Potassium titanate whisker reinforced and modified PP flame-retardant master batch and preparation method thereof

A technology of potassium titanate whiskers and flame retardant masterbatch, which is applied in the field of modified polymer materials, which can solve the problems of the influence of the surface finish of the workpiece, the wear of the screw and the mold, and the reduction of the fluidity of the matrix, and achieve excellent microscopic enhancement. and filling ability, reduction of molding shrinkage, and reduction of linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

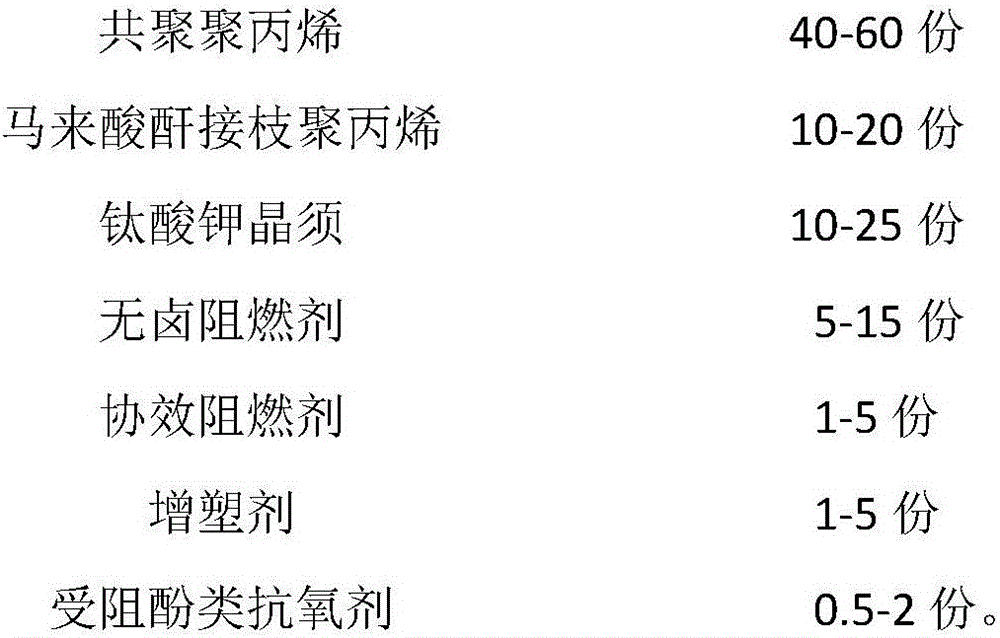

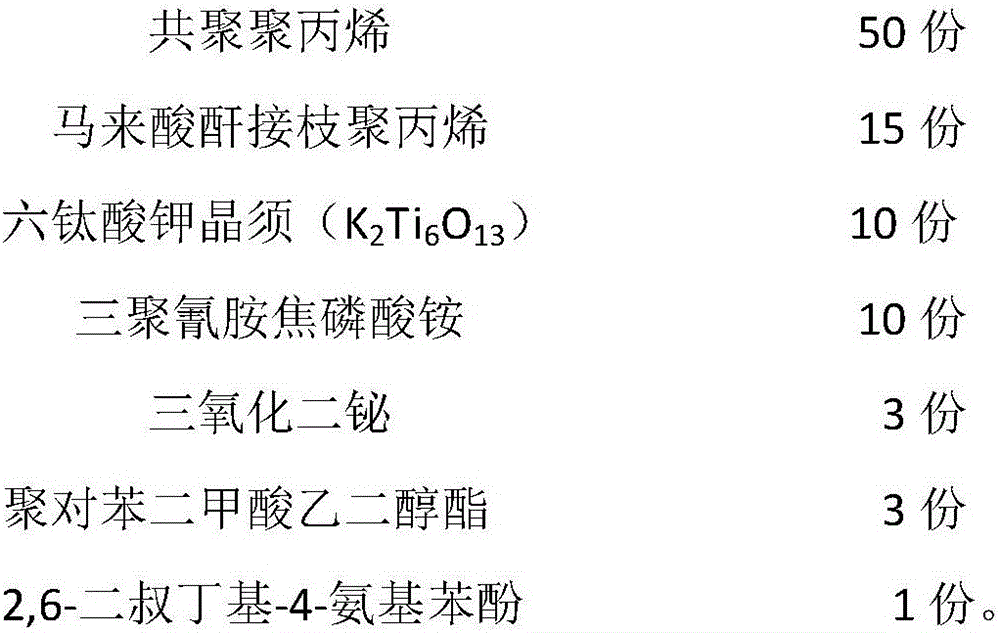

[0023] A potassium titanate whisker-reinforced modified PP flame-retardant masterbatch, prepared from the following raw materials in parts by weight:

[0024]

[0025] The above-mentioned potassium titanate whisker reinforced modified PP flame retardant masterbatch, the steps are:

[0026] 1) Take by weighing polypropylene copolymer, maleic anhydride grafted polypropylene, potassium hexatitanate whisker, melamine ammonium pyrophosphate, bismuth trioxide, polyethylene terephthalate and 2 according to the above proportioning ratio, 6-di-tert-butyl-4-aminophenol;

[0027] 2) Copolymerized polypropylene, maleic anhydride grafted polypropylene, potassium hexatitanate whisker, melamine ammonium pyrophosphate, bismuth trioxide, polyethylene terephthalate and 2,6-di-tert-butyl - Add 4-aminophenol to the twin-screw extruder for extrusion and granulation. Control the temperature of the first zone of the twin-screw extruder barrel to 170°C, the temperature of the second zone to 180°C...

