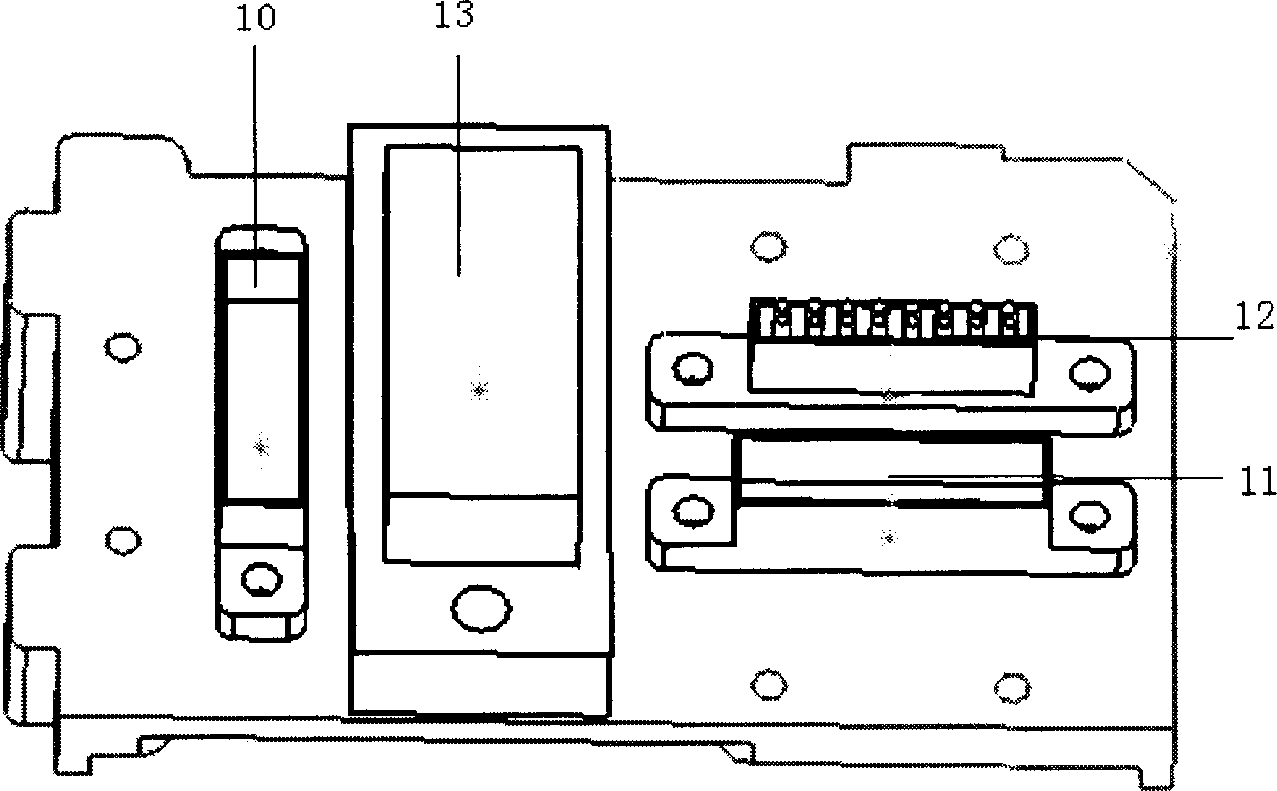

[0021] Such as figure 1 As shown, the x-axis gyro 3 and the y-axis gyro 4 are respectively installed on the outside of the side of the main body 5. The z-axis gyro 7 is located under the connector board 1 and installed on the inner side of the bottom plate of the main body 5. The x-axis gyro 3 and the y-axis gyro 4 The z-axis gyroscopes 7 are perpendicular to each other, forming an orthogonal system that respectively senses the angular velocities of the x-axis, y-axis, and z-axis in the orthogonal coordinate system. By integrating the angular velocities of the three axes, the position information of the spacecraft can be obtained to determine the satellite Posture information. The bottom surfaces of the three fiber optic gyroscopes are in full contact with the mounting surface of the body 5 to increase the heat conduction area between the lower surface of the gyro and the body, reduce the thermal resistance, and improve the heat transfer performance; at the same time, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com