Single-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

A multi-wire cutting machine and agitator technology, which is applied to mixers with rotating agitation devices, mixers, liquid and solid mixing, etc., can solve the problems of agitator stuck, cost increase, etc., achieve flexible use and operation, prevent The effect of crushing and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

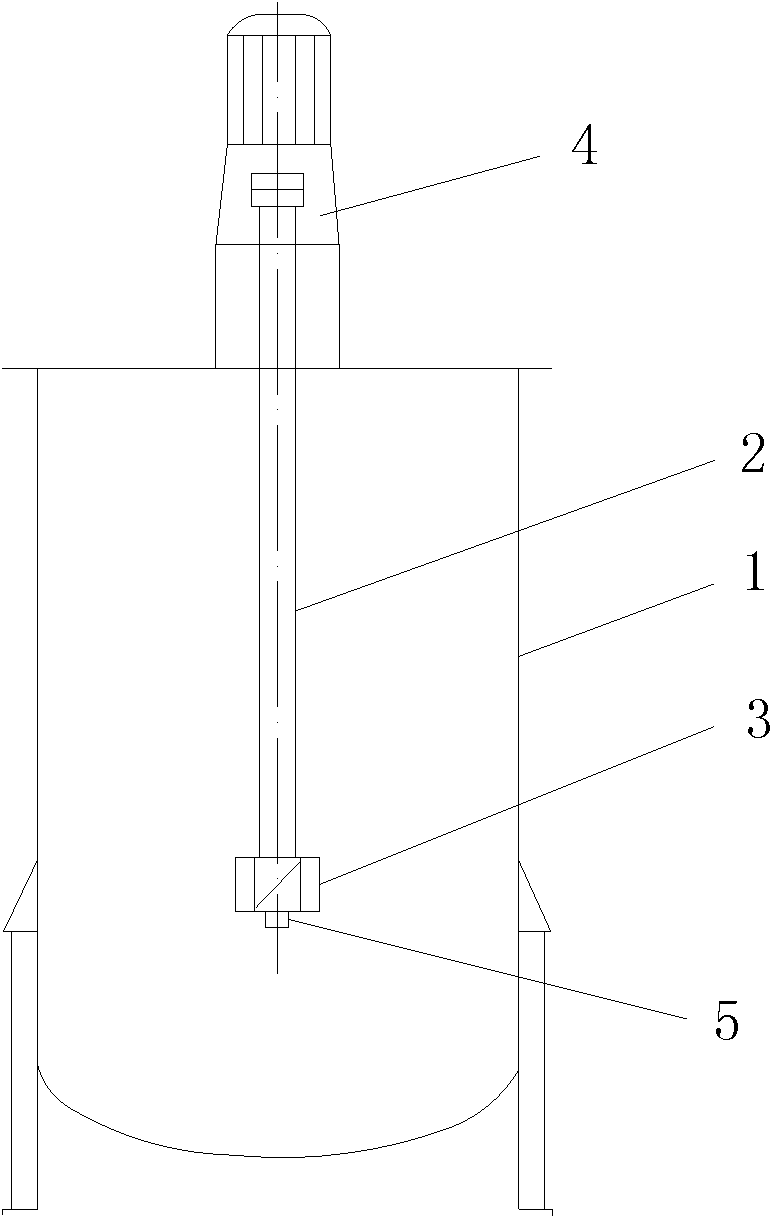

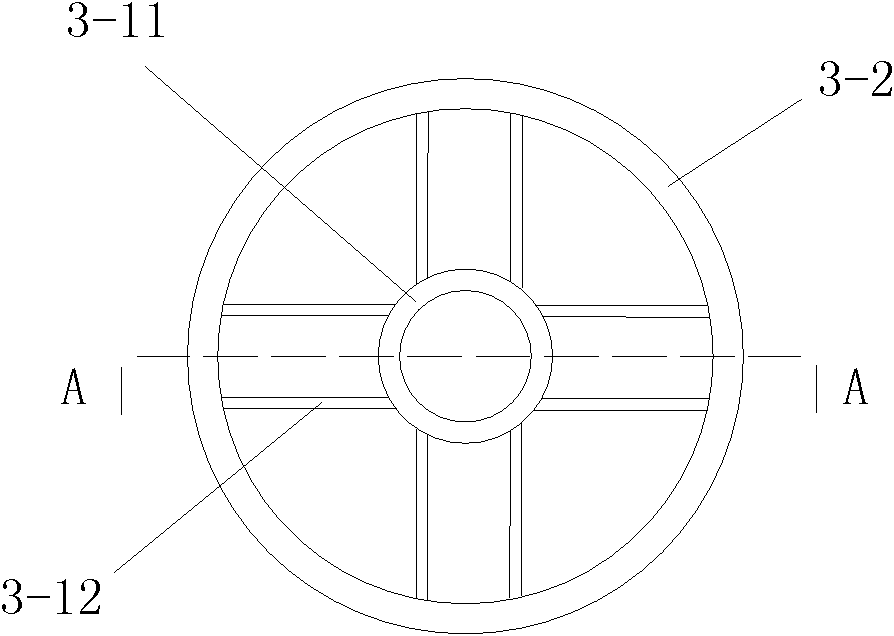

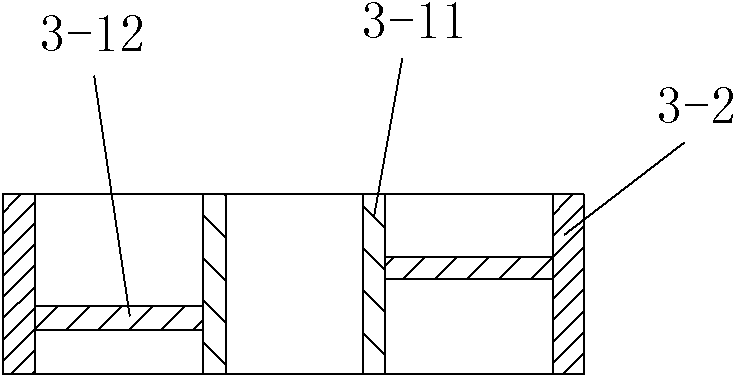

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the present invention includes a stirring shaft 2 coaxially installed in the stirring tank body 1, a stirring assembly 3 which continuously rotates with the stirring shaft 2 and uniformly stirs the materials in the stirring tank body 1, and a stirring assembly installed on the stirring shaft 2 The above drive mechanism drives the stirring shaft 2 to continuously rotate. The driving mechanism and the stirring shaft 2 are connected through a transmission mechanism. The stirring assembly 3 is coaxially installed at the bottom of the stirring shaft 2 . The mixing assembly 3 includes an impeller 3-1 that drives the material along the inner wall of the mixing tank body 1 to gradually move upward from the bottom of the tank or gradually downward from the upper surface of the material, and when the material performs a spiral movement, the flow direction of the material is limited to The short diversion tube 3-2 t...

Embodiment 2

