Patents

Literature

216results about How to "Improve polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

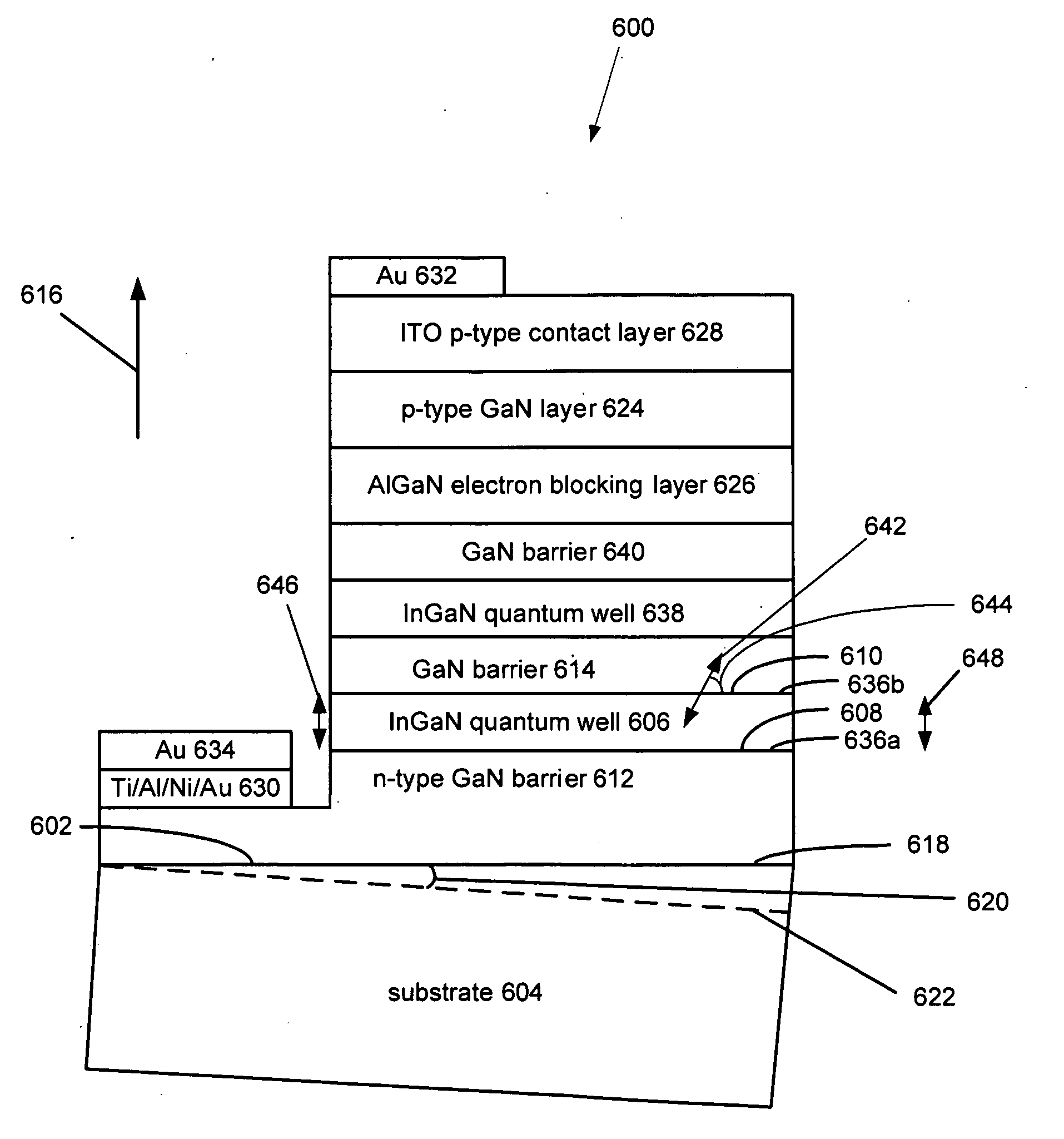

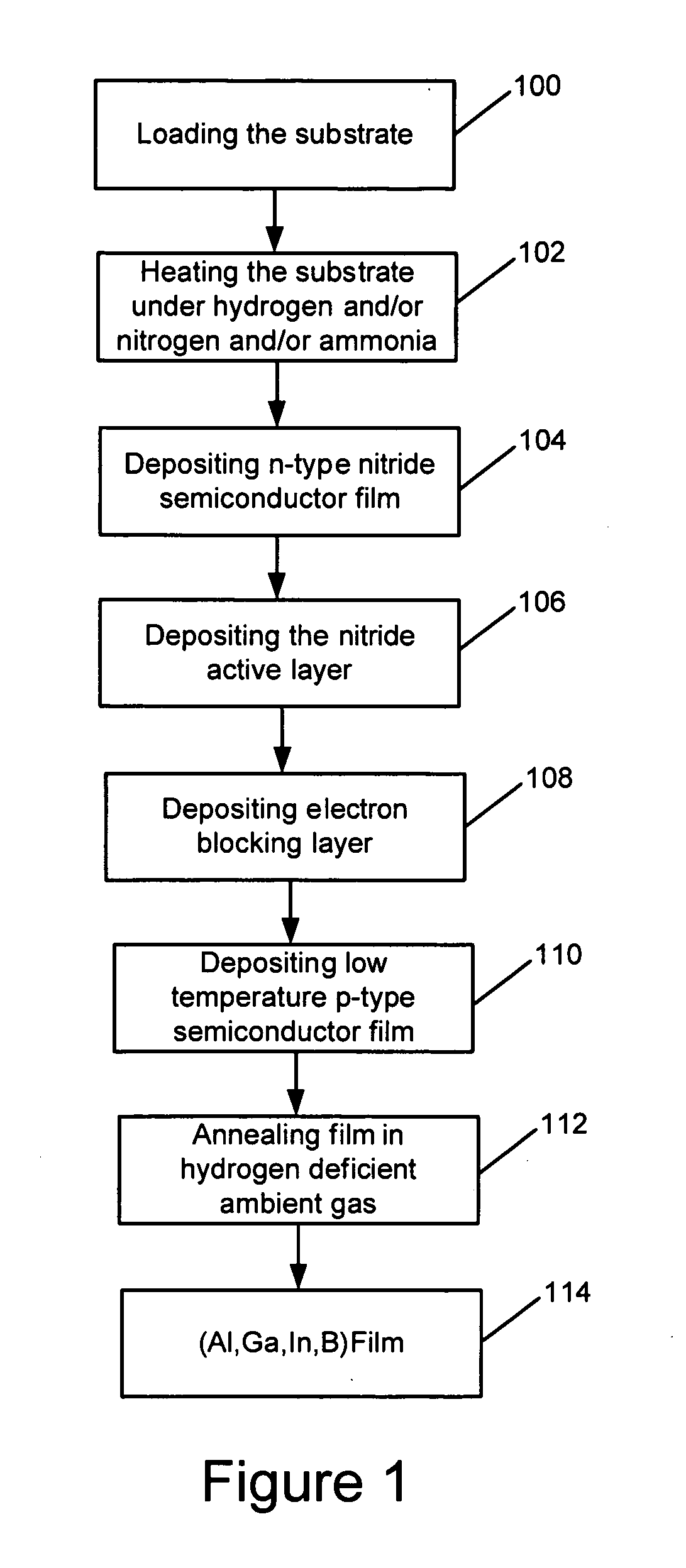

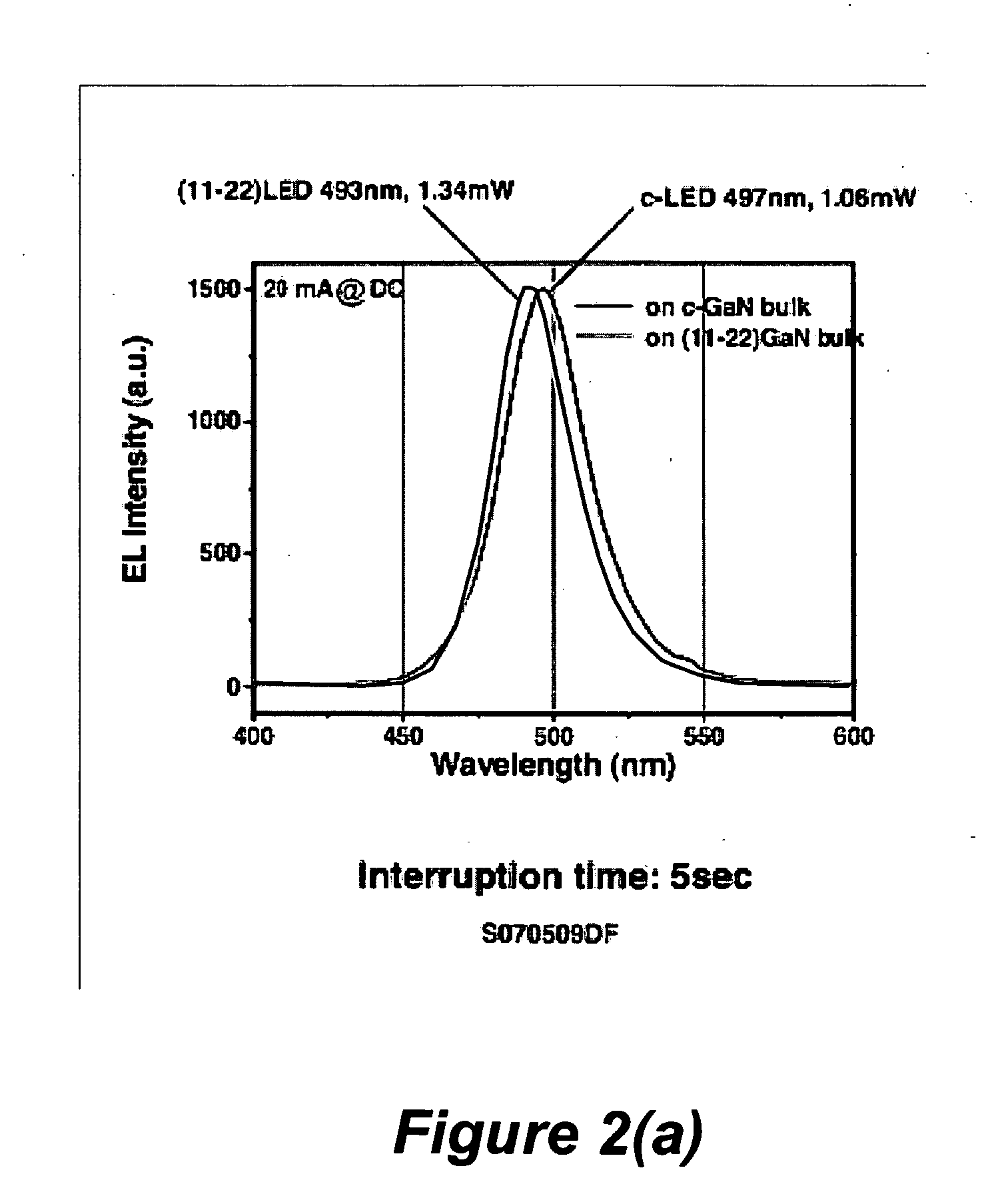

MOCVD GROWTH TECHNIQUE FOR PLANAR SEMIPOLAR (Al, In, Ga, B)N BASED LIGHT EMITTING DIODES

InactiveUS20090310640A1Quality improvementReduced internal electric fieldLaser detailsSemiconductor/solid-state device manufacturingIndiumLength wave

A III-nitride optoelectronic device comprising a light emitting diode (LED) or laser diode with a peak emission wavelength longer than 500 nm. The III-nitride device has a dislocation density, originating from interfaces between an indium containing well layer and barrier layers, less than 9×109 cm−2. The III-nitride device is grown with an interruption time, between growth of the well layer and barrier layers, of more than 1 minute.

Owner:RGT UNIV OF CALIFORNIA

Electric double layer capacitor

InactiveUS6466429B1Lower internal resistanceInhibit sheddingHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonLead dioxide

The present invention is directed to a novel capacitor. The capacitor may be used in electric double layer capacitors. The capacitors include a polarizable electrode including activated carbon and a non-polarizable electrode including lead dioxide and lead sulfate. The capacitors of the present invention provide considerably higher electric capacity, higher durability, and low resistance, while maintaining high conductivity. Additionally, the electrodes may be produced more quickly and inexpensively.

