Patents

Literature

285results about How to "Decrease phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

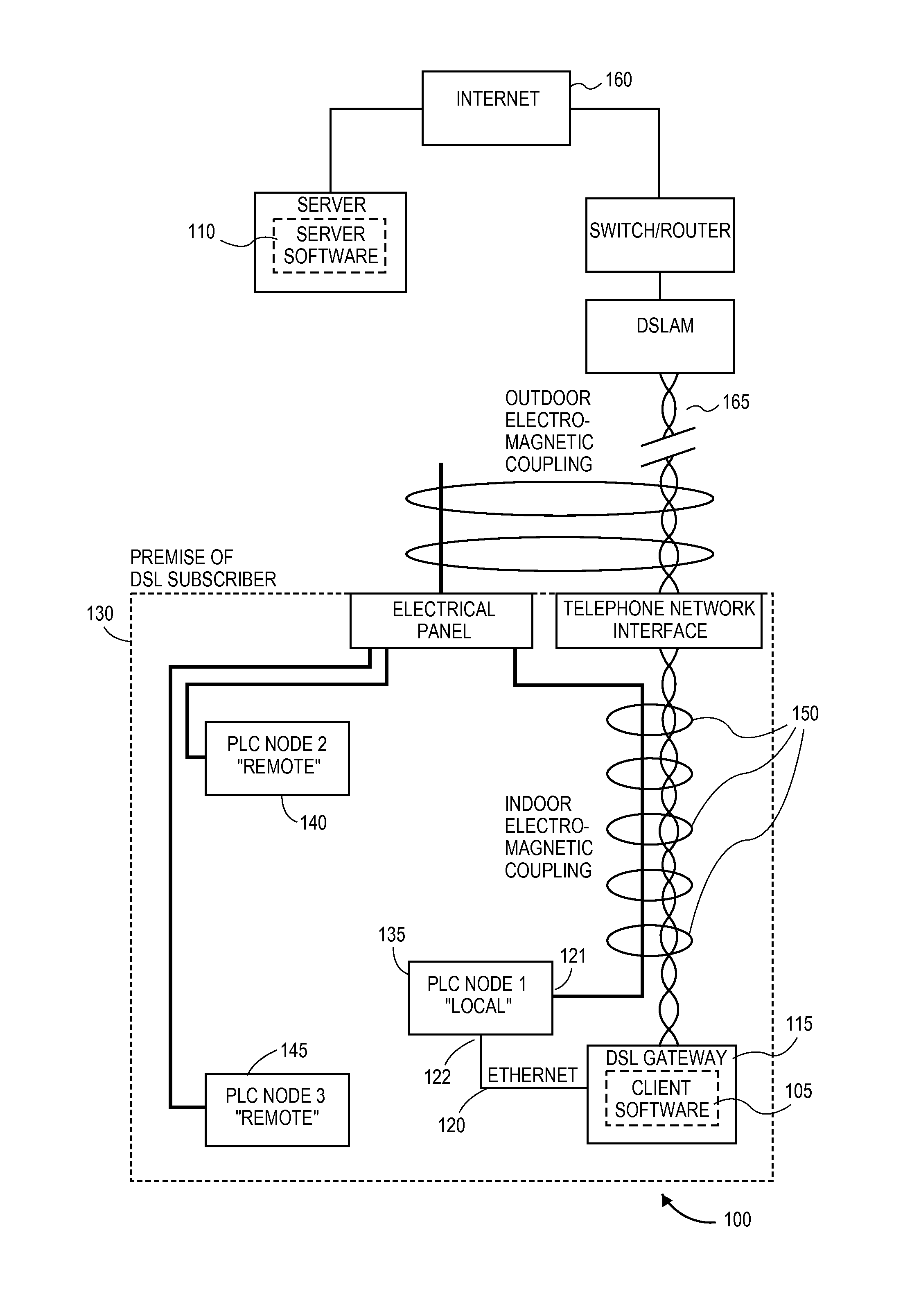

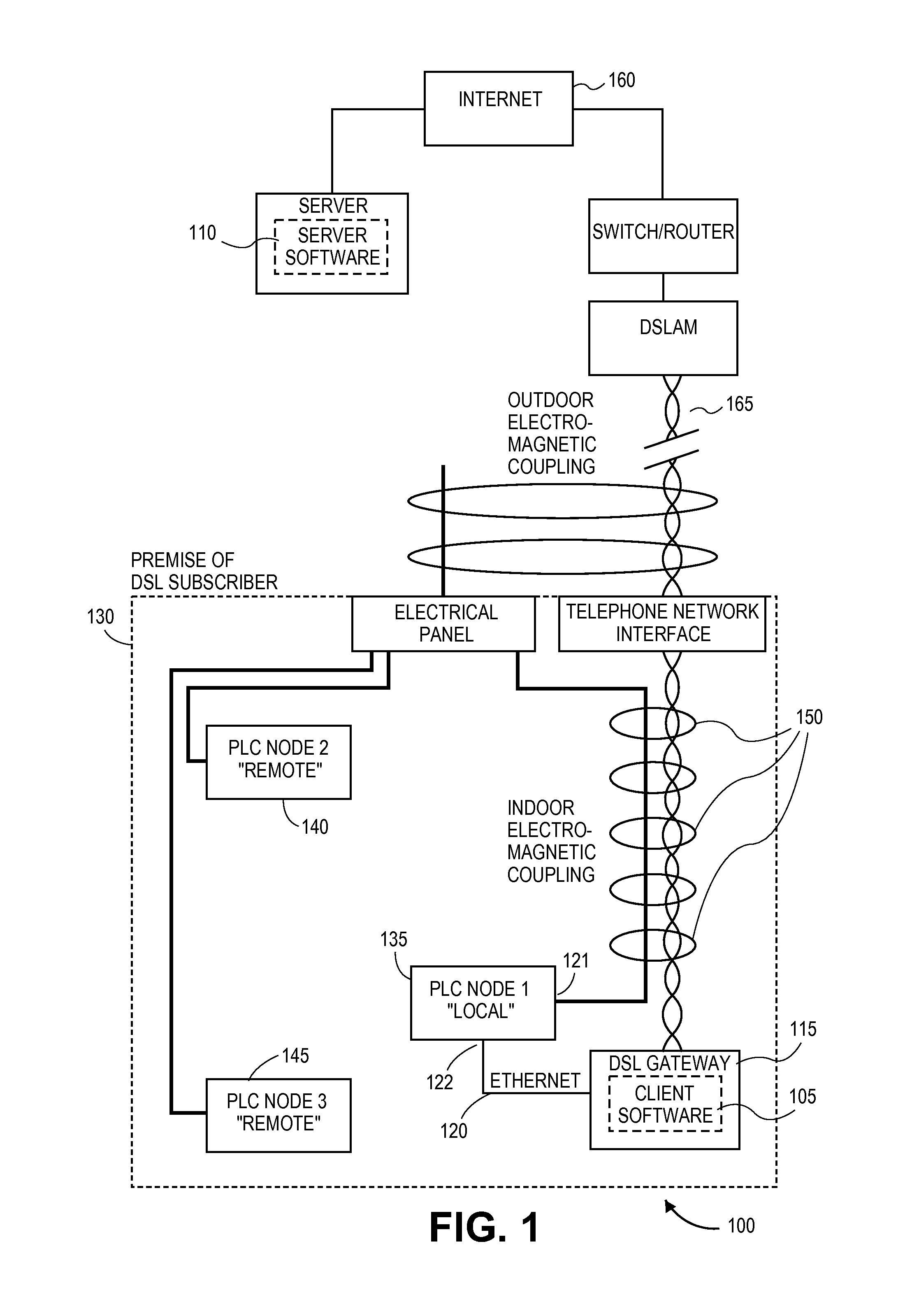

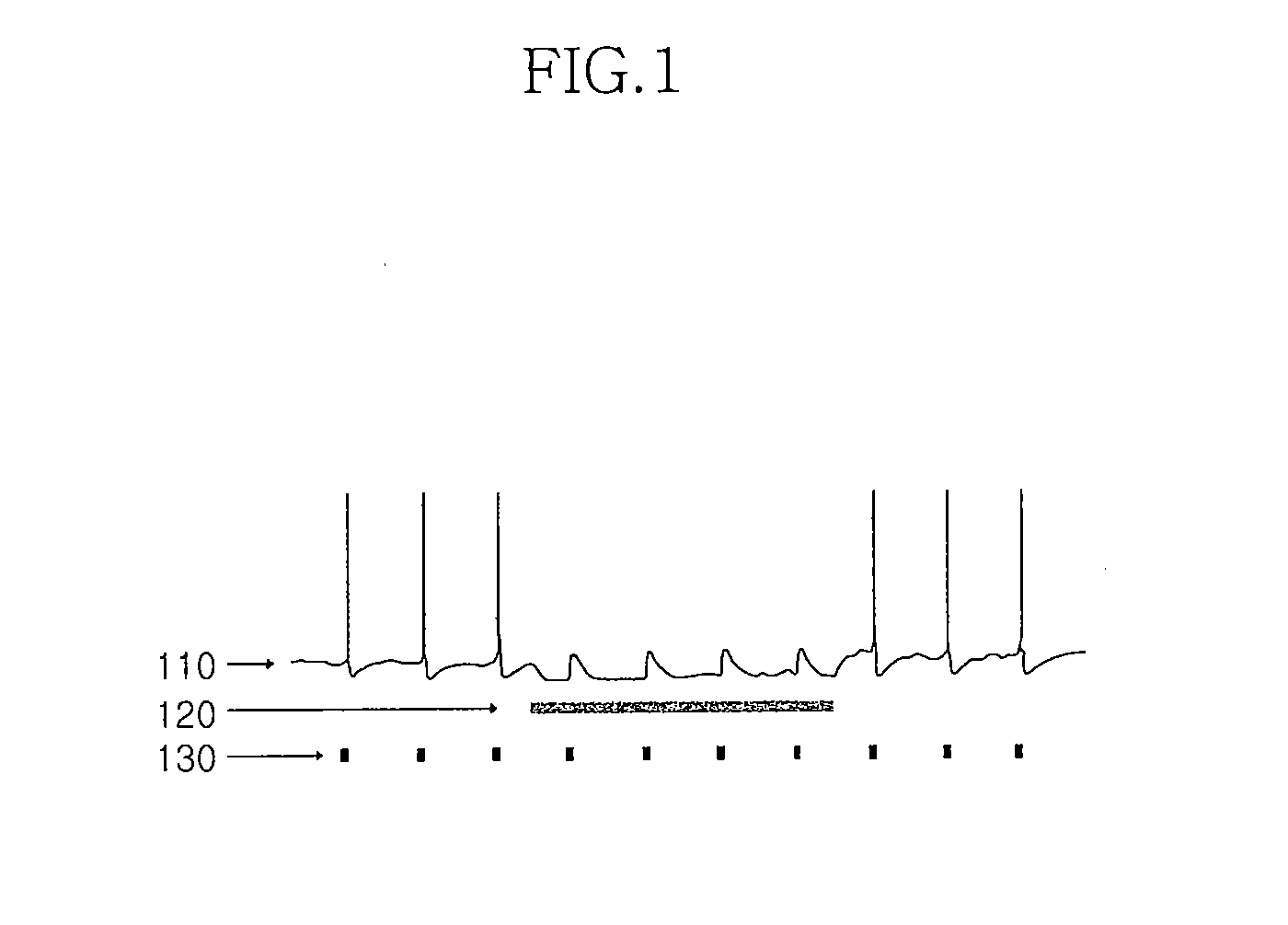

Method and apparatus for reducing the power of a signal electromagnetically coupled from a PLC medium to a DSL medium

ActiveUS20140369430A1Reduce impactDecrease phenomenonPower managementSystems with measurements/testing channelsDigital subscriber lineTransmitted power

Reducing a power of a signal electromagnetically coupled from a PLC medium to a digital subscriber line (DSL) medium. The method involves transmitting a data signal over the PLC medium at a first average power level from one of a plurality of PLC transmitters coupled to the PLC medium, then measuring first noise associated with a first signal received at a DSL receiver coupled to the DSL communication medium caused at least in part by the data signal transmitted over the PLC medium at a second average power level from the one PLC transmitter, the second average power level different than the first average power level, followed by measuring second noise associated with a second signal received at the DSL receiver coupled to the DSL communication medium caused at least in part by the data signal transmission over the PLC medium at the second average power level. A transmit power spectral density (PSD) for the data signal transmitted by the one PLC transmitter over the PLC medium is then changed, based on a difference between the first noise and the second noise, such that the changed transmit PSD for the data signal transmitted by the one PLC transmitter over the PLC medium reduces the power of the signal electromagnetically coupled from the PLC medium to the DSL medium caused by the data signal transmission from the one PLC transmitter over the PLC medium.

Owner:ASSIA SPE LLC CO THE CORP TRUST CO

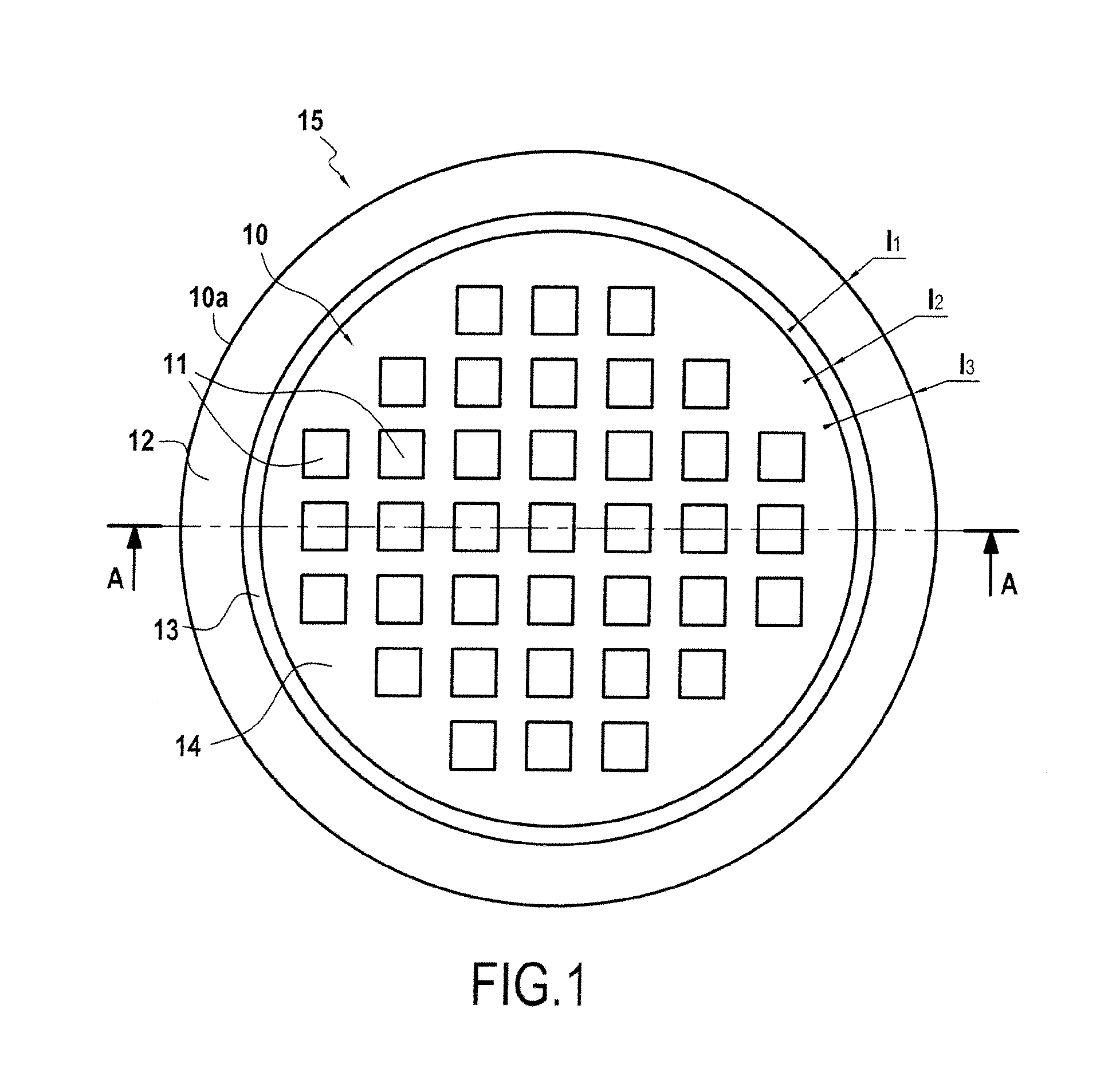

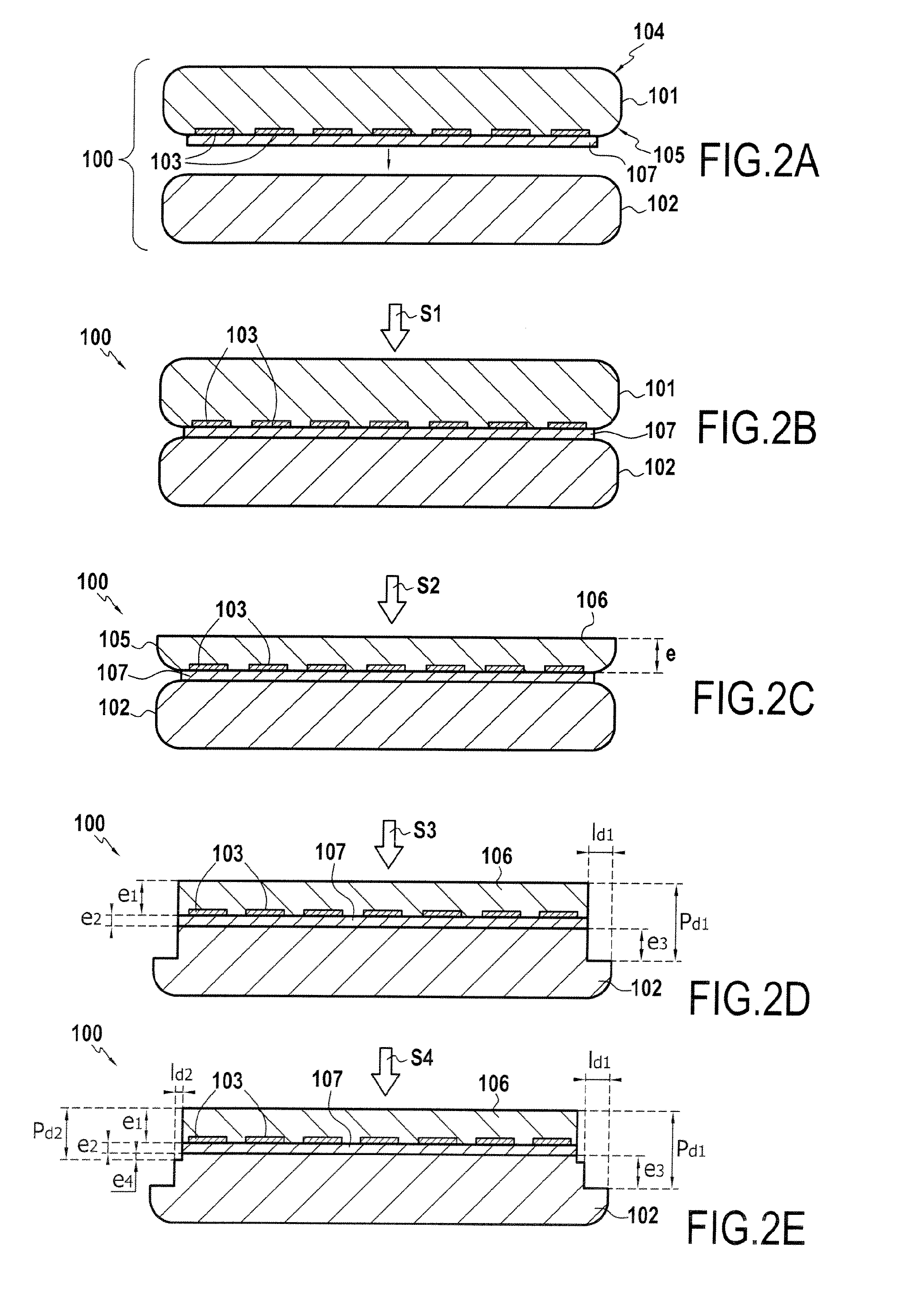

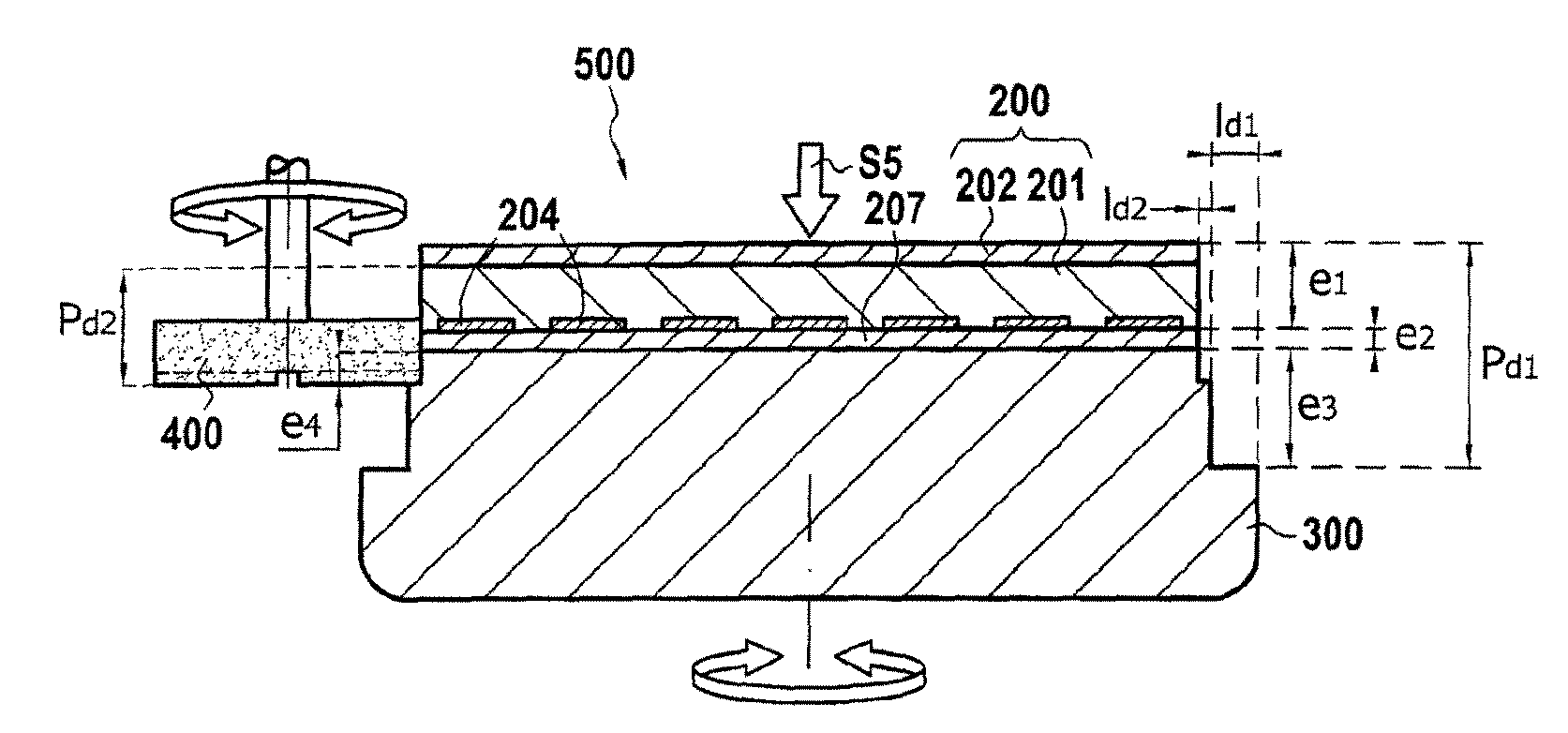

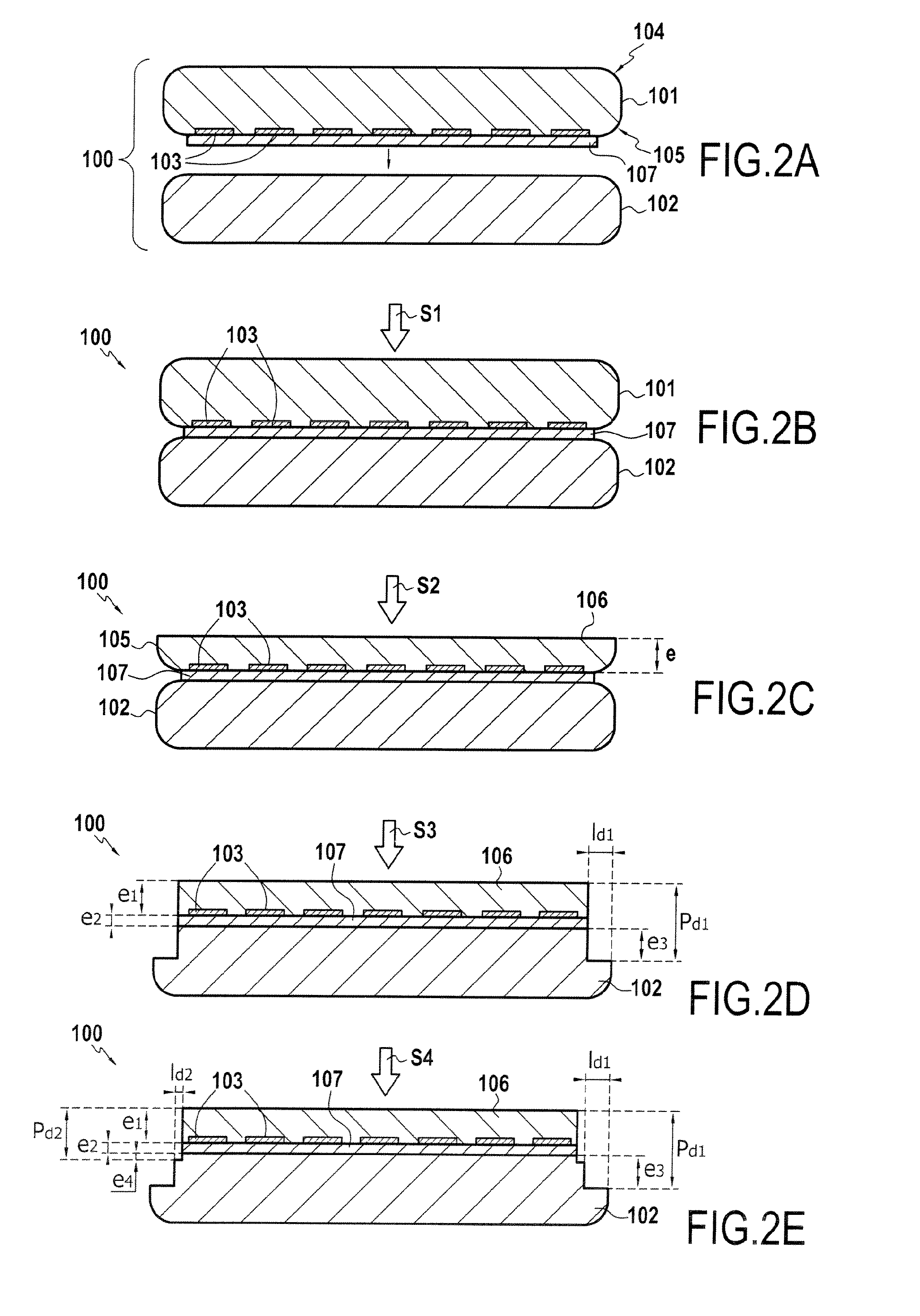

Progressive trimming method

ActiveUS20110097874A1Minimize riskLimit heating and stressSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWafer bonding

The invention provides a method of trimming a structure that includes a first wafer bonded to a second wafer, with the first wafer having a chamfered edge. The method includes a first trimming step carried out over a first depth that includes at least the thickness of the first wafer and over a first width determined from the edge of the first wafer. A second trimming step is then carried out over a second depth that includes at least the thickness of the first wafer and over a second width that is less than the first width.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

