High-rigidity optical diffusion PC material, and preparation method and application thereof

A light-diffusion, high-rigidity technology, applied in the field of materials, can solve the problems of reducing fluidity and interface bonding force, affecting light-diffusion PC light transmittance, and difficult to control size and curvature, so as to improve tensile strength and bending resistance Rigidity, flexible application, short material mixing time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

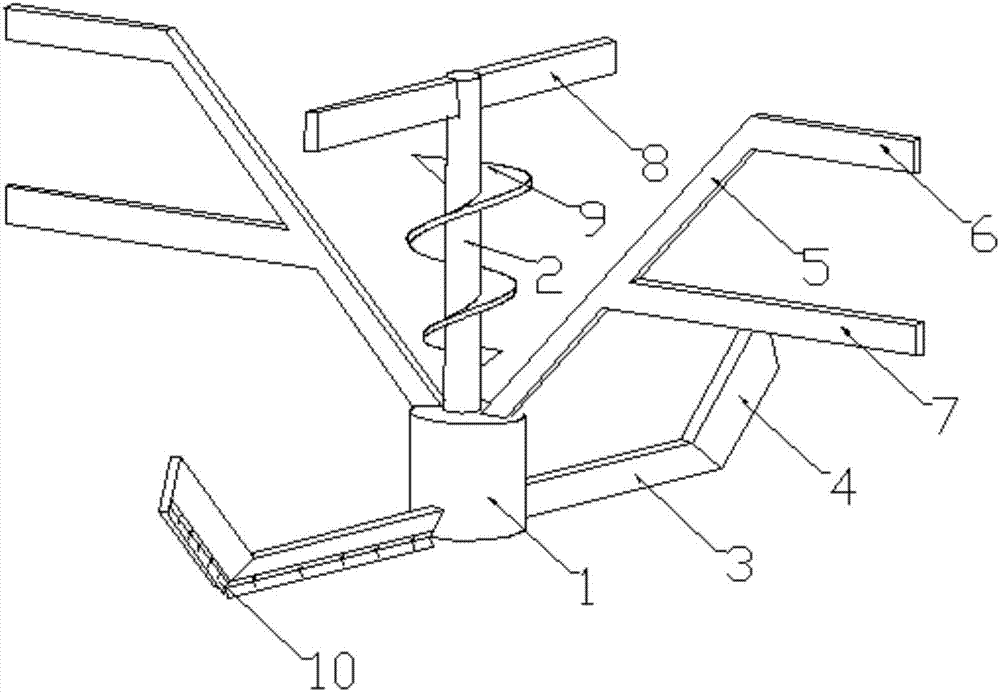

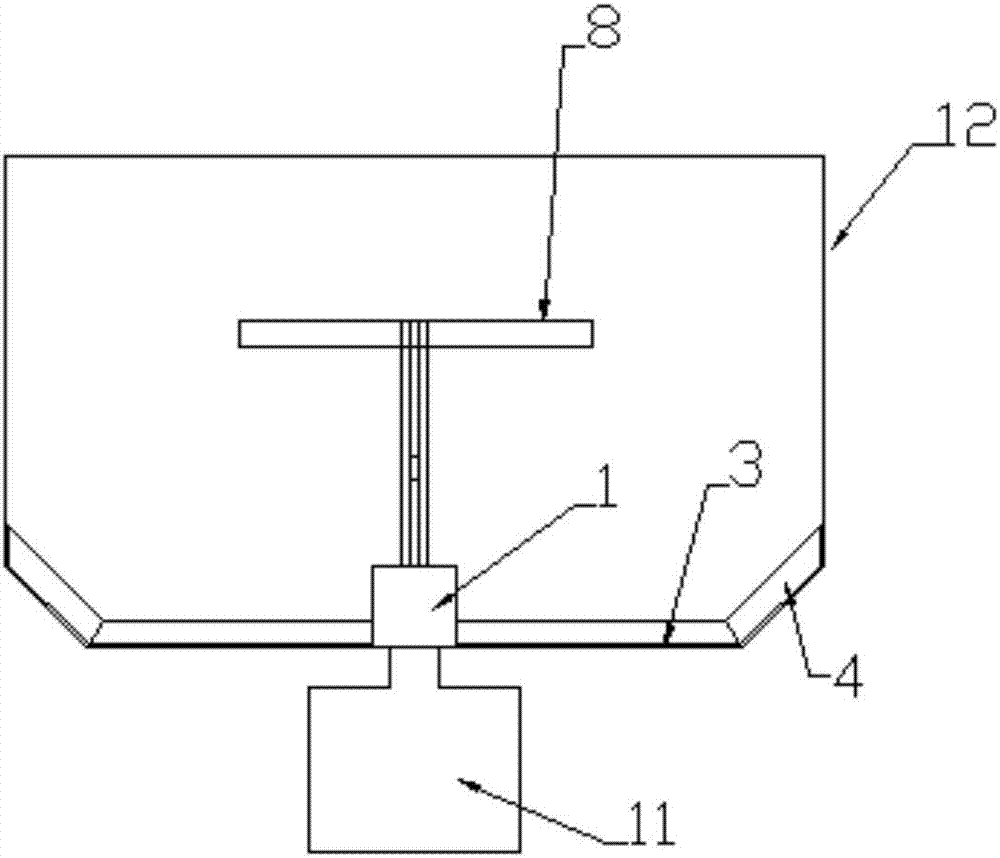

Method used

Image

Examples

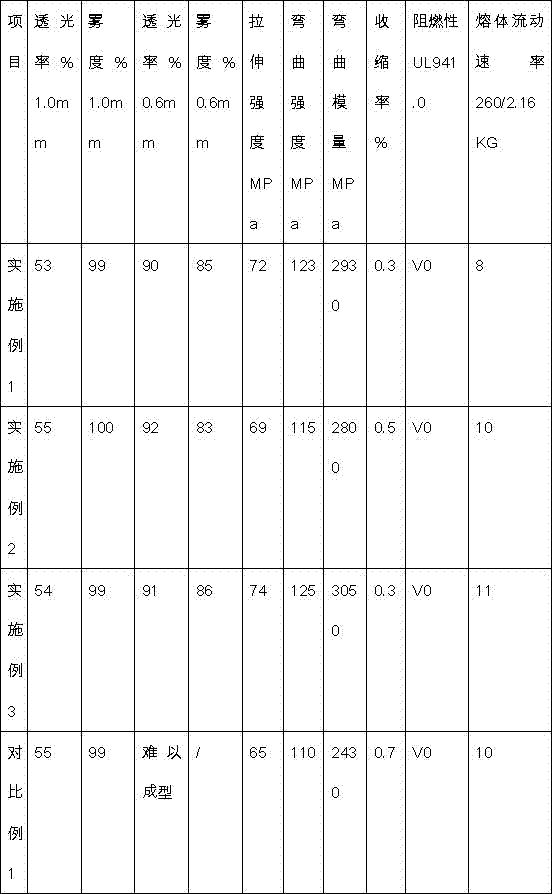

Embodiment 1

[0055] The composition of present embodiment is as follows:

[0056] PC resin Mitsubishi 7025: 100kg

[0057] Strengthening agent calcium sulfate whisker, glass microsphere 7: 3 composite: 5.3kg

[0058] Light diffusing agent: 1.5 micron, 2 micron silicone compounded at a weight ratio of 1:1, with a total weight of 1.6kg

[0059] Antioxidant: 1010: 0.2kg

[0060] Anti-UV agent: UV622: 0.5kg

[0061] Dispersant: pentaerythritol tetrastearate: 0.5kg

[0062] Dispersant: white mineral oil: 0.1kg

[0063] Flame retardant: Potassium perfluorobutane sulfonate: 0.08kg

[0064] Toner: 2,2,-(2,5-thiophene)bis[5-(1,1-dimethylethyl)]-benzotriazole: 0.05kg

[0065] The preparation process is as follows:

[0066] Dry PC resin at 120°C for 8 hours, mix with white mineral oil at low speed for 3 minutes, add toner, flame retardant, dispersant and mix for 5 minutes, add antioxidant, anti-UV agent and light diffusing agent for high-speed mixing for 10 minutes, and finally Add the reinfo...

Embodiment 2

[0068] The composition of present embodiment is as follows:

[0069] PC resin 1110R: 100kg

[0070] Reinforcing agent aluminum borate whisker and white carbon black compounded at a weight ratio of 8:2, a total of 7kg