Embodiment 2

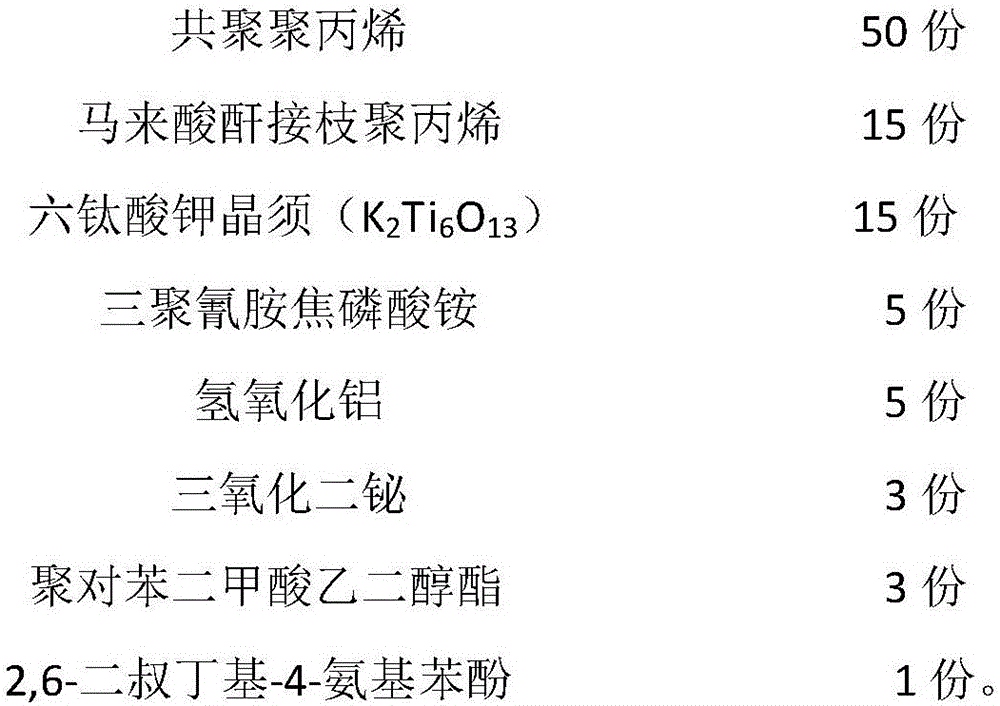

[0029] A potassium titanate whisker-reinforced modified PP flame-retardant masterbatch, prepared from the following raw materials in parts by weight:

[0030]

[0031] The above-mentioned potassium titanate whisker reinforced modified PP flame retardant masterbatch, the steps are:

[0032] 1) Weigh copolymerized polypropylene, maleic anhydride grafted polypropylene, potassium hexatitanate whisker, melamine ammonium pyrophosphate, aluminum hydroxide, bismuth trioxide, polyethylene terephthalate according to the above ratio Esters and 2,6-di-tert-butyl-4-aminophenol;

[0033] 2) Copolymerized polypropylene, maleic anhydride grafted polypropylene, potassium hexatitanate whiskers, melamine ammonium pyrophosphate, aluminum hydroxide, bismuth trioxide, polyethylene terephthalate and 2,6- Di-tert-butyl-4-aminophenol is added to the twin-screw extruder for extrusion and granulation. The temperature of the first zone of the twin-screw extruder barrel is 170°C, the temperature of th...

Embodiment 3

[0035] A potassium titanate whisker-reinforced modified PP flame-retardant masterbatch, prepared from the following raw materials in parts by weight:

[0036]

[0037]

[0038] The above-mentioned potassium titanate whisker reinforced modified PP flame retardant masterbatch, the steps are:

[0039] 1) Weigh copolymerized polypropylene, maleic anhydride grafted polypropylene, potassium hexatitanate whisker, melamine ammonium pyrophosphate, expandable graphite, bismuth trioxide, polyethylene terephthalate according to the above ratio Esters and 2,6-di-tert-butyl-4-aminophenol;

[0040] 2) Copolymerized polypropylene, maleic anhydride grafted polypropylene, potassium hexatitanate whiskers, melamine ammonium pyrophosphate, expandable graphite, bismuth trioxide, polyethylene terephthalate and 2,6- Di-tert-butyl-4-aminophenol is added to the twin-screw extruder for extrusion and granulation. The temperature of the first zone of the twin-screw extruder barrel is 170°C, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com