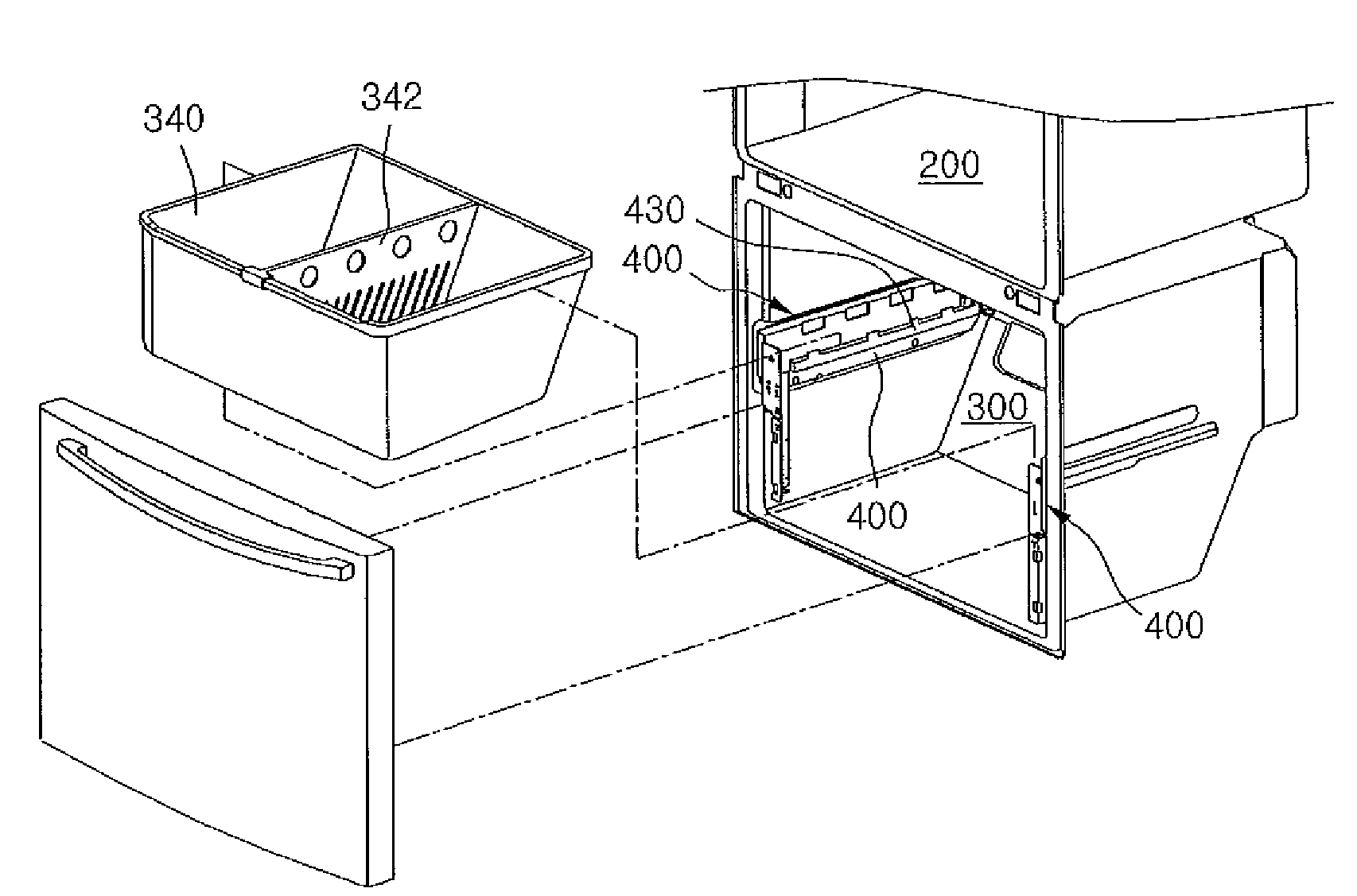

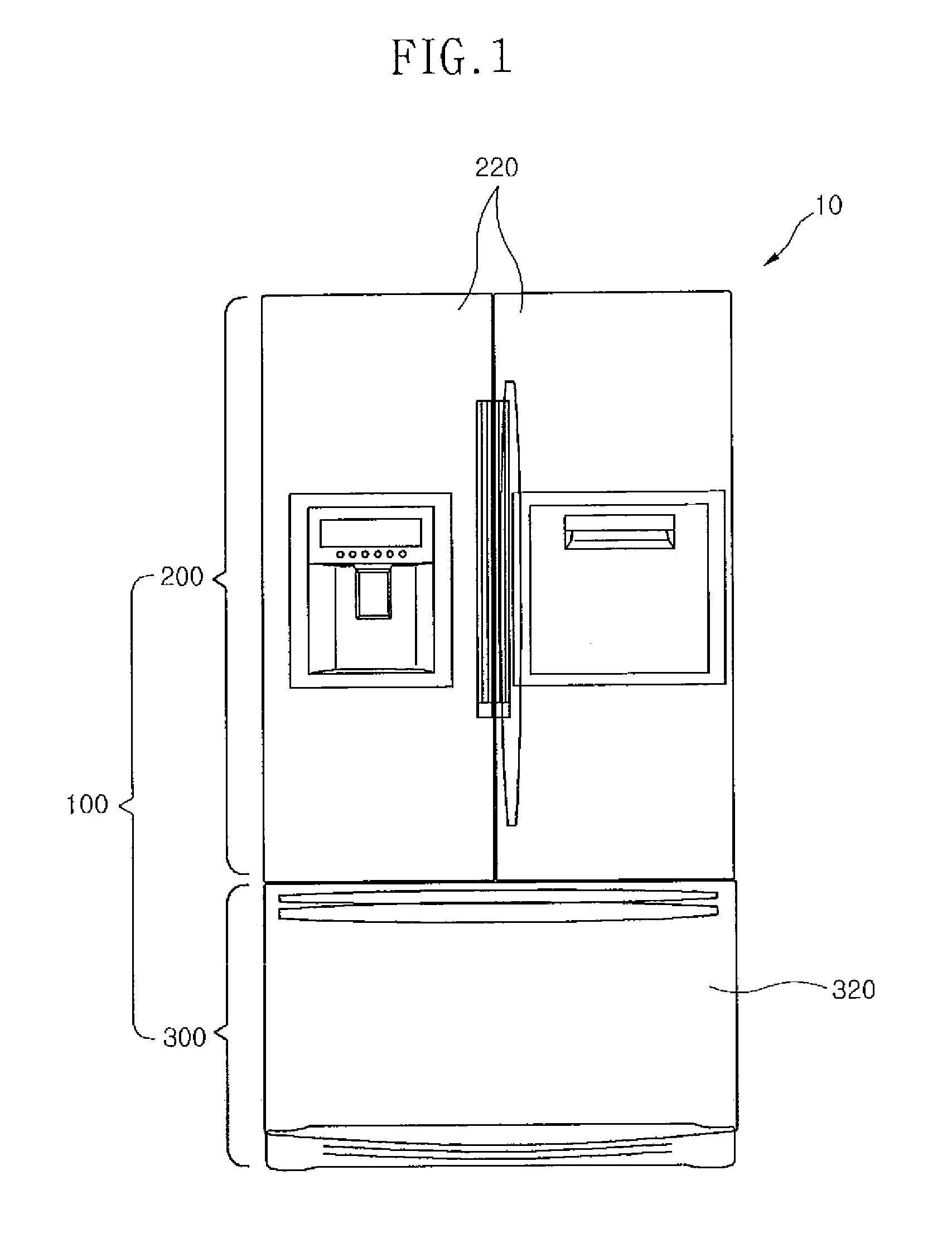

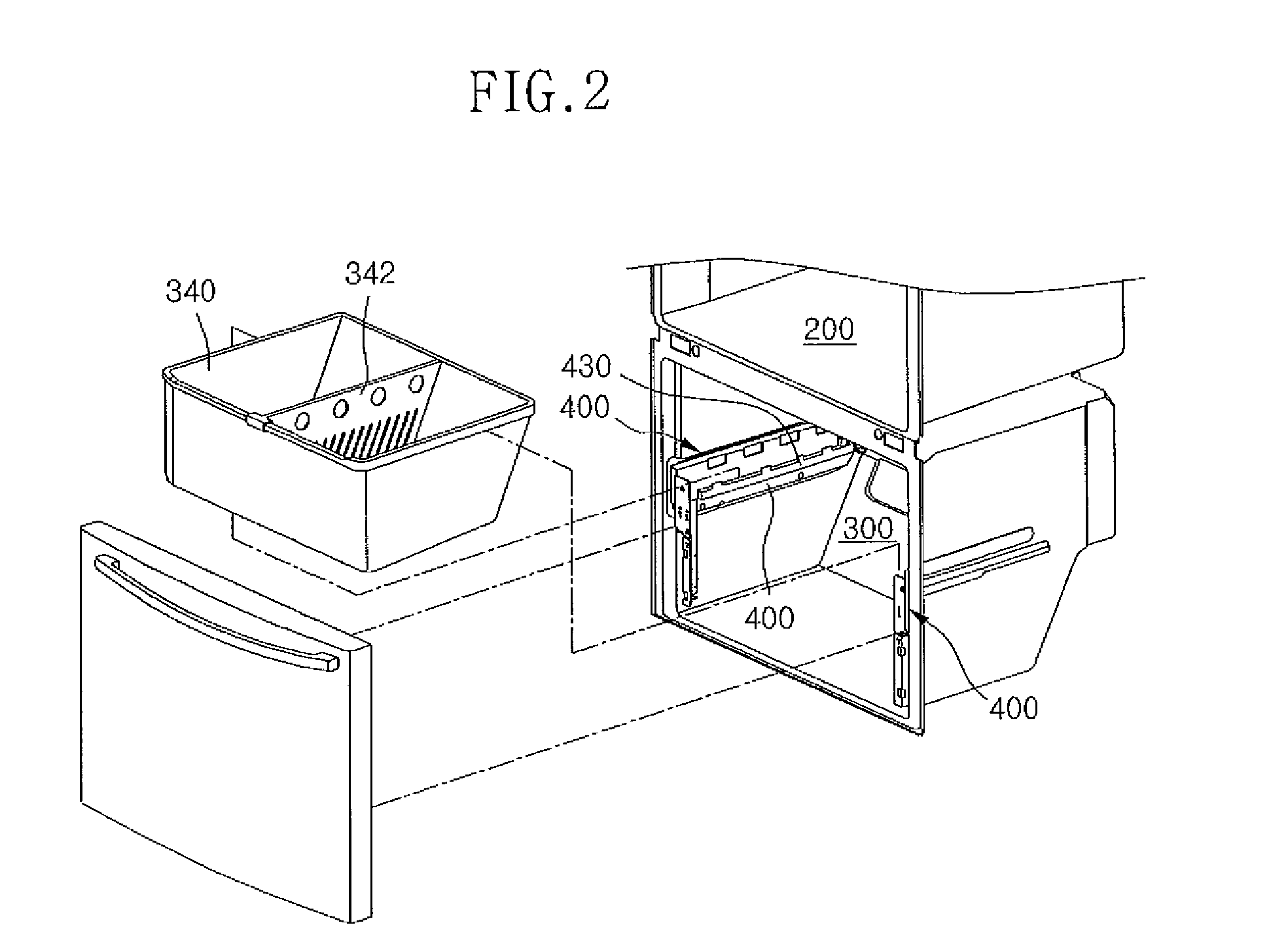

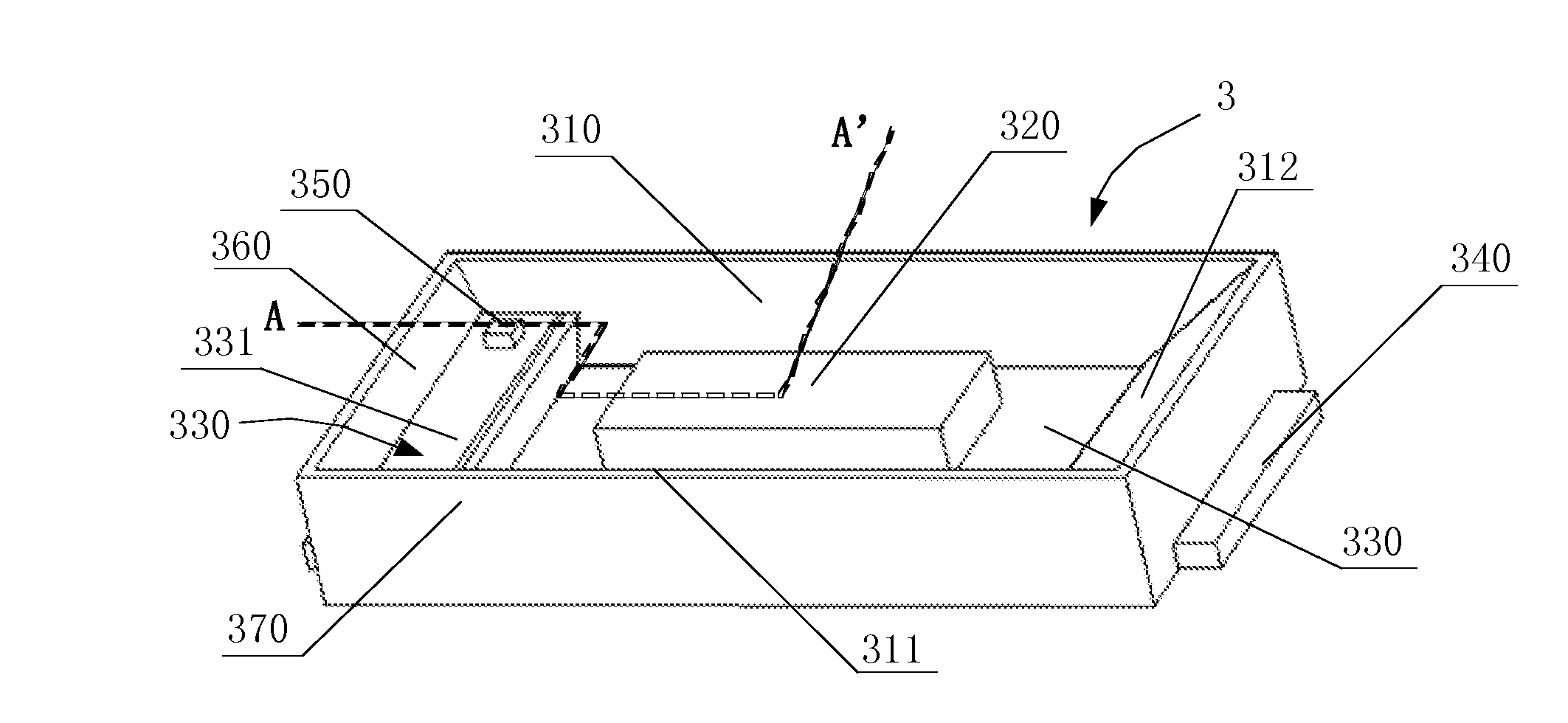

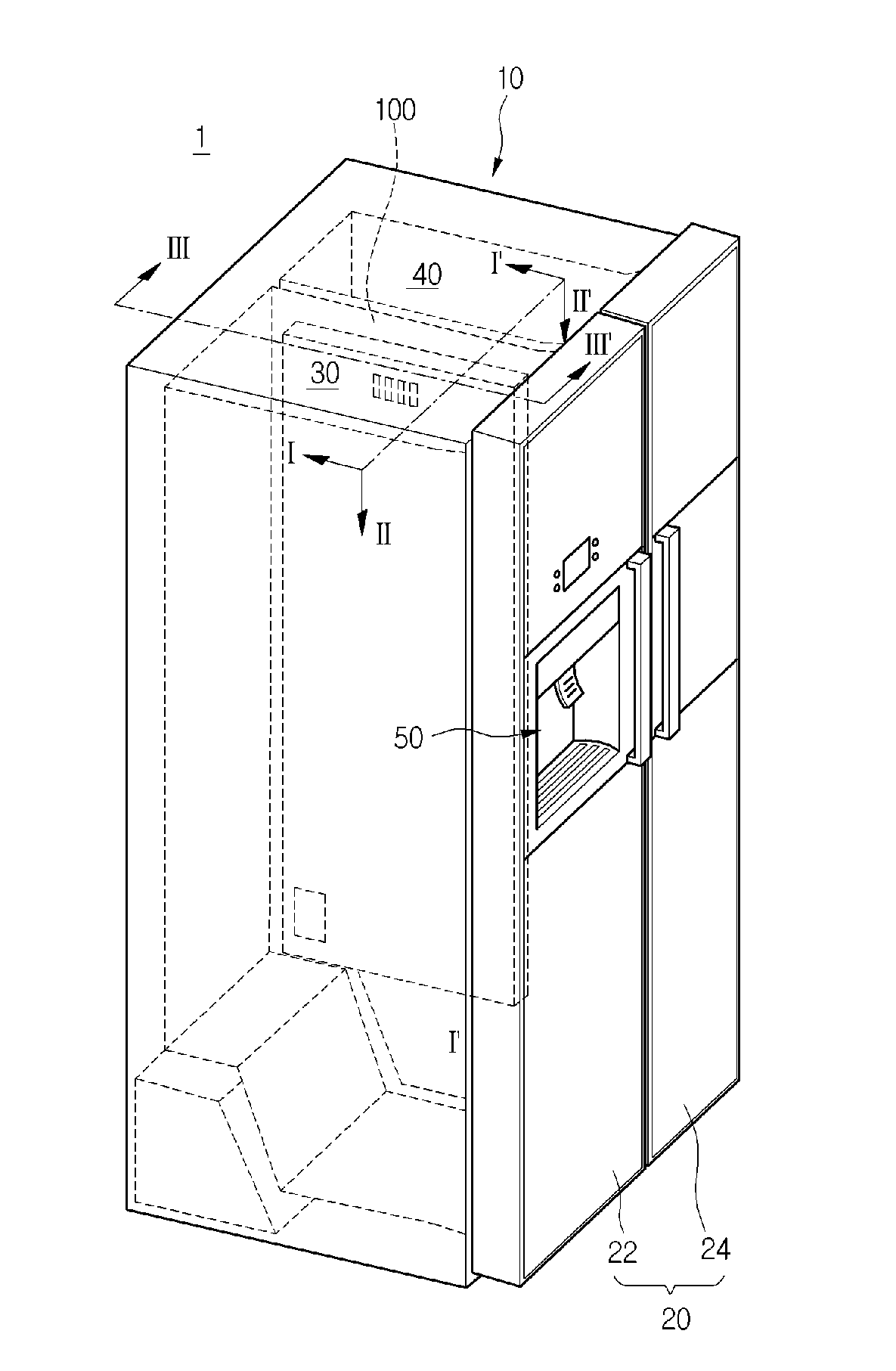

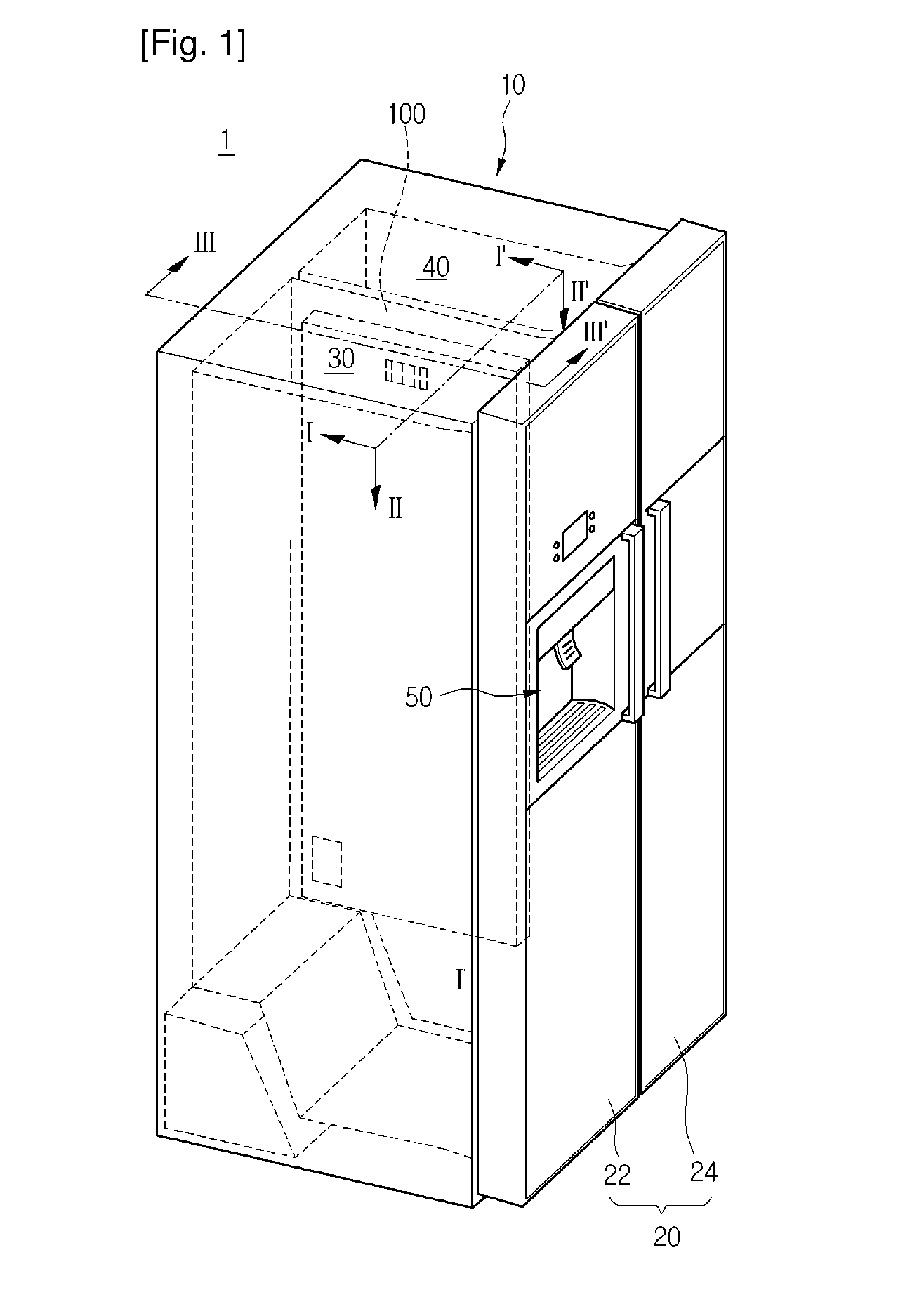

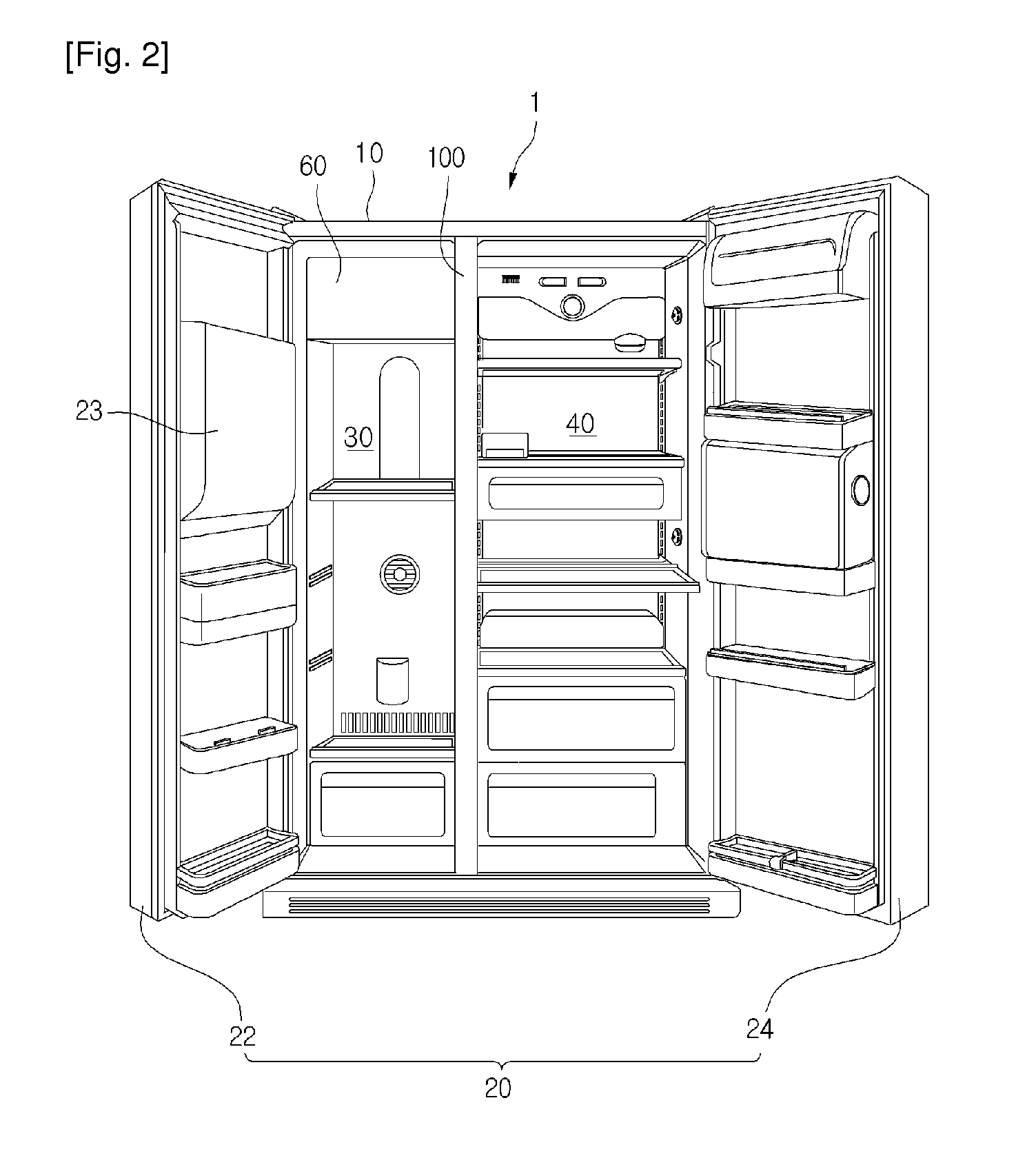

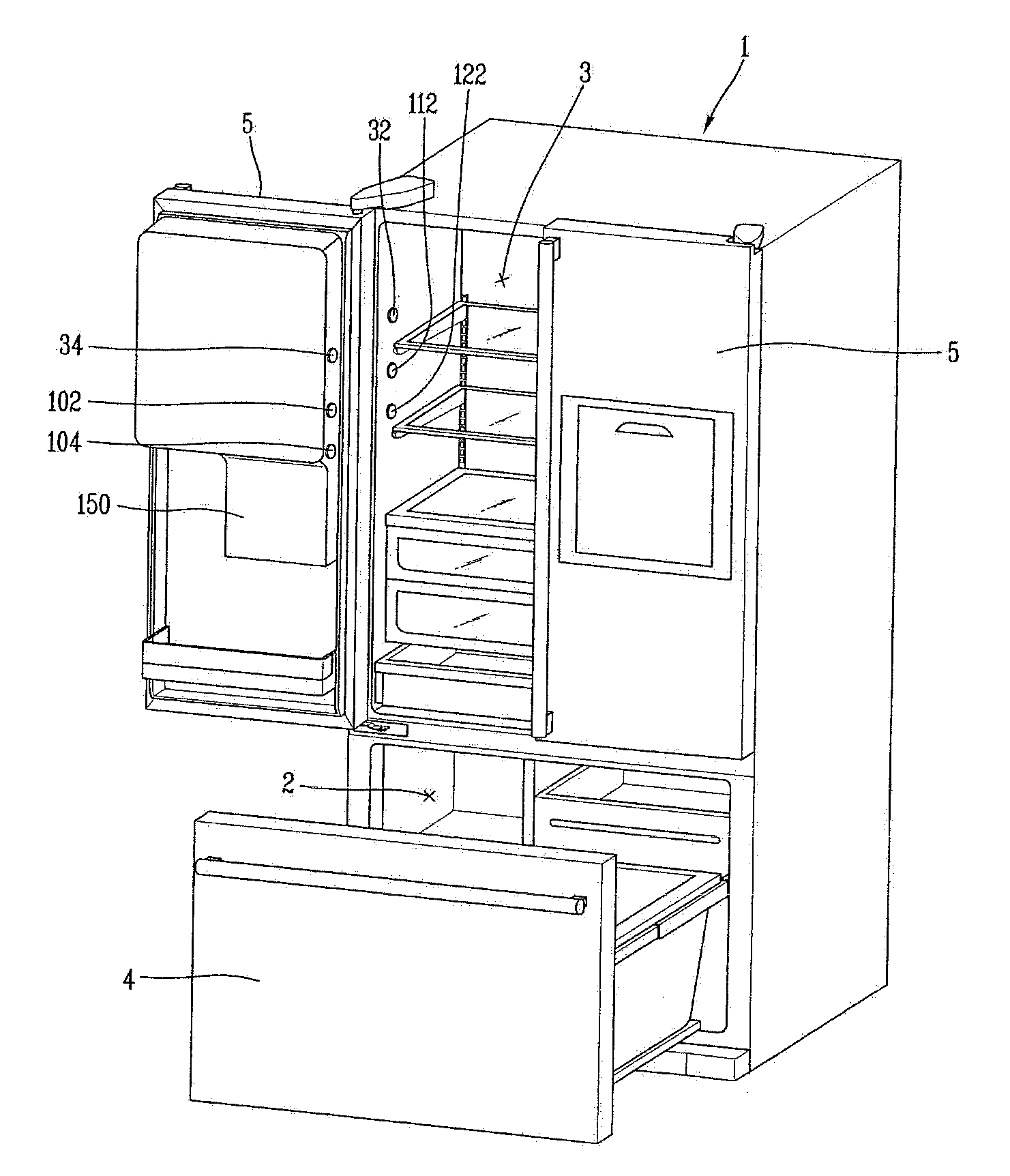

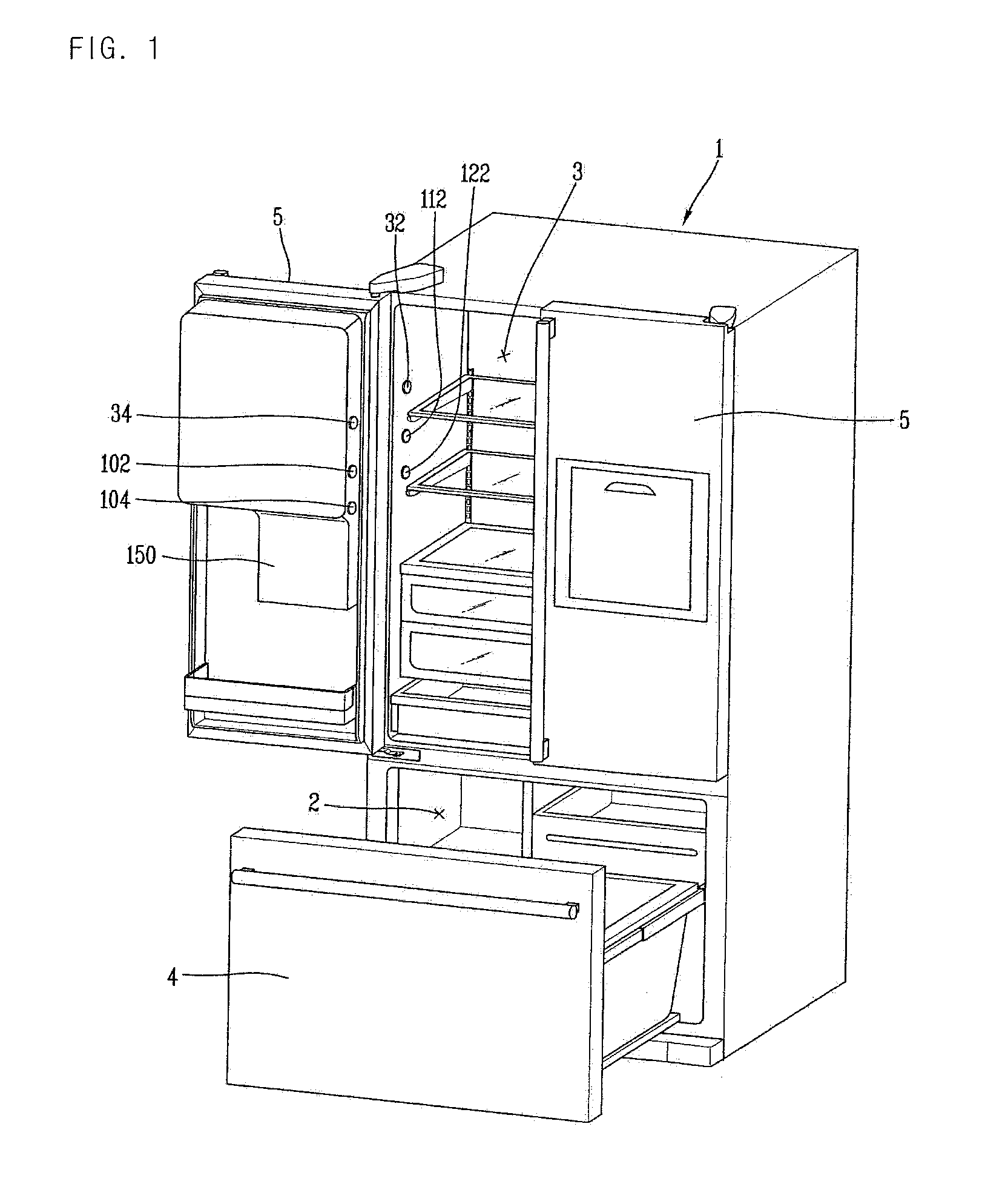

Refrigerator

ActiveUS20090026906A1Improve ease of useImprove reliabilityLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureStructural element

Owner:LG ELECTRONICS INC

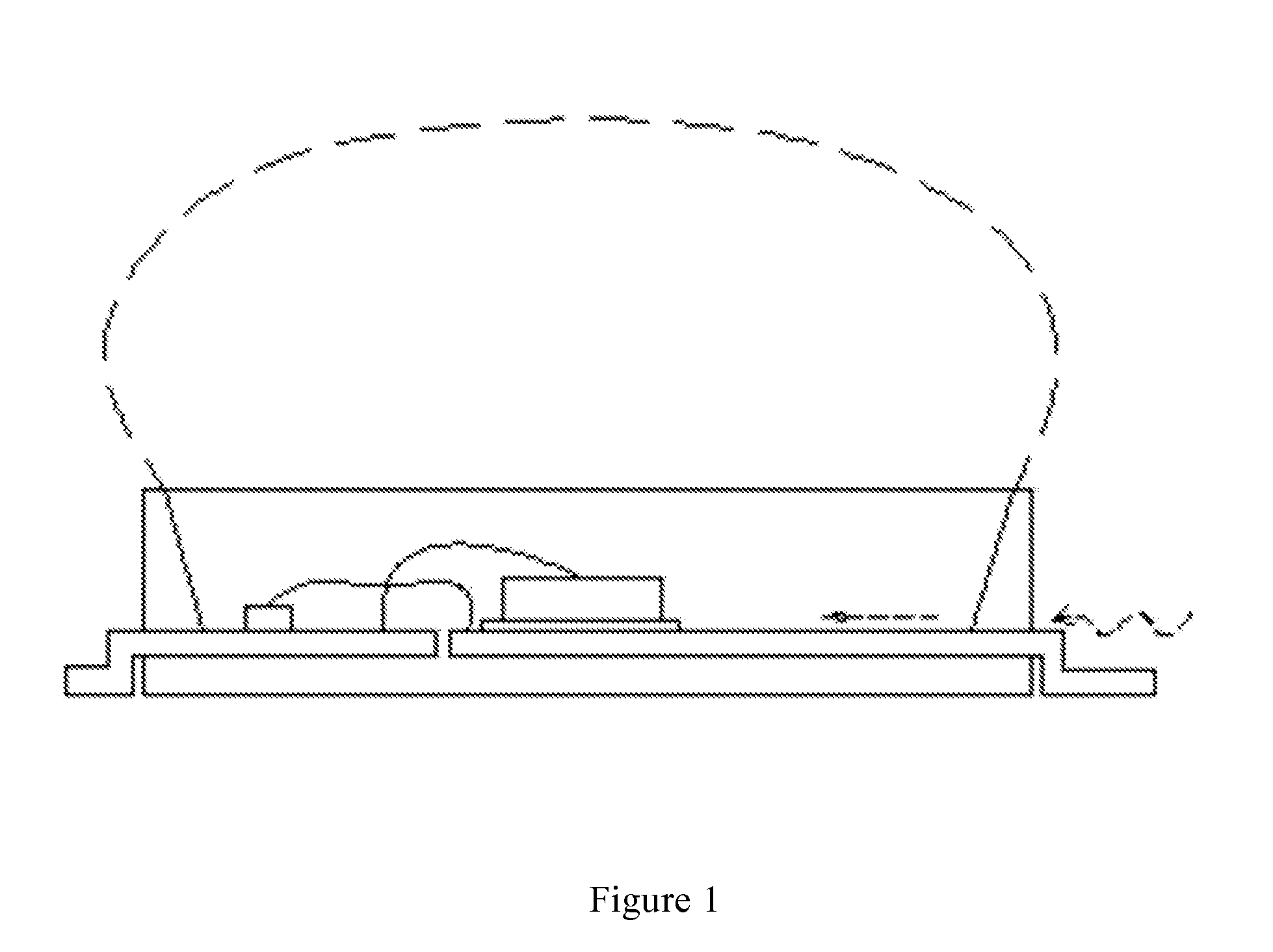

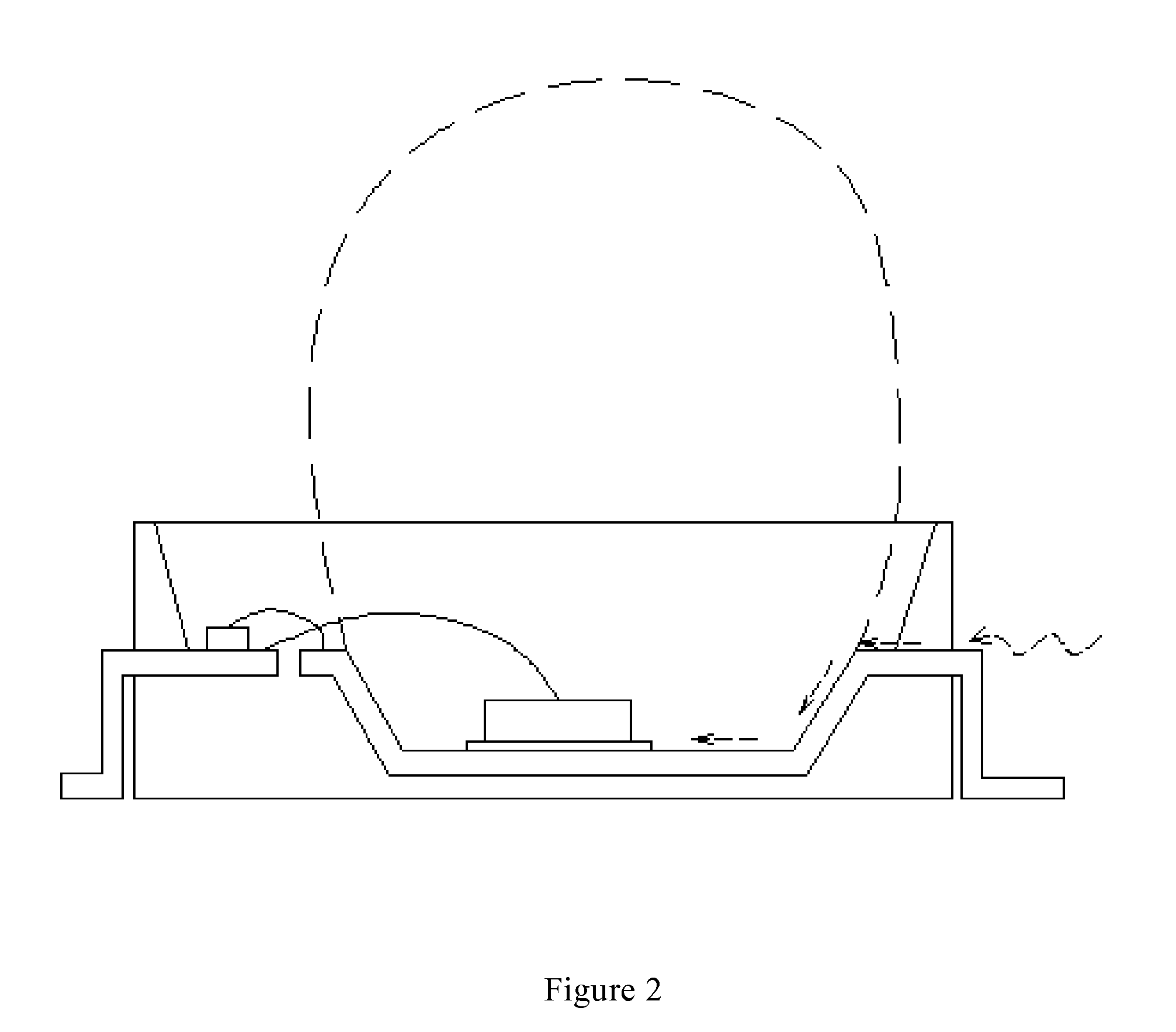

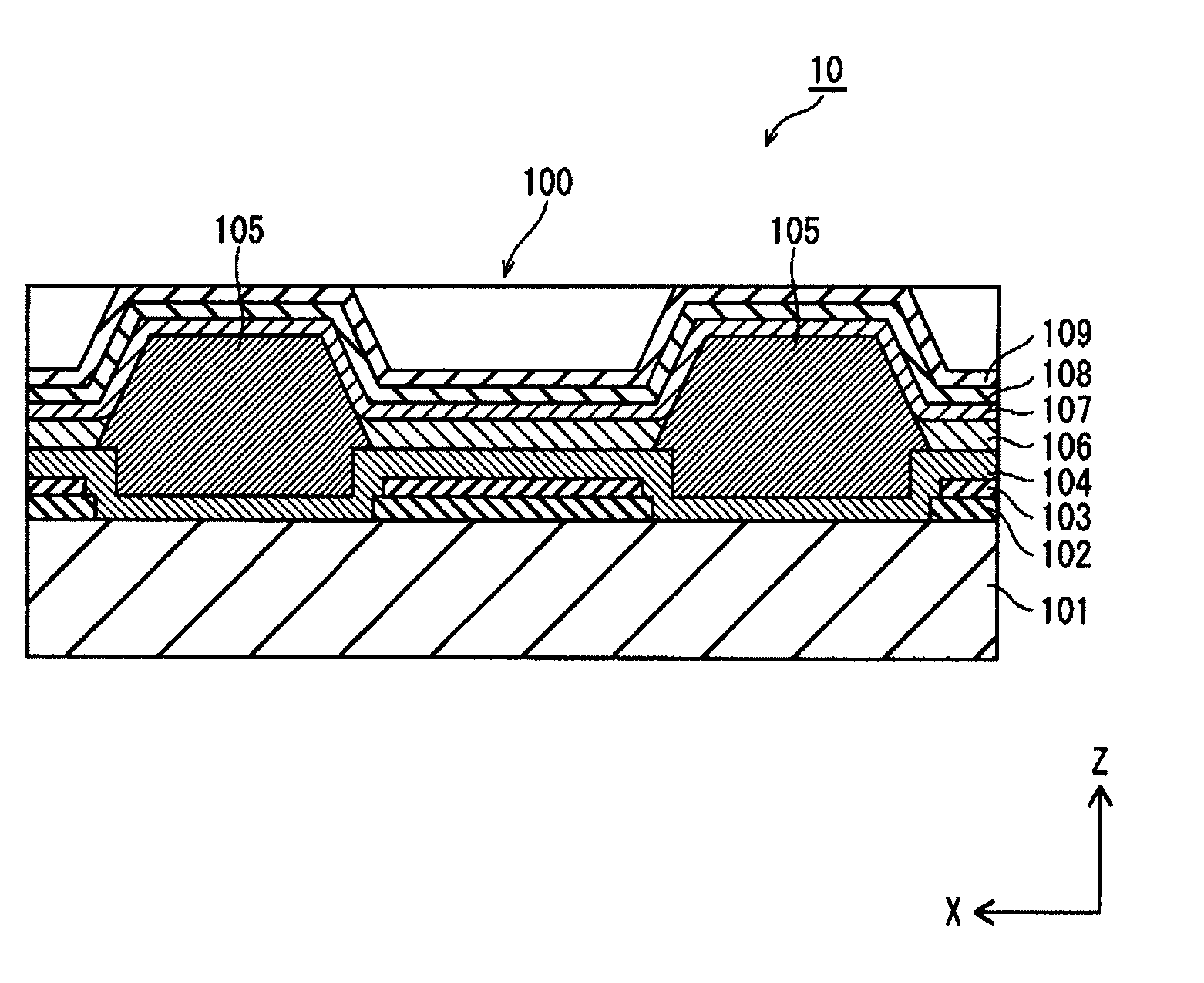

LED, Backlight Module, and LCD Device

InactiveUS20130256704A1Increase contact areaReduce electrode oxidationSolid-state devicesSemiconductor devicesLight guideEngineering

The invention provides a LED, a backlight module, and a LCD device. The LED includes an inner cavity. The bottom of the inner cavity is provided with a chip. Four side walls are arranged around the bottom of the inner cavity. Both ends of the chip are respectively connected with electrodes. Two opposite side walls of the bottom of the inner cavity are provided with at least one convex step surface, and the electrodes at the two ends of the chip are extended to the step surface from the bottom of the inner cavity; the other two side walls adjacent to the step surface are provided with at least one inclined surface which makes an obtuse angle with the bottom of the inner cavity. By selecting the inclination angle of different inclined surfaces, the invention can freely control the scattering range of the emitted light, has strong adaptability, and is suitable for being used as a backlight source of the LCD device. When light enters from the side, the large light emitting angle enables the light to be uniformly emitted into a light guide panel, thereby reducing the phenomenon of hot spots.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

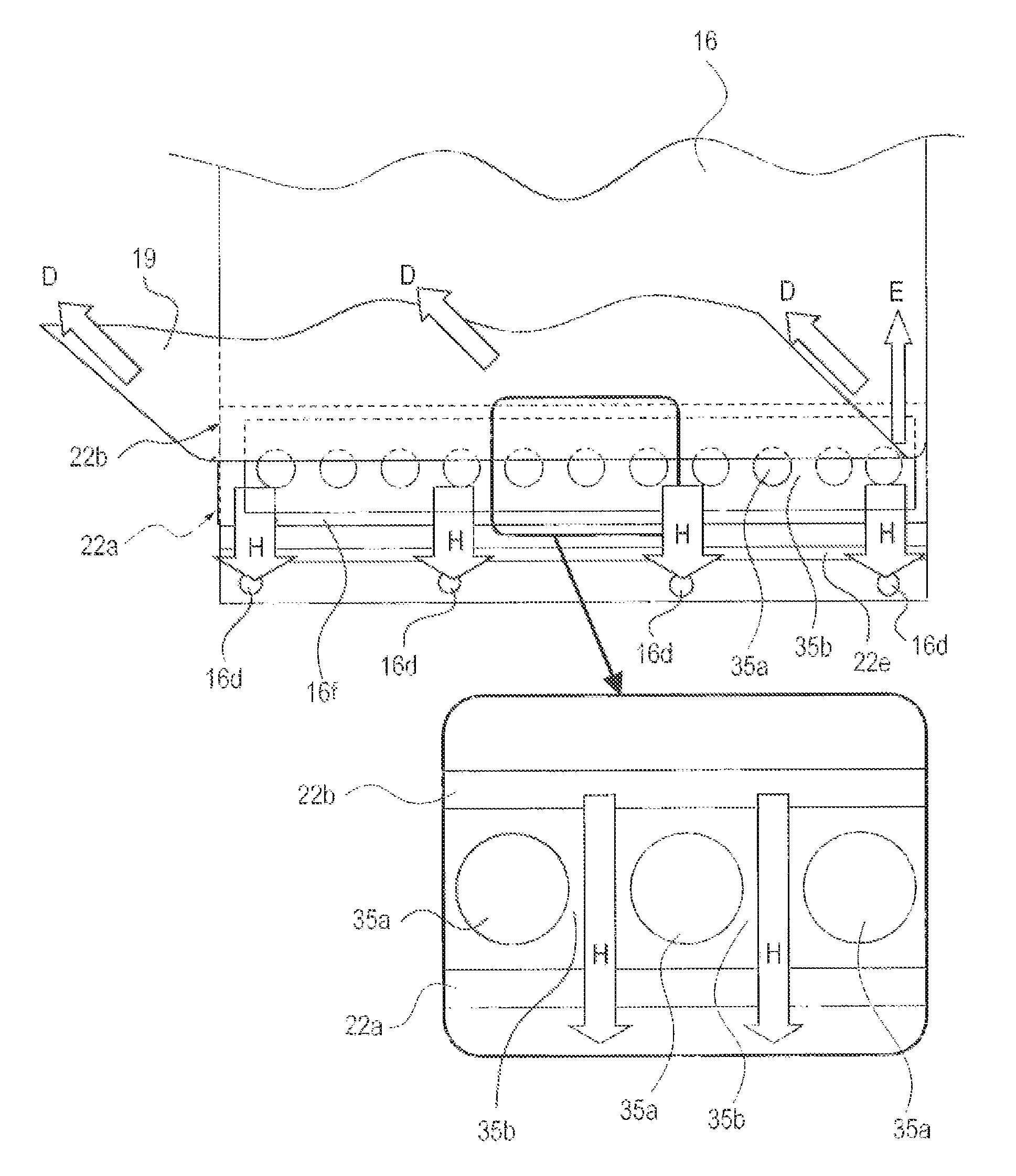

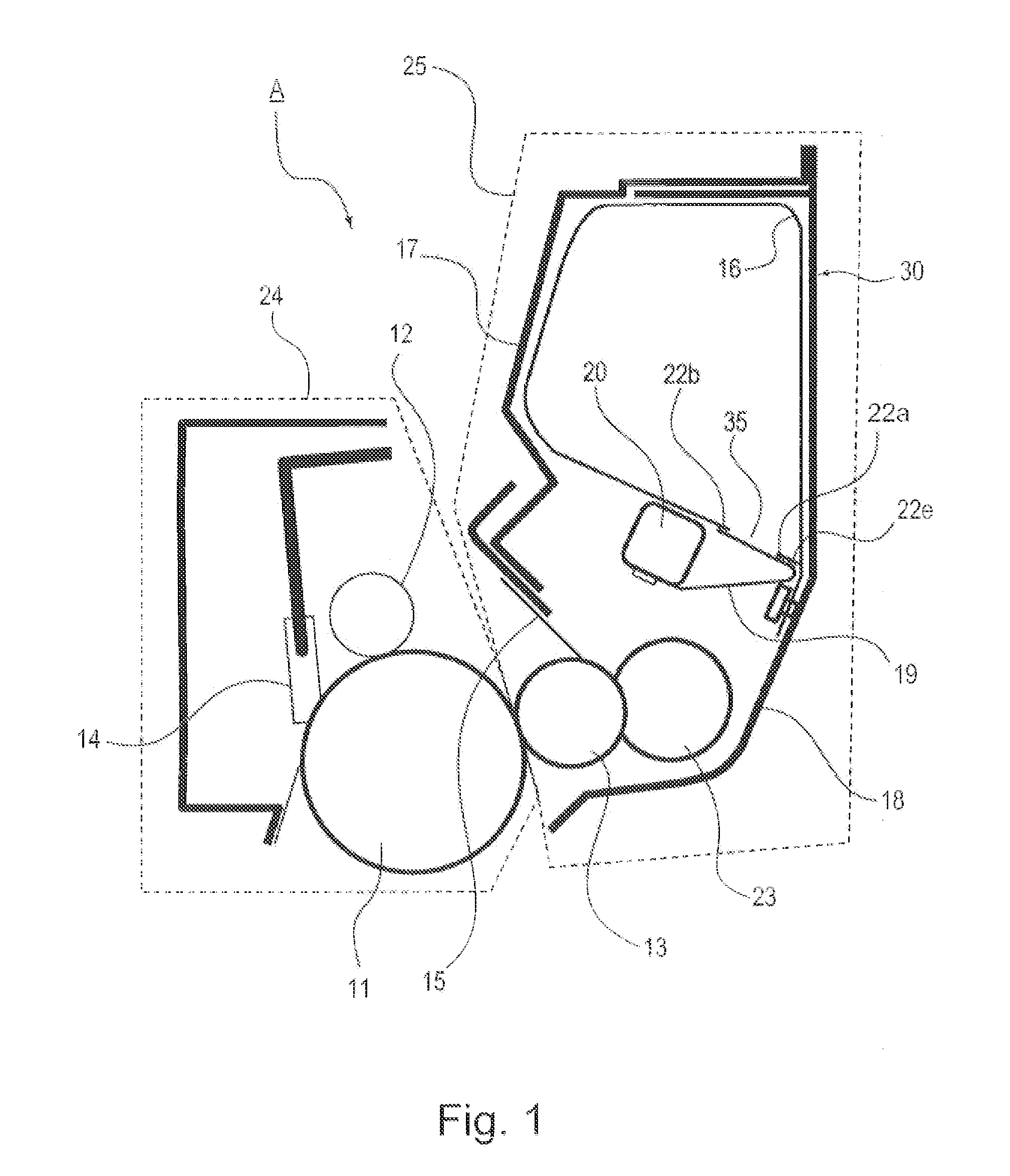

Developer accommodating unit, process cartridge and electrophotographic image forming apparatus

ActiveUS9304440B2Decrease phenomenonElectrographic process apparatusEngineeringMechanical engineering

A developer accommodating unit includes: a flexible container including an opening for permitting discharge of a developer; a sealing member for forming a bonding portion between itself and the flexible container; an unsealing member; and an accommodating container. The bonding portion includes a first bonding portion extending in a longitudinal direction of the sealing member at a periphery of the opening in an upstream side of a peeling direction of the sealing member, a second bonding portion extending in the longitudinal direction at the periphery of the opening in a downstream side of the peeling direction, and a third bonding portion bonded upstream of the first bonding portion with respect to the peeling direction. When the sealing member exposes the opening, the bonding portion is peeled in the order of the third bonding portion, the first bonding portion and the second bonding portion.