Owner:WAINWRIGHT D WALKER

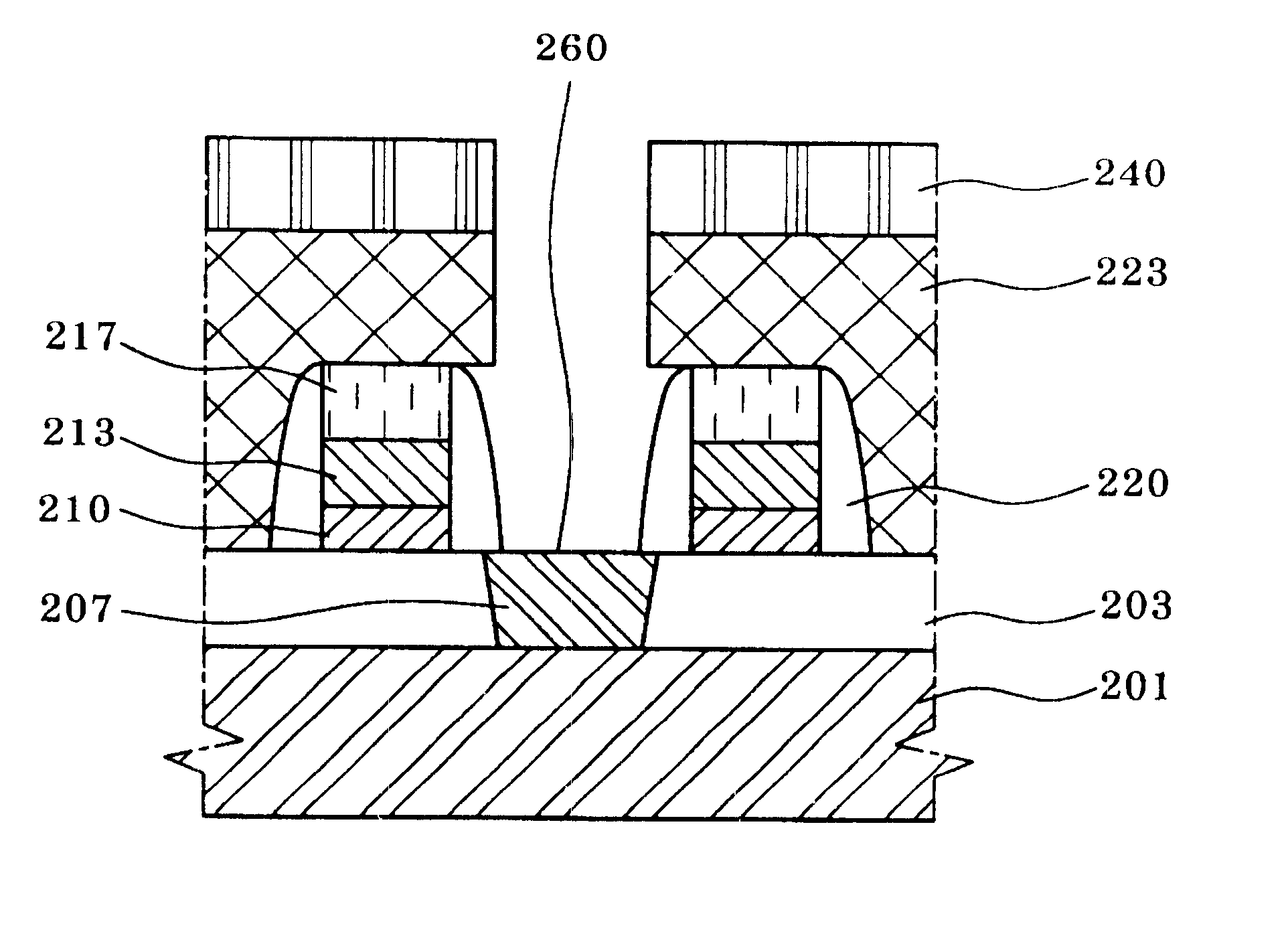

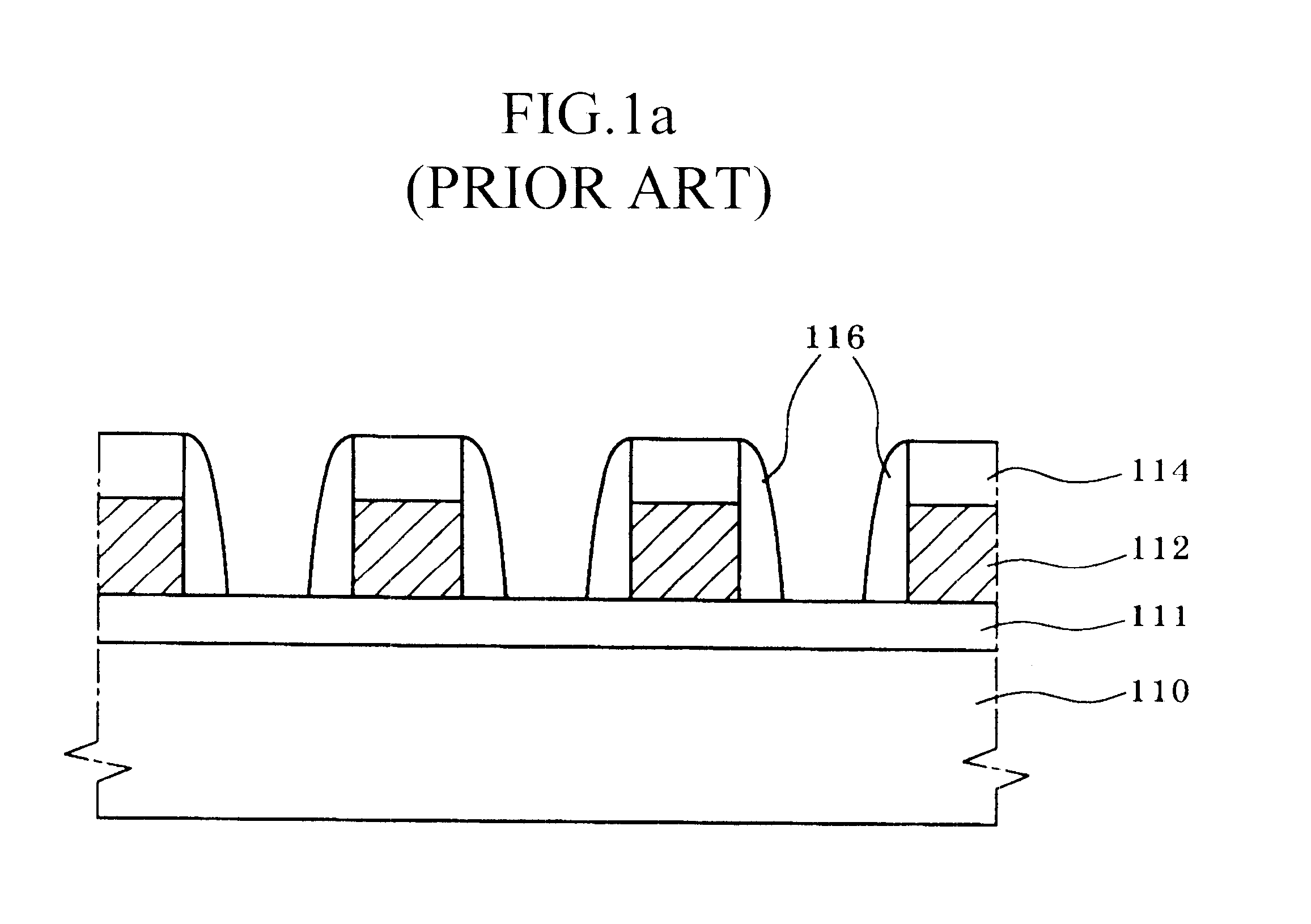

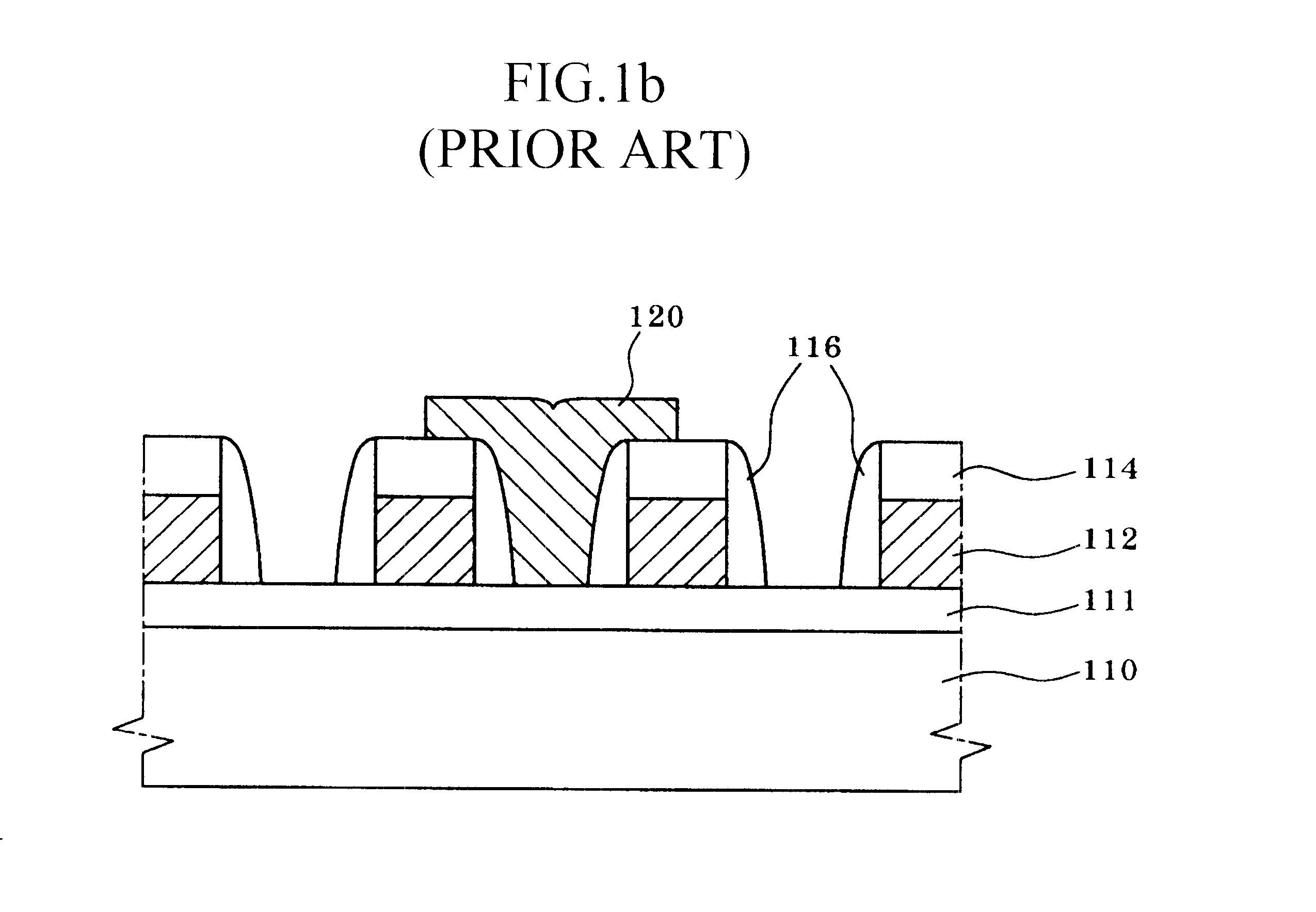

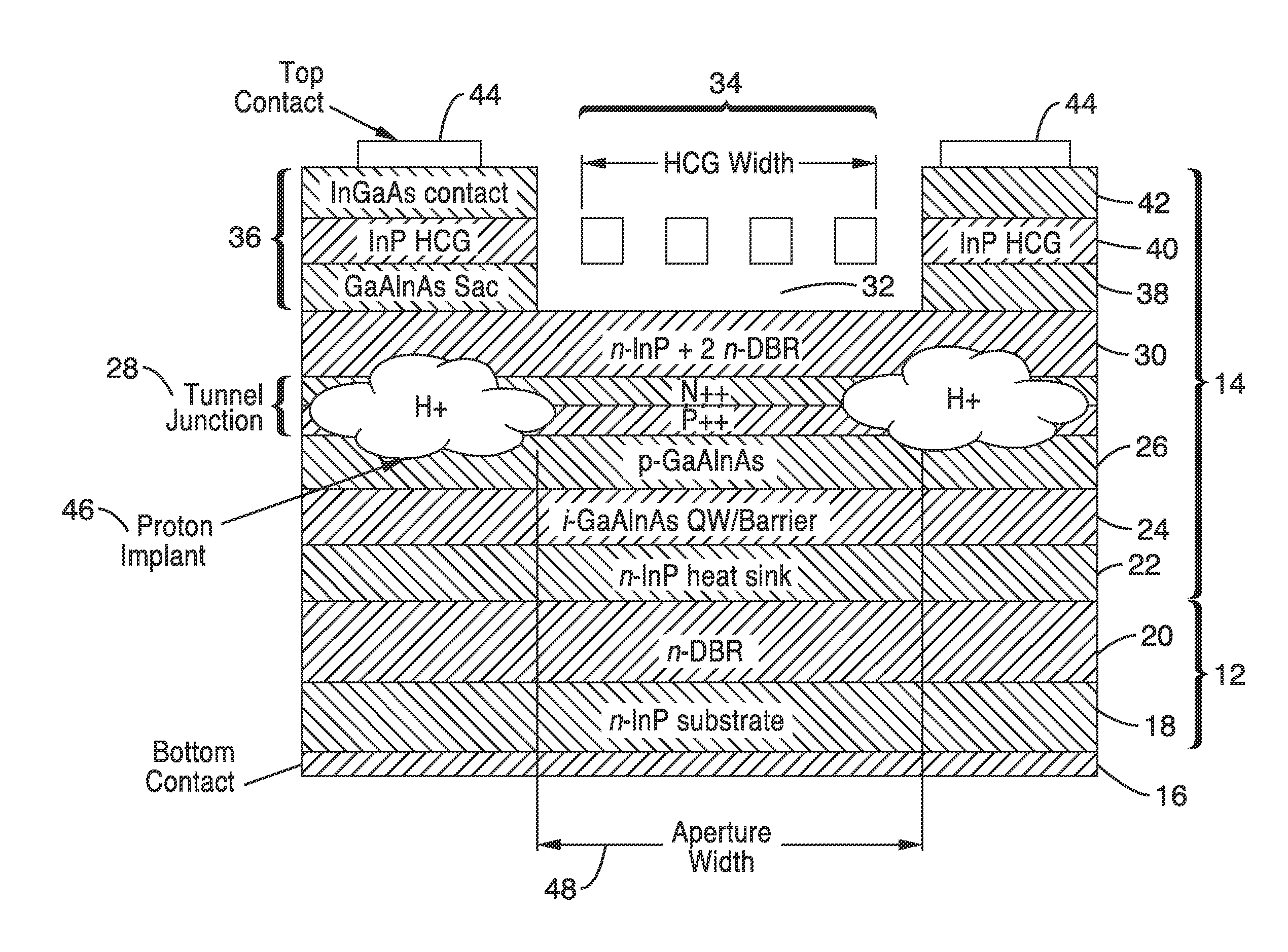

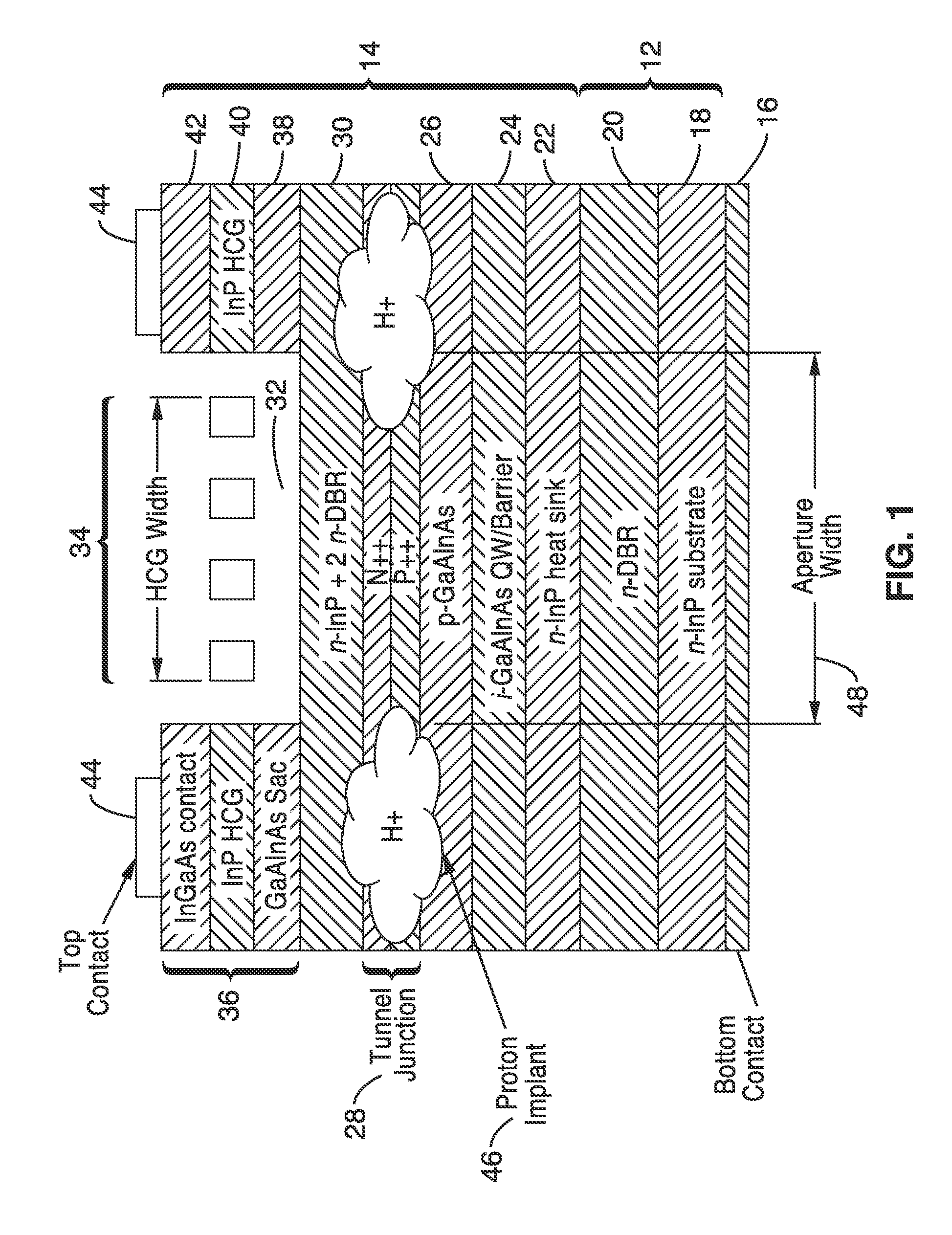

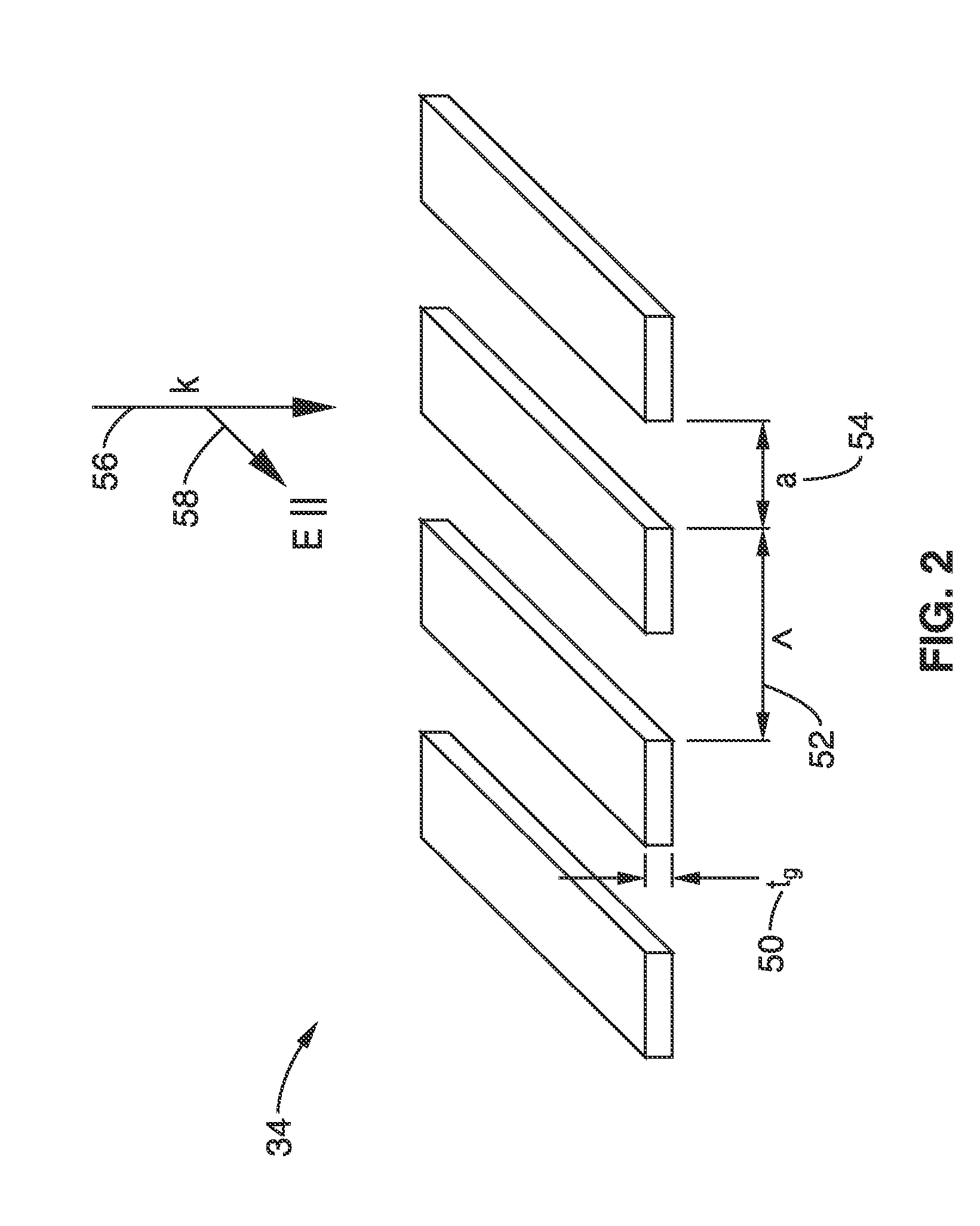

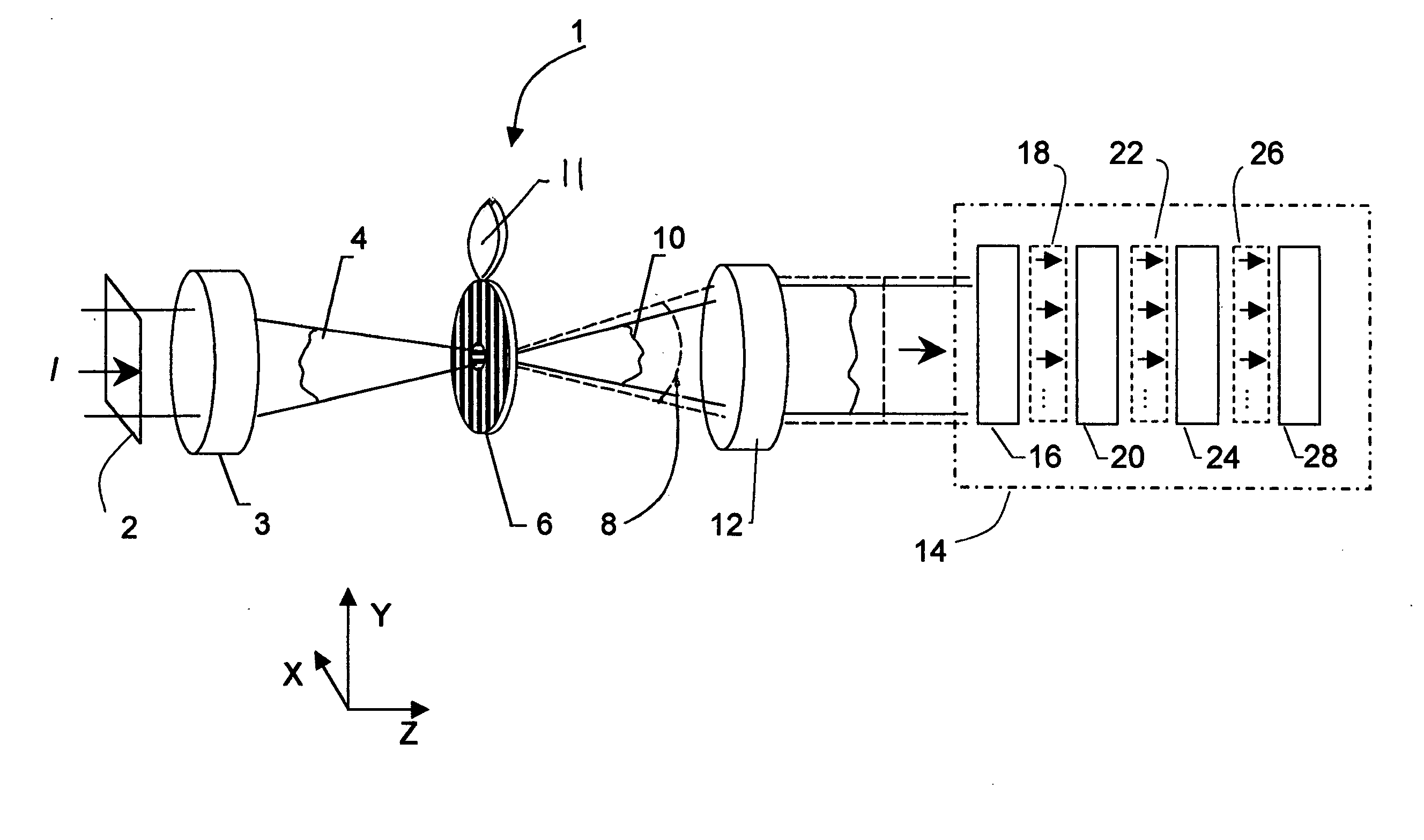

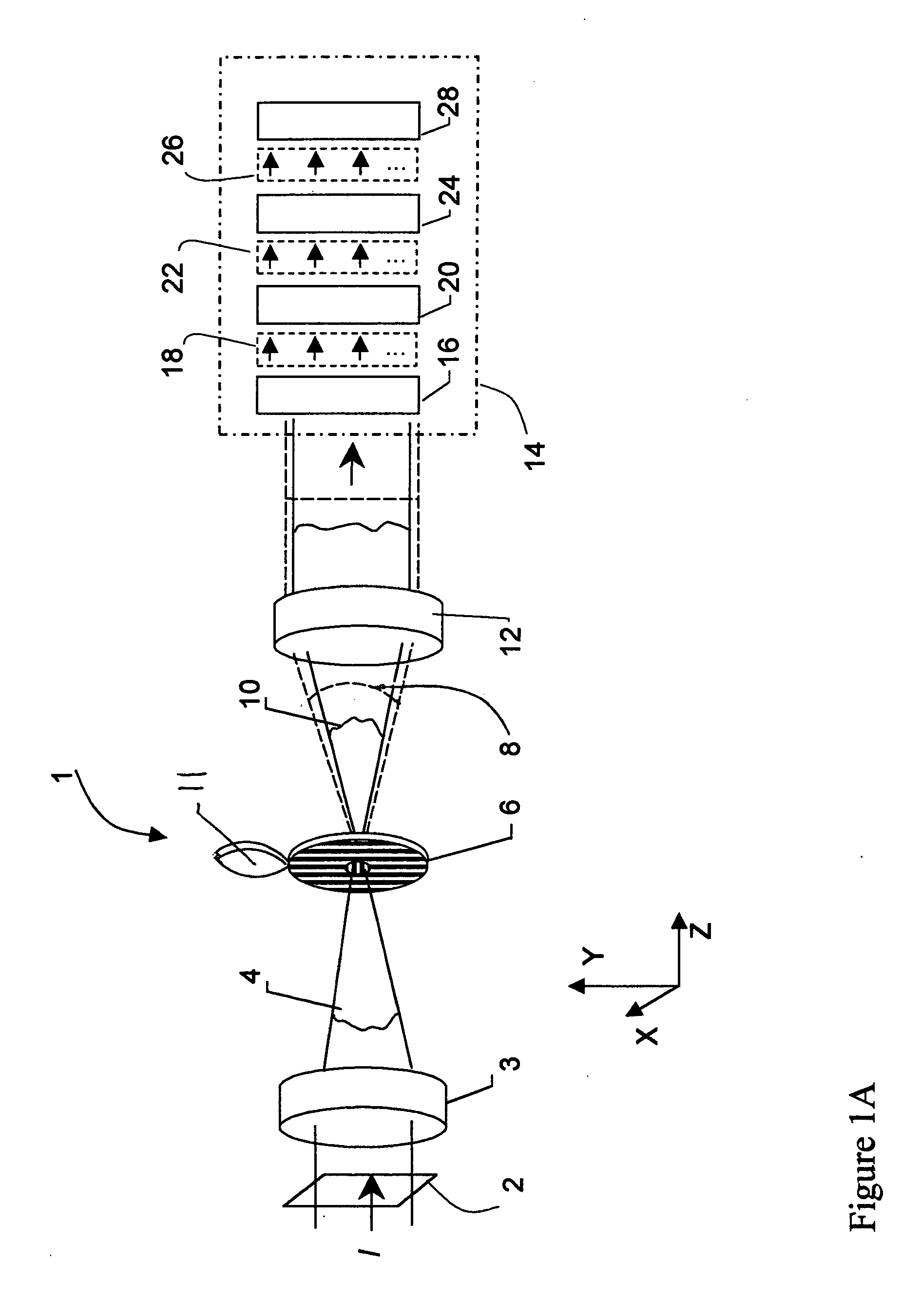

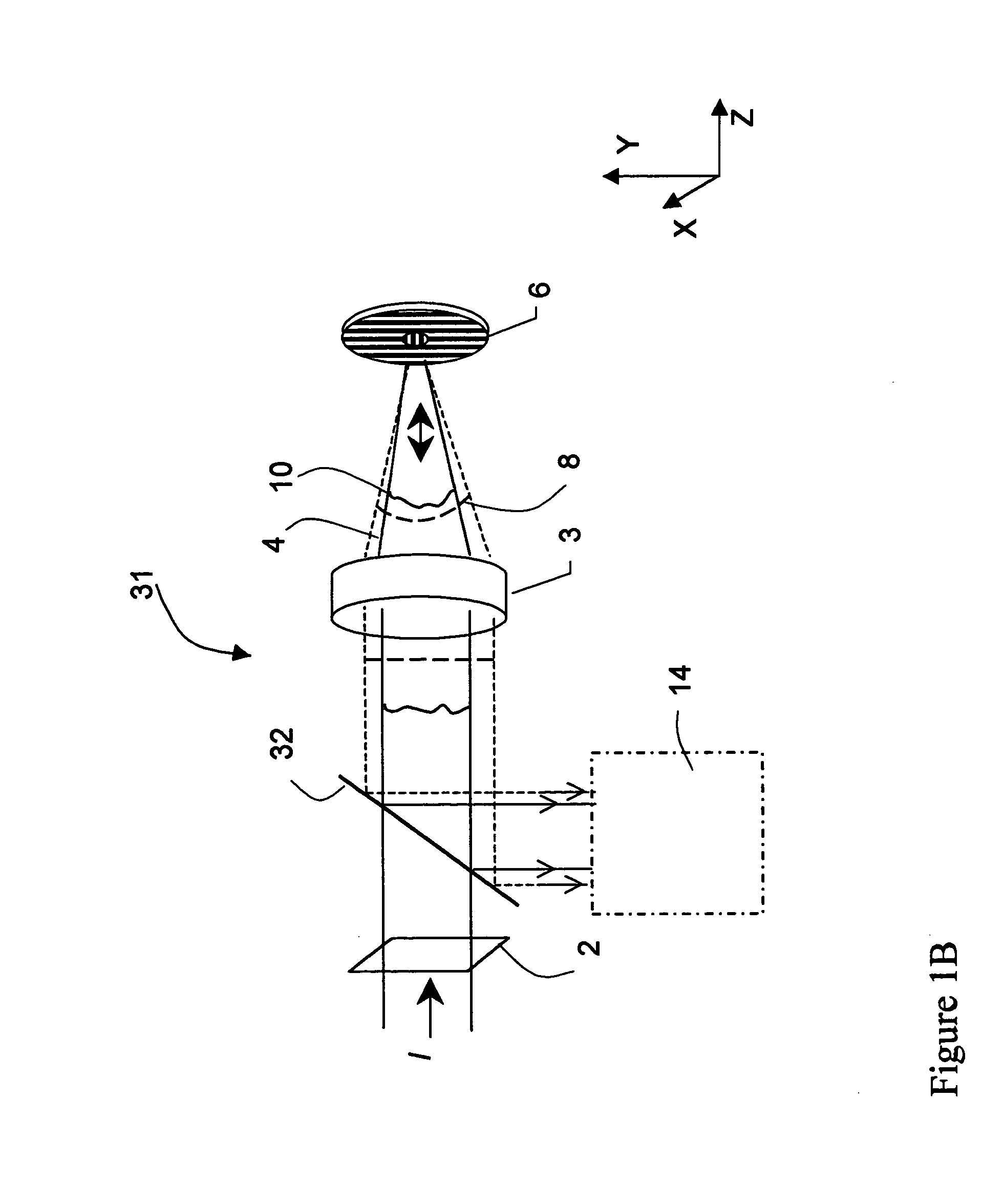

High contrast grating integrated vcsel using ion implantation

InactiveUS20110280269A1Tuning speedSmall massLaser detailsNanoopticsVertical-cavity surface-emitting laserGrating

A Vertical Cavity Surface Emitting Laser (VCSEL) and its fabrication are taught which incorporate a high contrast grating (HCG) to replace the top mirror of the device and which can operate at long-wavelengths, such as beyond 0.85 μm. The HCG beneficially provides a high degree of polarization differentiation and provides optical containment in response to lensing by the HCG. The device incorporates a quantum well active layer, a tunnel junction, and control of aperture width using ion implantation. A tunable VCSEL is taught which controls output wavelength in response to controlling a micro-mechanical actuator coupled to a HCG top mirror which can be moved to, or from, the body of the VCSEL. A fabrication process for the VCSEL includes patterning the HCG using a wet etching process, and highly anisotropic wet etching while precisely controlling temperature and PH.