[0050] In this embodiment, the difference from Embodiment 1 is that the diameter is Φ1000mm and the height is 1200mm elliptical head stirring tank, the power of the driving motor is 4KW and the rotating speed is 1500rpm, the effective length of the stirring shaft 2 is 840mm and its diameter is Φ50mm, the outer diameter of the diversion short pipe 3-2 is Φ180mm and its wall thickness is 5mm, the outer diameter of the shaft sleeve 3-11 is Φ55mm and its height is 50mm, the wall thickness of the shaft sleeve 3-11 is 5mm, the blade The installation angle is 45°, the vertical height of the blade 3-12 is 50mm and its thickness is 3mm, and the connection between the shaft sleeve 3-11 and the stirring shaft 2 is carried out in a threaded manner. In actual use, the blades 3-12 may also be arc-shaped blades with a curvature radius of 500 mm. In actual use, after putting in 800 liters of cutting fluid at a time, put in 800 kg of silicon carbide at one time, cover the top cover of the agit...

Embodiment 3

[0052] In this embodiment, the difference from Embodiment 2 is that the effective length of the stirring shaft 2 is 480 mm and its diameter is Φ30 mm, the radius of the short diversion pipe 3-2 is Φ150 mm and its wall thickness is 5 mm, and the shaft sleeve 3-11 The outer diameter of the blade is Φ35mm and its height is 50mm, the wall thickness of the shaft sleeve 3-11 is 5mm, the blade installation angle is 20°, the vertical height of the blade 3-12 is 50mm and its thickness is 5mm, and the shaft sleeve 3 -11 and the stirring shaft 2 are connected by a key mode. In actual use, the blades 3-12 may also adopt arc-shaped blades with a curvature radius of 35 mm. The stirring speed of the stirring shaft 2 is 600rmp. In this embodiment, the structures, connections and working principles of the remaining parts are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com