Owner:CANON KK

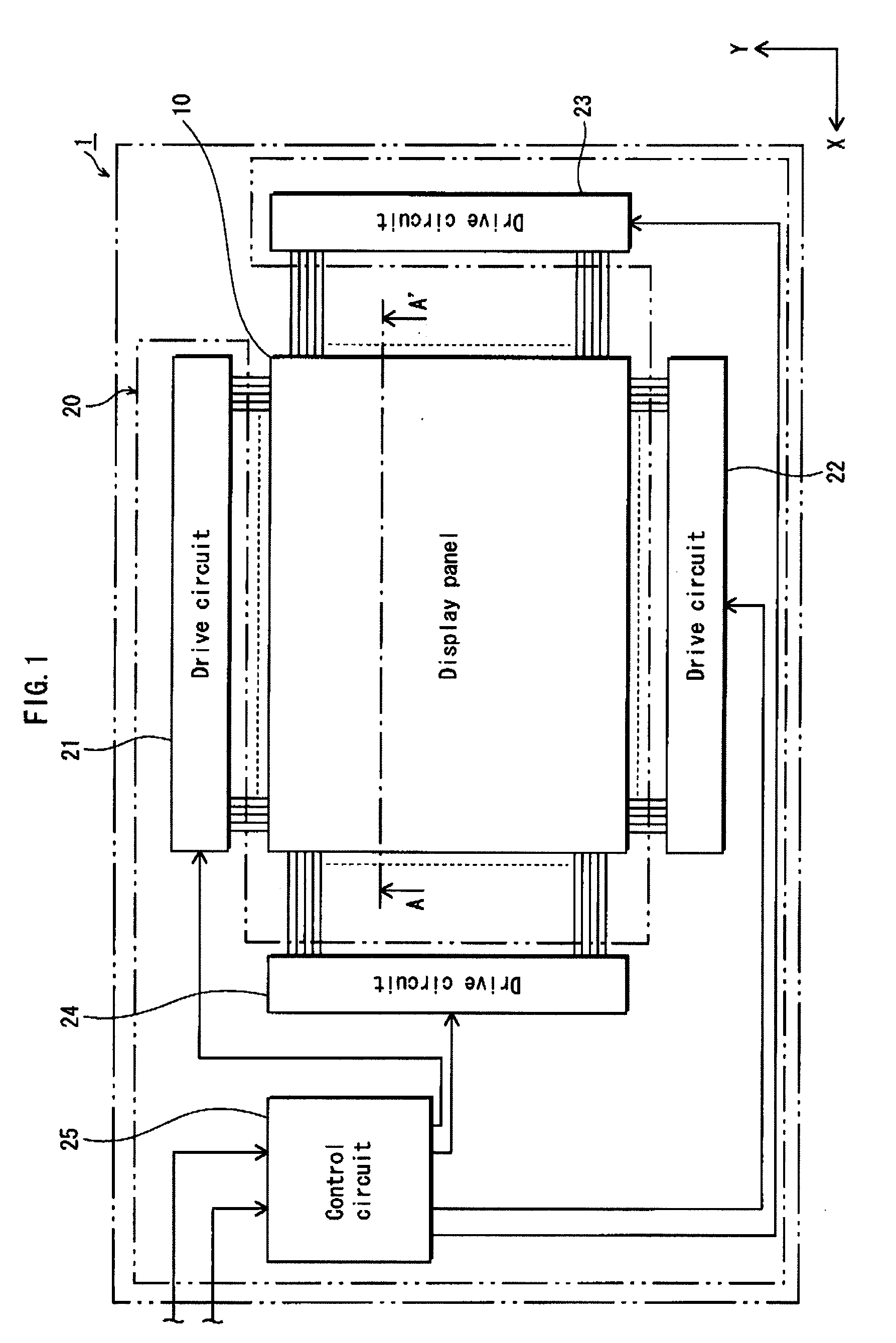

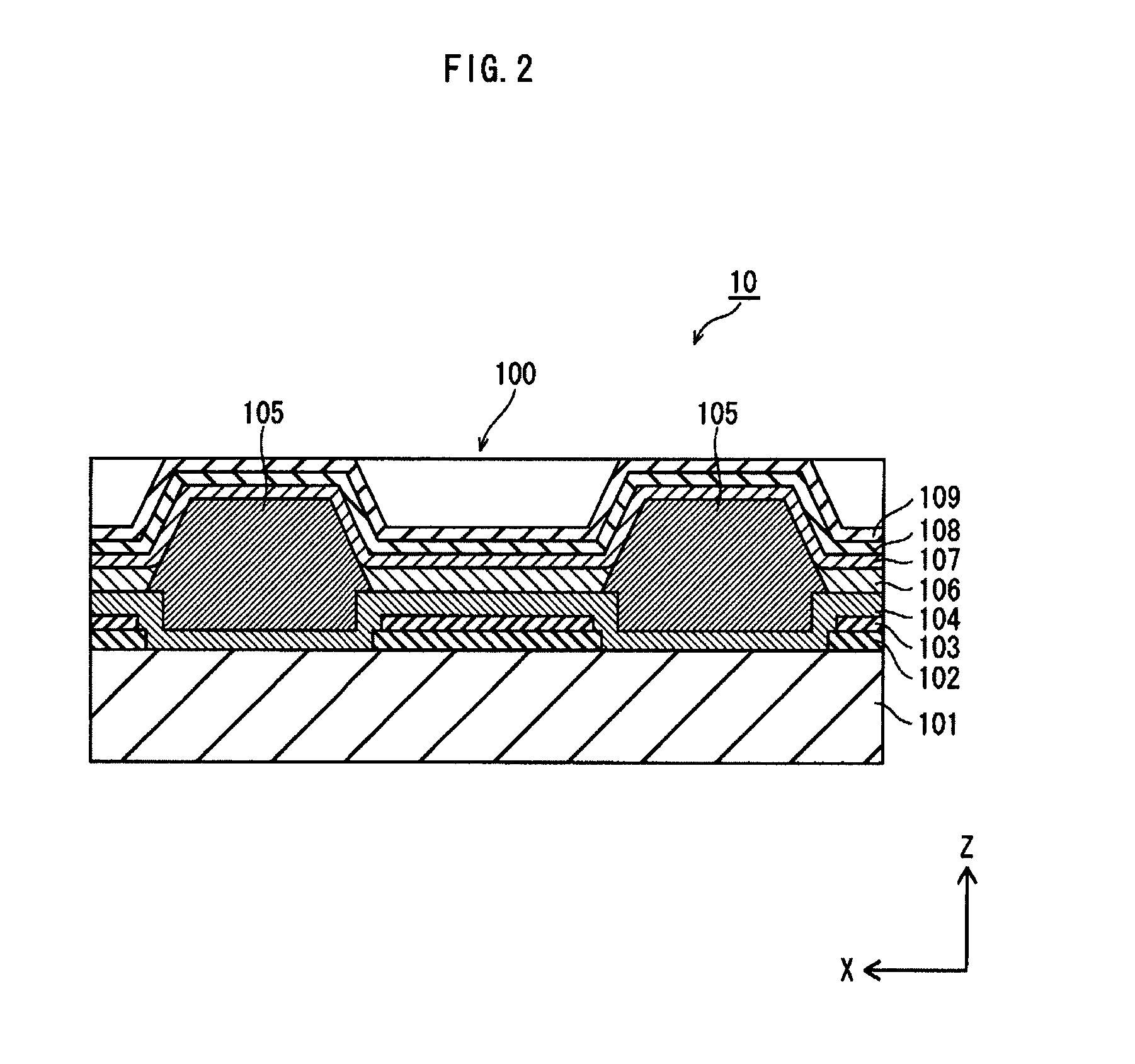

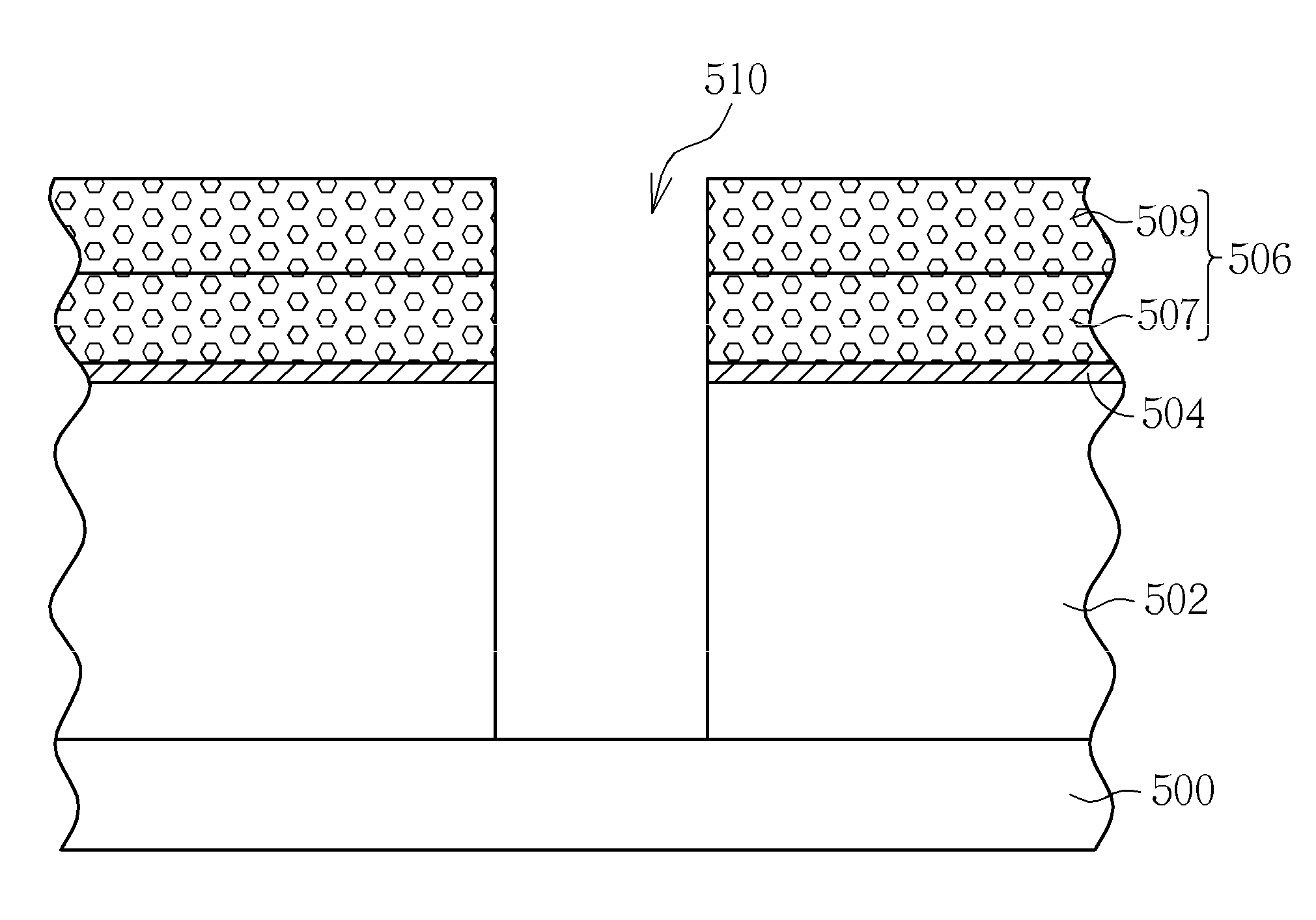

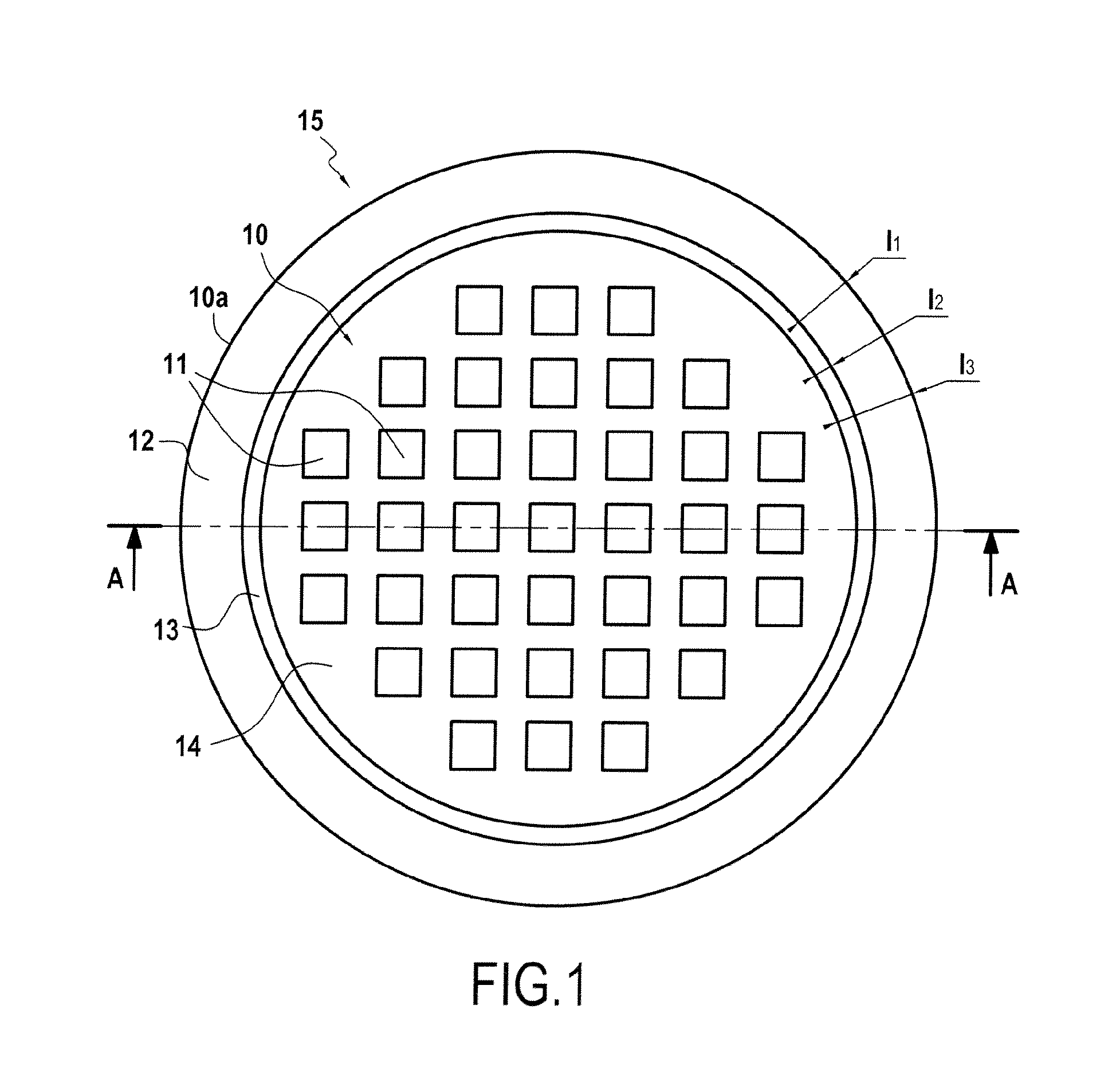

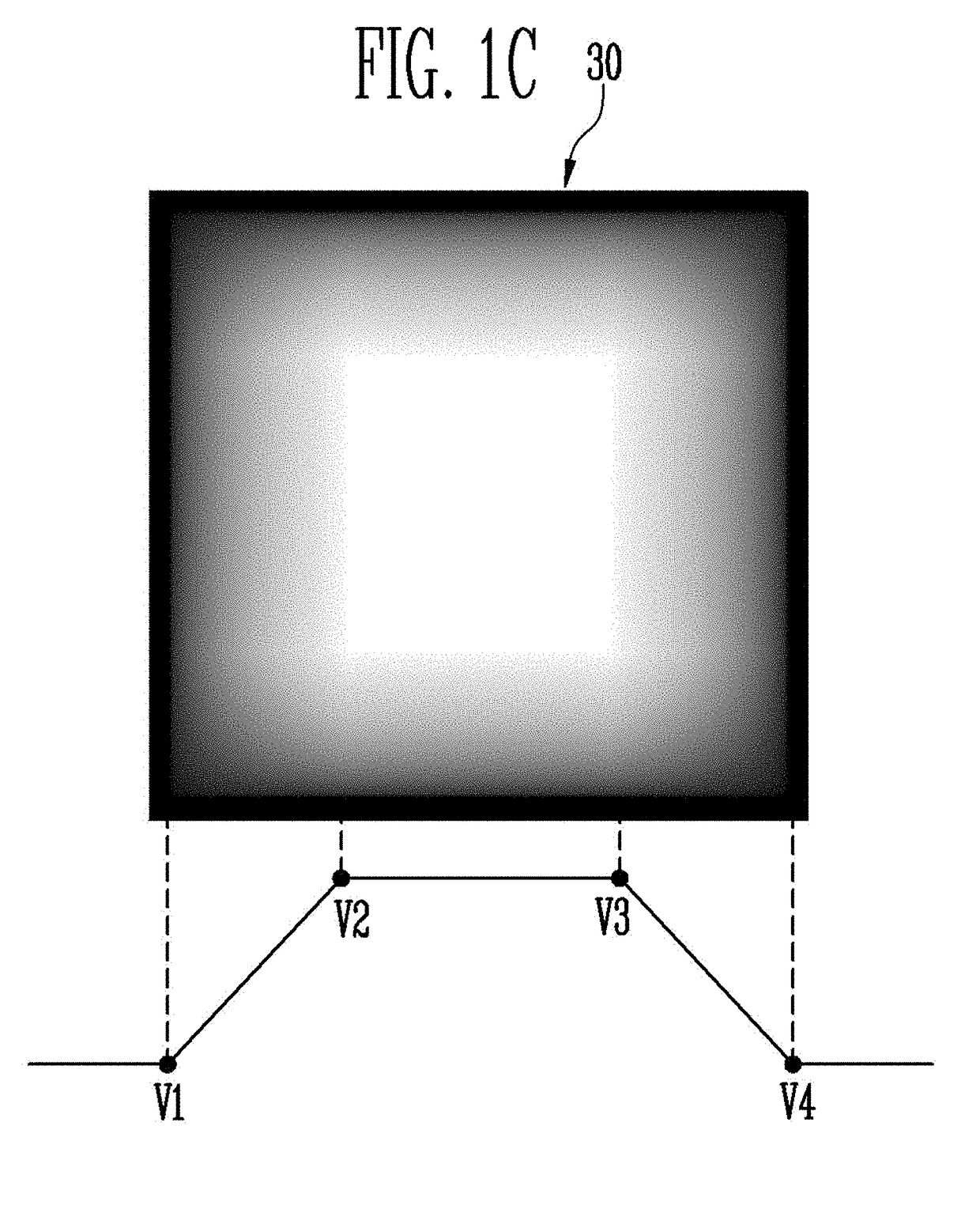

Display device and manufacturing method thereof

ActiveUS20110198623A1Uniform film thicknessNo luminance unevennessElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

A display device includes an array of light emitting cells. Banks define each of the light emitting cells. The light emitting cells include a first light emitting cell that is located in a central region of the array and a second light emitting cell that is located in a peripheral region of the array. First and third banks border the first light emitting cell with the first bank being closer to a periphery of the array than the second bank. Second and fourth banks border the second light emitting cell with the third bank being closer to the periphery of the array than the fourth bank. An inclination angle of an innermost sidewall of the third bank that is adjacent the second light emitting cell is different than an inclination angle of an innermost sidewall of the first bank that is adjacent the first light emitting cell.

Owner:JOLED INC

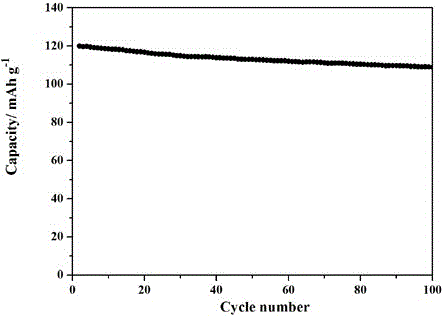

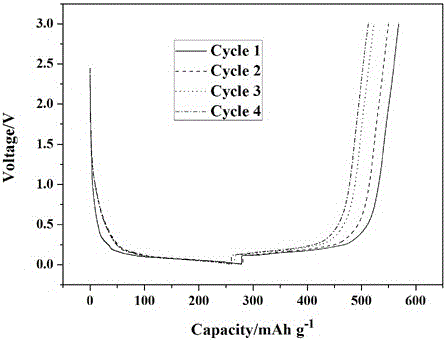

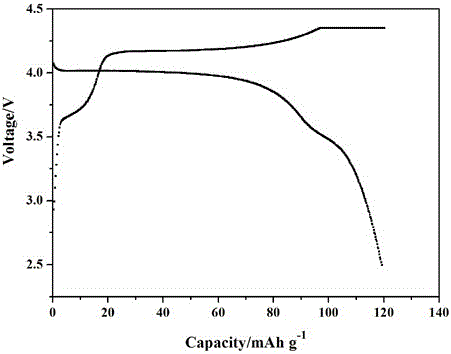

Lithium battery electrode preparation method including polymer material with stable interface and application of lithium battery electrode in solid lithium battery

ActiveCN105702919AImprove discharge capacityReduce discharge capacityCell electrodesLi-accumulatorsSolid state electrolyteDecomposition

The invention discloses a lithium battery electrode preparation method including polymer material with a stable interface and the application of a lithium battery electrode in a solid lithium battery. The preparation method is characterized in that the polymer material with the stable interface is poly-vinylene carbonate (PVCA) or copolymers thereof. The free radical triggers the monomer to perform mass polymerization to obtain a polymer, the polymer material with the stable interface can form a cover film on the surface of the electrode, thus destruction on the electrode material and decomposition of the solid electrolyte on the surfaces of the positive and negative electrodes can be effectively restrained. Meanwhile, the polymer material can form a stable protection layer on the surface of lithium metal to inhibit the growth of the lithium dendrites, thus the cycle performance of the solid lithium battery is improved. The invention also provides a preparation method of the electrochemical stable polymer material, and the solid lithium battery assembled by using the polymer material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

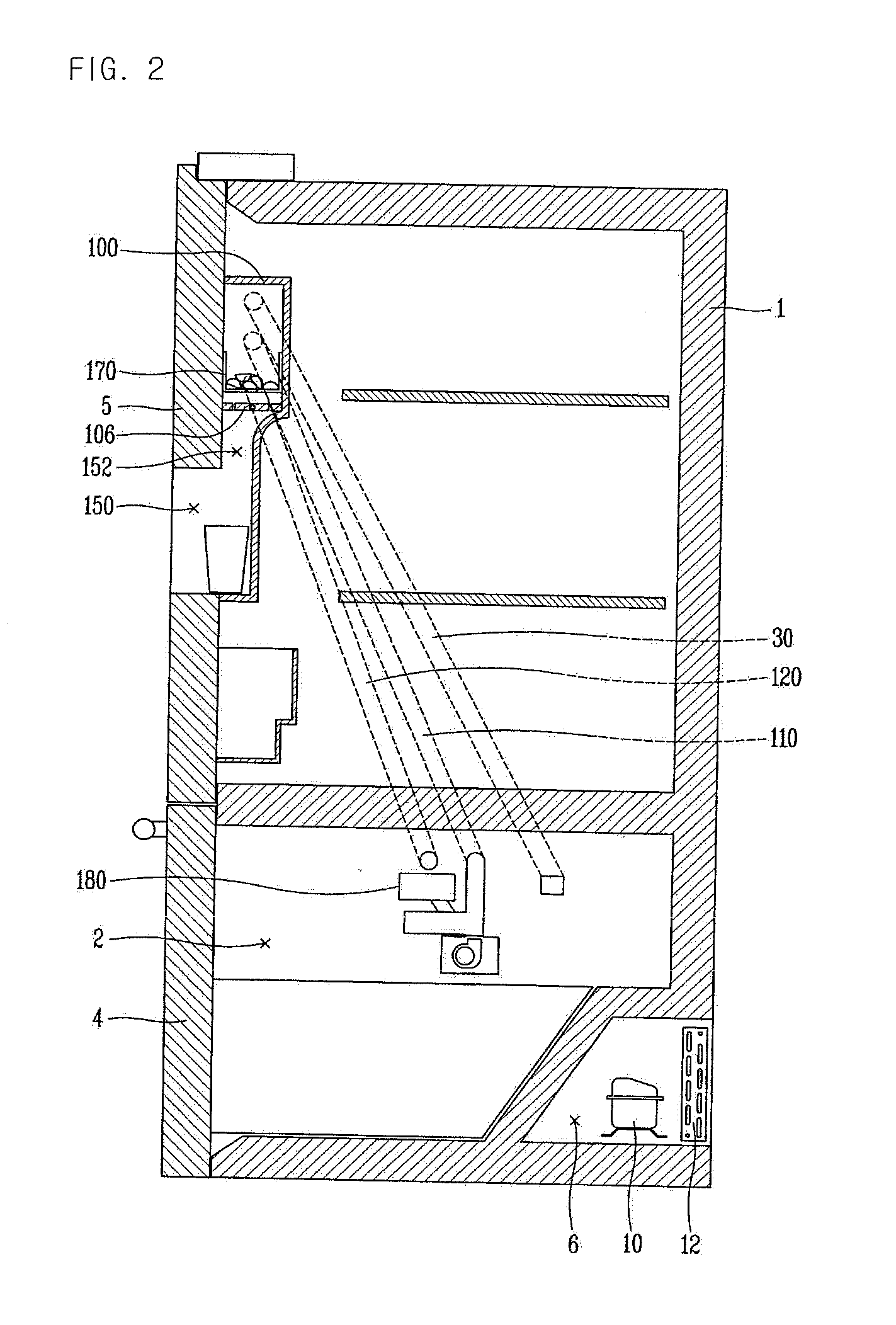

Refrigerator and control method thereof

InactiveUS20120272670A1Thin thicknessAvoid thickness thinningLighting and heating apparatusCooling fluid circulationCold airEngineering

A refrigerator includes a cabinet having a storage space; a barrier to divide the storage space into a freezing compartment and a refrigerating compartment, filled with a heat insulator, and having a depression part formed on one side surface thereof; an evaporator accommodated in a part of the depression part; a blowing unit accommodated in another part of the depression part corresponding to a upper side of the evaporator; a barrier cover to shield the depression part by covering one side surface of the barrier. The depression part includes an evaporator accommodating part to accommodate the evaporator, a blowing unit accommodating part configured to accommodate the blowing unit, and a cold air passage extended from the blowing unit accommodating part to allow the cold air to be guided into the freezing compartment and to refrigerating compartment. The blowing unit accommodating part is depressed greater than the evaporator accommodating part.

Owner:LG ELECTRONICS INC

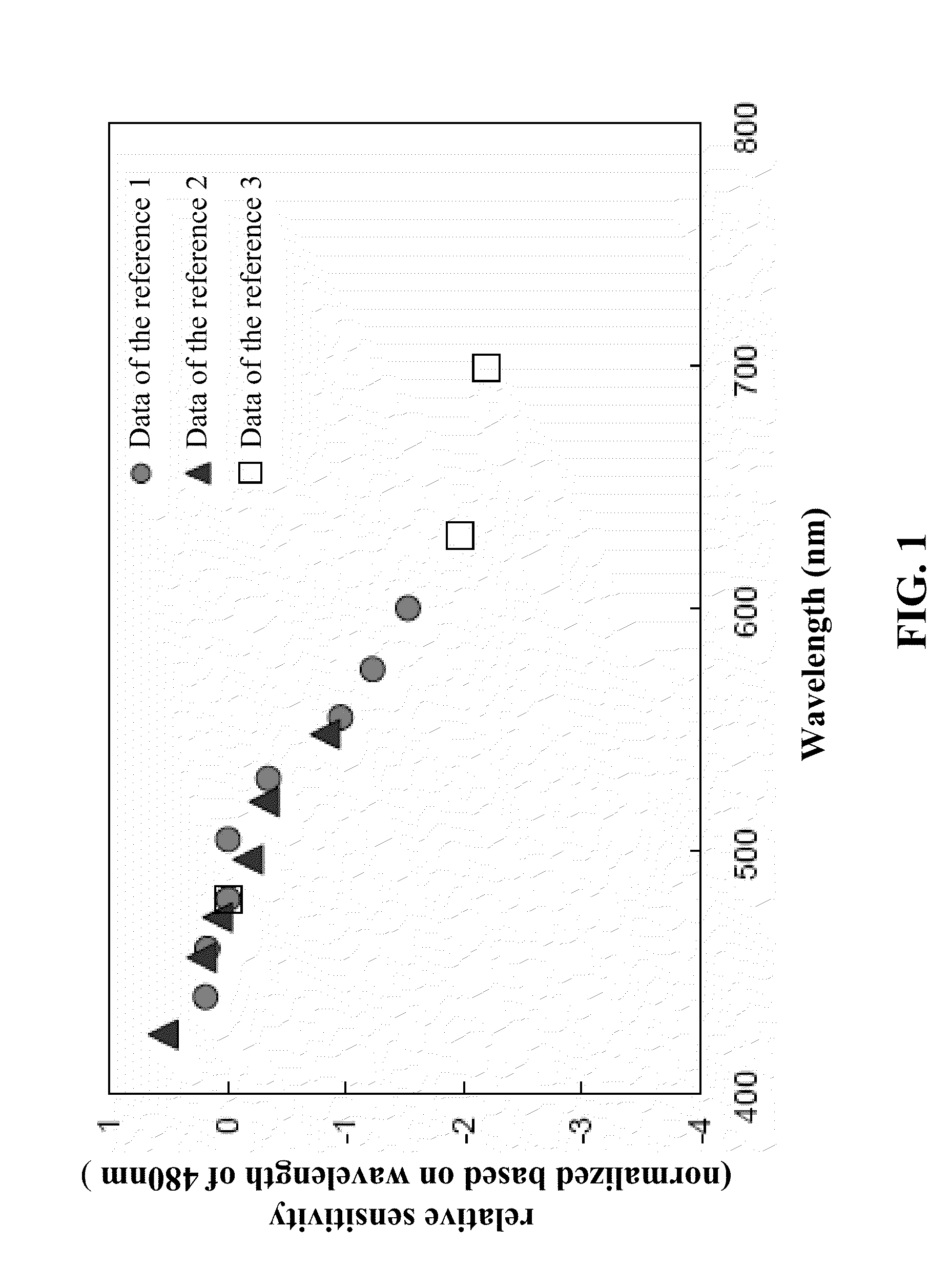

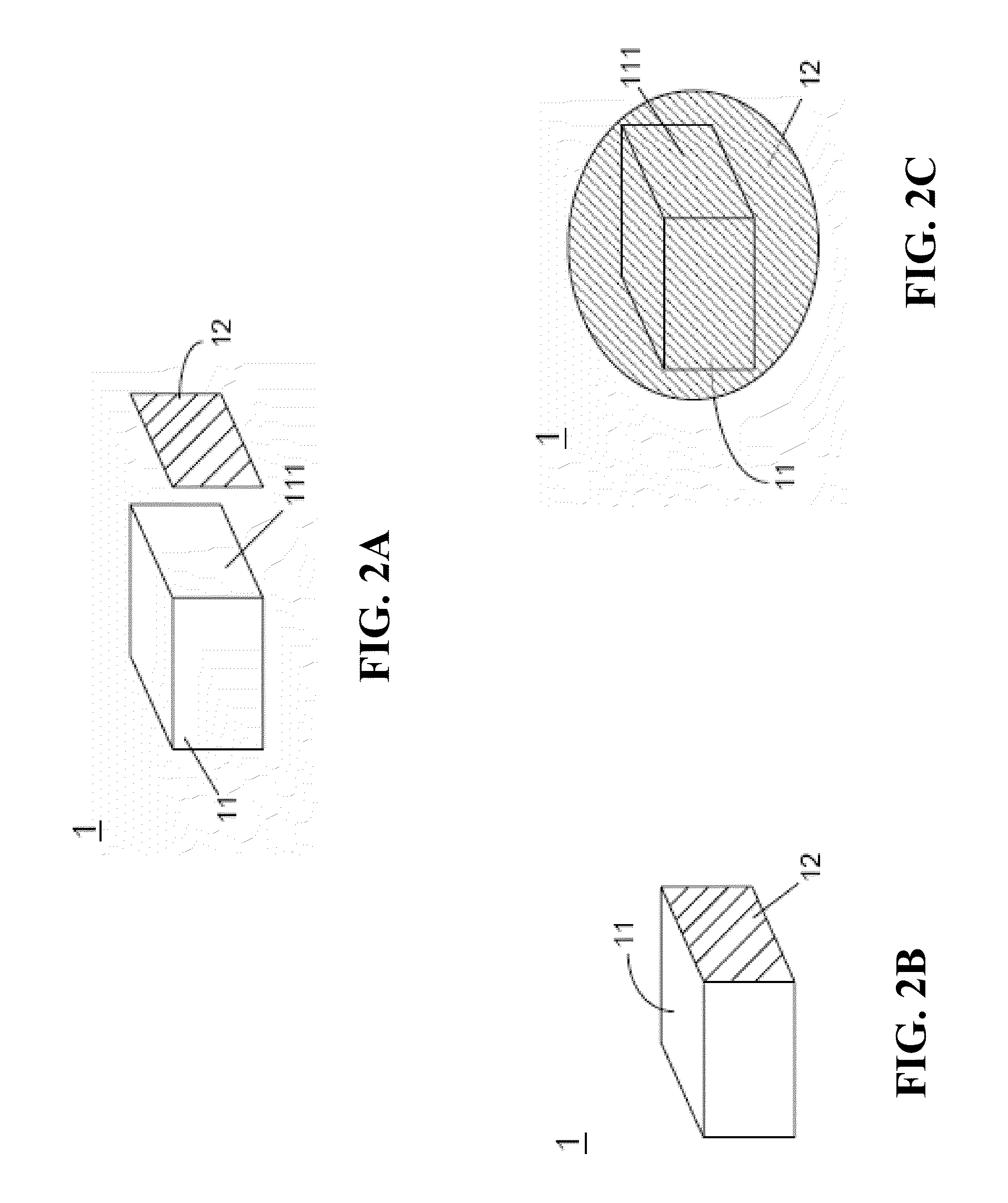

Lighting Device Capable of Reducing the Phenomenon of Melatonin Suppression

InactiveUS20120008326A1Reduces melatonin suppressionReduce phenomenonLight therapySpectral modifiersEngineeringLight filter

According to research, it found that blue light may cause significant effects on suppressing melatonin. For this reason, a lighting device capable of reducing the phenomenon of melatonin suppression is disclosed in the present invention, the lighting device comprises: a light-emitting device being able to emit a visible light; and a light-filtering device being close to the light-emitting device, wherein when the light-emitting device emits the visible light, the light-filtering device is able to filter a blue light component of the visible light, so as to reduce the blue light component within the visible light emitted by the light-emitting device, then the effects on suppressing the melatonin caused by the visible light are reduced.