Owner:RGT UNIV OF CALIFORNIA

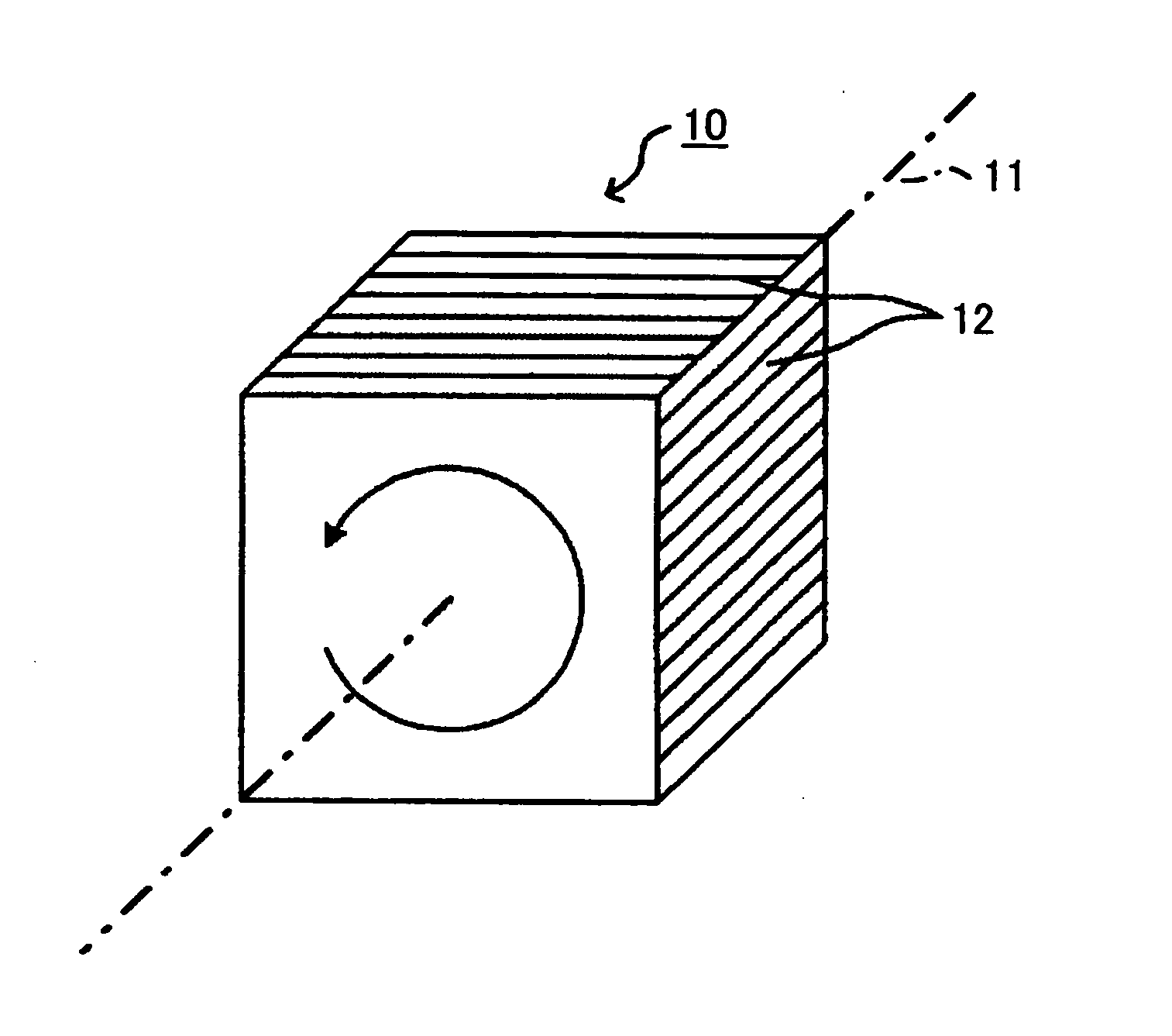

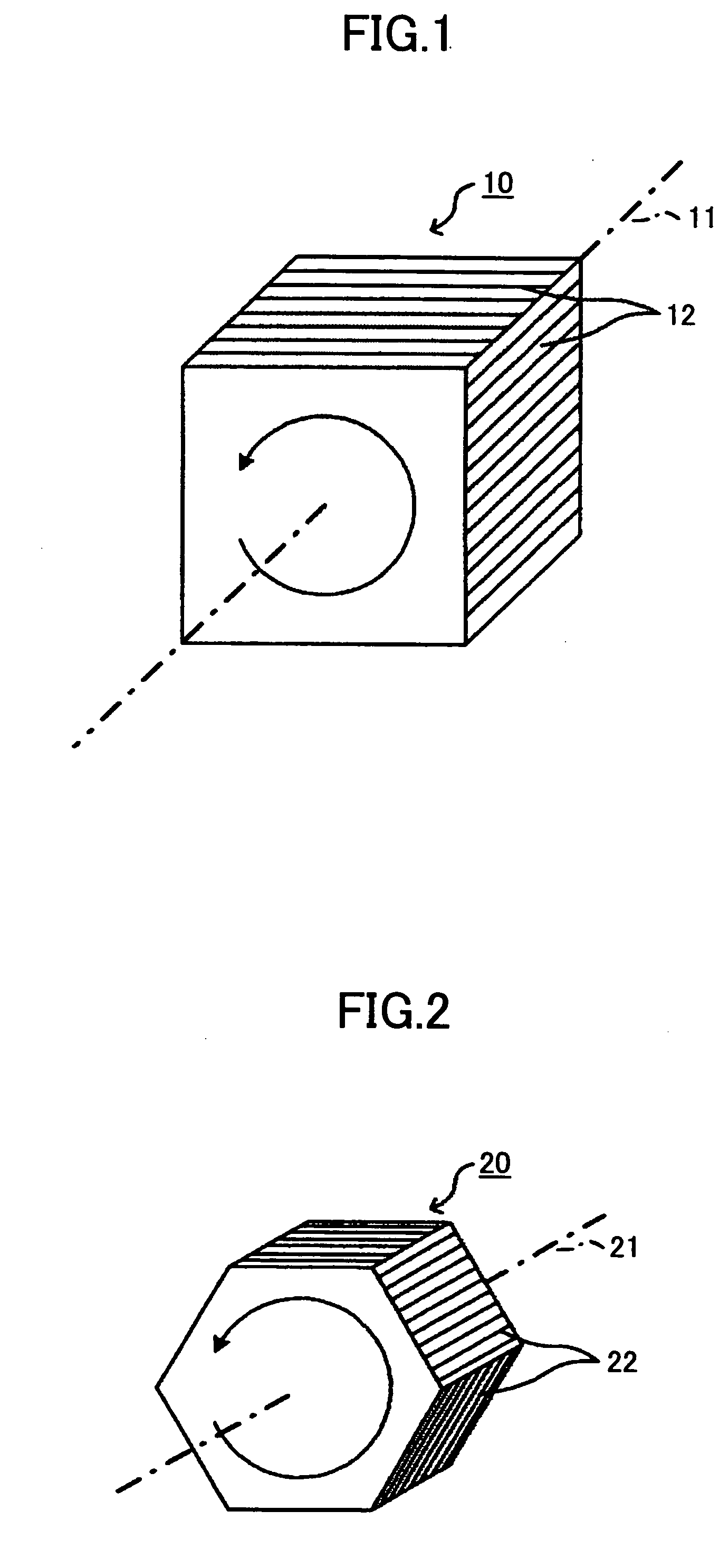

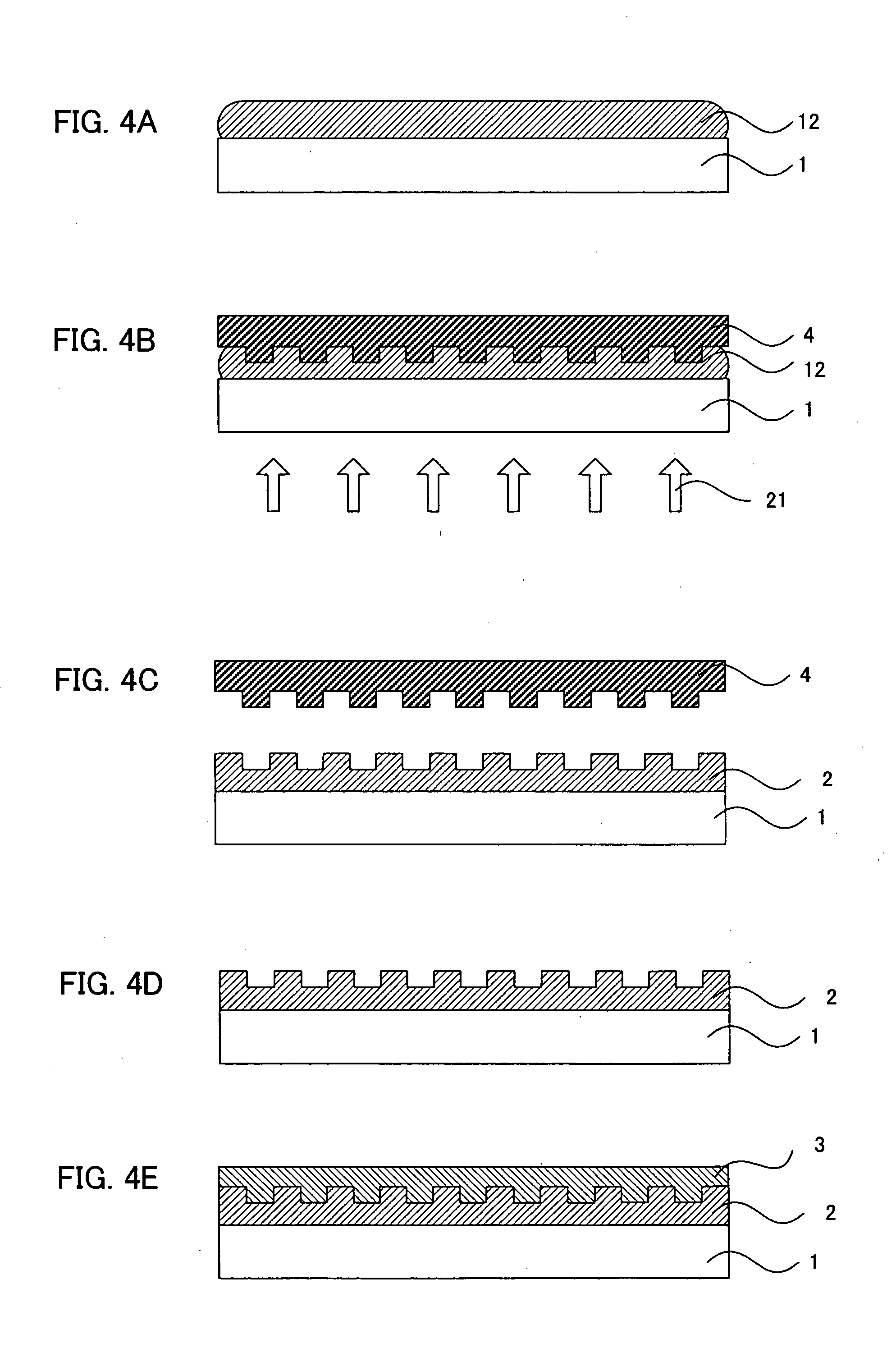

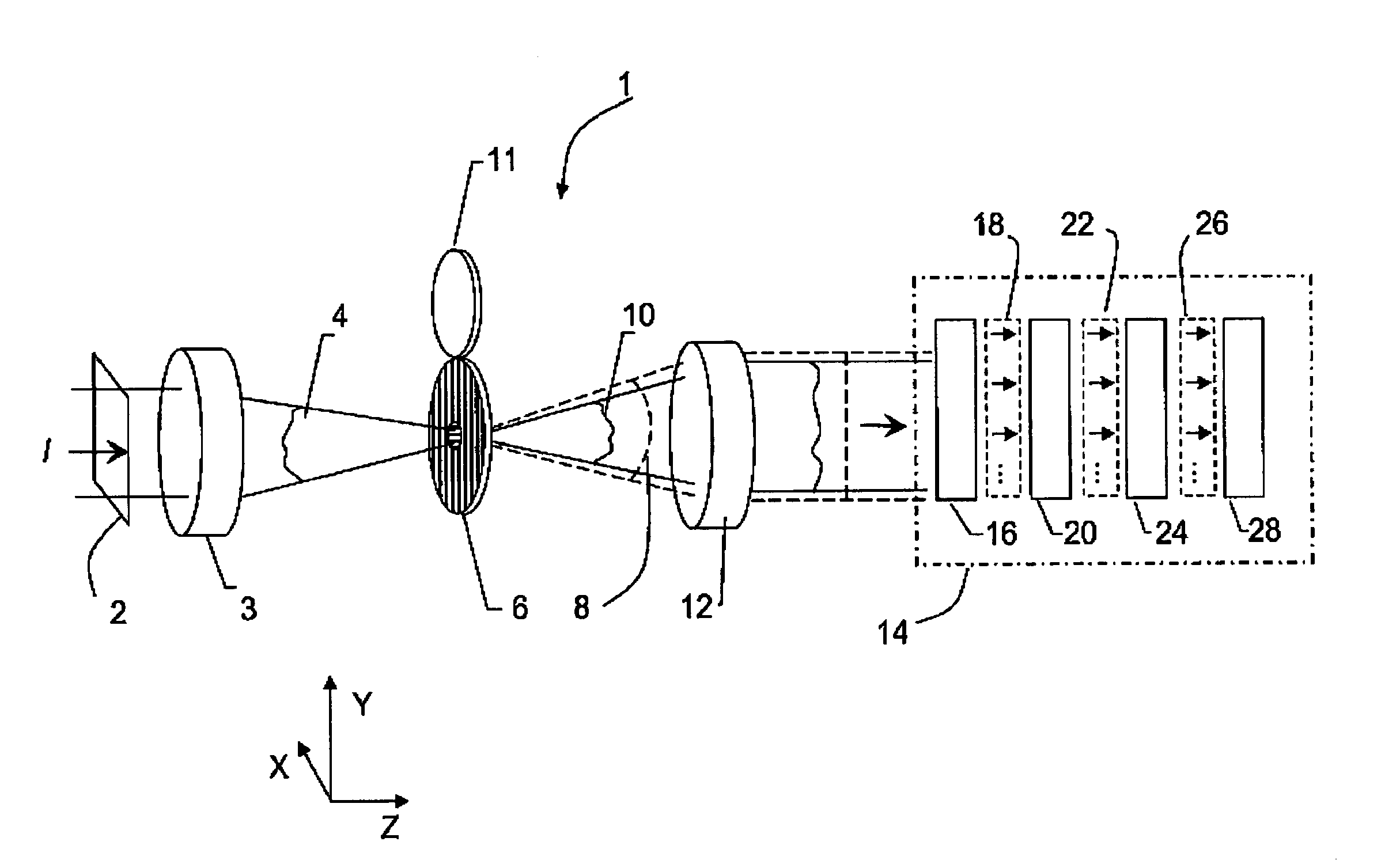

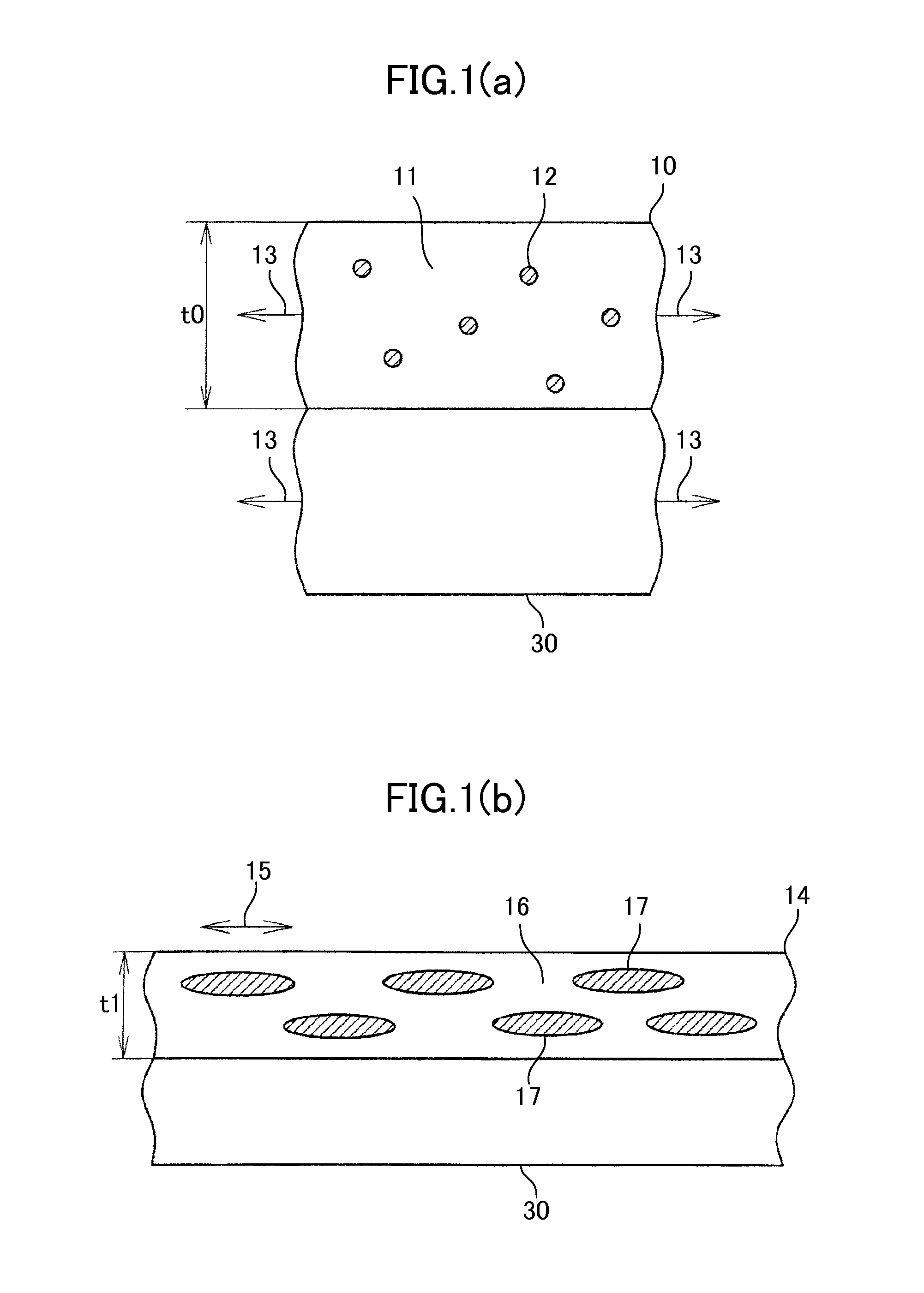

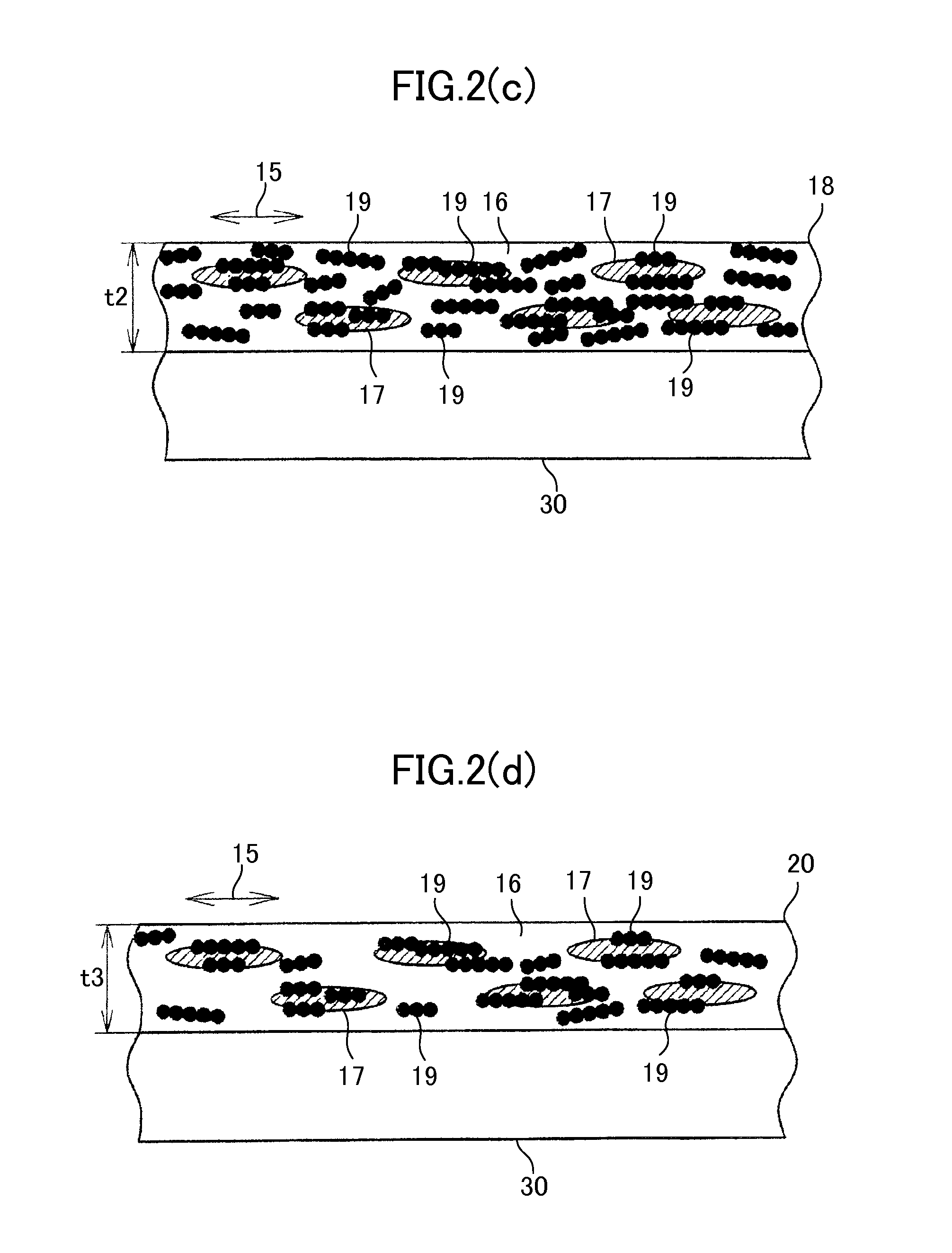

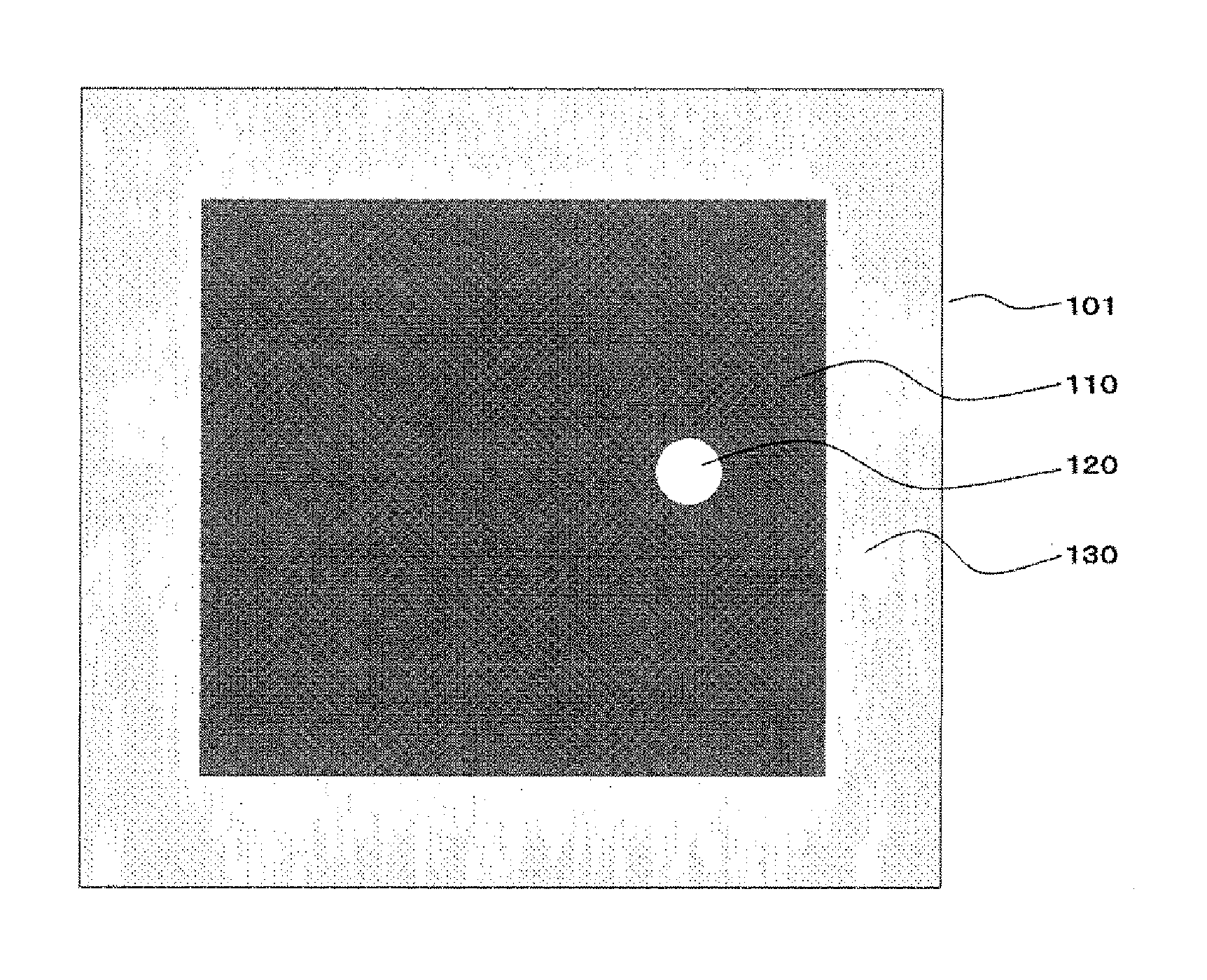

Optical device, display device, and three-dimension image display device

InactiveUS20060039068A1Small wavelength dependenceSuperior in polarization purityProjectorsPolarising elementsRotational axisLight beam

An optical element, an optical device, and a display device are disclosed that are able to change a polarization state in time order and to produce polarized light with little wavelength dependence and superior in polarization purity, and able to perform pixel shift easily and accurately to realize high resolution image display. The optical element has a translucent surface parallel to the rotational axis of the optical element, and at least a portion of the translucent surface is formed from an optically anisotropic medium. A polarization state of a light beam transmitting through the translucent surface is switched in time order along with rotation of the optical element.

