Vortex-type mixing sedimentation integrated reactor

A mixed reactor and mixed sedimentation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of difficult maintenance, large power consumption, and high operating costs, and achieve short mixing time and high water output. The effect of low speed and cost saving of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

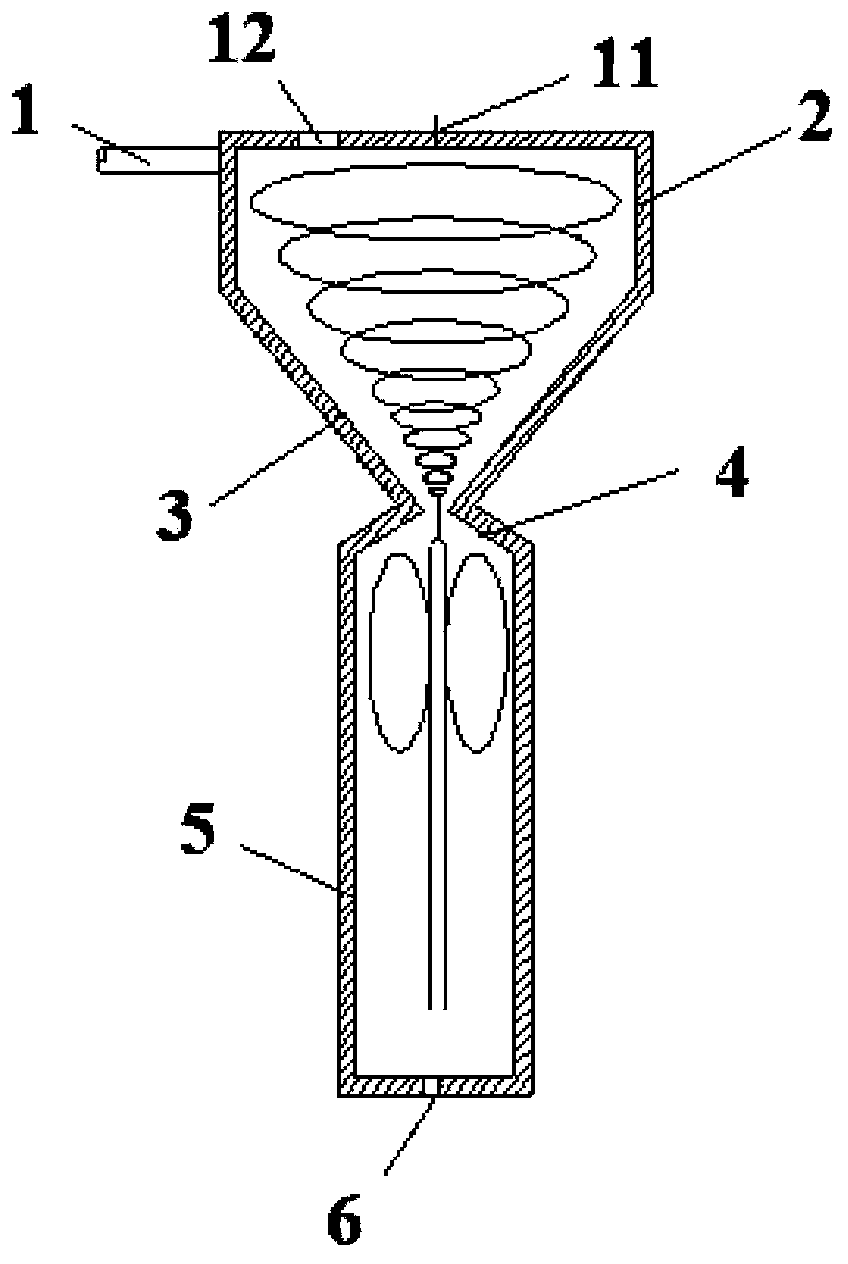

[0042] Reference example figure 1 , the present embodiment provides the concrete structure of the mixing zone of a kind of vortex type mixing reactor, is made up of first cylinder 2, contraction vertebral body 3, expansion vertebral body 4, second cylinder body 5, in the first cylinder body 2 A water inlet pipe 1 is arranged on the top, a drug inlet 11 and an observation and sampling port 12 are provided on the top of the first cylinder 2 , and a water outlet 6 is provided at the bottom of the second cylinder 5 .