Owner:NATIONAL TSING HUA UNIVERSITY

Developer accommodating unit, process cartridge and electrophotographic image forming apparatus

ActiveUS20140072330A1Decrease phenomenonElectrographic process apparatusEngineeringImaging equipment

A developer accommodating unit includes: a flexible container including an opening for permitting discharge of a developer; a sealing member for forming a bonding portion between itself and the flexible container; an unsealing member; and an accommodating container. The bonding portion includes a first bonding portion extending in a longitudinal direction of the sealing member at a periphery of the opening in an upstream side of a peeling direction of the sealing member, a second bonding portion extending in the longitudinal direction at the periphery of the opening in a downstream side of the peeling direction, and a third bonding portion bonded upstream of the first bonding portion with respect to the peeling direction. When the sealing member exposes the opening, the bonding portion is peeled in the order of the third bonding portion, the first bonding portion and the second bonding portion.

Owner:CANON KK

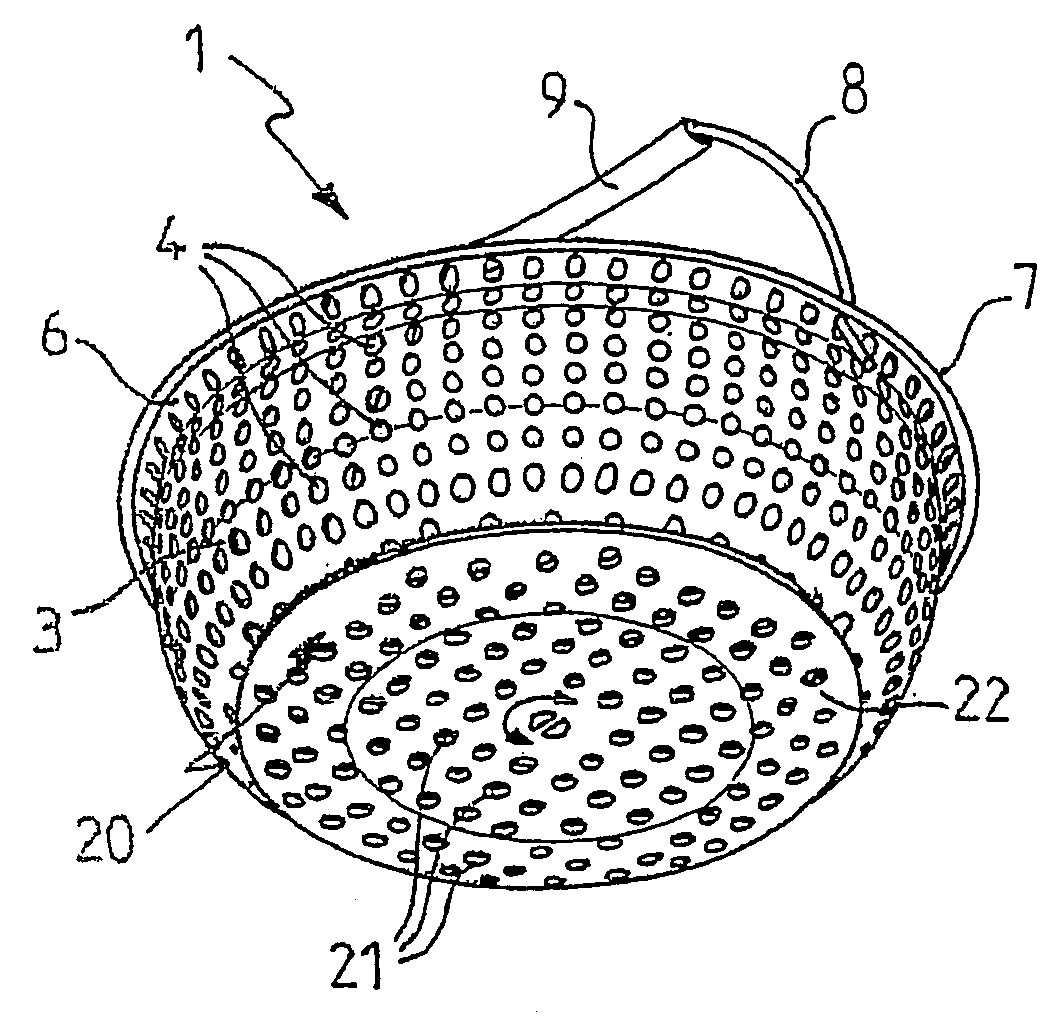

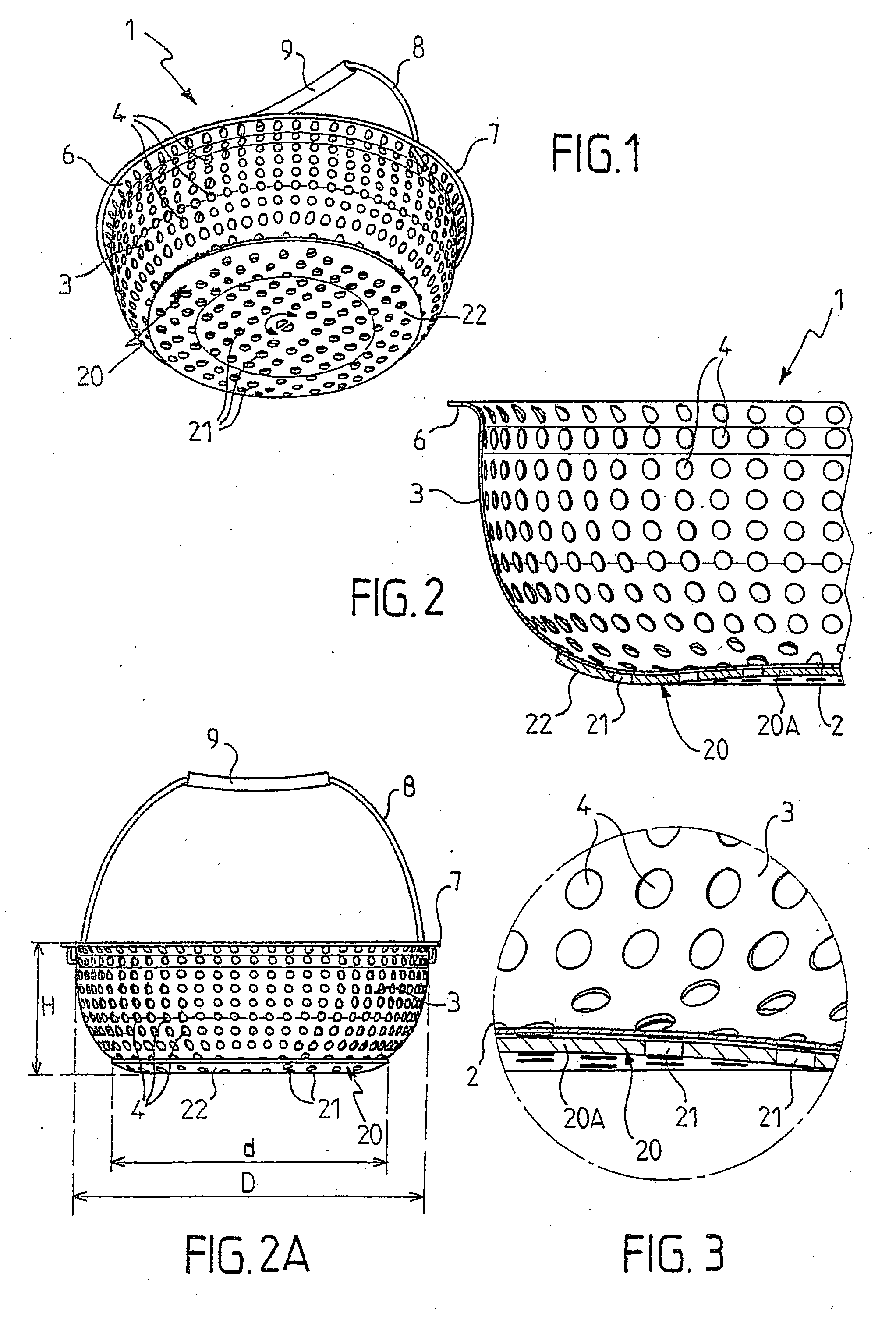

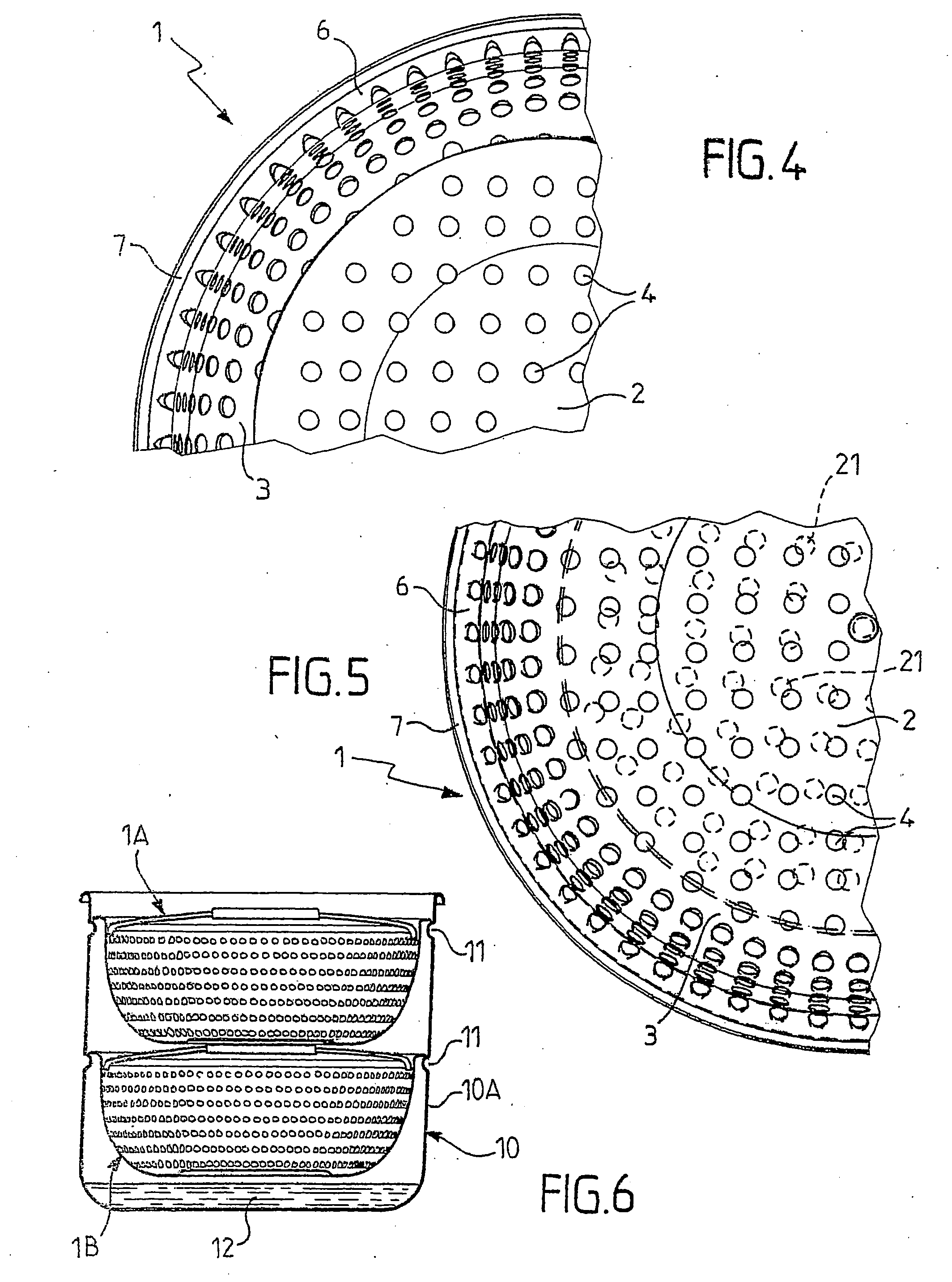

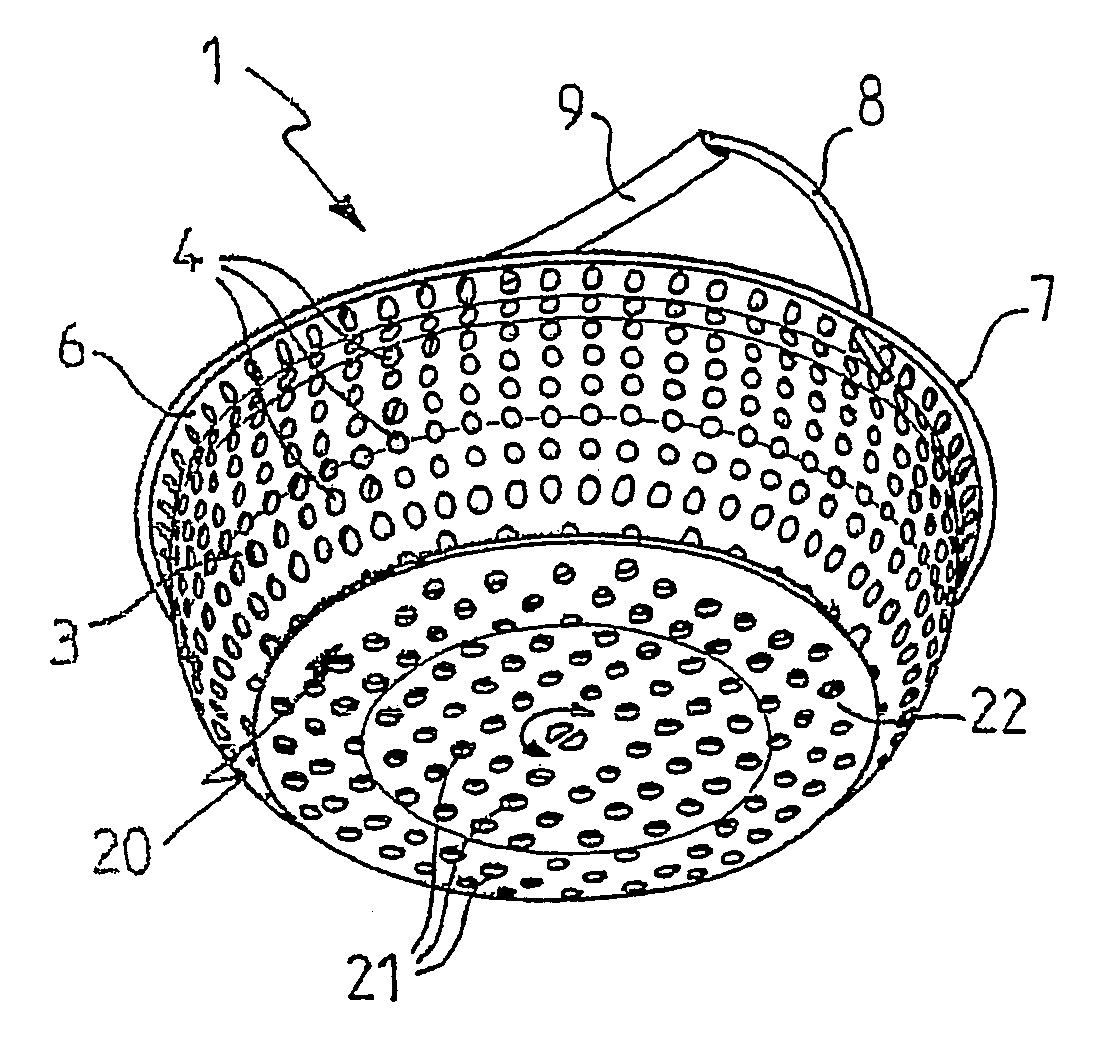

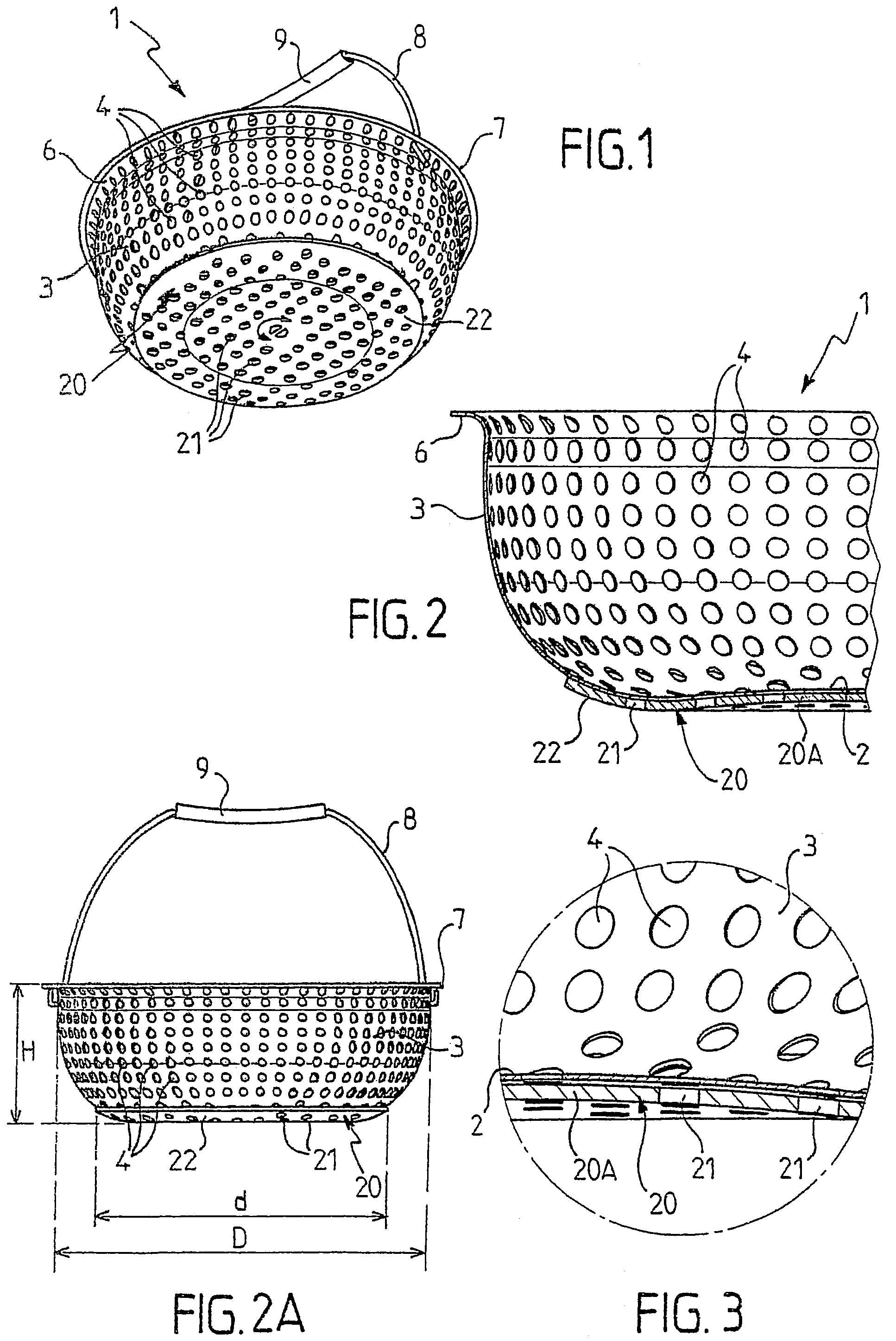

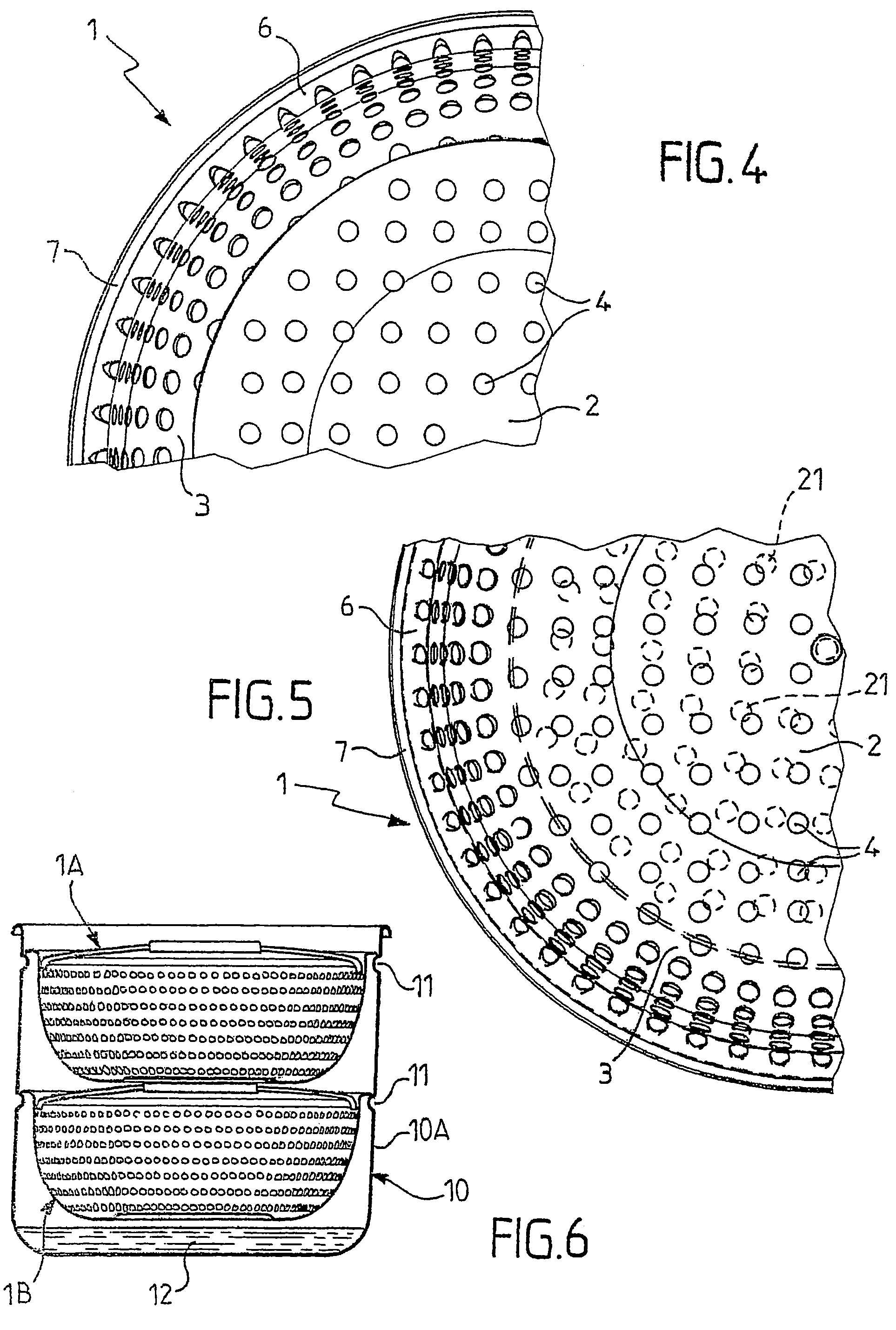

Cooking basket for pressure cooker comprising means for adjusting the passage of steam

InactiveUS20050115417A1Decrease phenomenonShorten the timeCooking-vessel materialsRefuse receptaclesEngineeringMaterial Perforation

The invention provides a food-cooking basket for pressure cooking in a pressure cooker, the basket being formed by a sheet of rigid material defining a bottom and side walls of the basket. The sheet is provided with perforations that are made through the bottom and through the side walls. The basket is provided with a structure for adjusting the flow rate of steam passing through the basket via the perforations, the structure being associated with the bottom in such a manner as to enable the flow rate of steam through the perforations at least in the bottom to be adjusted. The invention is applicable to appliances for pressure cooking.

Owner:SEB SA

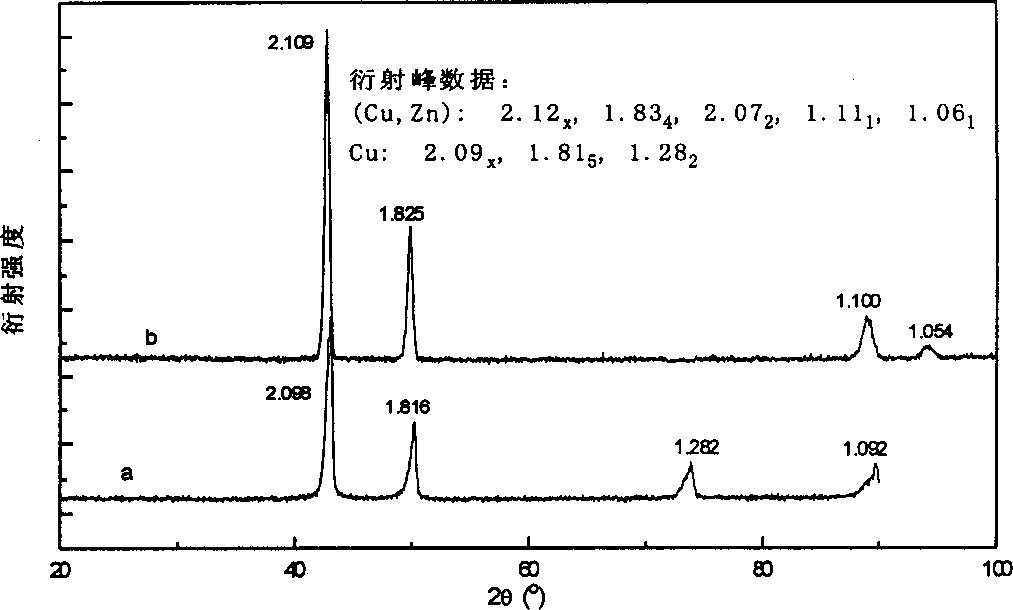

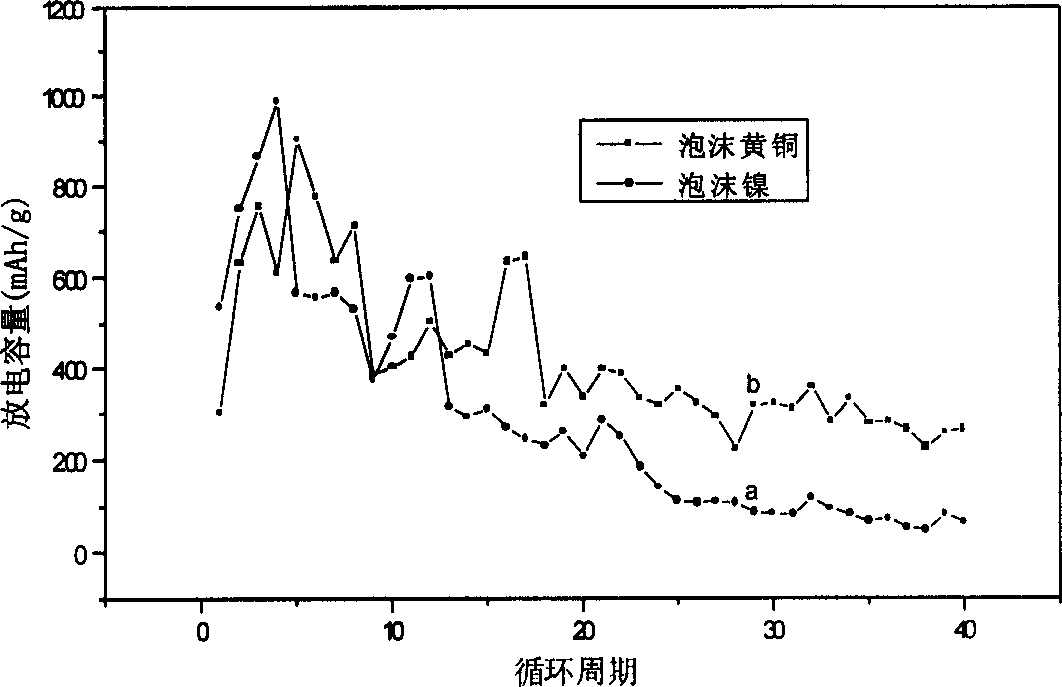

Foam-metal current collector of secondary battery using zinc as negative electrode and its preparing process

InactiveCN1360356ALow costSimple processElectrode manufacturing processesElectrode carriers/collectorsPorosityMetal framework

The invention relates to a method for preparing foam metal current collector (substrate) of new type secondary battery that uses zinc as negative pole. It possesses foamy space structure whose space cellular structure in three dimension is composed of metal framework connected eath other. Its surface ingredient includes copper 68%-75% (Wt), zinc 32-25%, that is copper-zinc alloy or foamy brass. The collector (substrate) being as zinc pole has very good performance in electrochemistry and better circular performance. The invention possesses merits of stable characteristic, low cost, simple technique, lower relative density, good electrical conductivity etc. The invention is particularly suitable for zinc-nickel secondary battery, also other zinc based secondary battery and alkaline secondary battery.

