PHOTOCURABLE AND THERMOSETTING RESIN COMPOSITION, DRY FILM SOLDER RESIST fabricated therefrom and circuit board comprising dry film solder resist

A resin composition, thermosetting technology, applied in photosensitive materials for optomechanical equipment, optomechanical equipment, optics, etc., can solve problems such as difficult adhesion of electronic components, inability to fully demonstrate thermal radiation performance, etc., to improve thermal radiation performance, excellent light-curing performance, reduction in dimensional stability and minimization of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0172] Embodiment and comparative example: the preparation of resin composition, dry film and printed circuit board

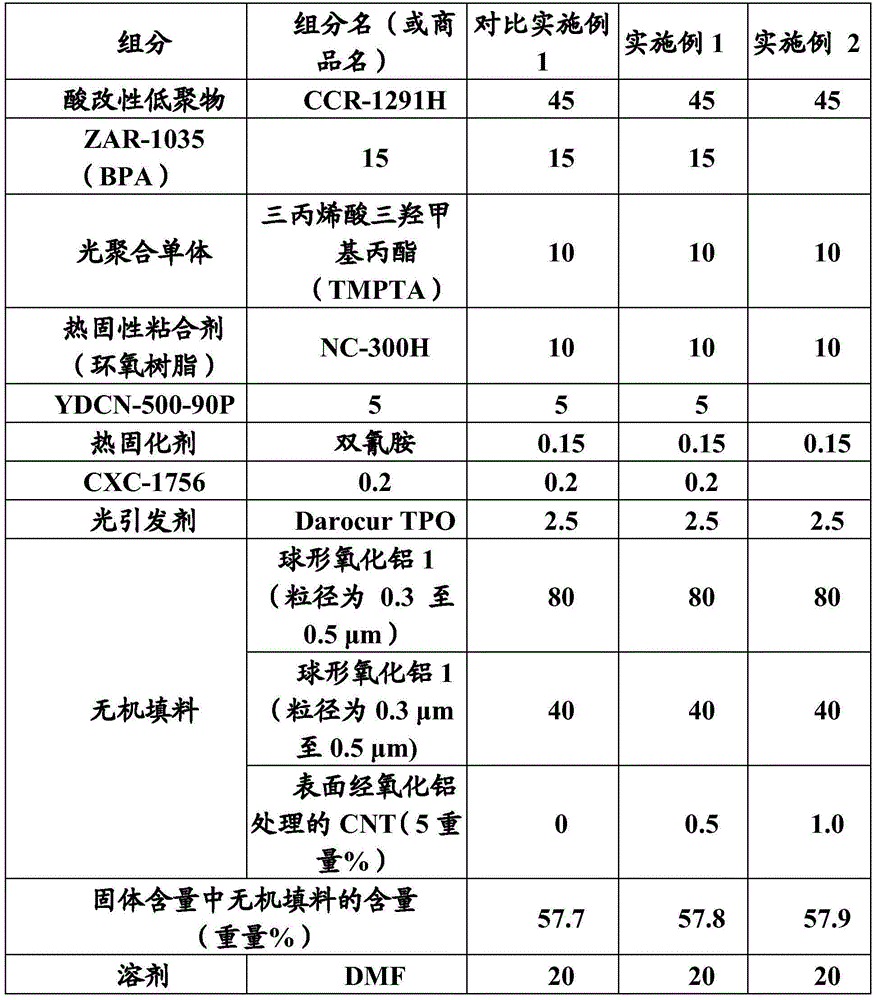

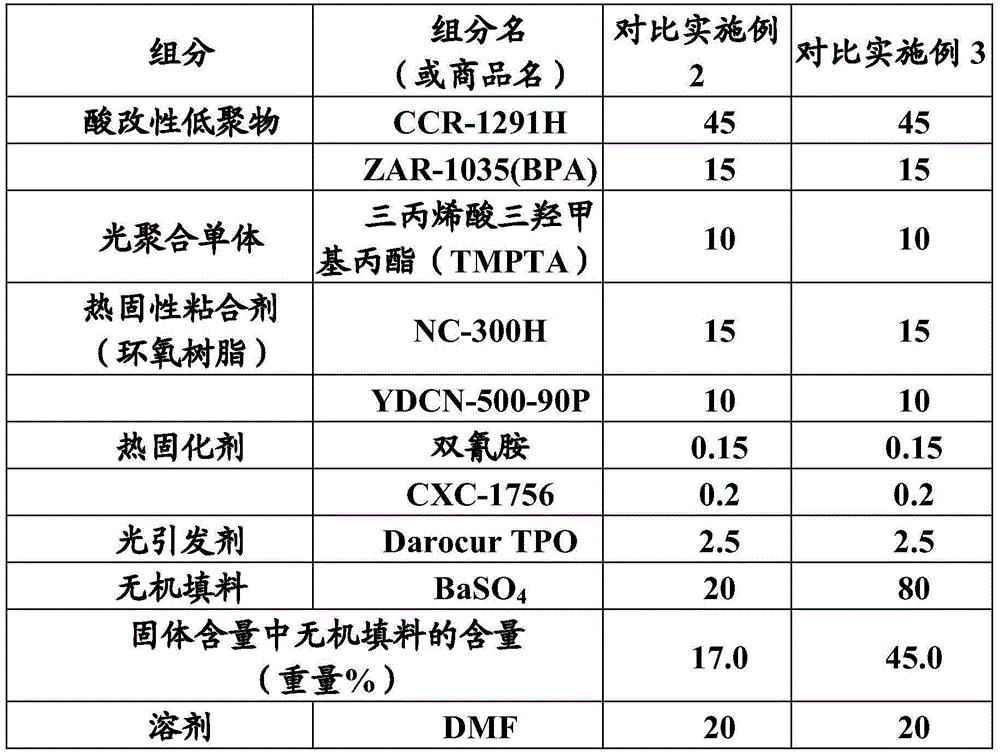

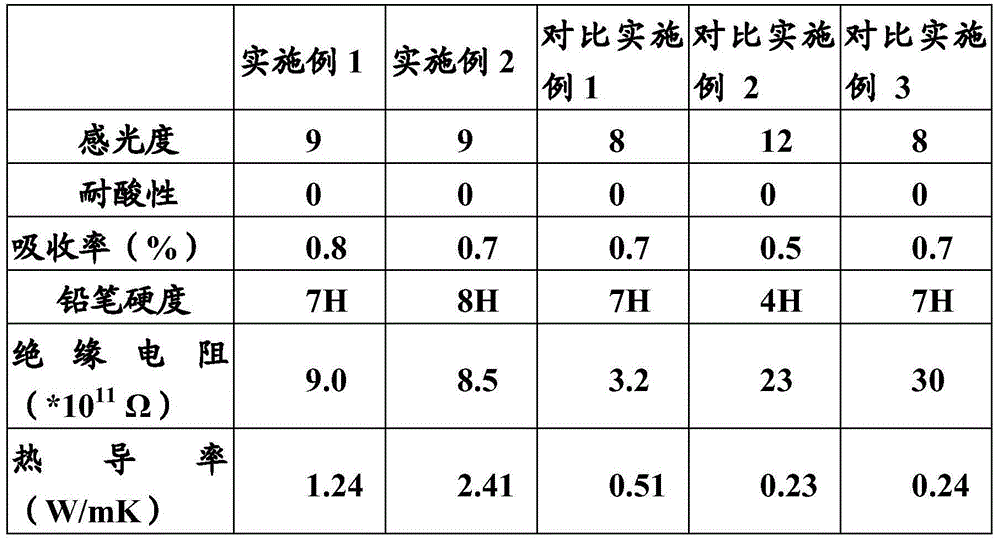

Embodiment 1 and 2 and comparative Embodiment 1

[0174] A resin composition was prepared by mixing the components shown in Table 1 below. In this paper, a mixture of epoxy (meth)acrylate compounds derived from cresol novolac and epoxy (meth)acrylate compounds derived from bisphenol F in a weight ratio of 3:1 was used as the acid-modified low Polymer.

[0175] The resin composition prepared as above was applied on PET as a carrier film, and it was dried by an oven at 75° C., and then PE was laminated as a release film, thereby preparing a carrier film, a photosensitive film (thickness: 20μm) and a dry film composed of a release film.

[0176] After peeling off the cover film of the prepared dry film, the photosensitive film layer is vacuum laminated on the circuit-forming substrate, and a light shield corresponding to the circuit pattern is placed on the photosensitive film layer and exposed to ultraviolet light. Using ultraviolet light with a wavelength of 365nm at 350mJ / cm 2 exposure at the exposure level.

[0177] Ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com