[0071] Light diffusing agent: polysiloxane-based organic powder 1.6 microns: 0.9kg

[0072] Light diffuser: 3 micron methyl methacrylate beads: 0.8kg

[0073] Antioxidant: 300: 0.2kg

[0074] Anti-UV agent: UV5411: 0.3kg

[0075] Dispersant: stearic acid: 0.5kg

[0076] Dispersant: white mineral oil: 0.1kg

[0077] Flame retardant: Potassium perfluorobutane sulfonate: 0.08kg

[0078] Toner: 2,2,-(2,5-thiophene)bis[5-(1,1-dimethylethyl)]-benzotriazole: 0.06kg

[0079] The preparation process is as follows:

[0080] Dry PC resin at 120°C for 8 hours, mix with white mineral oil at low speed for 3 minutes, add toner, flame retardant, dispersant and mix for 5 minutes, add antioxidant, anti-UV agent and light diffusing agent for high-speed mixing for 10 minute...

Embodiment 3

[0082] The composition of present embodiment is as follows:

[0083] PC resin IR2200: 100kg

[0084] Strengthening agent: Zinc oxide and glass microspheres are mixed at a weight ratio of 5:5 to obtain a weight of 8kg

[0085] Light diffuser: 2 micron silicone 1.5kg

[0086] Antioxidant: 1010 / 168: 0.2 / 0.1kg

[0087] Anti-UV agent: UV531: 0.4kg

[0088] Dispersant: polyamide wax: 0.5kg

[0089] Dispersant: white mineral oil: 0.1kg

[0090] Flame retardant: Potassium benzenesulfonylbenzenesulfonate: 0.1kg

[0091] Toner: 2,2,-(2,5-thiophene)bis[5-(1,1-dimethylethyl)]-benzotriazole: 0.1 kg.

[0092] The production process is as follows:

[0093] Dry PC resin at 120°C for 8 hours, mix with white mineral oil at low speed for 3 minutes, add toner, flame retardant, dispersant and mix for 5 minutes, add antioxidant, anti-UV agent and light diffusing agent for high-speed mixing for 10 minutes, and finally Add the reinforcing agent and mix for 3 minutes; the screw temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com