Owner:NANKAI UNIV

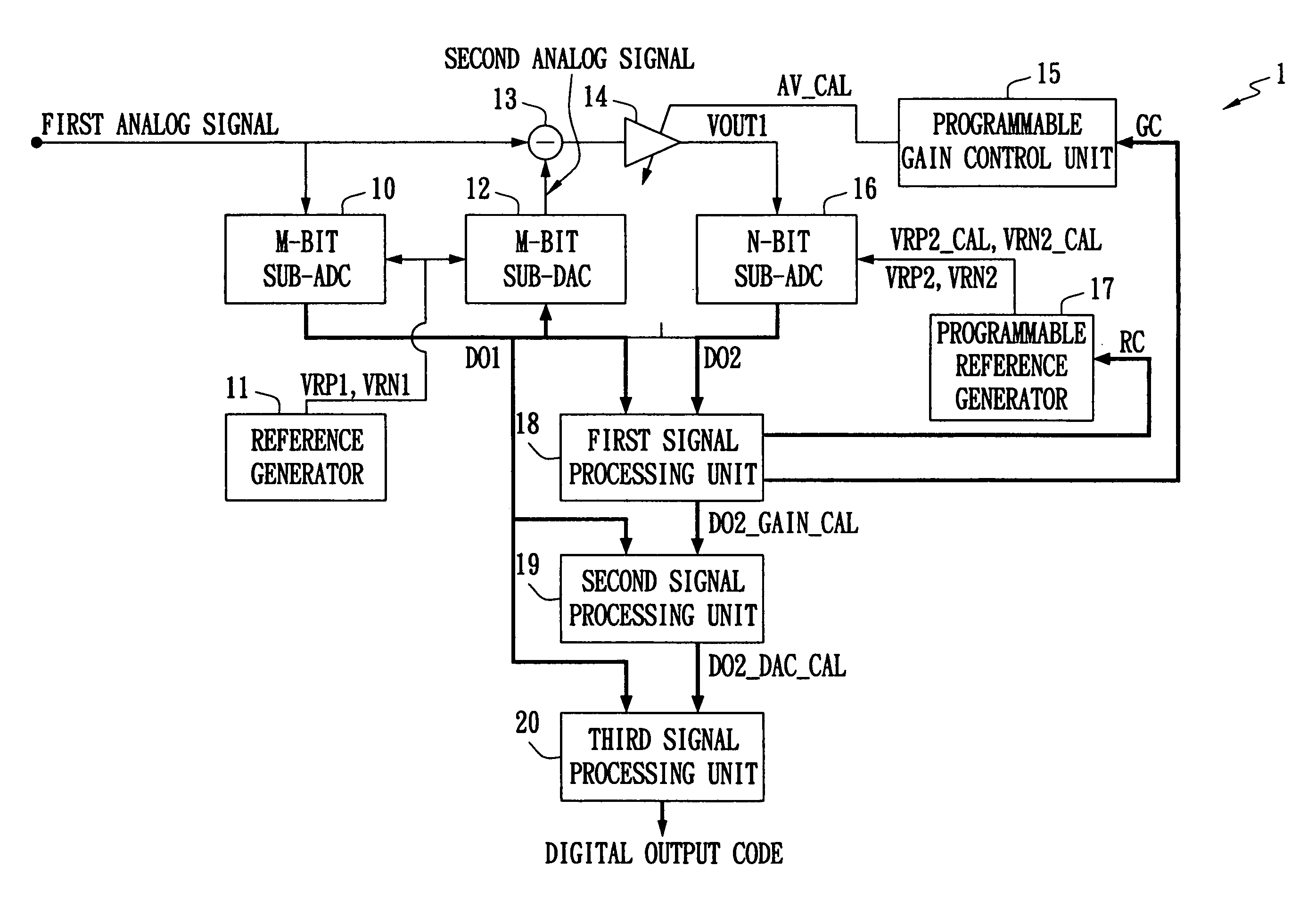

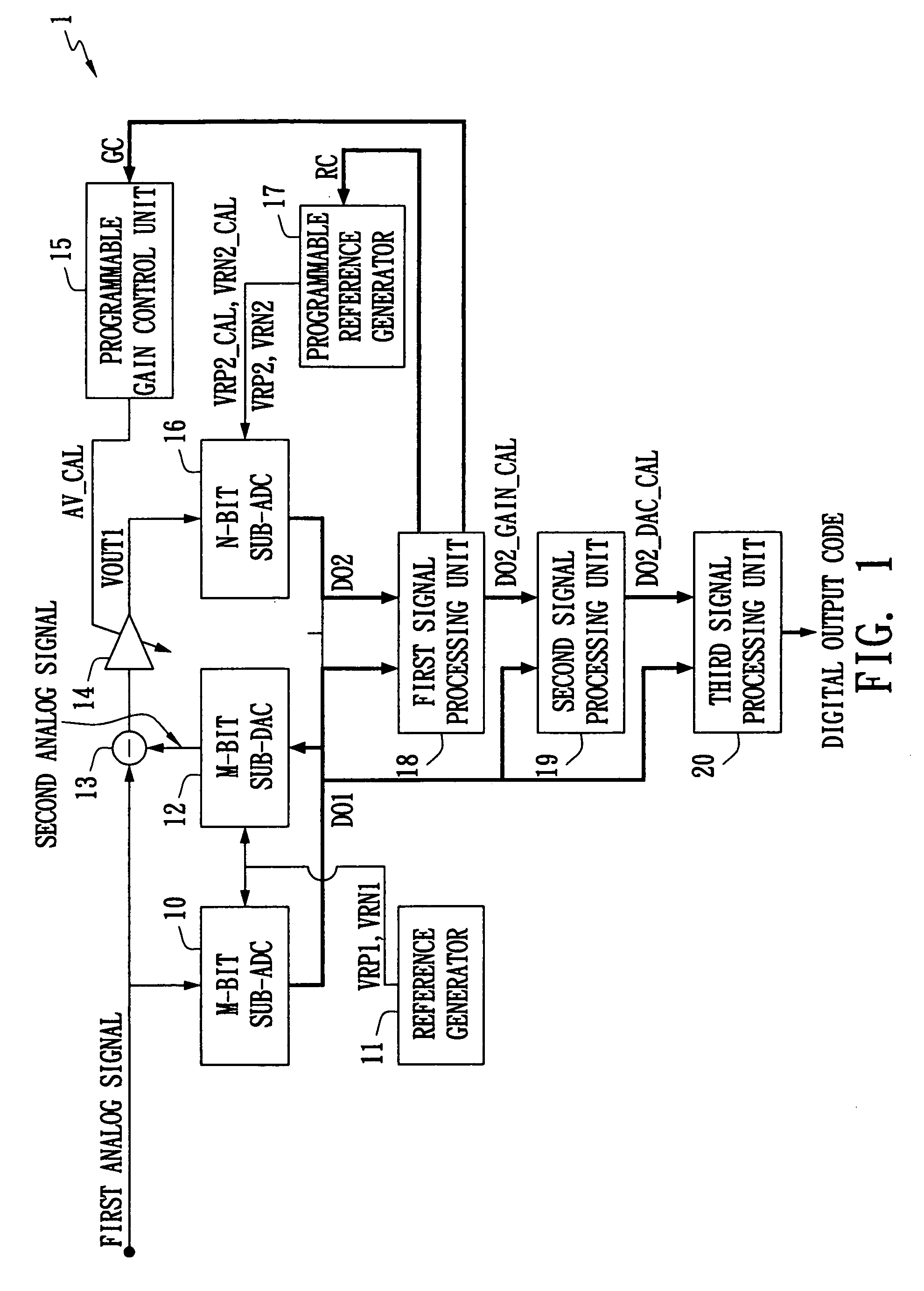

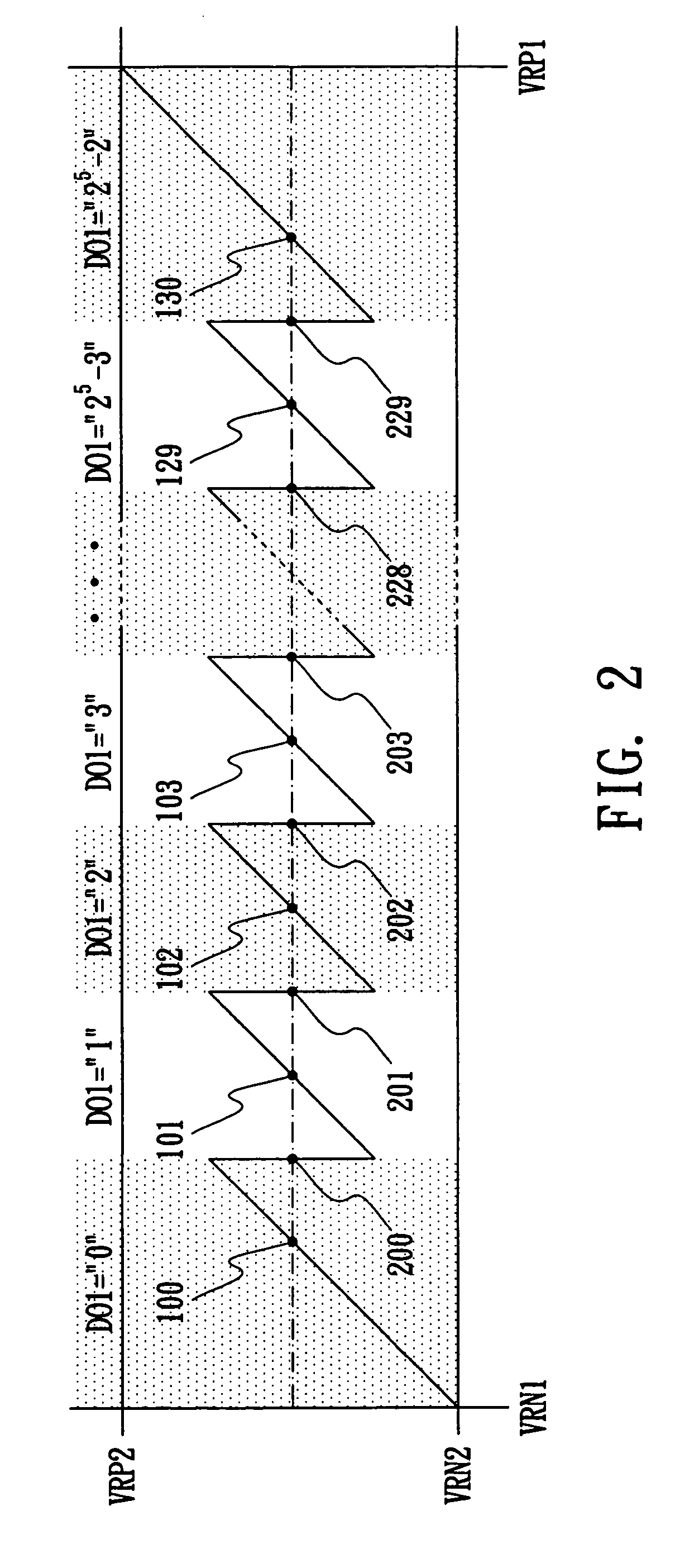

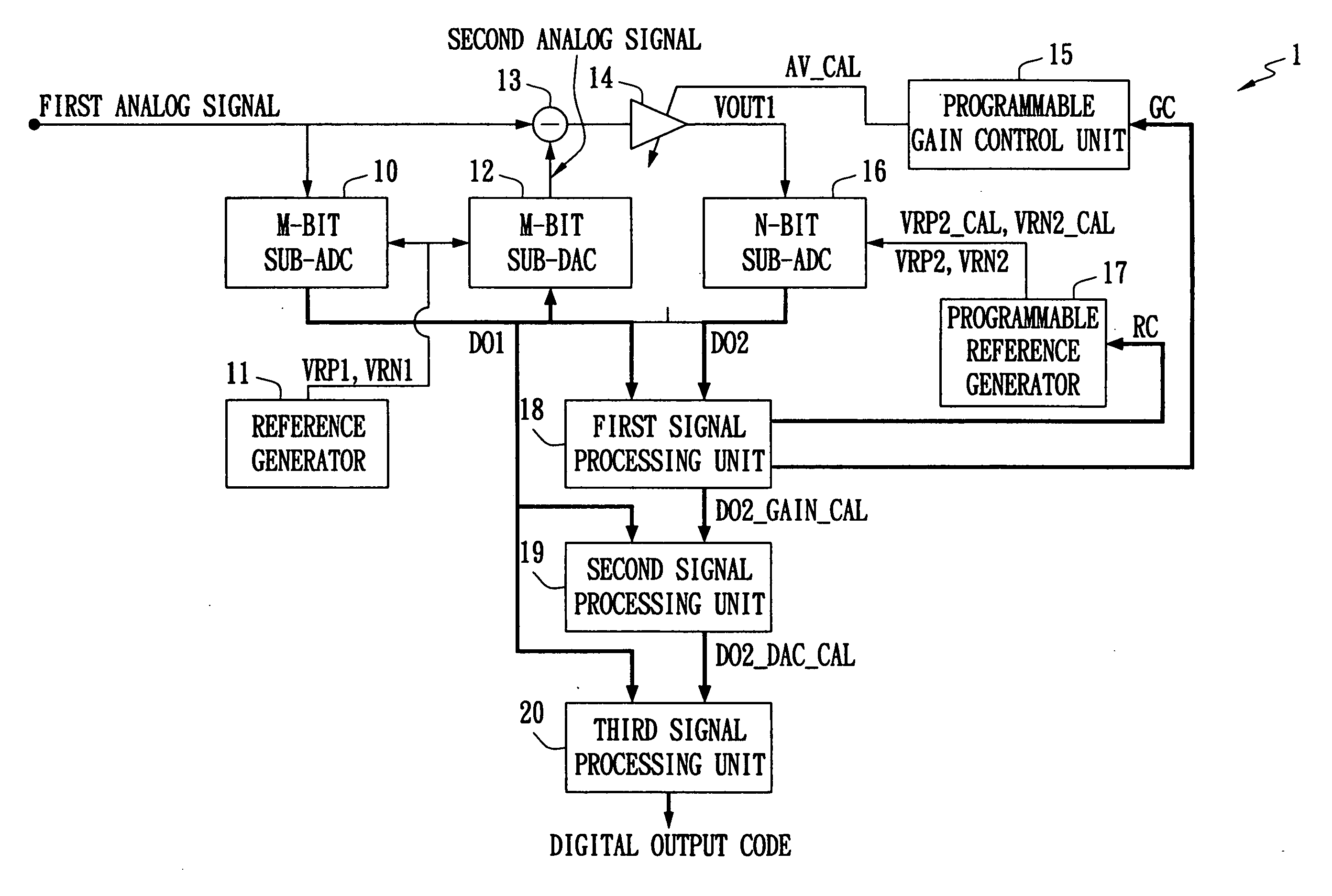

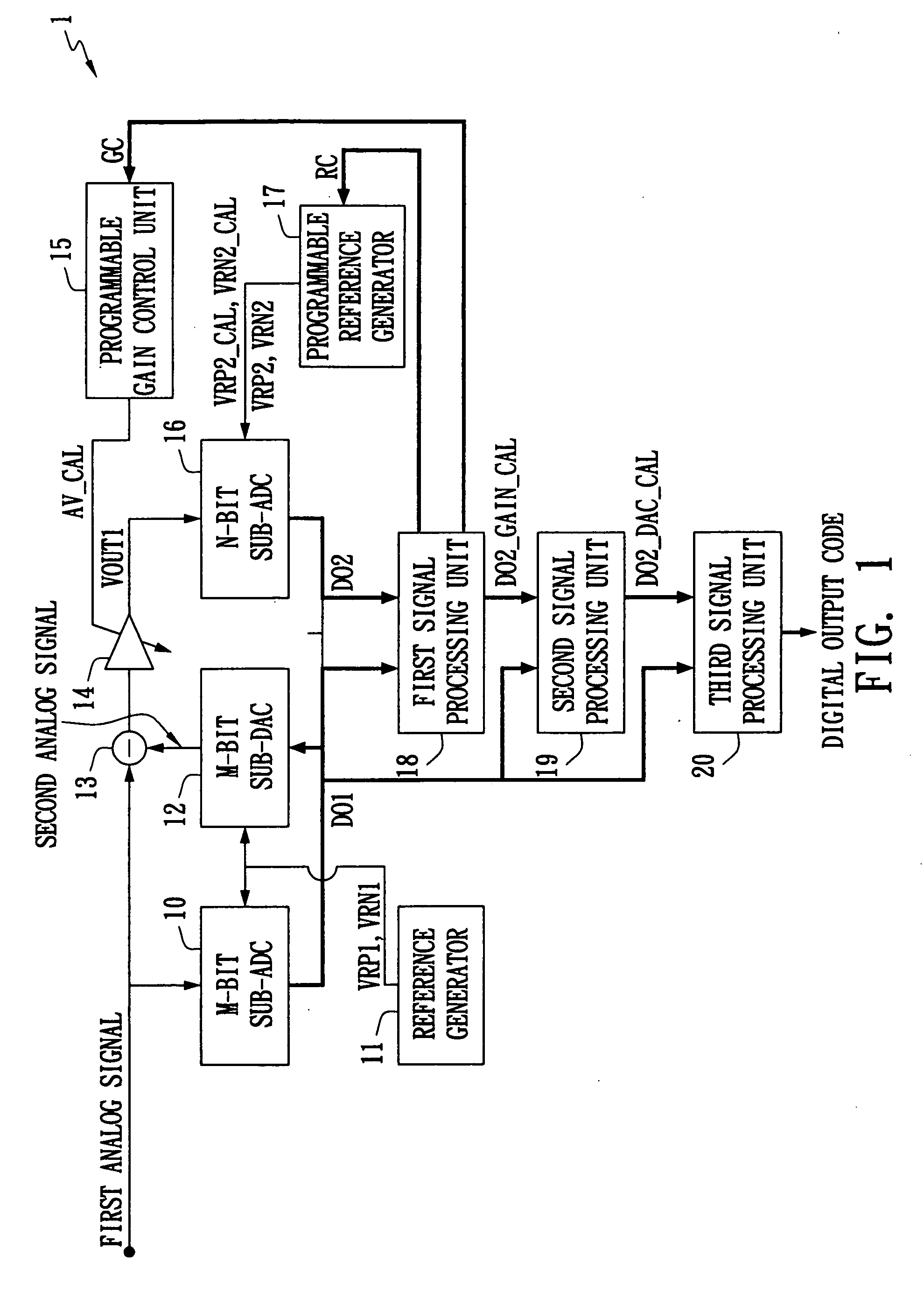

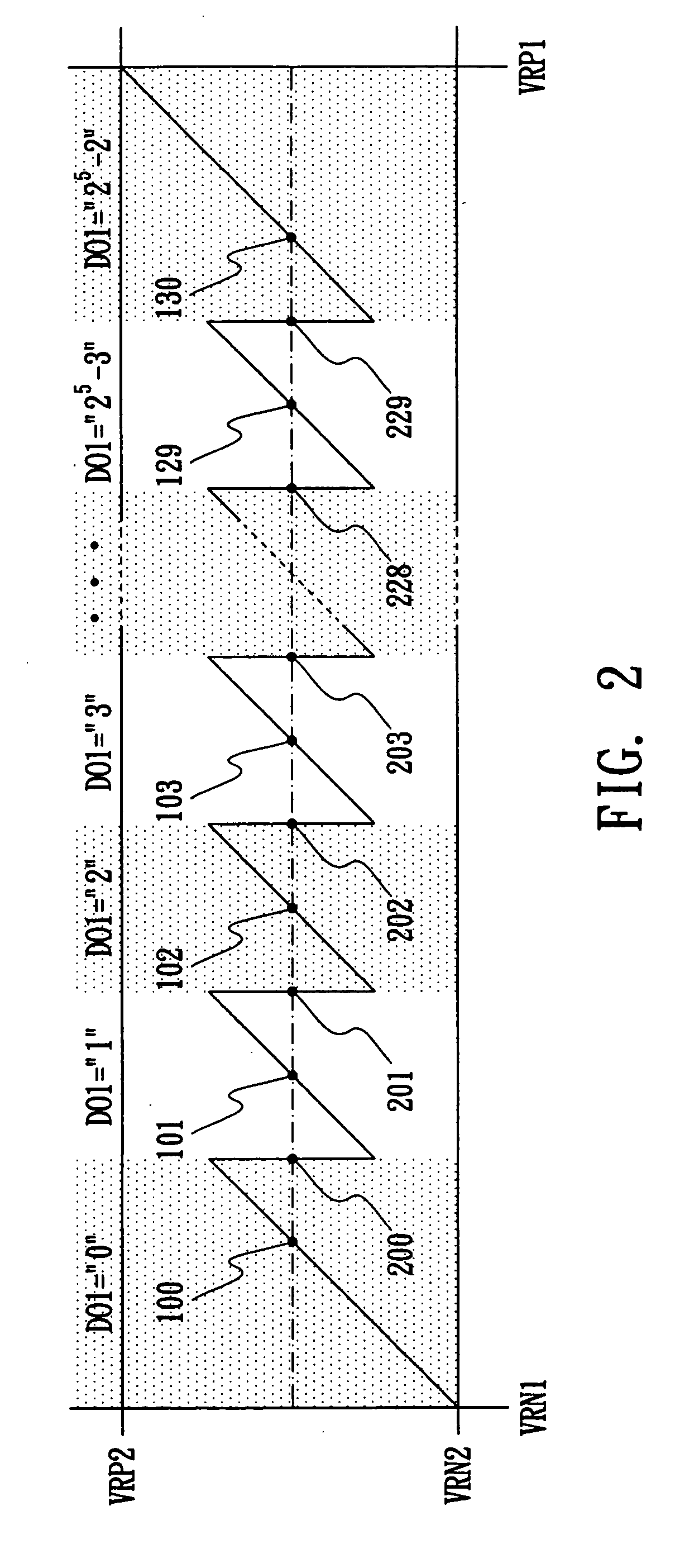

Multi-step analog/digital converter and on-line calibration method thereof

InactiveUS7142138B2Decrease phenomenonPrecision requirement of the residue amplifier are reducedElectric signal transmission systemsAnalogue/digital conversion calibration/testingDigital down converterVoltage reference

Owner:NATIONAL TSING HUA UNIVERSITY

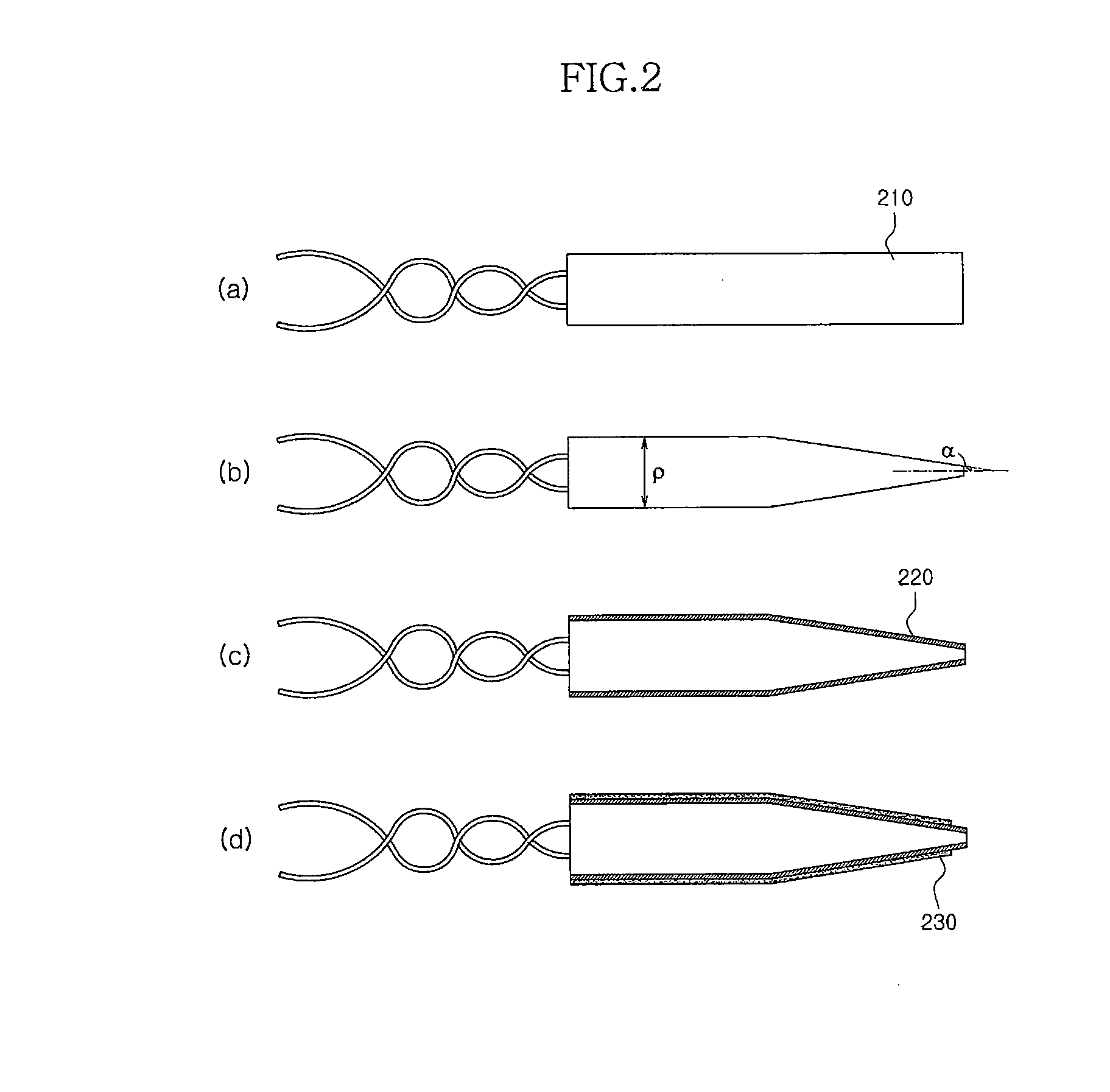

Apparatus for stimulating the brain and measuring the light induced neuronal activity and method for manufacturing the same

ActiveUS20100161017A1Lower the volumeReduce insertionInternal electrodesSensorsMedicineElectro physiology

Disclosed is an apparatus for stimulating the brain and measuring the light induced neuronal activity including a signal application unit which applies a signal to a living tissue to stimulate the neuronal cells in the living tissue; an electrode unit which detects an electrophysiological signal of the neuronal cell in response to the signal; and an insulation unit which controls an impedance of the electrode unit. The signal application unit is formed integrally with the electrode unit, so that the site where the signal is applied to the living tissue is approximated to the site where the response to the stimulation is measured.

Owner:DIGISONIC CO LTD

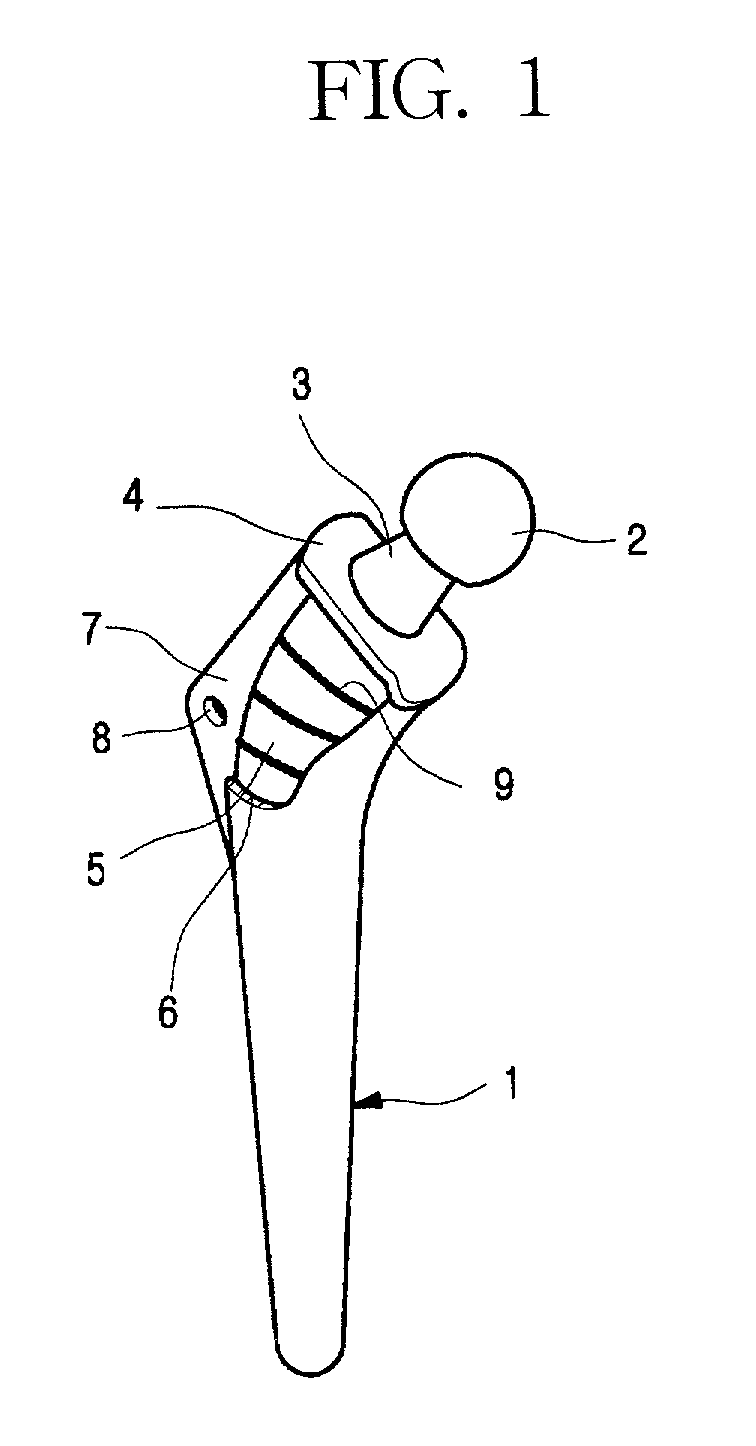

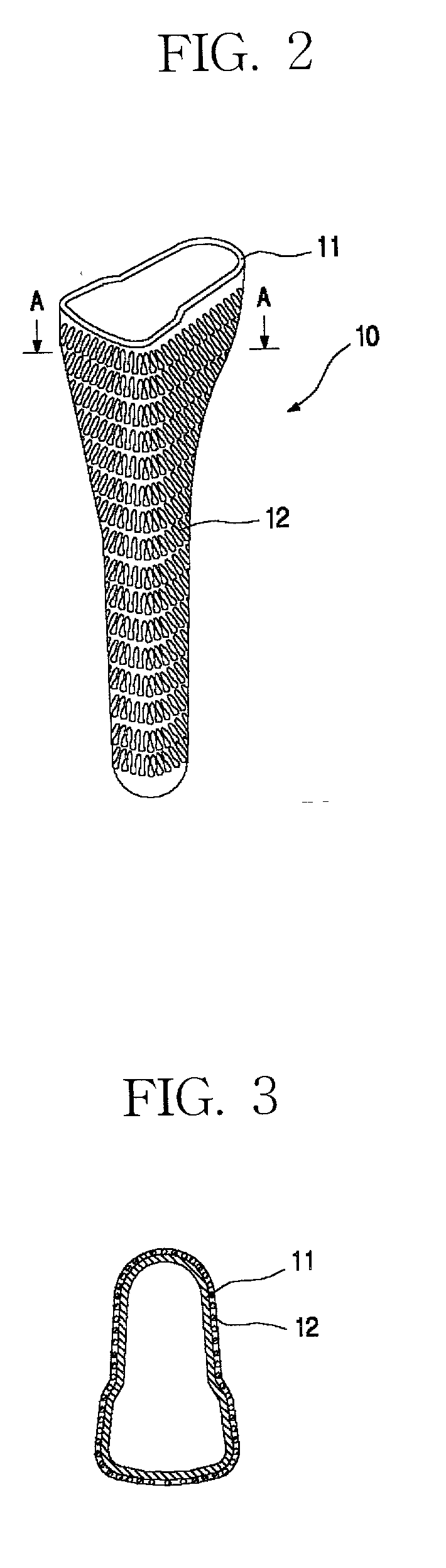

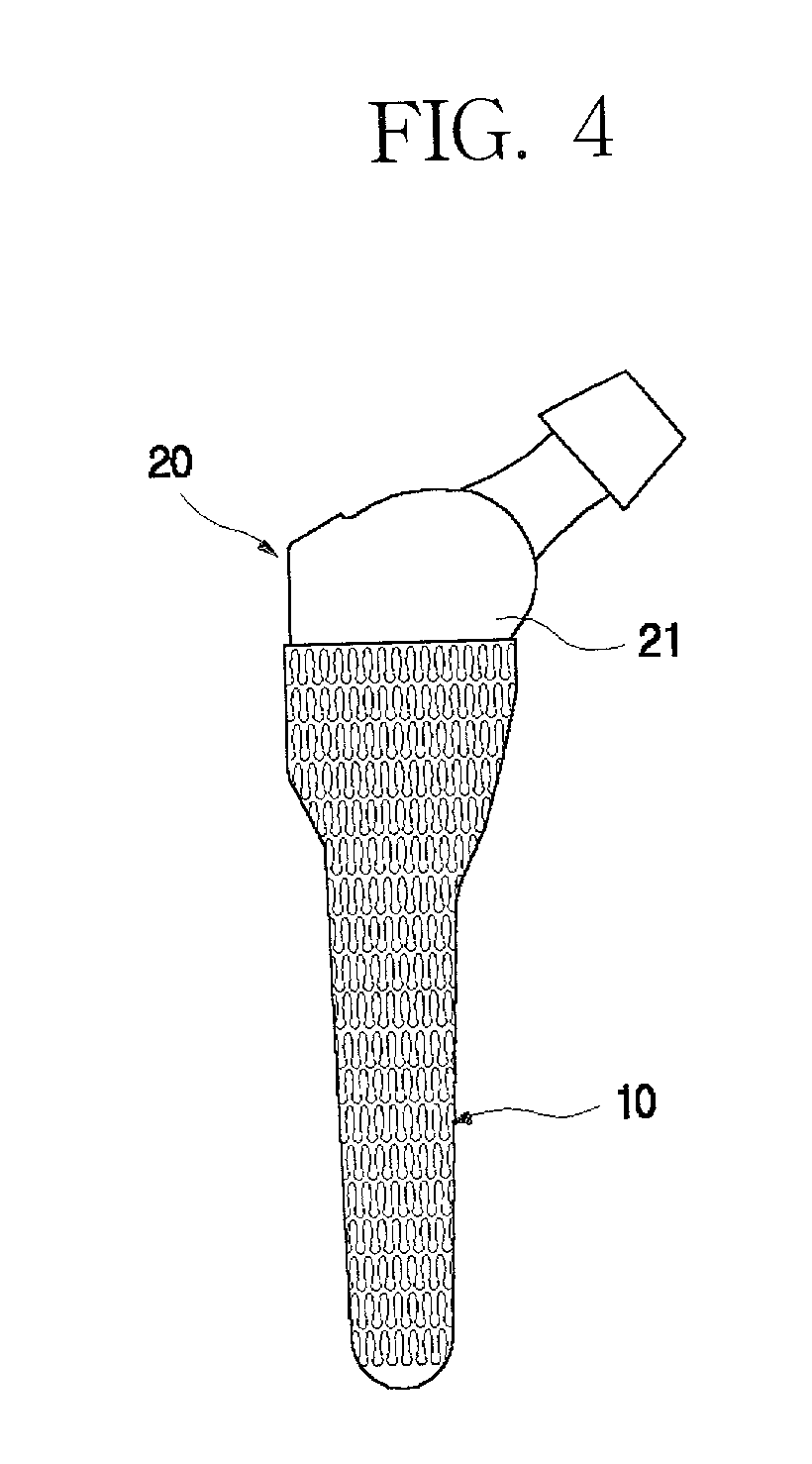

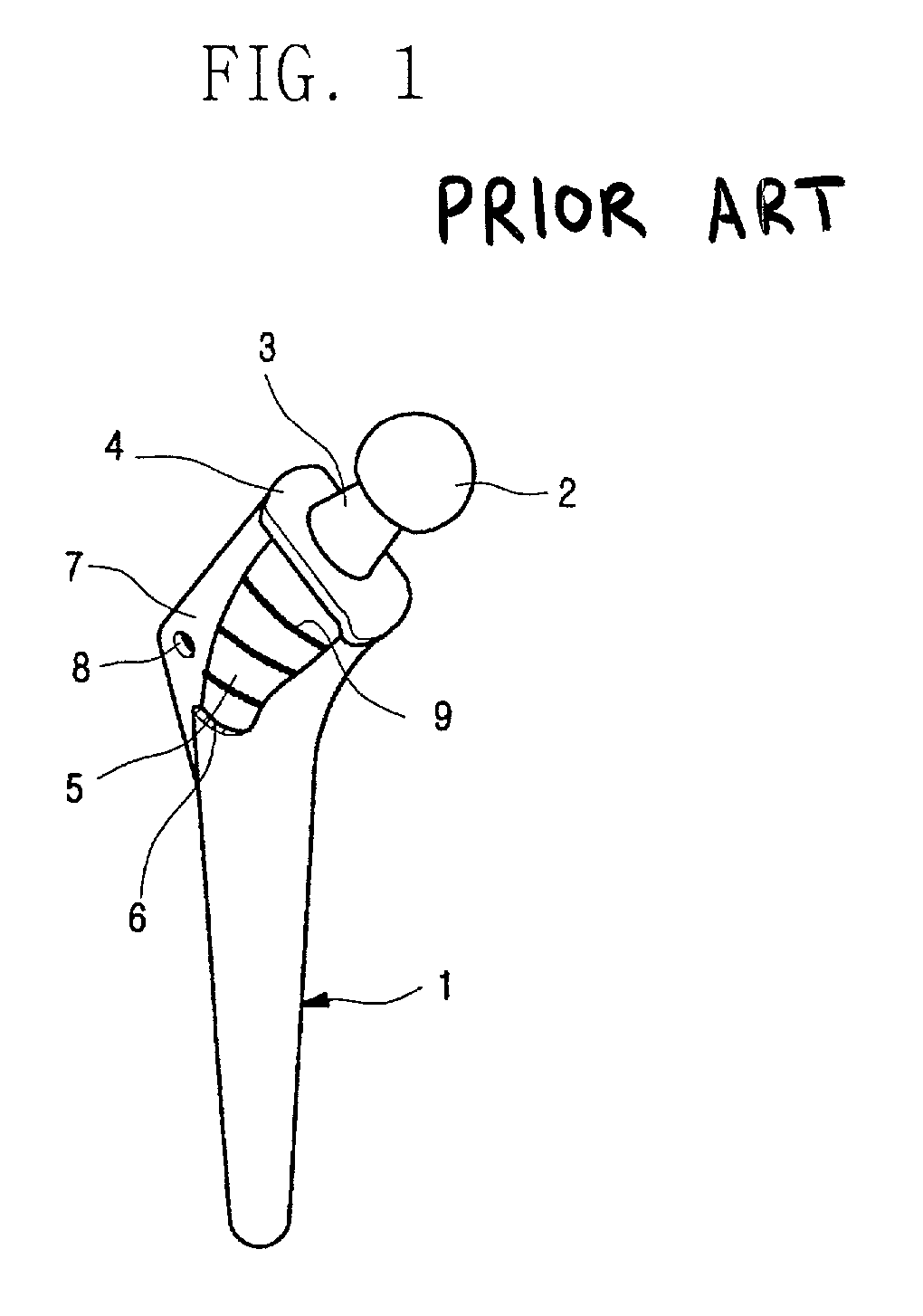

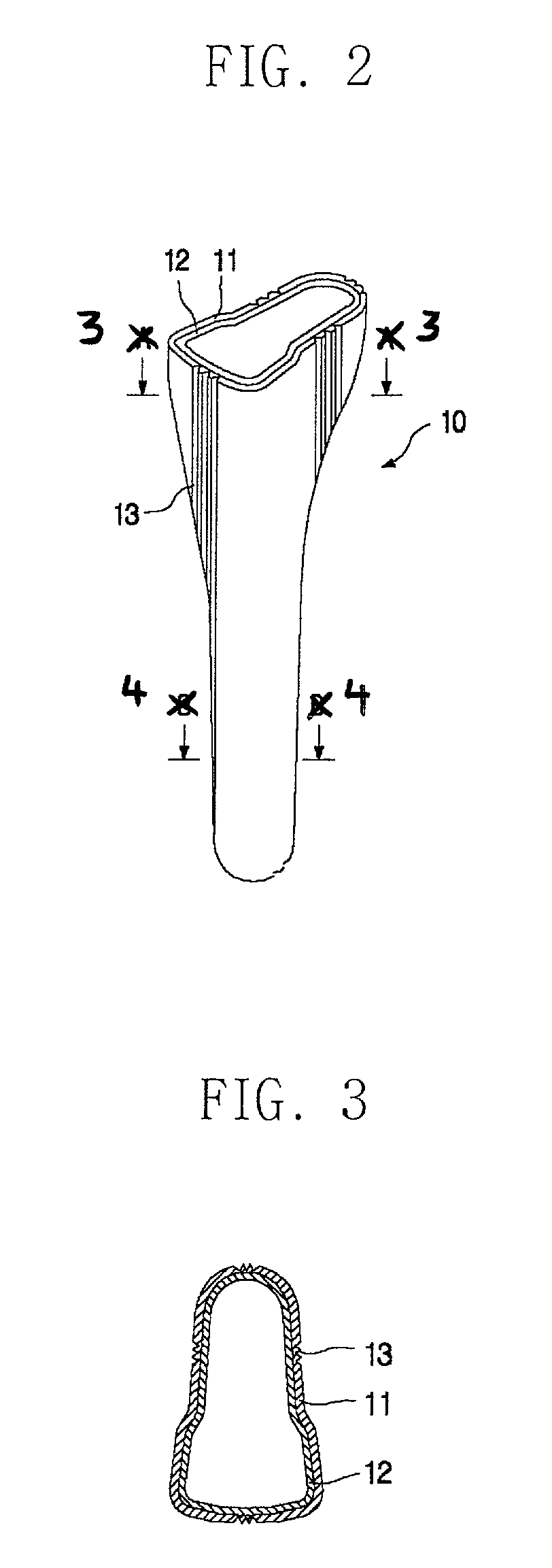

Metal jacket for a cementless artificial joint stem and artificial joint having the jacket

InactiveUS20010016780A1Suppress formationMinimize osteolysisBone implantJoint implantsHuman bodyStress shielding

The present invention is intended to provide a metal jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the metal jacket which can be fixed to the bone and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem. To that end, there is provided according to the invention, a metal jacket for a cementless artificial joint stem, which jacket is so formed as to enclose at least a part of the cementless artificial joint stem 21, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and on the surface of which jacket surface-processed metal layer or metal wires 12 is formed so that the bone can make interlocking with the metal jacket as the bone gets on-growth onto the metal jacket.

Owner:KOREA ADVANCED INST OF SCI & TECH

Molding sand capable of quick air permeation and heat dissipation and preparation method thereof

InactiveCN103586399AImprove smoothnessImprove adhesionFoundry mouldsFoundry coresPorositySodium Bentonite

The invention relates to a molding sand capable of quick air permeation and heat dissipation, which is prepared from the following raw materials in parts by weight: 100-120 parts of return sand, 140-150 parts of quartz sand, 30-40 parts of dry coal ash, 50-60 parts of vitrified microbead, 14-20 parts of hydroxyl-aluminum pillared bentonite, 1-2 parts of sodium carboxymethyl cellulose, 20-25 parts of starch, 2-3 parts of raw tung oil, 1-2 parts of lime powder, 4-5 parts of calcium fluoride, 4-5 parts of aluminum nitride, 40-45 parts of haydite, 4-5 parts of cement and a right amount of water. The return sand, quartz sand and the like are calcined, pulverized and subjected to high-temperature calcination, and the sodium carboxymethyl cellulose and other assistants are dispersed and ground, so that the molding sand has excellent smoothness, binding property, toughness and plasticity; the vitrified microbeads are utilized to greatly enhance the air permeability and reduce the subsurface porosity; the starch is utilized to enhance the collapsibility; and the aluminum nitride is utilized to increase the heat conductivity and enhance the production efficiency.