[0043] The vortex mixing reactor has a volume of 12.3L and is made of plexiglass. It is mainly used to treat a small amount of acid wastewater in the laboratory, and the dosed agent is magnesium hydroxide. Simulation results refer to Figure 4 , Figure 5 , Image 6 , Figure 7 , which is mainly the simulation result of the internal flow field of the vortex mixing reactor. The dimensions of each part of the vortex mixing reactor are as follows:

[0044] 1) The ...

Embodiment 2

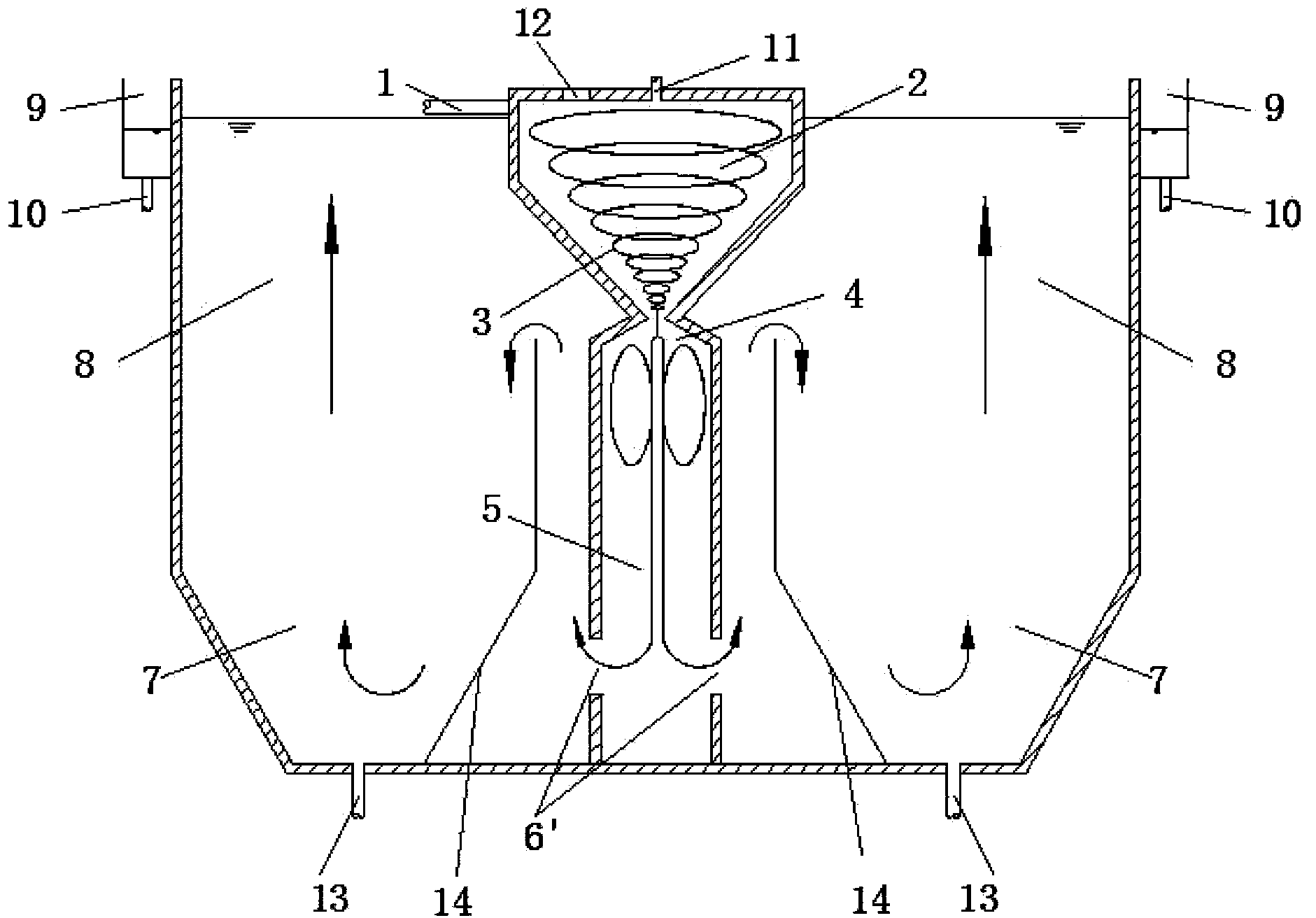

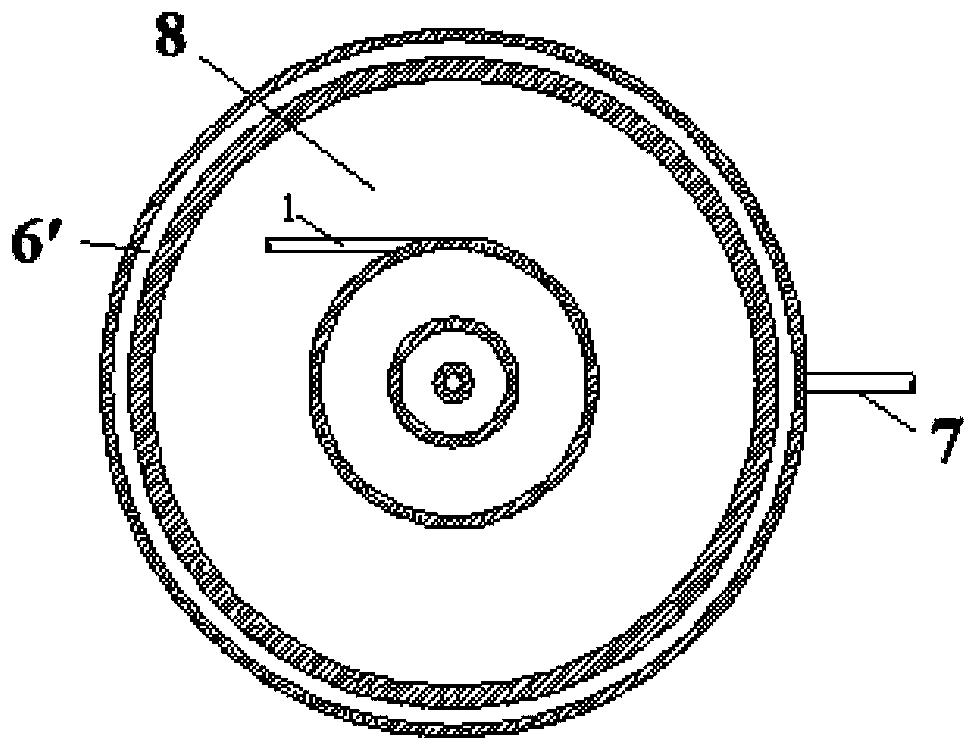

[0059] Reference example figure 2 , this embodiment provides a specific structure of a vortex-type mixed-sedimentation integrated reactor, which is composed of the mixing zone and the settling zone 8 in Example 1. The difference is that the mixing zone of the vortex-type mixed-sedimentation integrated reactor in Example 1 The second cylinder 5 in the part is connected to the sedimentation area 8 through a deflector to form an integrated structure. There is an annular sump 9 on the sedimentation area 8, an outlet pipe 10 below the annular sump 9, and an outlet pipe 10 below the sedimentation area 8. Mud bucket 7 and mud discharge pipe 13.

[0060] In this example, the designed reaction time of the integrated vortex mixing and sedimentation reactor in Example 1 is 20 minutes, and the designed reaction time of the precipitation zone 8 is 1.8 hours.

[0061] The volume of the vortex type mixing and sedimentation integrated reactor in this embodiment is 12.3m 3 It is mainly used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com