Owner:RICOH KK

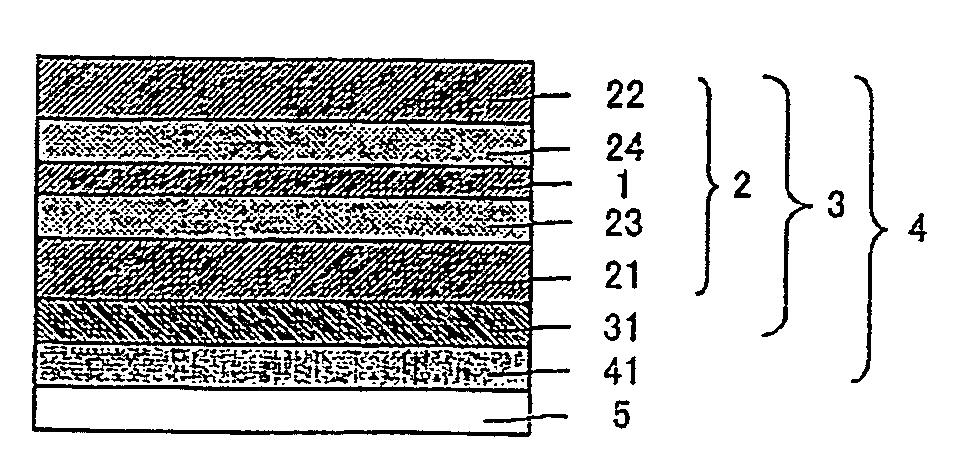

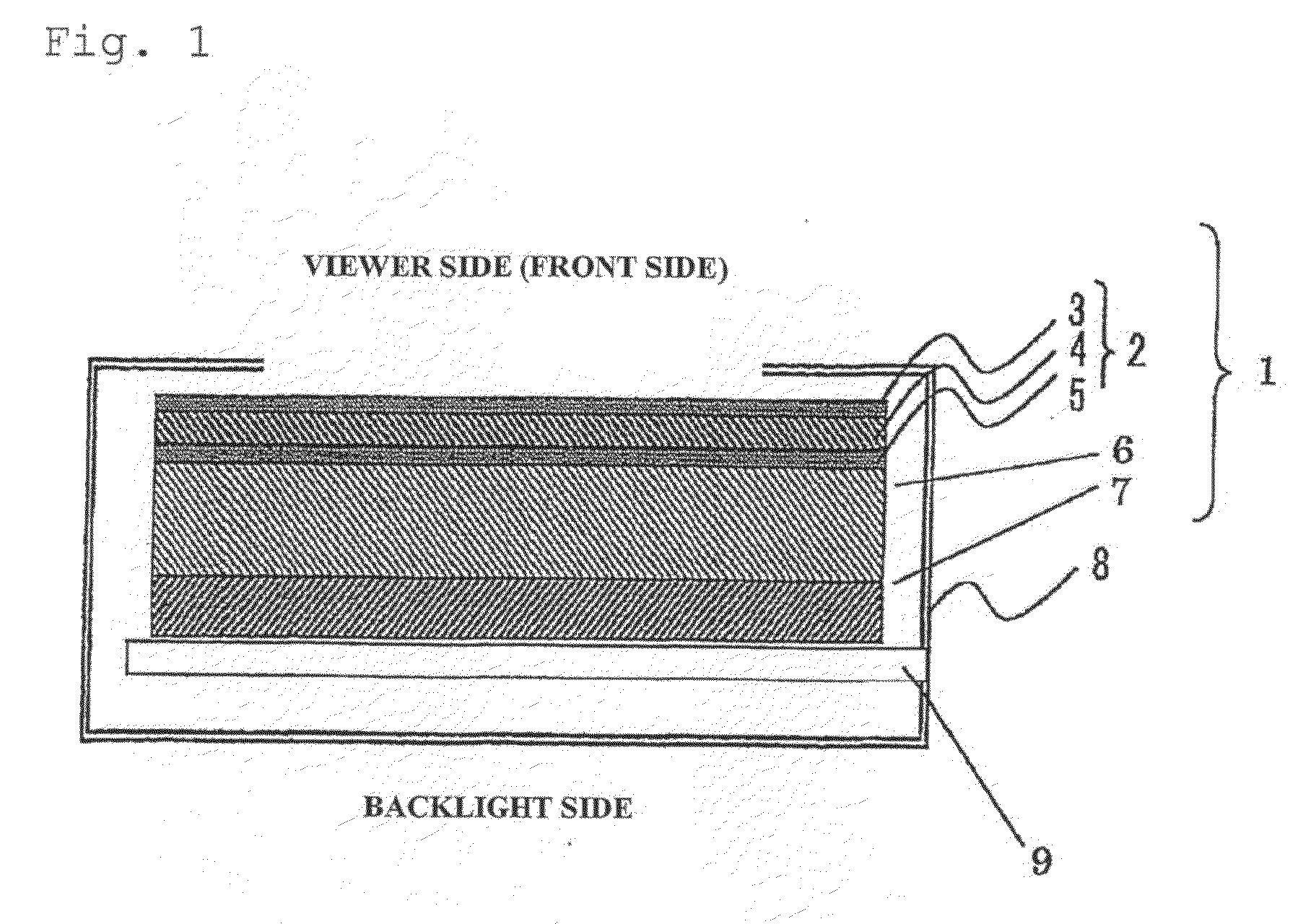

Pressure-sensitive adhesive and retardation layer-attached polarizing plate, method for manufacturing thereof, optical film, and image display

ActiveUS20100039590A1Improve visibilityVisibility can be maintainedLiquid crystal compositionsPolarising elementsTectorial membranePolyvinyl alcohol

A pressure-sensitive adhesive and retardation layer-attached polarizing plate (4) of the invention comprises a retardation layer-attached polarizing plate (3) comprising a polarizing plate (2) that comprises an iodine-based polarizer (1) and a transparent protective film laminated on both sides of the polarizer (1); and a retardation layer provided on at least one of the transparent protective films; and an acrylic pressure-sensitive adhesive layer laminated on the retardation layer side of the retardation layer-attached polarizing plate (3), wherein the iodine-based polarizer (1) has a ratio (K / I), which is the content (% by weight) of potassium (K) to the content (% by weight) of iodine (I) in the polarizer, of 0.200 to 0.235, the polarizing plate (2) comprises the iodine-based polarizer (1) and the transparent protective film laminated with an adhesive layer formed from a water-soluble adhesive containing an acetoacetyl group-containing polyvinyl alcohol resin and a crosslinking agent, the retardation layer-attached polarizing plate (3) has a measured dimensional shrinkage of 0.5% or less in the direction of its absorption axis after it is allowed to stand at 80° C. for 24 hours, the pressure-sensitive adhesive and retardation layer-attached polarizing plate (4) has a single-piece transmittance of 41.0% to 43.2%. The pressure-sensitive adhesive and retardation layer-attached polarizing plate can resist a change in optical properties and keep visibility high, even under heated or humidified conditions.