Owner:CHANGLI FORGING

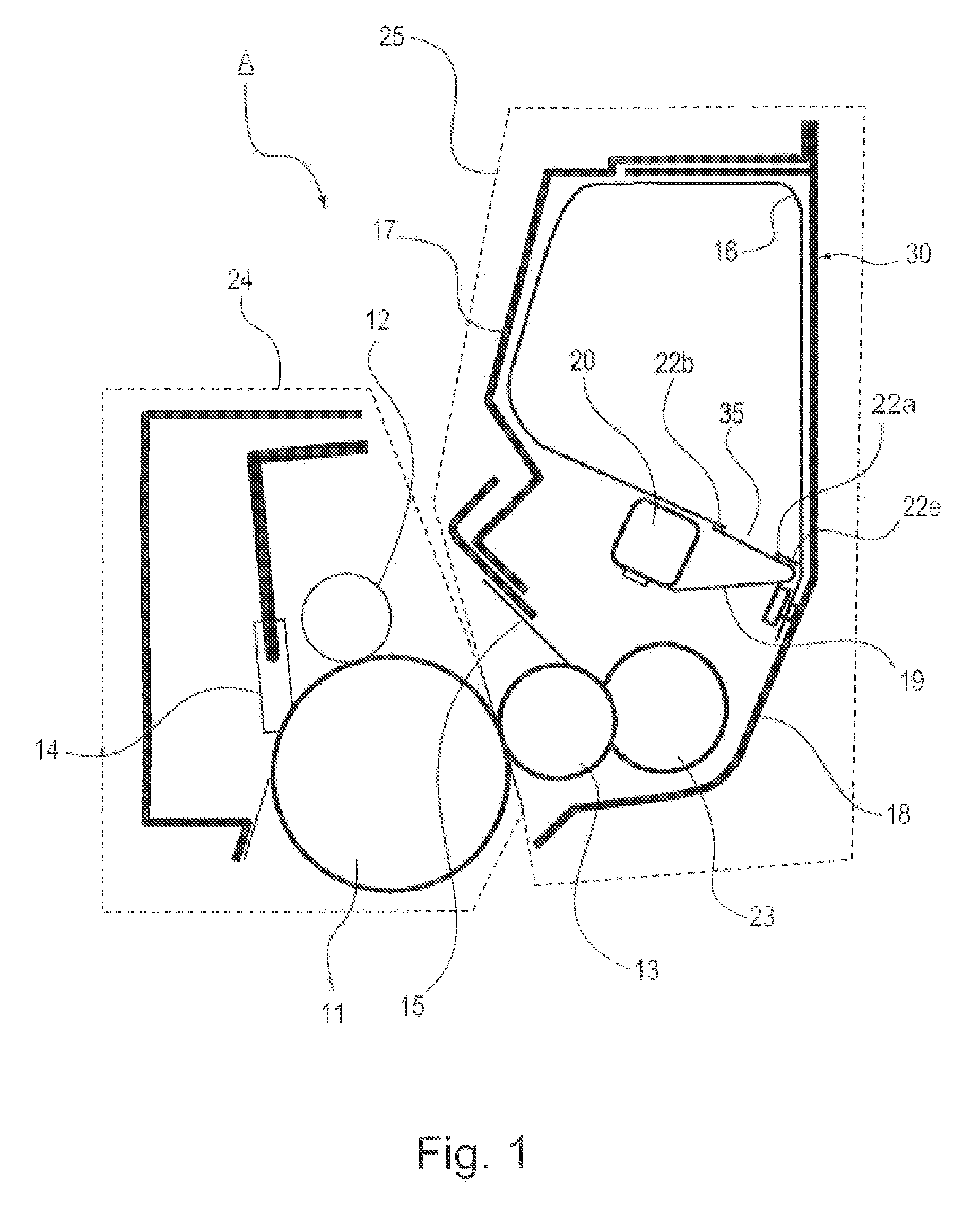

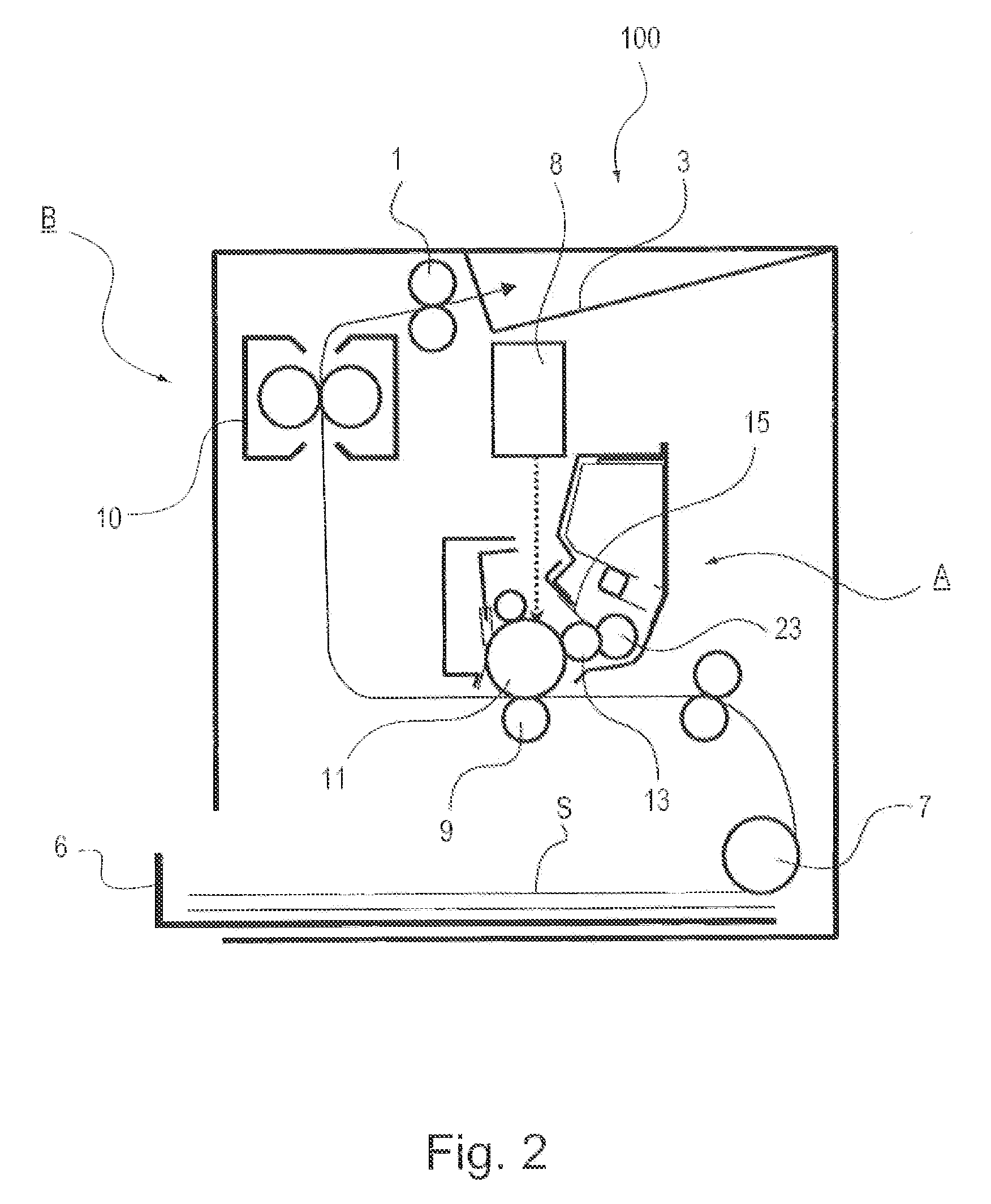

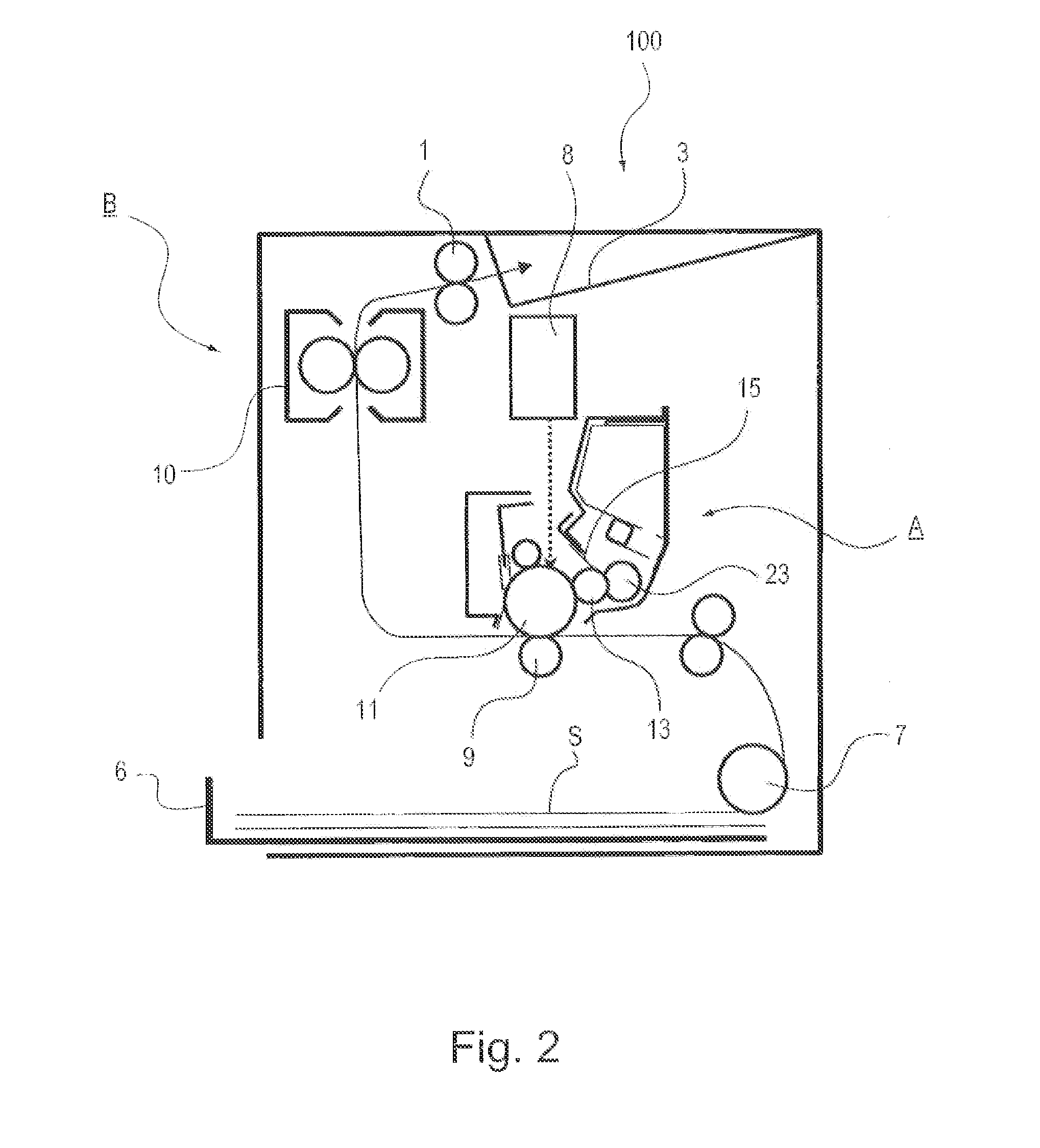

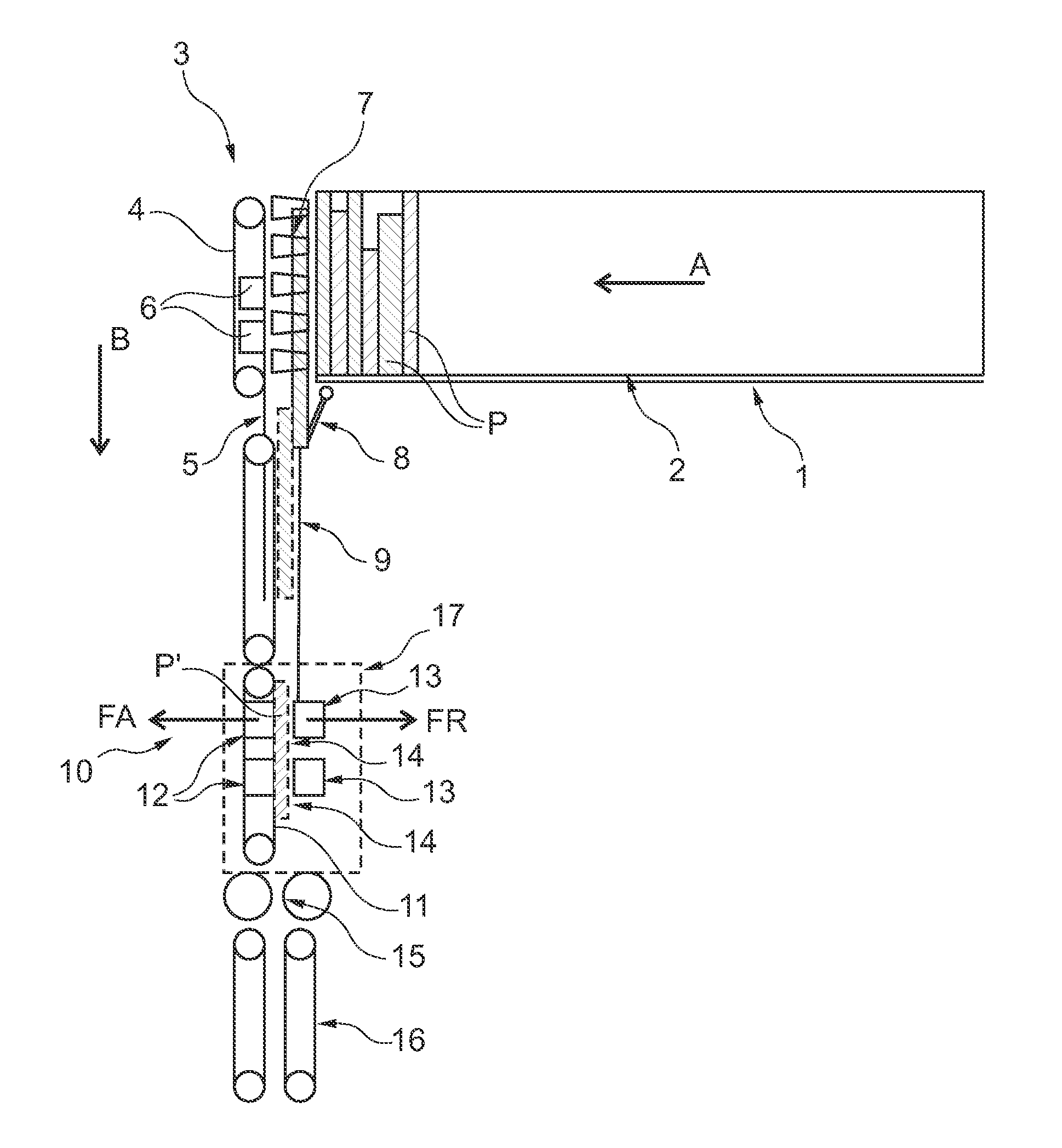

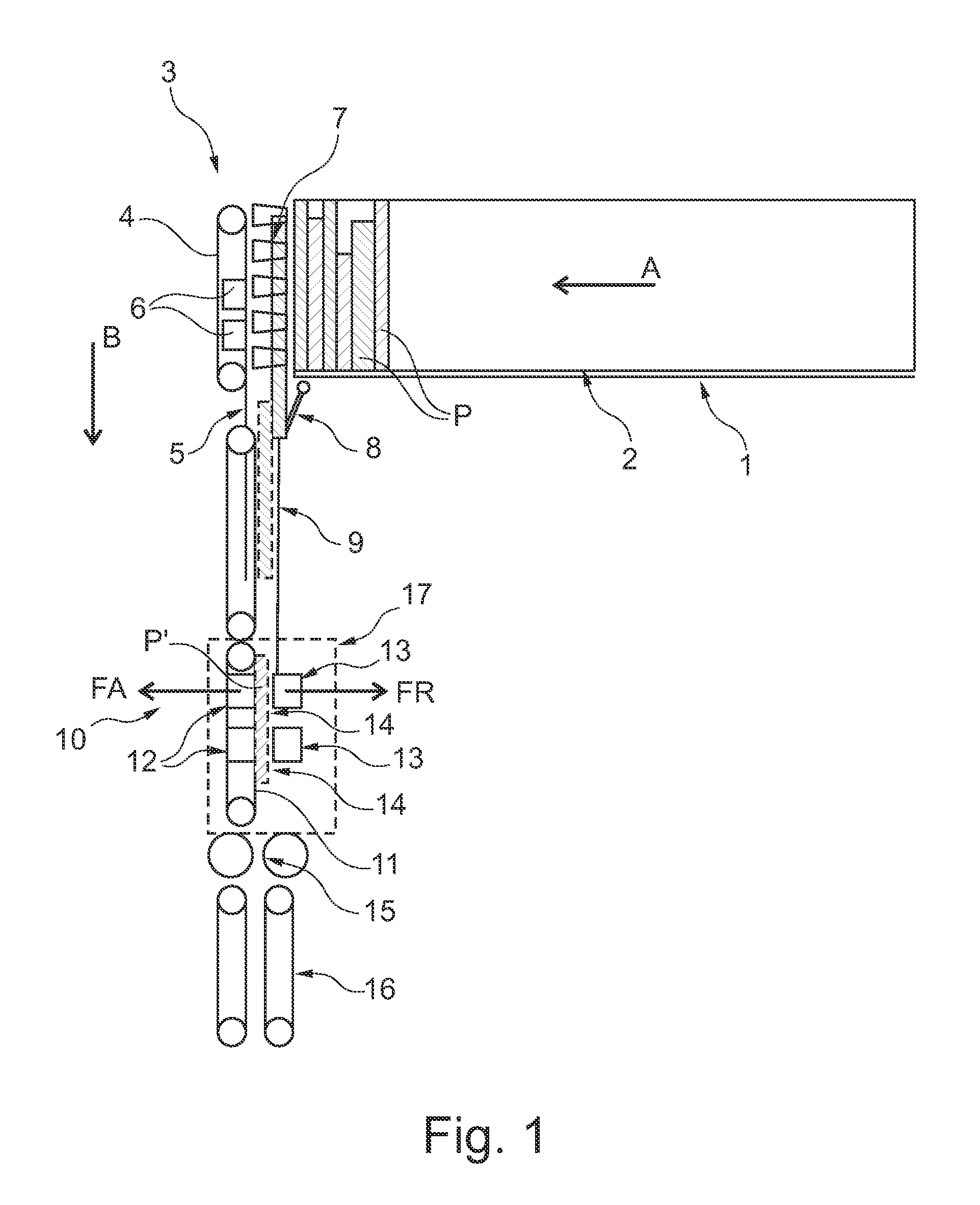

Flat-article feed device and a postal sorting machine

InactiveUS20120013064A1Quality improvementDecrease phenomenonArticle feedersArticle separationEngineeringMechanical engineering

The invention relates to a flat-article feed device, comprising a supply magazine (1) in which flat articles are moved in a stack on edge in a first transfer direction (A), separator means (3) for separating the leading flat article of the stack from the remainder of the stack and for driving it in a second transfer direction (B) that is substantially perpendicular to the first transfer direction, unstacker means (10) that take a flat article that is being unstacked and bring it in said second transfer direction (B) to the inlet of a conveyor, and retaining means (13) that exert a retaining force that opposes movement of the flat article towards the conveyor, said unstacker means being offset from said separator means by a distance not less than the maximum length of a flat article, and said retaining means being provided facing the unstacker means. The invention also relates to a postal sorting machine including such a feed device.

Owner:SOLYSTIC

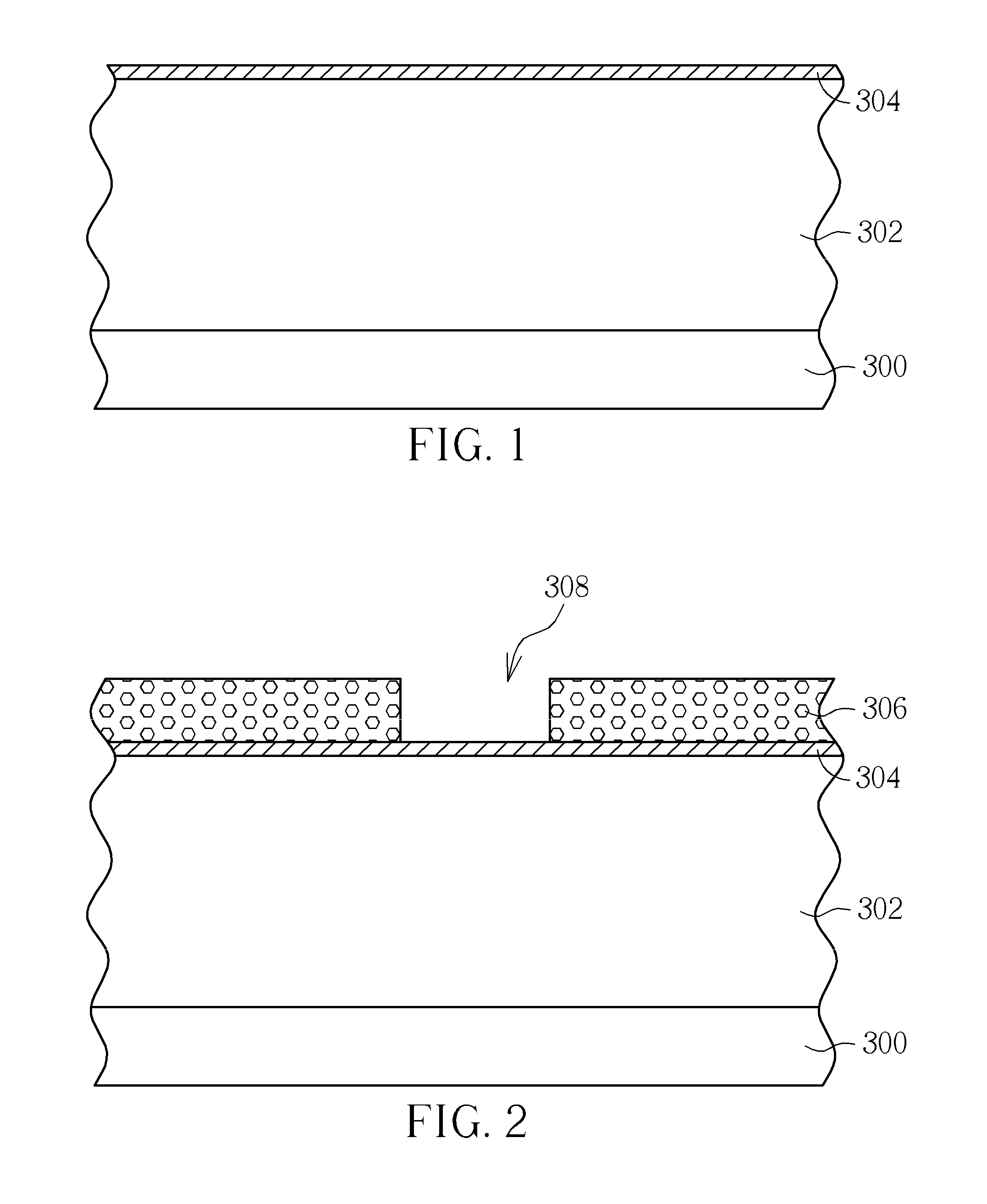

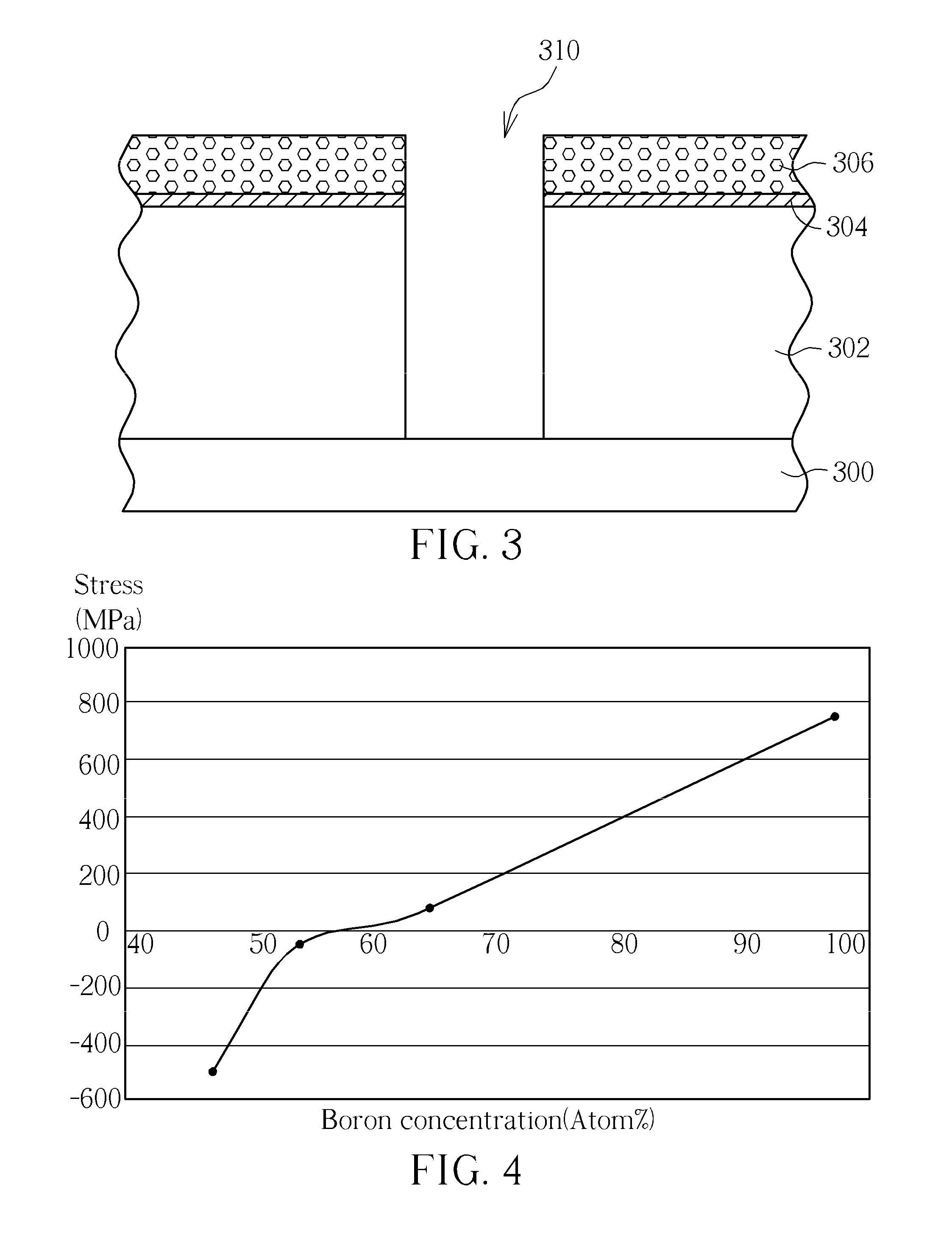

Method of Forming Opening on Semiconductor Substrate

ActiveUS20120264306A1Improve etch selectivityLine distortion can be alleviatedSemiconductor/solid-state device manufacturingOptoelectronicsBoron nitride

The present invention provides a method of forming an opening on a semiconductor substrate. First, a substrate is provided. Then a dielectric layer and a cap layer are formed on the substrate. A ratio of a thickness of the dielectric layer and a thickness of the cap layer is substantially between 15 and 1.5. Next, a patterned boron nitride layer is formed on the cap layer. Lastly, an etching process is performed by using the patterned hard mask as a mask to etch the cap layer and the dielectric layer so as to form an opening in the cap layer and the dielectric layer.

Owner:UNITED MICROELECTRONICS CORP

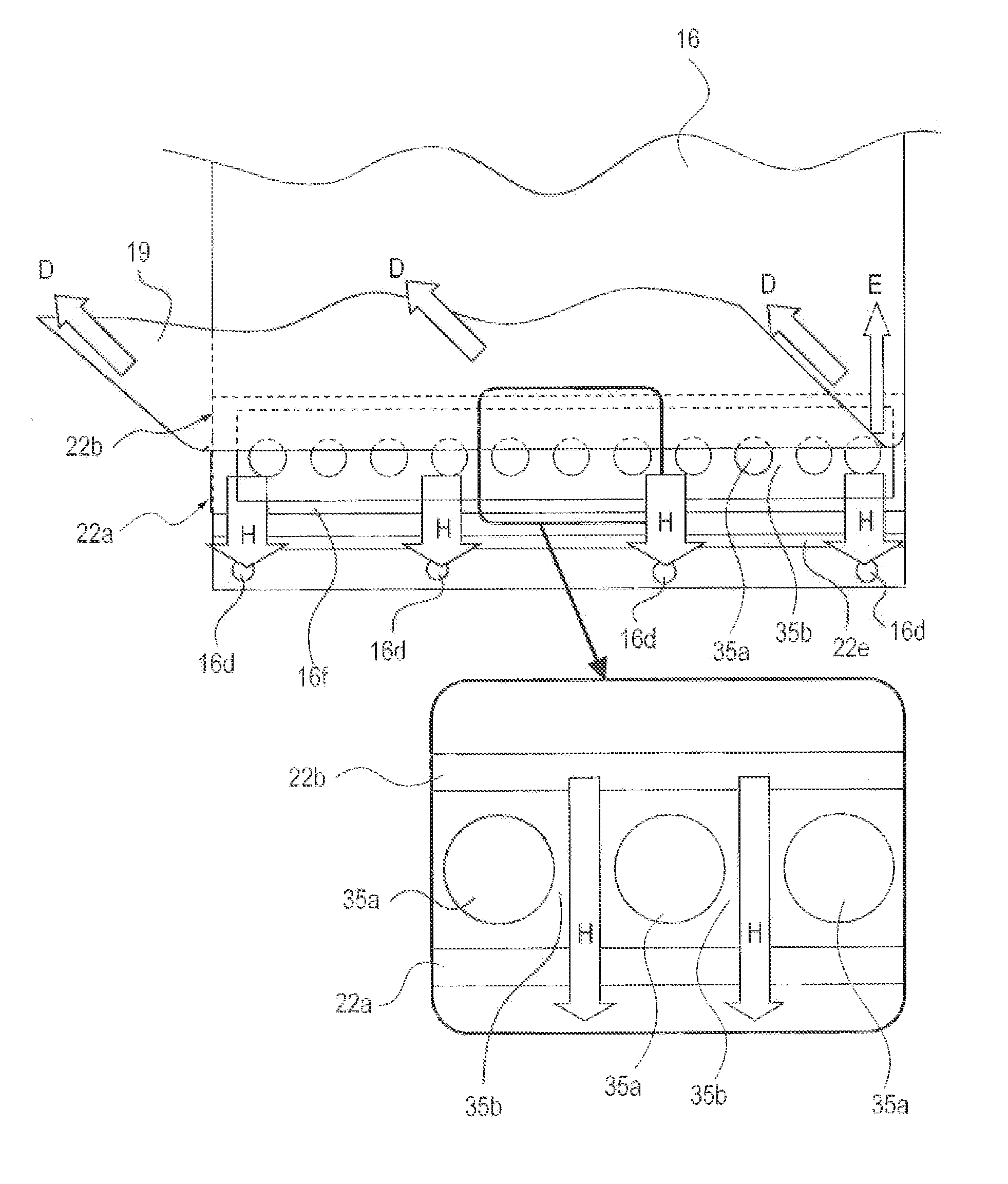

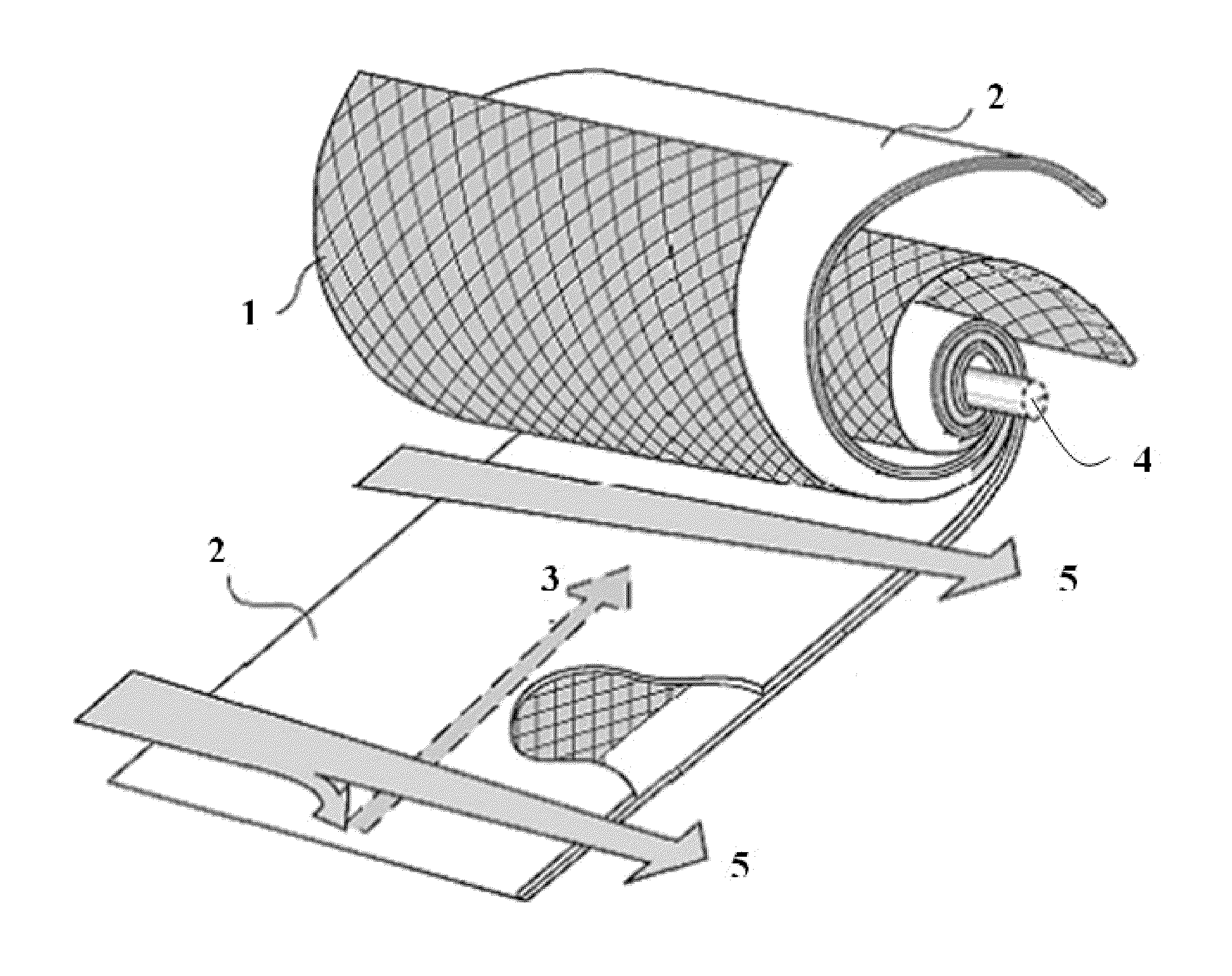

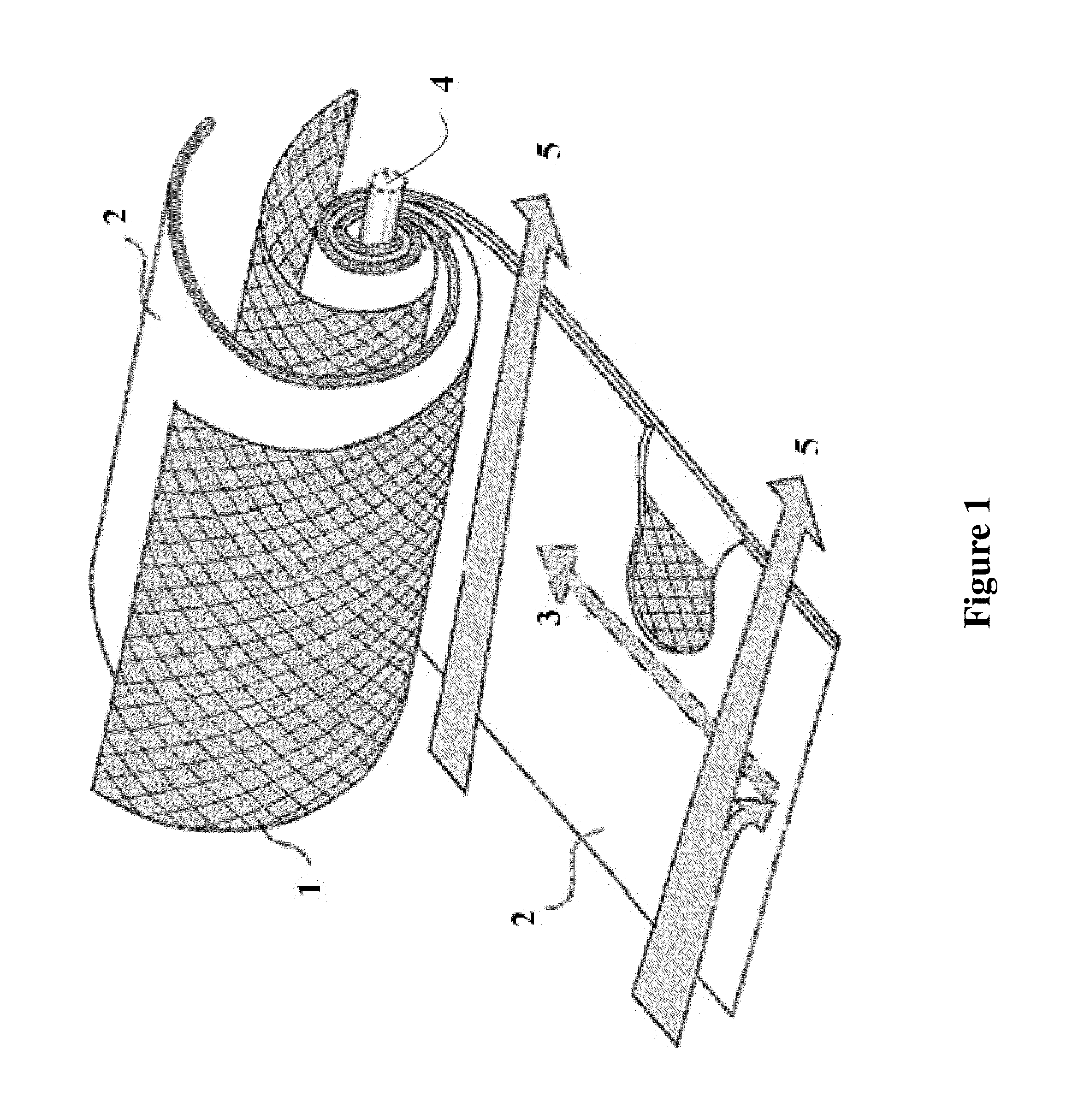

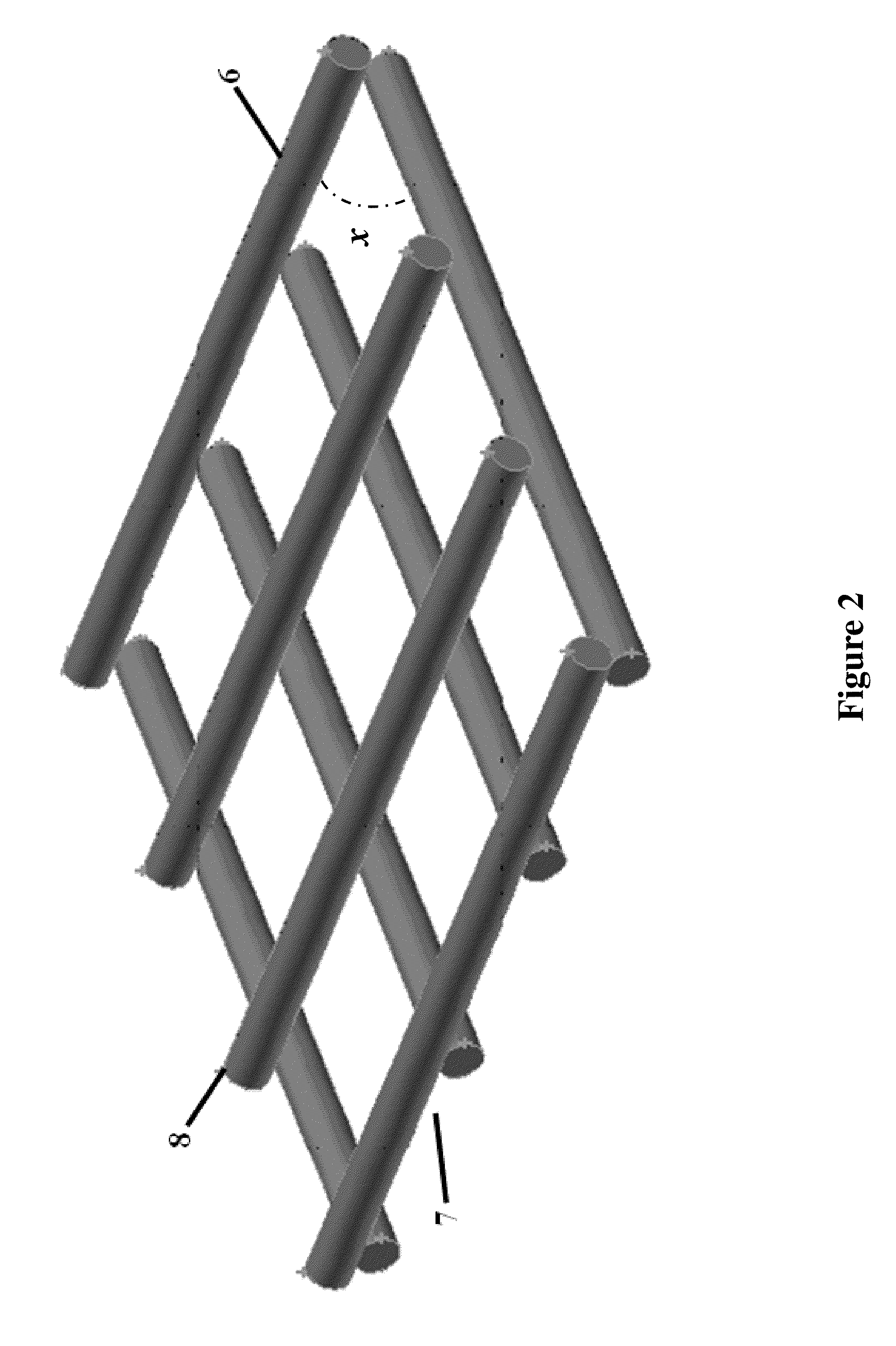

Membrane modules utilizing innovative geometries of net-type feed spacers for improved performance in separations and spacer-fabrication methods therein

ActiveUS20160151745A1Improve methodEasy to separateMembranesSemi-permeable membranesFiltrationMembrane surface

The present invention discloses membrane modules utilizing innovative geometries of net-type feed spacers for improved performance in separations and spacer-fabrication methods therein. Membrane modules include: a central tube having perforations along its length for collecting a permeate; at least two filtration envelopes, each filtration envelope having two membrane sheets and a porous, fabric-type insert in between the two membrane sheets for facilitating the permeate to flow, wherein each envelope is closed along three edges of the two membrane sheets, and wherein each envelope is configured to allow the permeate to exit from a fourth, open edge attached to the central tube; and a respective feed-spacer sheet in planar contact with an outer membrane surface of a respective filtration envelope; wherein the respective feed-spacer sheet is in the form of net having nodes connected by flexible segments such that the net forms a regular planar net.

Owner:CENT FOR RES & TECH HELLAS CERTH

Multi-step analog/digital converter and on-line calibration method thereof

InactiveUS20060208933A1Decrease phenomenonPrecision requirement of the residue amplifier are reducedElectric signal transmission systemsAnalogue/digital conversion calibration/testingEngineeringAnalog signal processing

The present invention discloses an on-line calibration method, which utilizes two calibration algorithms running in the background without interrupting the normal operation of the analog signal process. The method includes performing a residue amplifier gain error calibration and performing a DAC non-linearity calibration. The residue amplifier gain error calibration can reduce the gain error of the residue amplifier for a missing code or a missing decision level phenomenon. The DAC non-linearity calibration can relax the matching requirement of passive components in current semiconductor processes. The present invention discloses a two-step ADC (Analog-to-Digital Converter), which includes a first signal processing unit, a second signal processing unit, a programmable gain control unit and a programmable reference voltage generator, performing the on-line calibration method.

Owner:NATIONAL TSING HUA UNIVERSITY

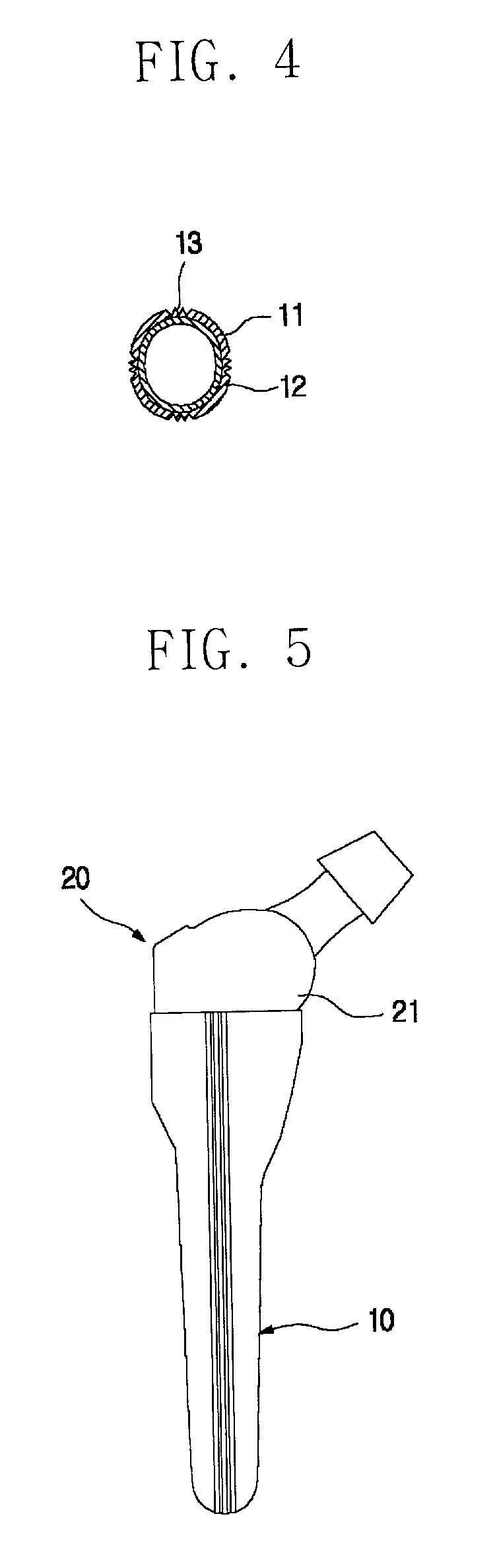

Cement jacket for a cemented artificial joint stem and artificial joint having the cement jacket

InactiveUS20010014828A1Increase anchorageEasy dischargeBone implantJoint implantsHigh resistanceFiber

The present invention relates to a cement jacket for a cemented artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced while the compressive force beneficial for the strengthening of the bone is significantly increased and stress shielding phenomena which makes the bone resorbed can also be markedly relieved, due to the construction of the cement jacket which can be fixed within the bone canal and can enclose the surface of the stem so as to allow for the artificial joint stem to slide vertically relative to the bone, and wherein the osteolysis of a femur due to the infiltration of wear particle can be minimized by curbing the gap formation between the femur and the stem. According to the invention, there is provided a cement jacket 10 for an artificial joint stem 21 for enclosing at least a part of the cemented artificial joint which is inserted longitudinally in the opening formed in the bone canal of a human body. The cement jacket 10 may be made of all cement, or the inner surface of said jacket of cement is coated with a plastic film 12 having a high resistance to abrasion. The cement jacket itself could be reinforced by imbedded wire or fiber. And preferably the outer surface of said cement jacket 10 is formed with discharging paths 13 in the longitudinal direction, so that excessive cement paste poured into the bone canal previously for the surgical purpose can be easily discharged upward at the time of inserting the jacket. (FIG. 2).

Owner:KOREA ADVANCED INST OF SCI & TECH

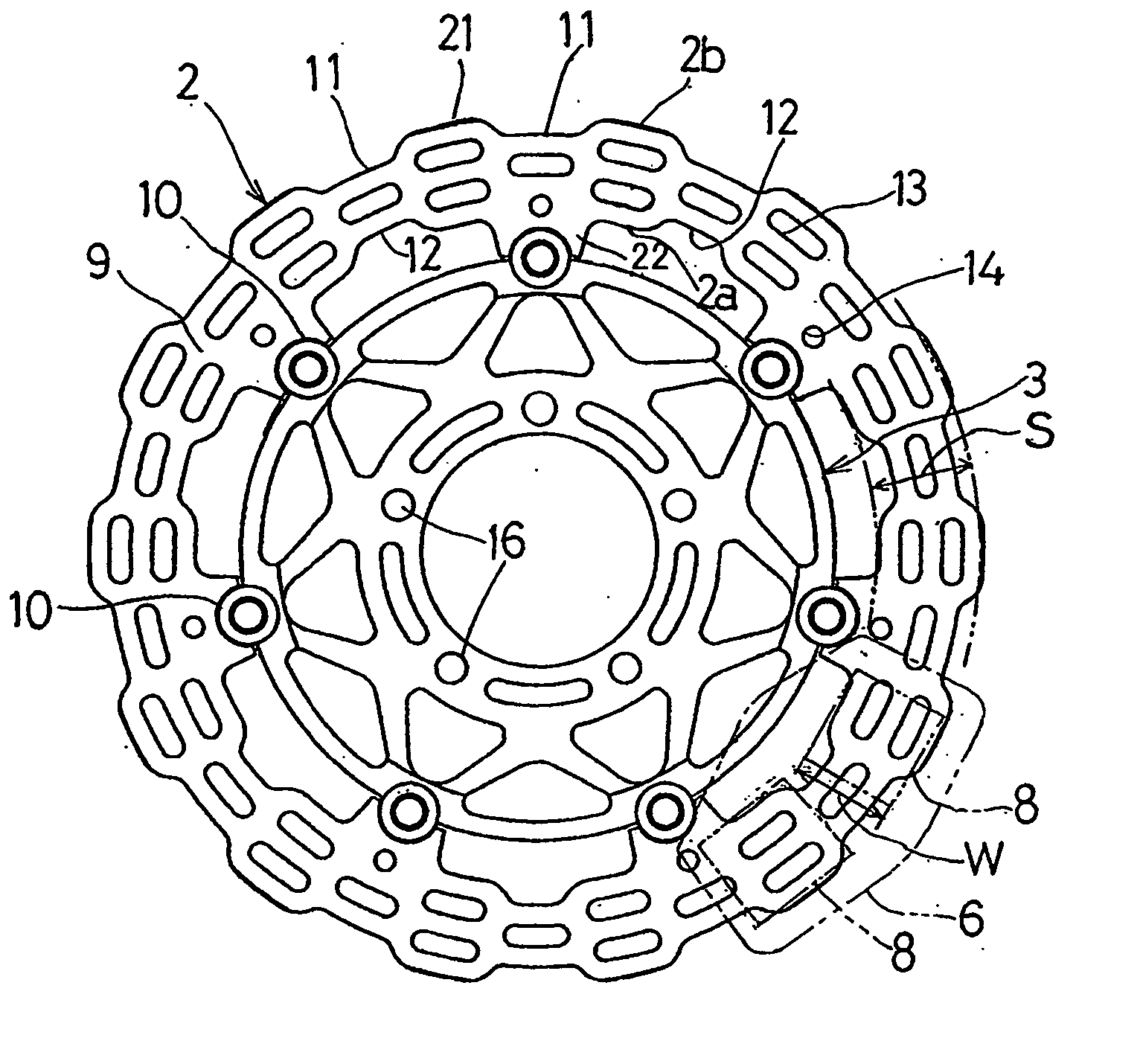

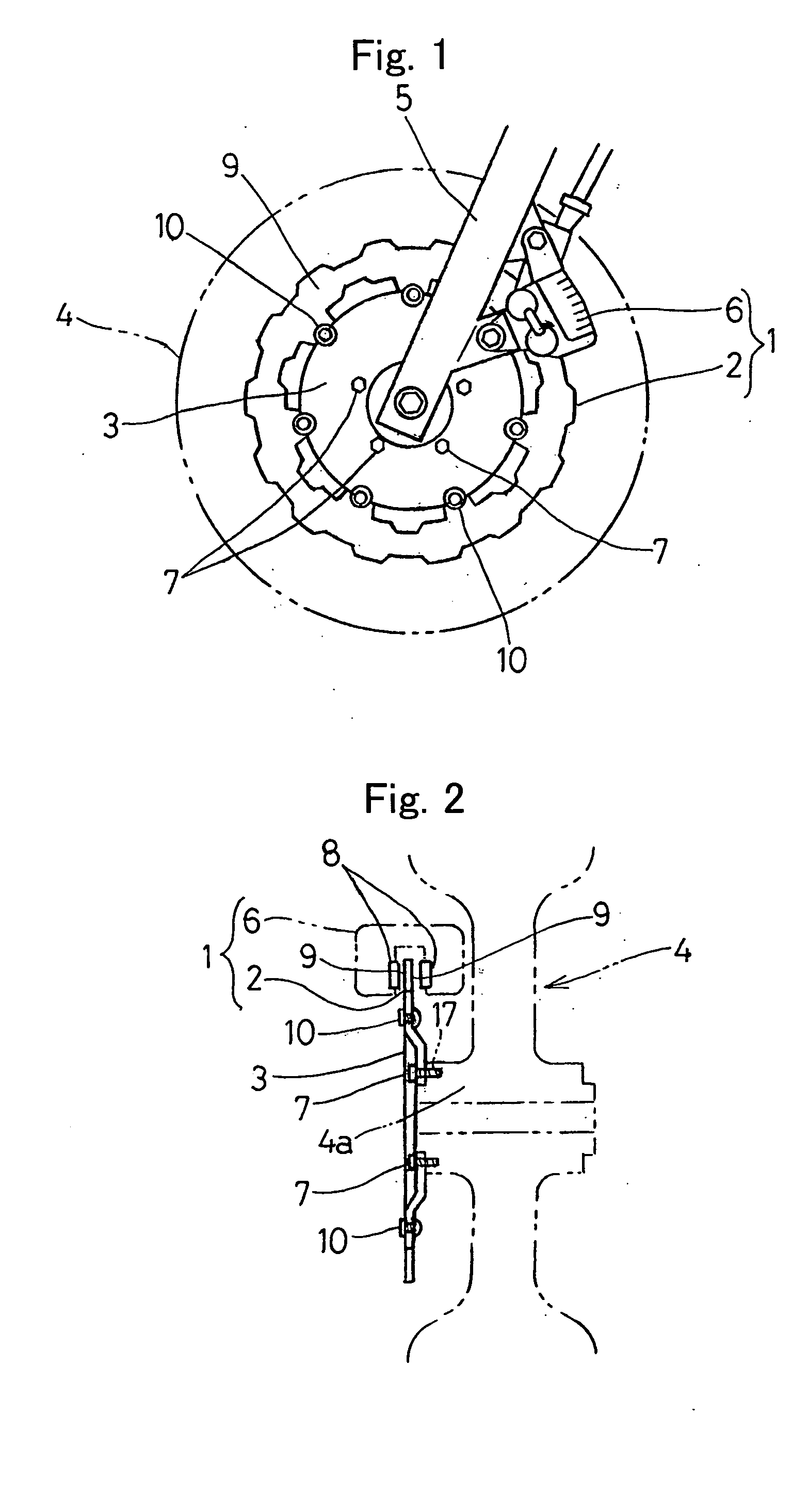

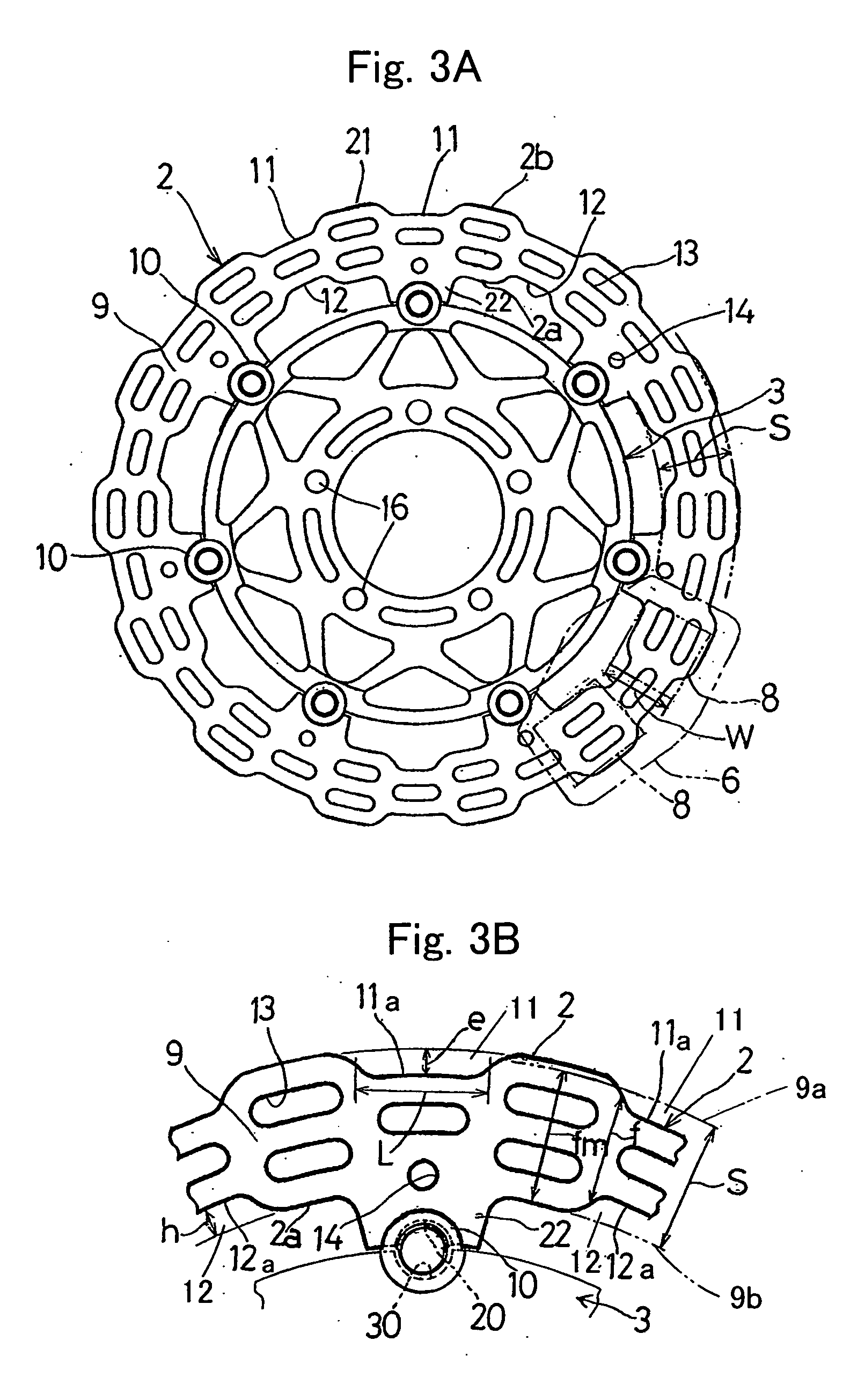

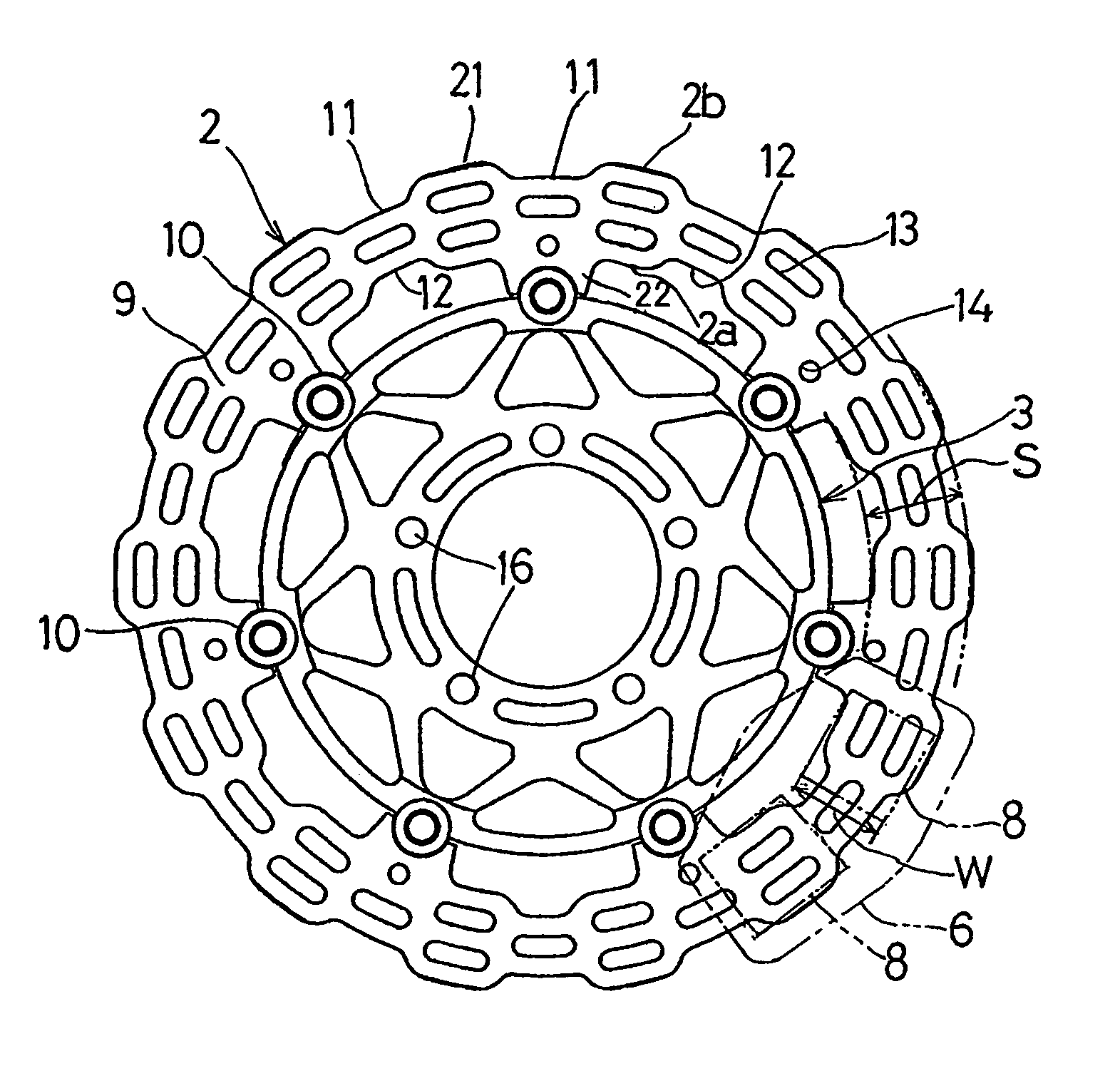

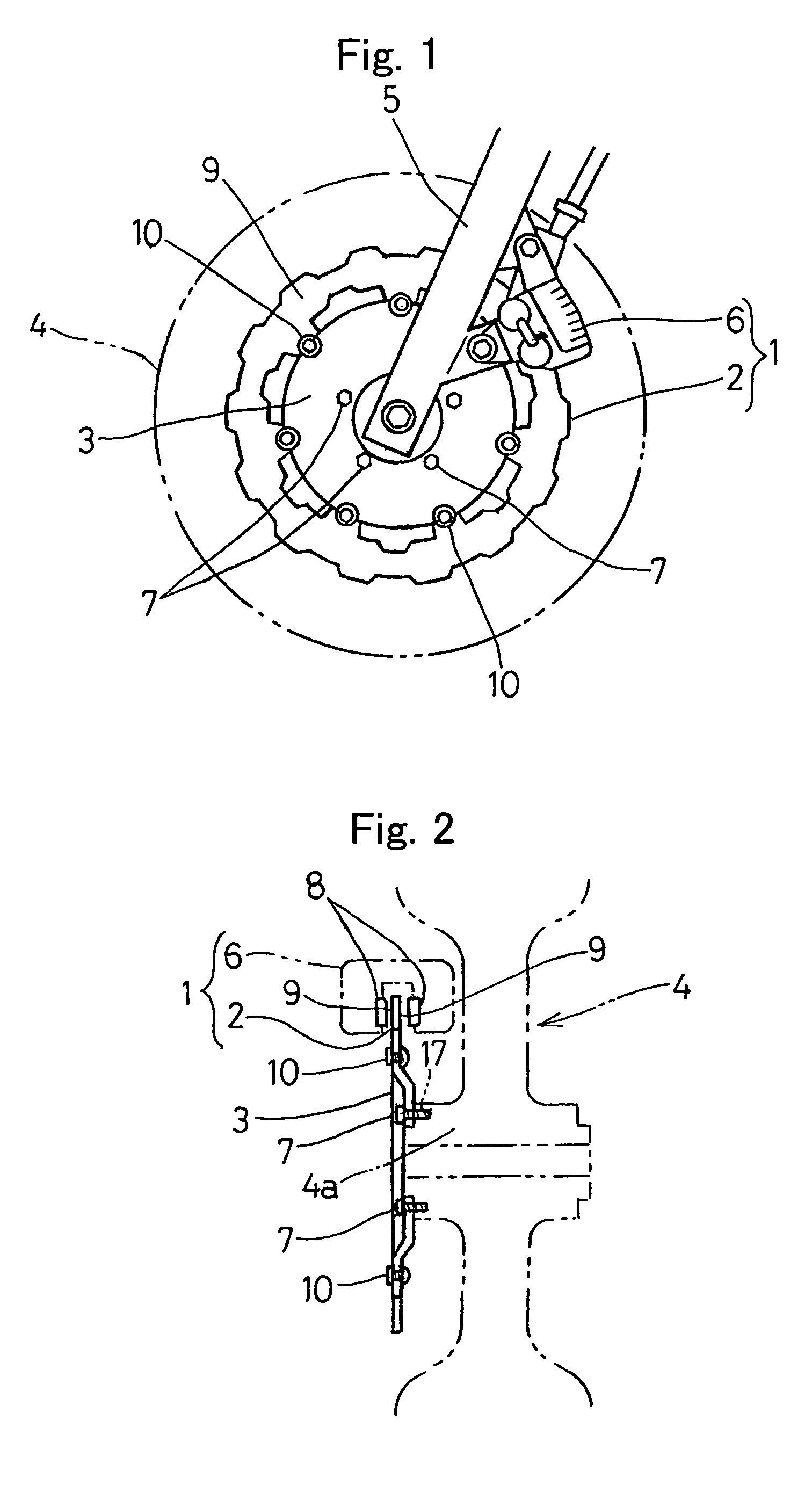

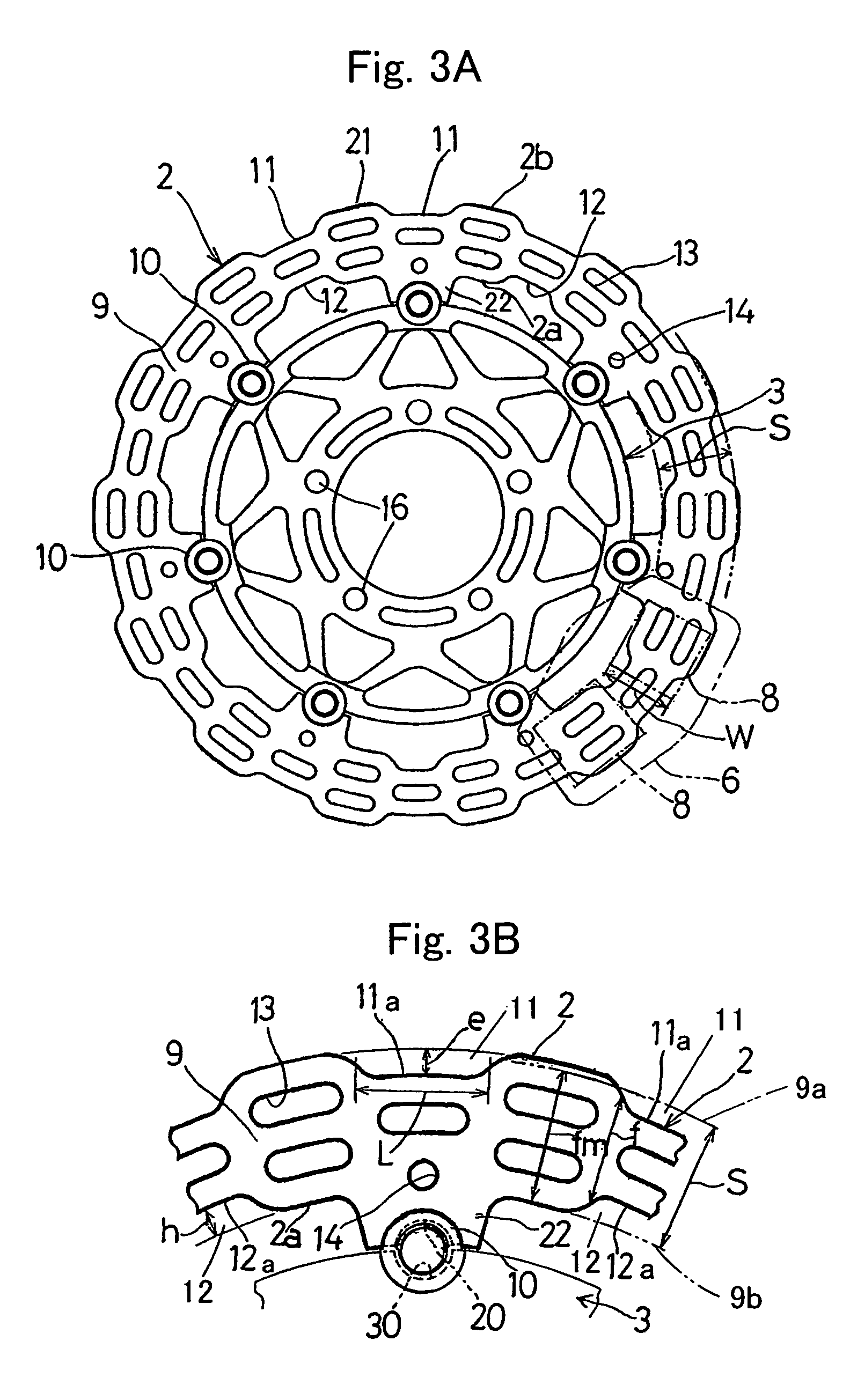

Brake disc for automotive disc brake assembly

ActiveUS20050092561A1Prevent thermal deformationPrevent brake noiseBraking discsCycle brakesThermal deformationEngineering

There is provided a brake disc in a disc brake for a vehicle, which can be manufactured lightweight, suppress the thermal deformation and is effective to prevent the brake noises. This brake disc (2) is supported by a wheel 4 through a plurality of support members (10) and is operable to exert a braking force when sandwiched by frictional pads (8, 8). The brake disc (2) has an outer peripheral face (2b) formed with a plurality of outer recesses (11) deploying in a circumferential direction. Accordingly, the radial width (f) of the braking surfaces (9), with which the frictional pads (8) is engageable, varies in a direction circumferentially thereof.

Owner:KAWASAKI MOTORS LTD

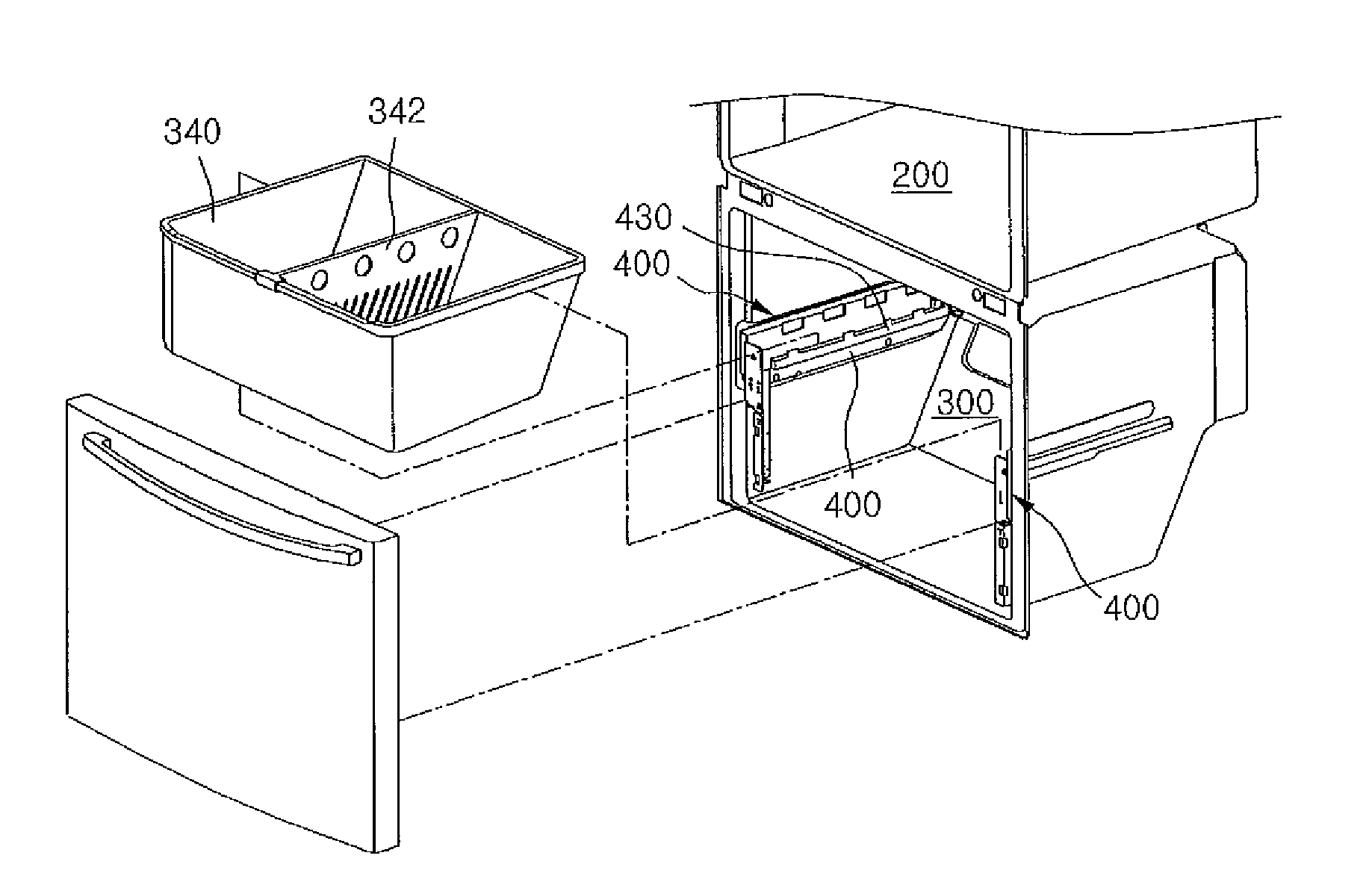

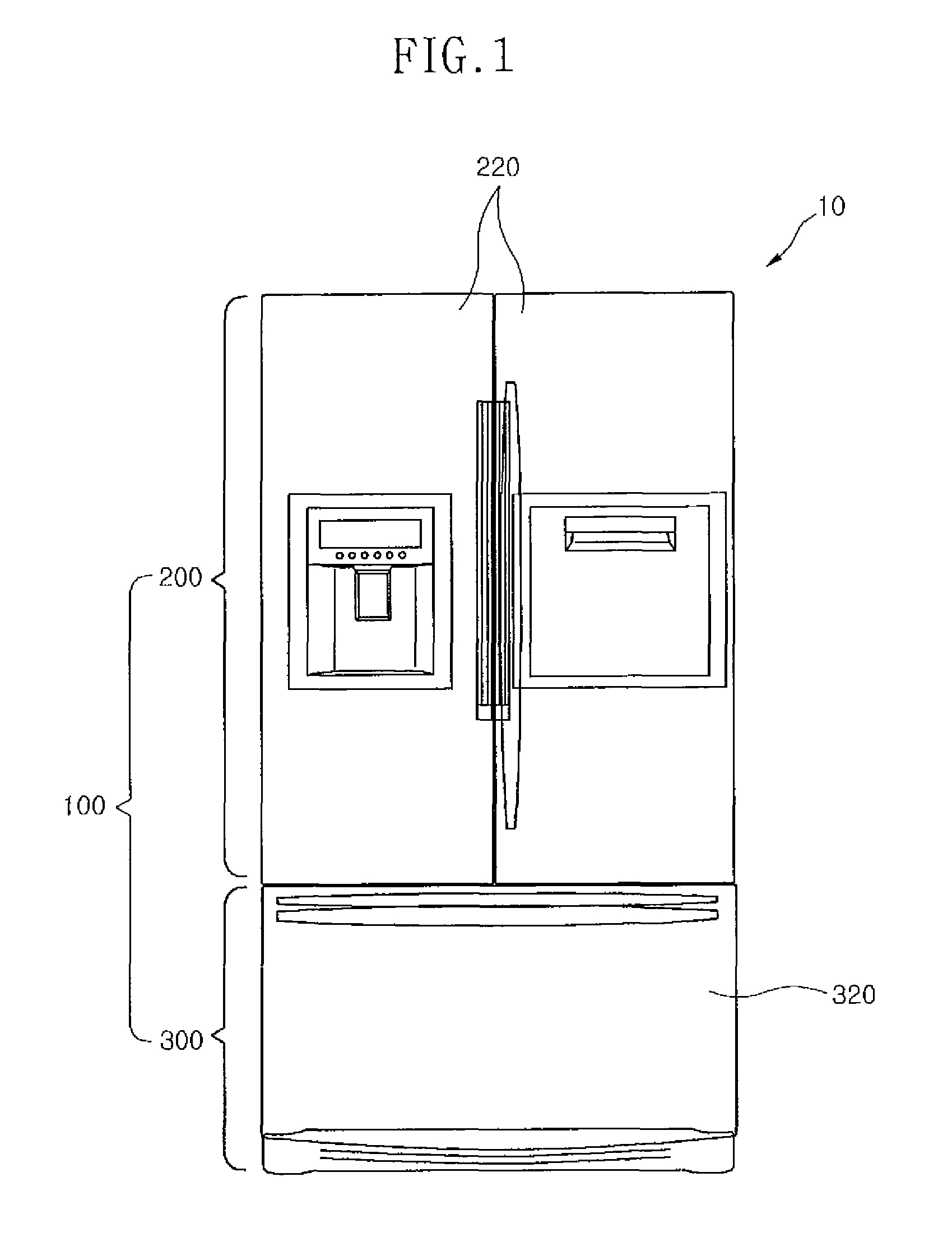

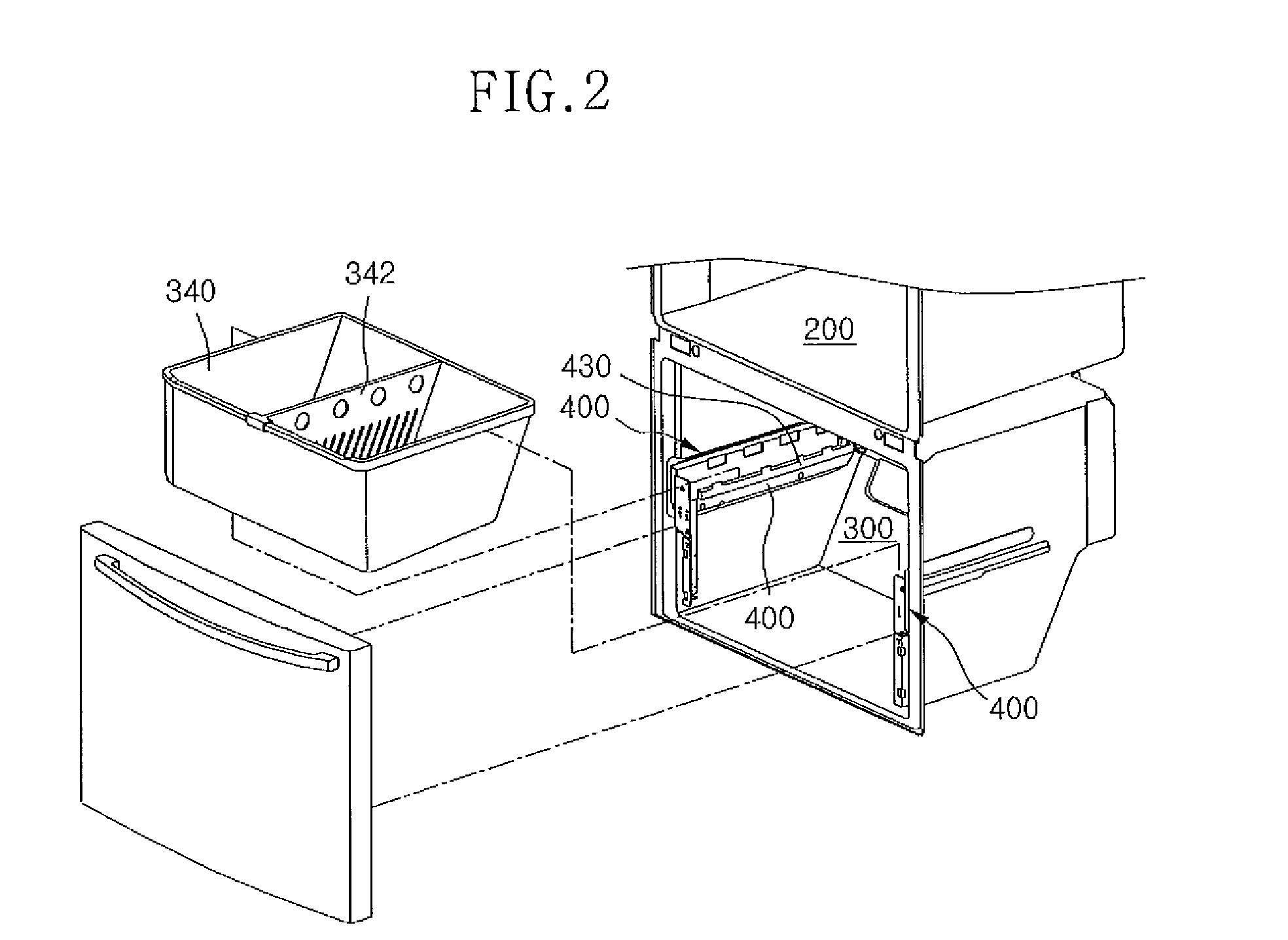

Refrigerator having multiple ice banks

InactiveUS20120024002A1Increase storage capacityDecrease phenomenonLighting and heating apparatusIce productionMarine engineeringCold store

A refrigerator includes: a refrigerator main body including a freezing chamber positioned at a lower portion thereof and a refrigerating chamber positioned at an upper side of the freezing chamber; an ice maker positioned at a portion in any of the freezing chamber and the refrigerating chamber; first and second ice banks storing ice made by the ice maker; an ice dispenser supplying ice stored in the first ice bank and positioned in the refrigerating chamber; and an ice transfer unit transferring ice between the first and second ice banks, wherein the first and second ice banks are installed in separate spaces which are thermally insulated and maintained at a different temperature, respectively.

Owner:LG ELECTRONICS INC

Refrigerator

ActiveUS8152254B2Decrease phenomenonImprove convenienceLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

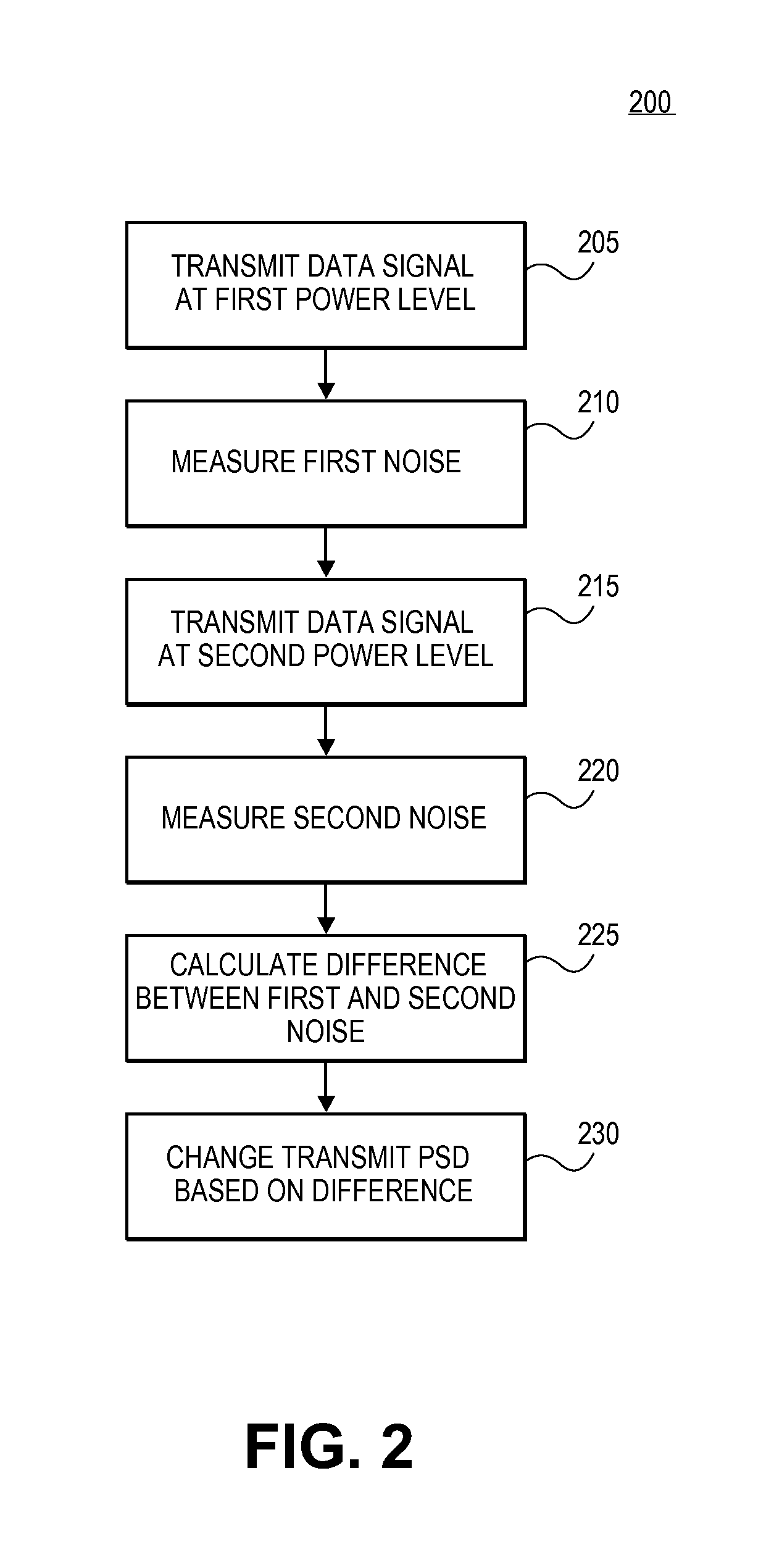

Progressive trimming method

ActiveUS8679944B2Limit heating and stressDecrease phenomenonSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWafer bonding

The invention provides a method of trimming a structure that includes a first wafer bonded to a second wafer, with the first wafer having a chamfered edge. The method includes a first trimming step carried out over a first depth that includes at least the thickness of the first wafer and over a first width determined from the edge of the first wafer. A second trimming step is then carried out over a second depth that includes at least the thickness of the first wafer and over a second width that is less than the first width.

Owner:SOITEC SA

Brake disc for automotive disc brake assembly

InactiveUS7331433B2Prevent thermal deformationAvoid noiseBraking drumsBraking discsThermal deformationEngineering

Owner:KAWASAKI MOTORS LTD

Cooking basket for pressure cooker comprising means for adjusting the passage of steam

InactiveUS7481154B2Decrease phenomenonShorten the timeCooking-vessel materialsRefuse receptaclesEngineeringMaterial Perforation

The invention provides a food-cooking basket for pressure cooking in a pressure cooker, the basket being formed by a sheet of rigid material defining a bottom and side walls of the basket. The sheet is provided with perforations that are made through the bottom and through the side walls. The basket is provided with a structure for adjusting the flow rate of steam passing through the basket via the perforations, the structure being associated with the bottom in such a manner as to enable the flow rate of steam through the perforations at least in the bottom to be adjusted. The invention is applicable to appliances for pressure cooking.

Owner:SEB SA

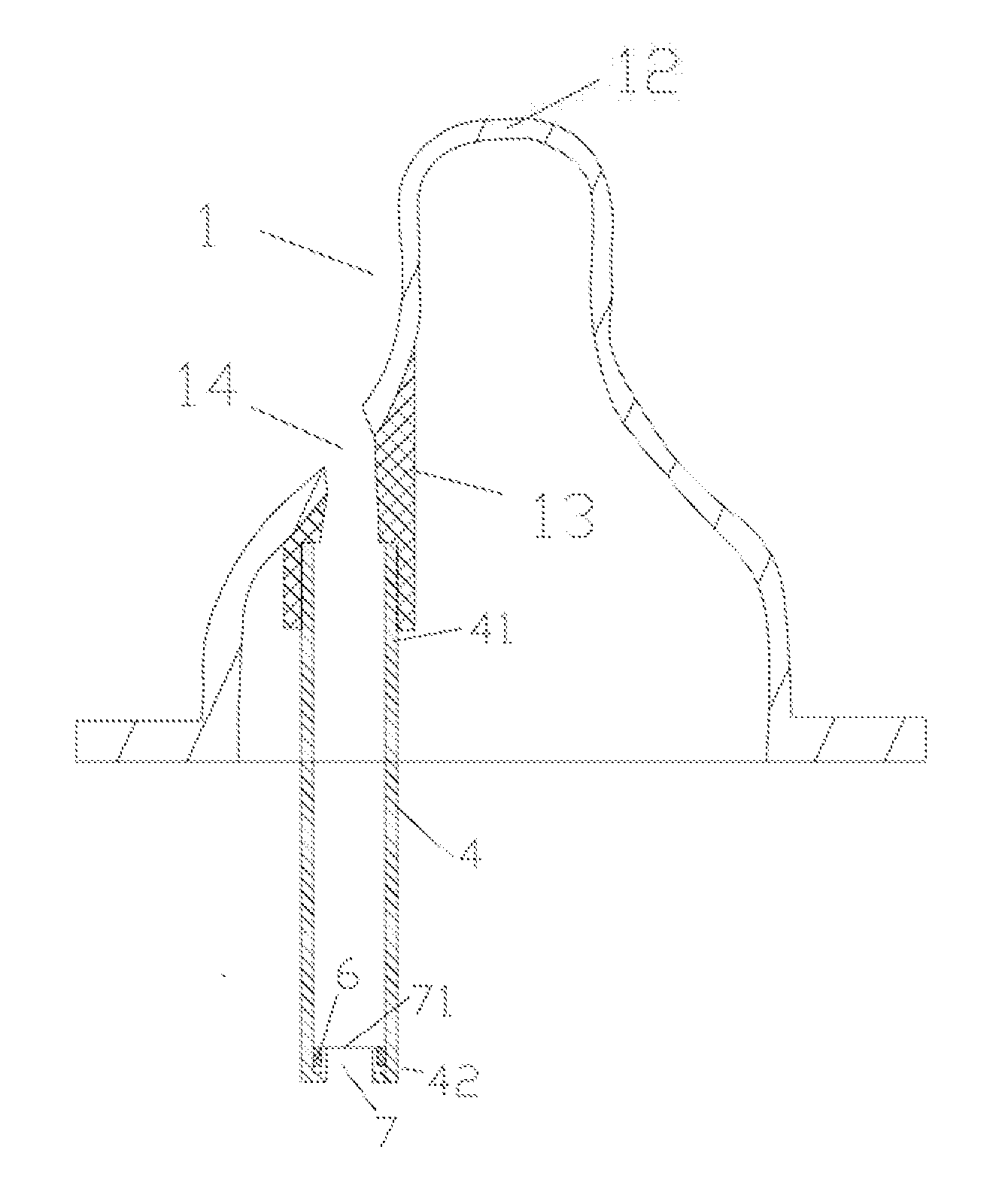

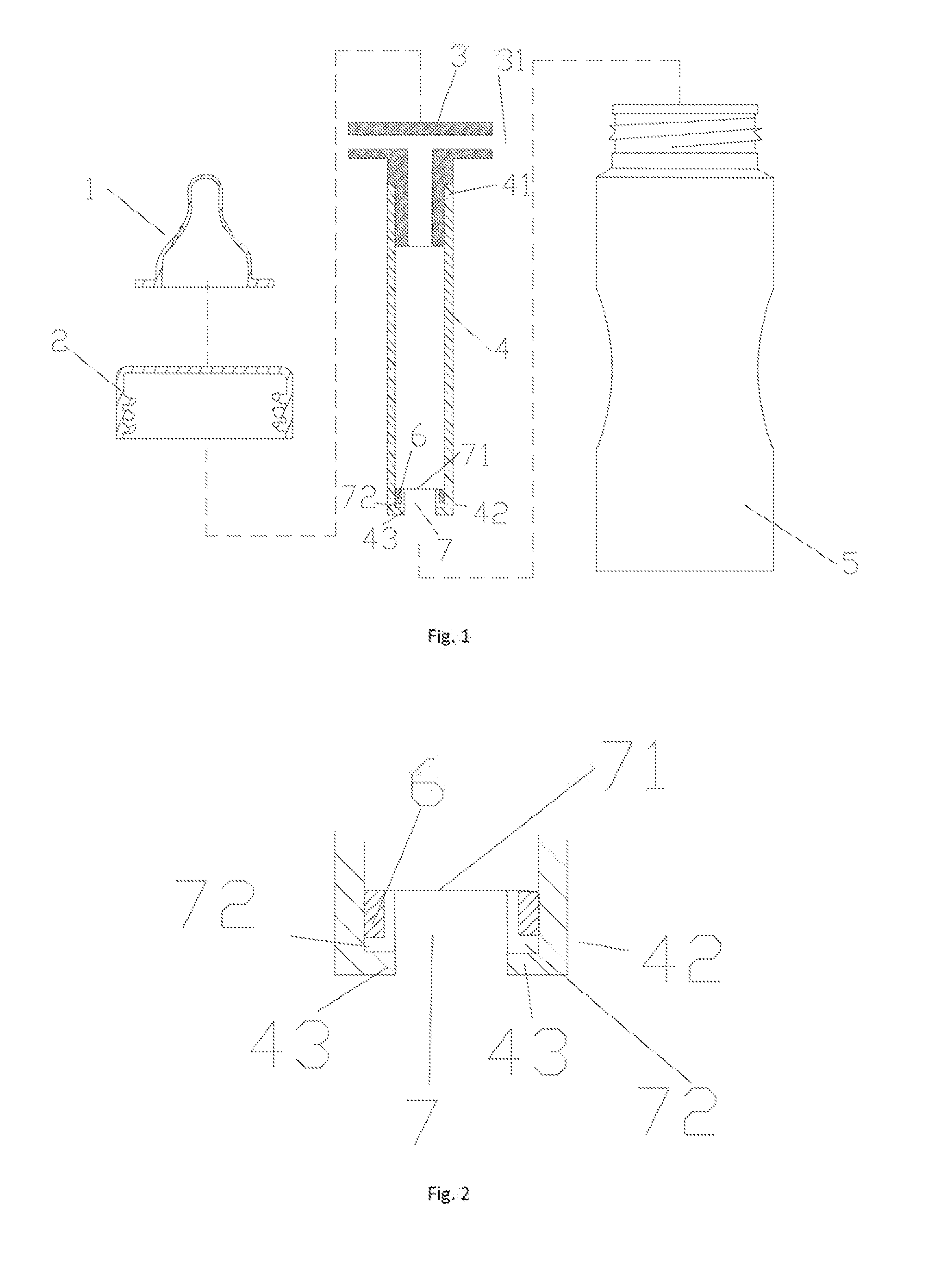

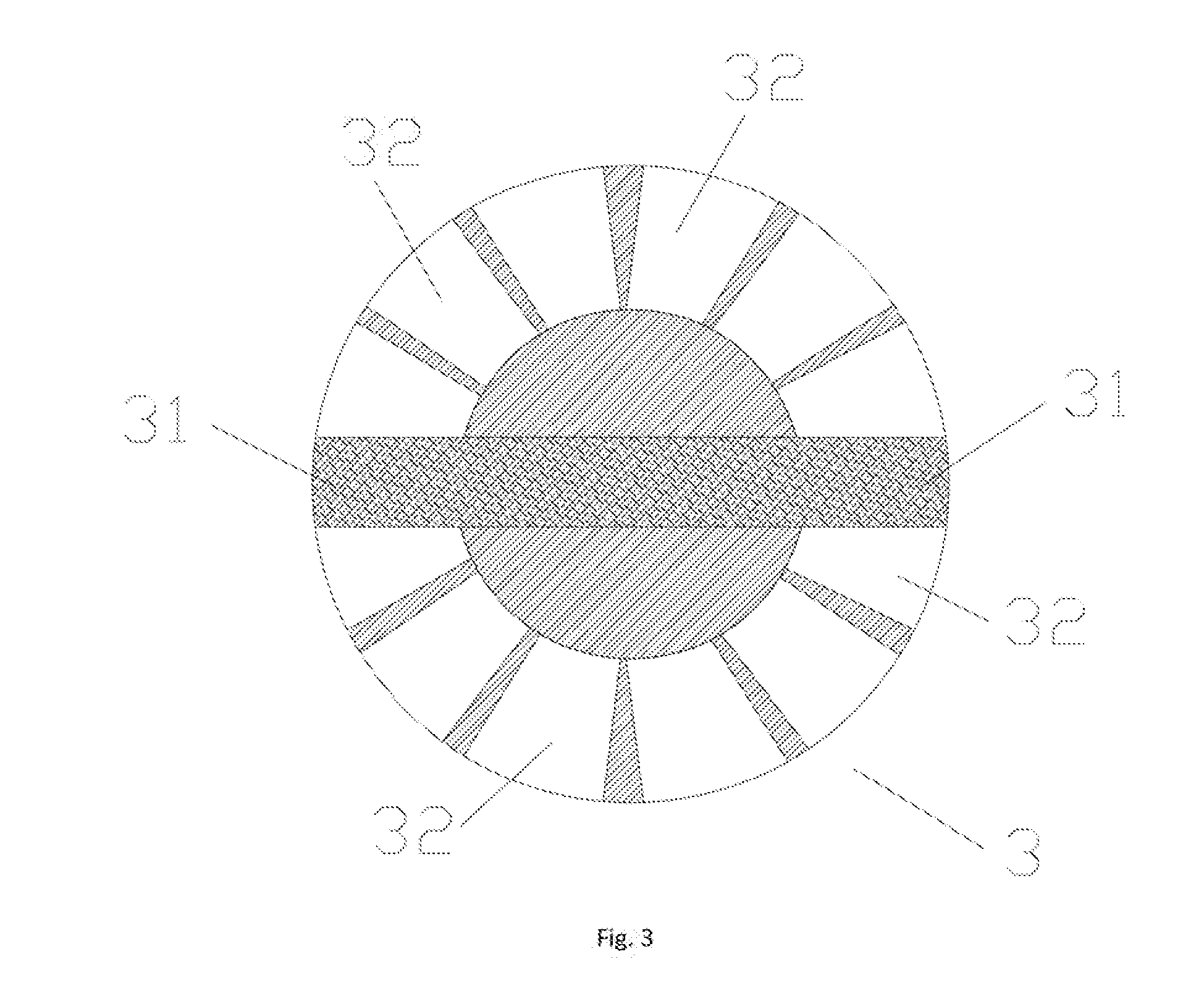

Nursing bottle having air returning function

InactiveUS20160346168A1Decrease phenomenonSimple manufacturing processFeeding-bottlesTeatsReturn functionEngineering

A nursing bottle having an air returning function comprises a bottle body, a fixing cover, a nipple, a ventilation component, an air conduit, an elastic one-way valve set at a second opening of the air conduit and is located at the interior of the air conduit, a mounting pan located on the second opening of the air conduit to secure the elastic one-way valve. The ventilation component, the air conduit, the elastic one-way valve and the mounting part forms a gas returning device and are located on the interior of the bottle. The present invention reduces the contacting area between the air and the milk, lowering the amount of loss of vitamin. The phenomenon of vomiting milk, choking and flatulence will be omitted since no air bubble is generated.

Owner:SUN QINGYANG

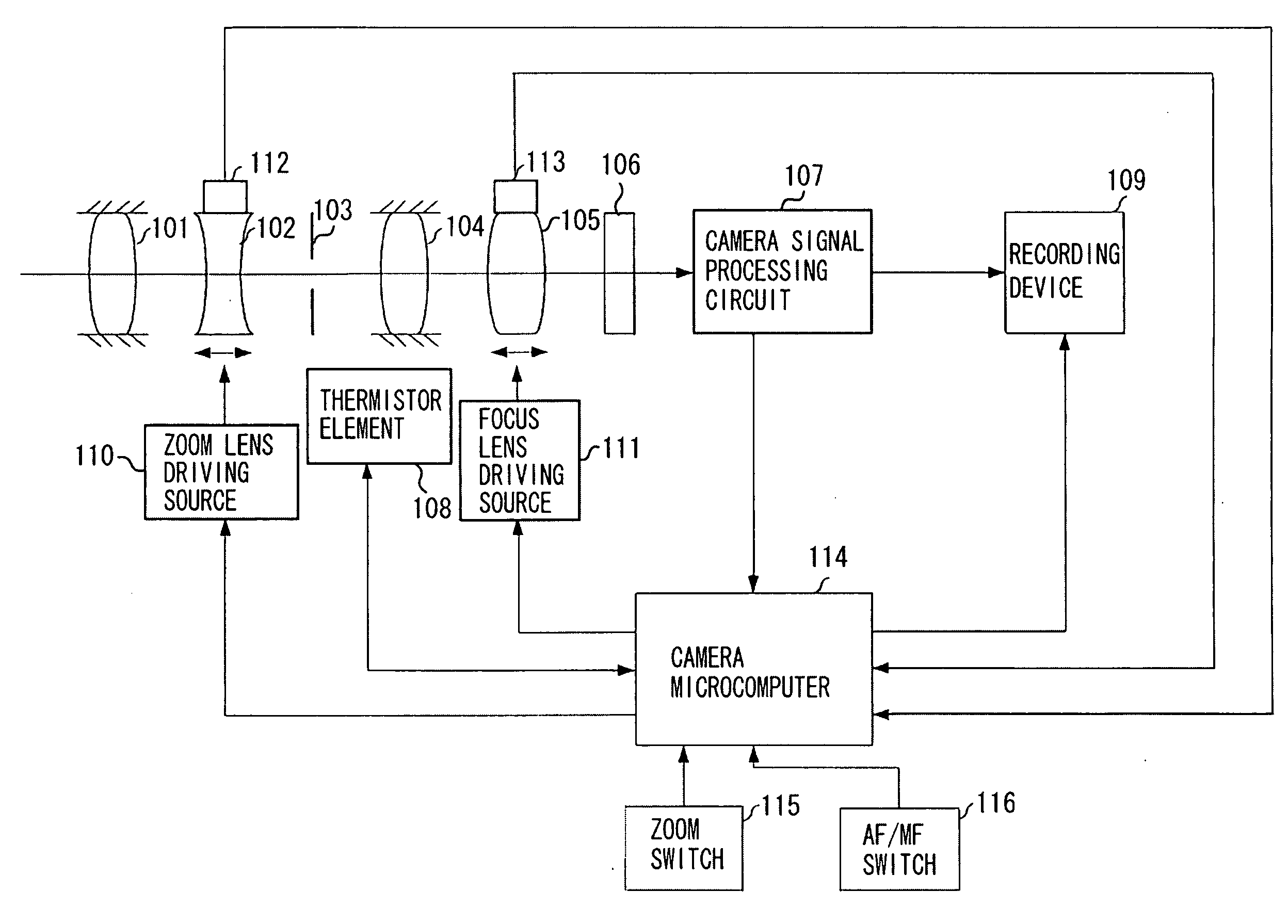

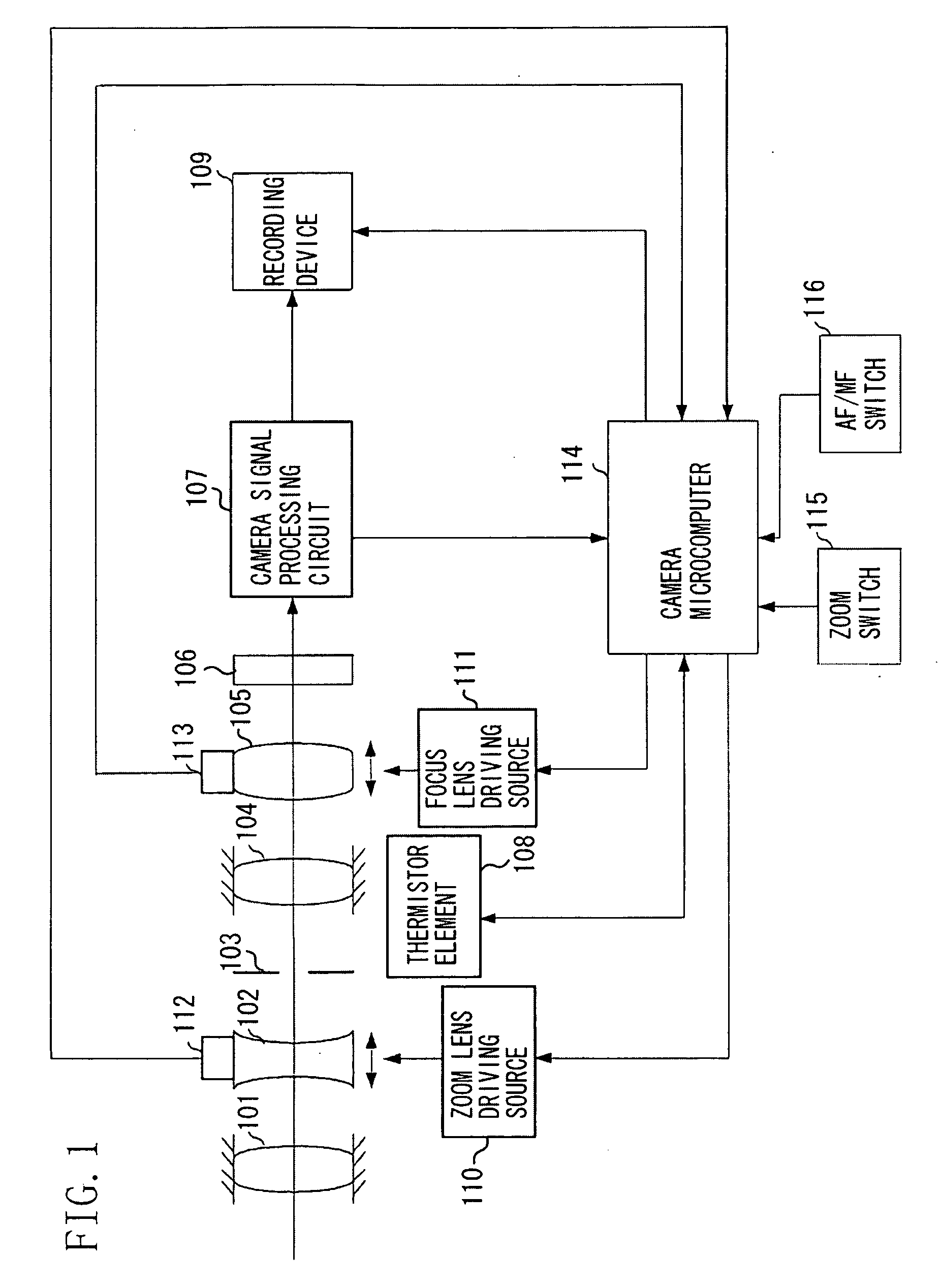

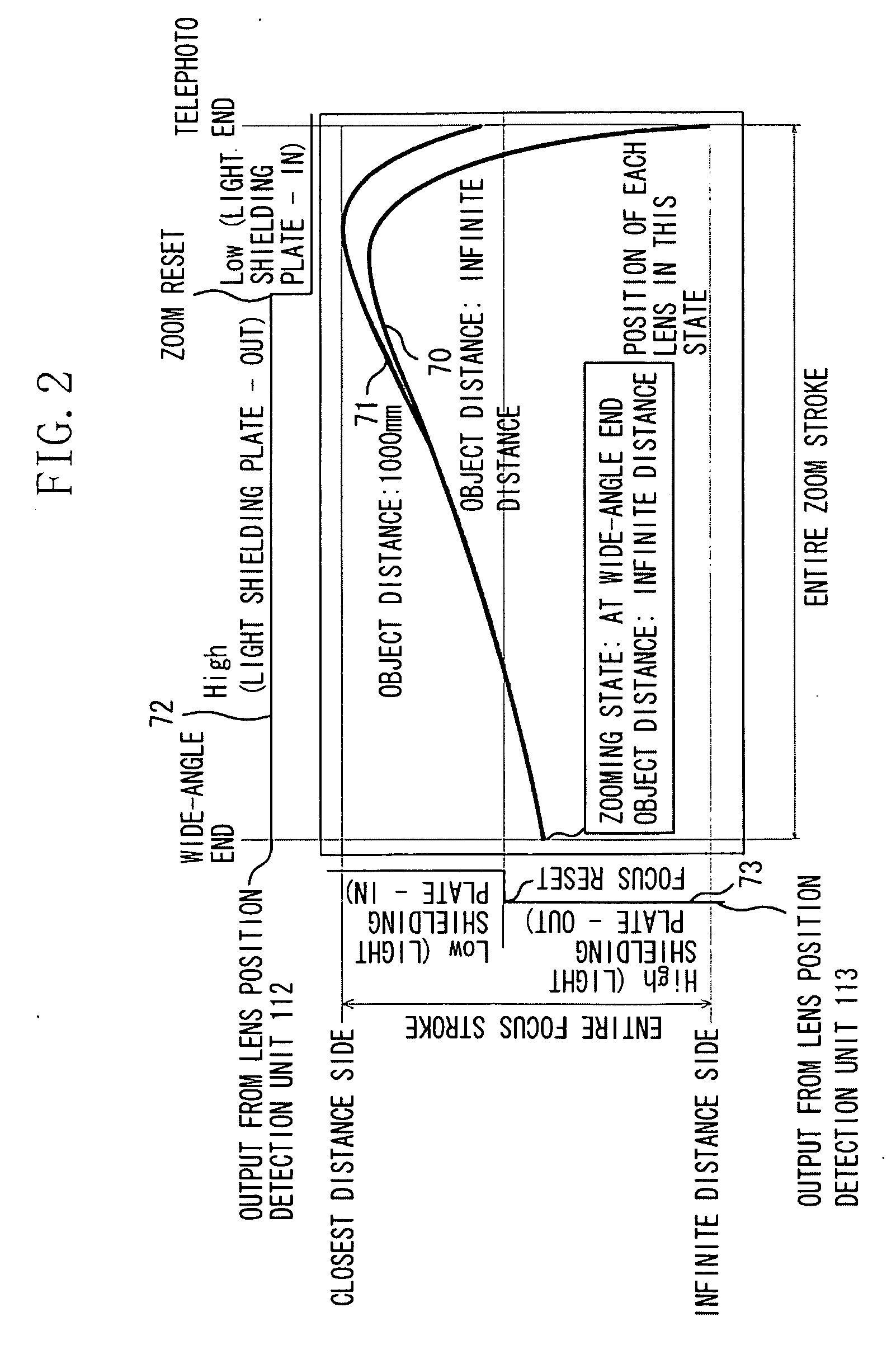

Lens control apparatus, lens barrel, imaging apparatus, and optical apparatus

A lens control apparatus includes a temperature detection unit configured to detect a temperature near a zoom lens and a focus lens, a zoom lens drive unit configured to drive the zoom lens, and a controller configured, if it is determined that a current temperature near the zoom lens and the focus lens detected by the temperature detection unit is higher than a reference temperature, to acquire a telephoto end position to be set at the current temperature, to compare the telephoto end position with a current position of the zoom lens, and to cause the zoom lens drive unit to move the zoom lens to the telephoto end position if the current position of the zoom lens is located beyond the telephoto end position on a telephoto side.

Owner:CANON KK

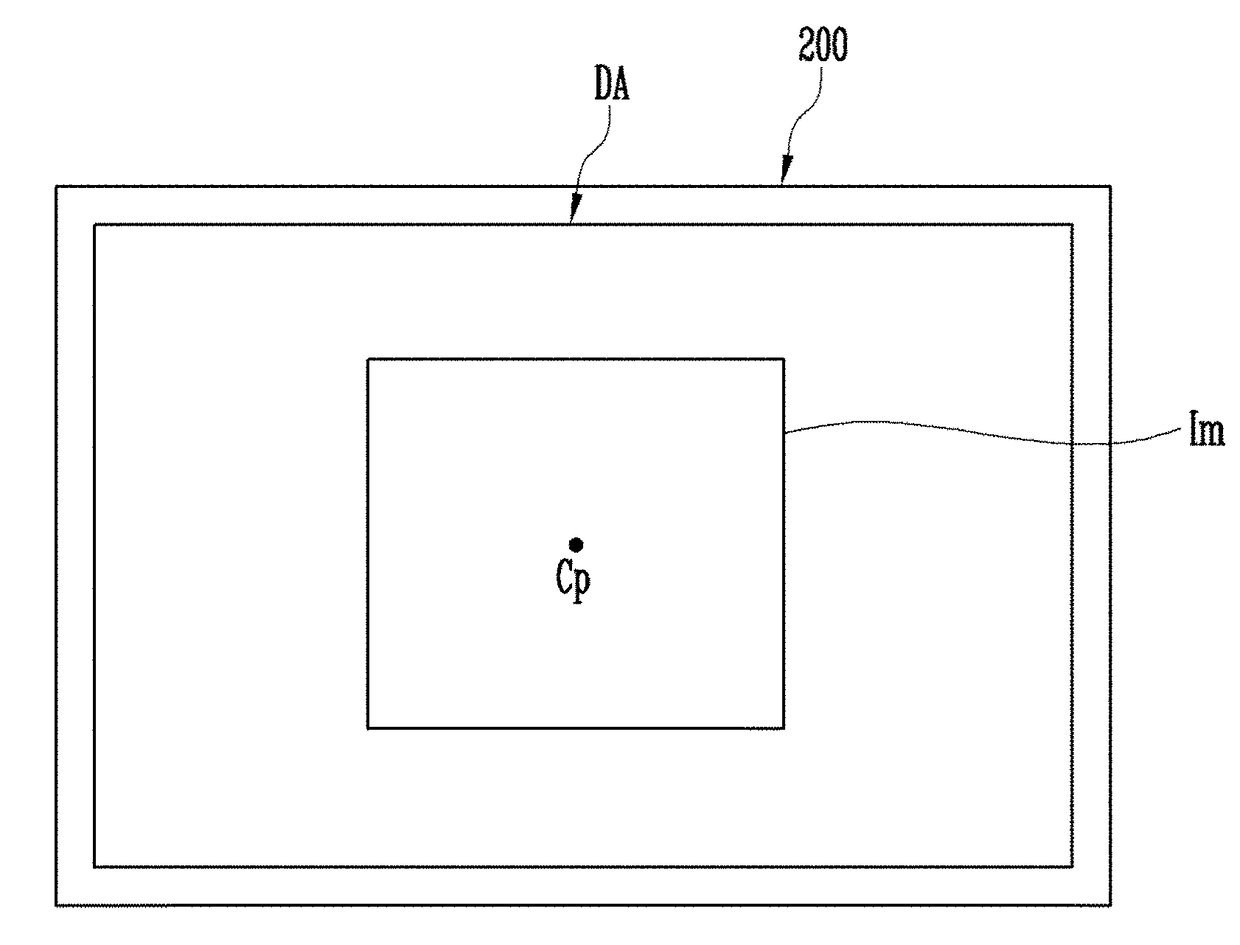

Display device and method for displaying an image thereon

ActiveUS20170221455A1Decrease phenomenonGeometric image transformationCathode-ray tube indicatorsComputer graphics (images)Radiology

In an embodiment of the present invention, a method for displaying an image of a display device includes moving the image displayed on an image display region along a movement path including a first position and a second position during a period of time, wherein, during the period of time, a total time for which the image is located at the first position is greater than a total time for which the image is located at the second position.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com