Owner:NITTO DENKO CORP

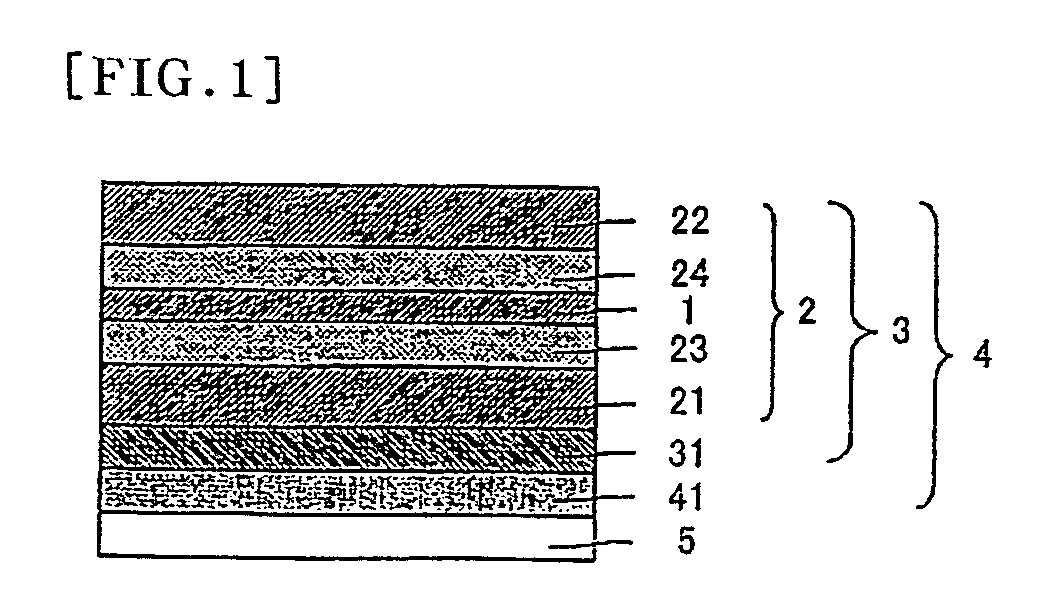

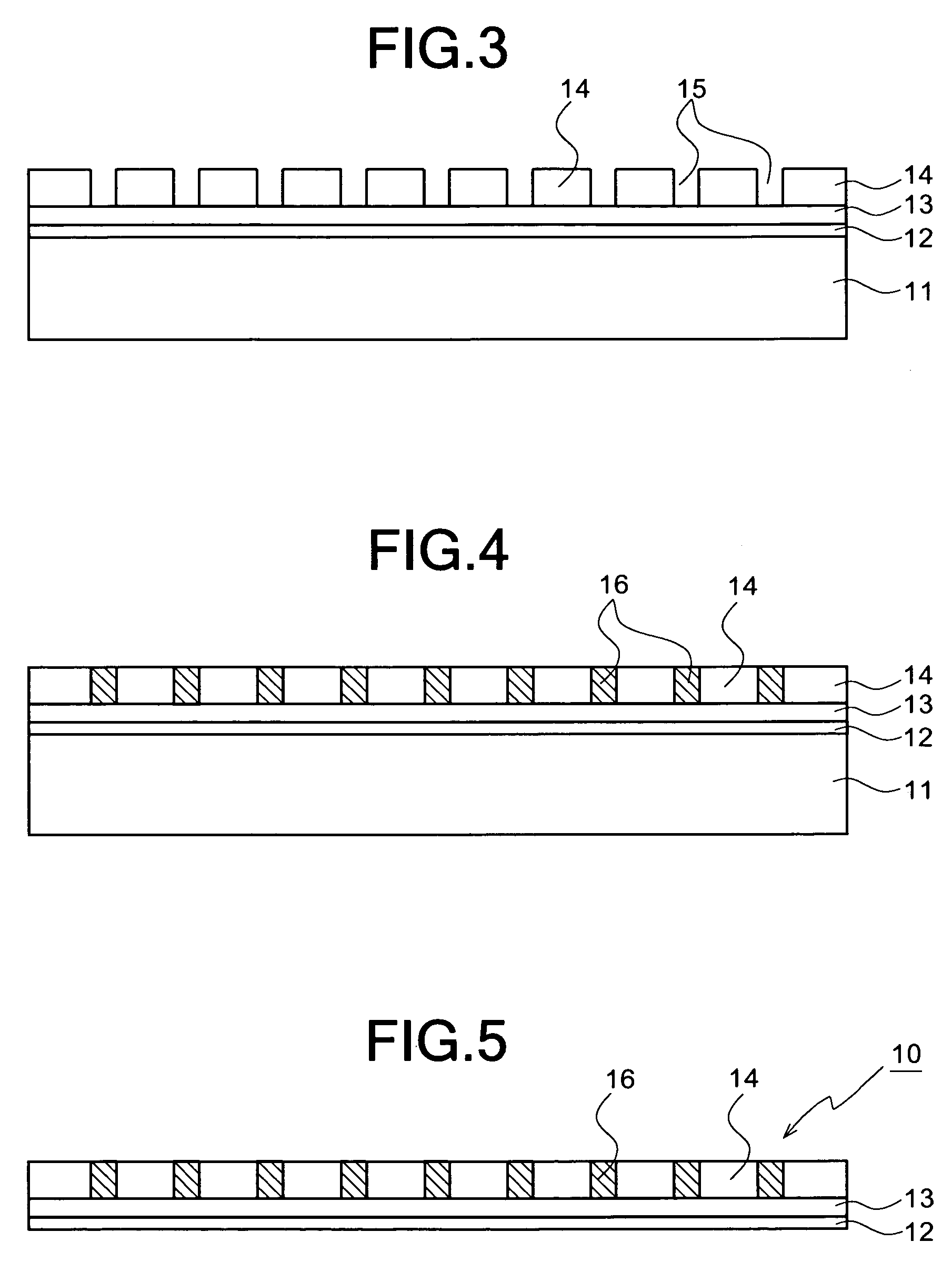

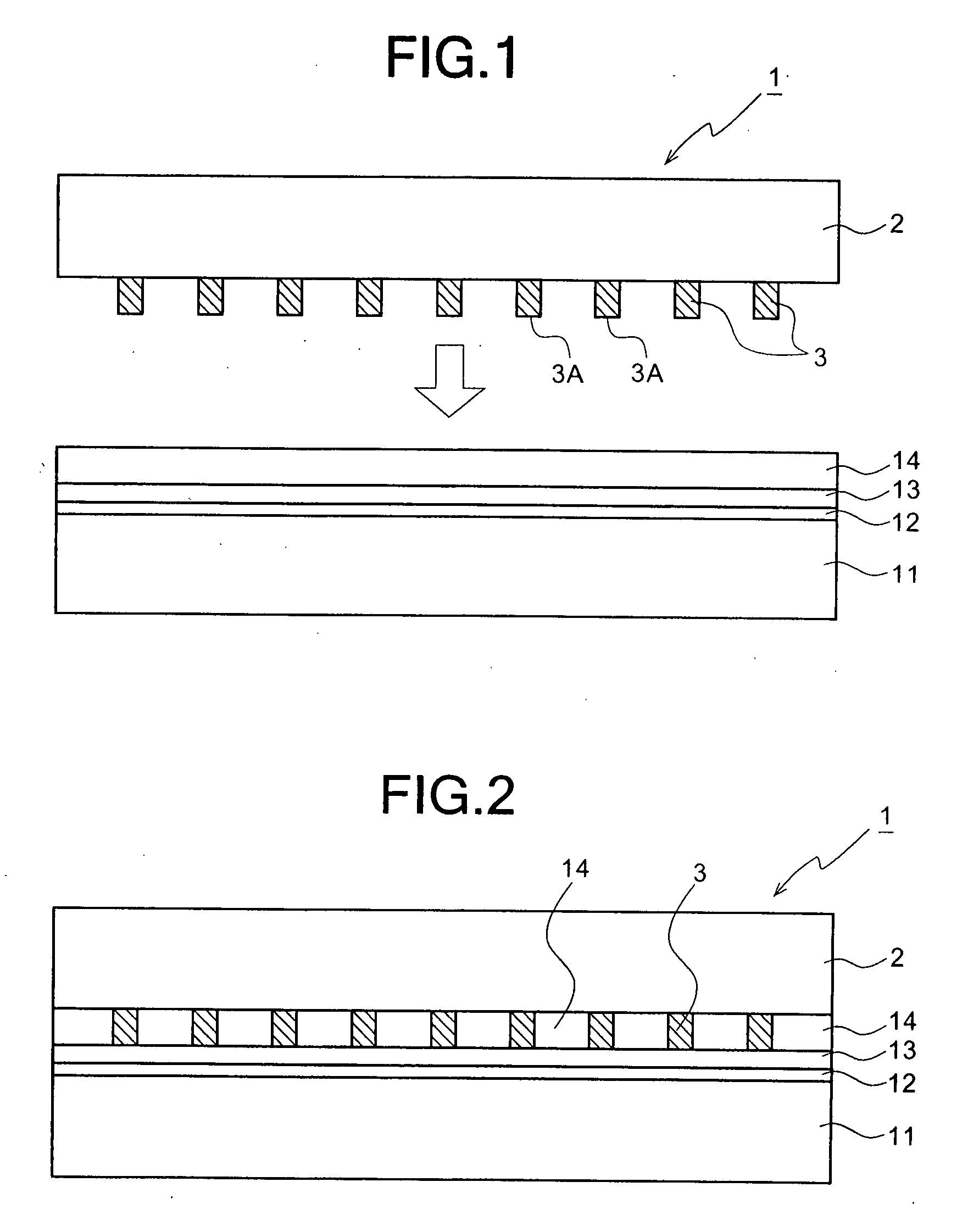

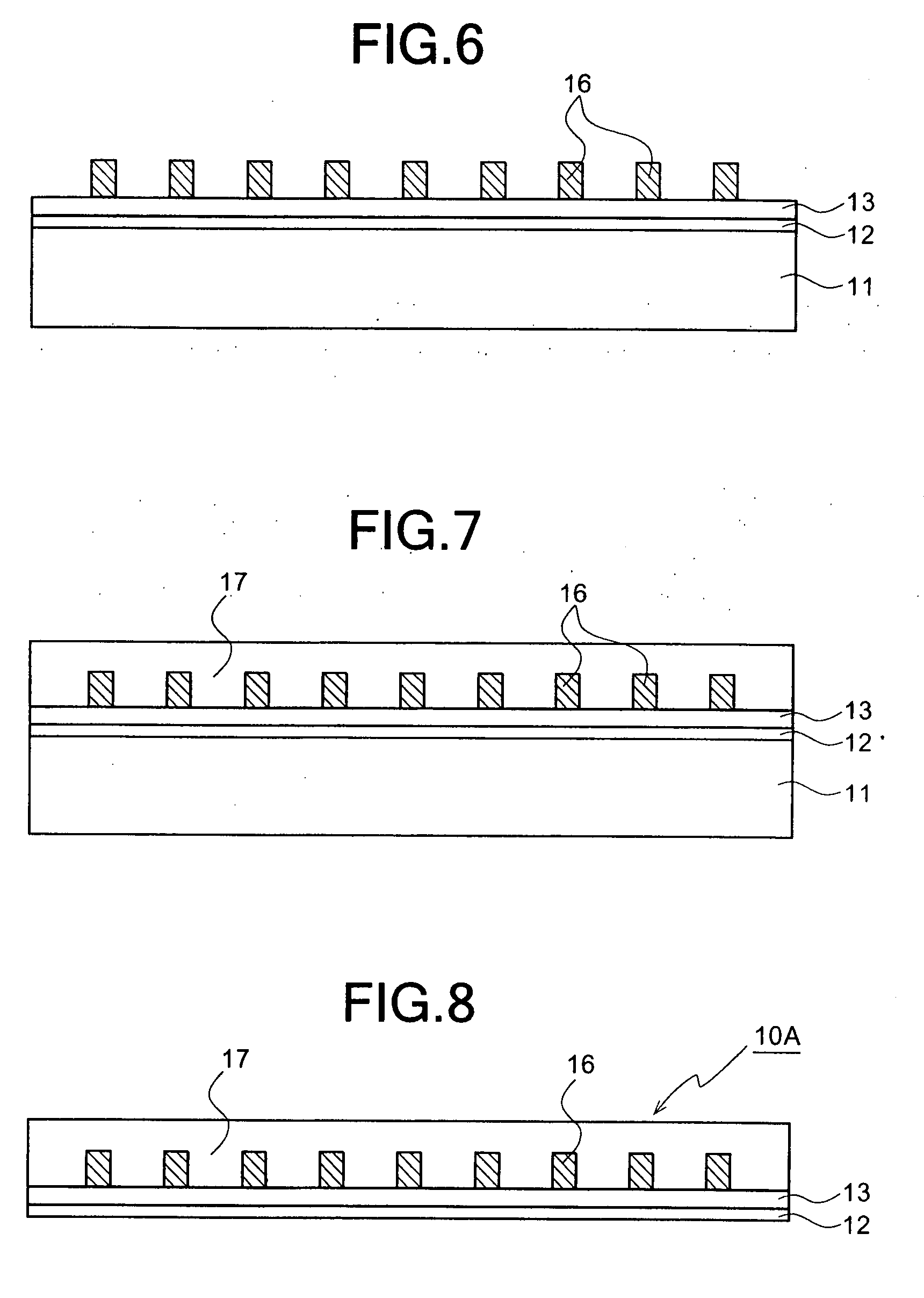

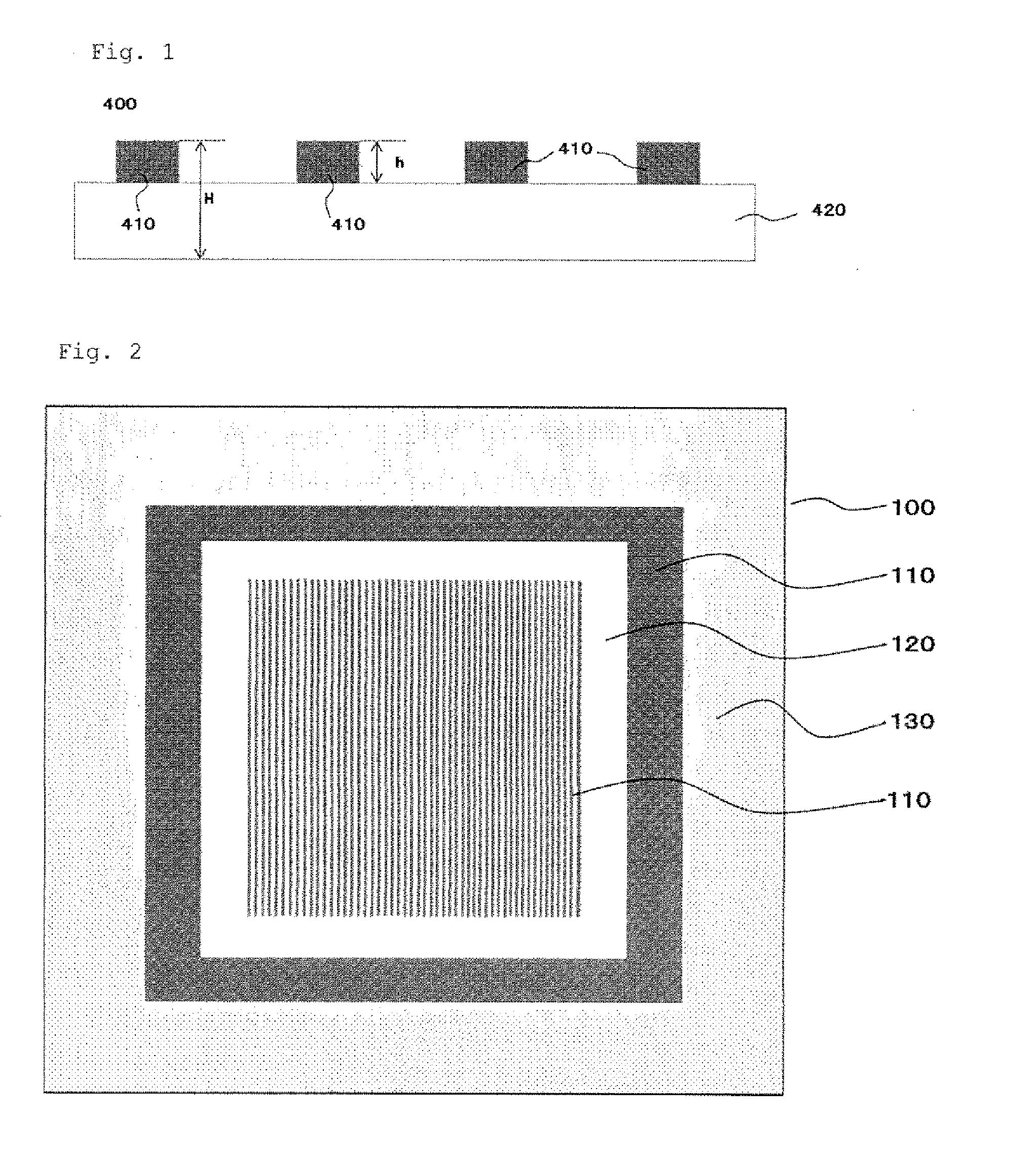

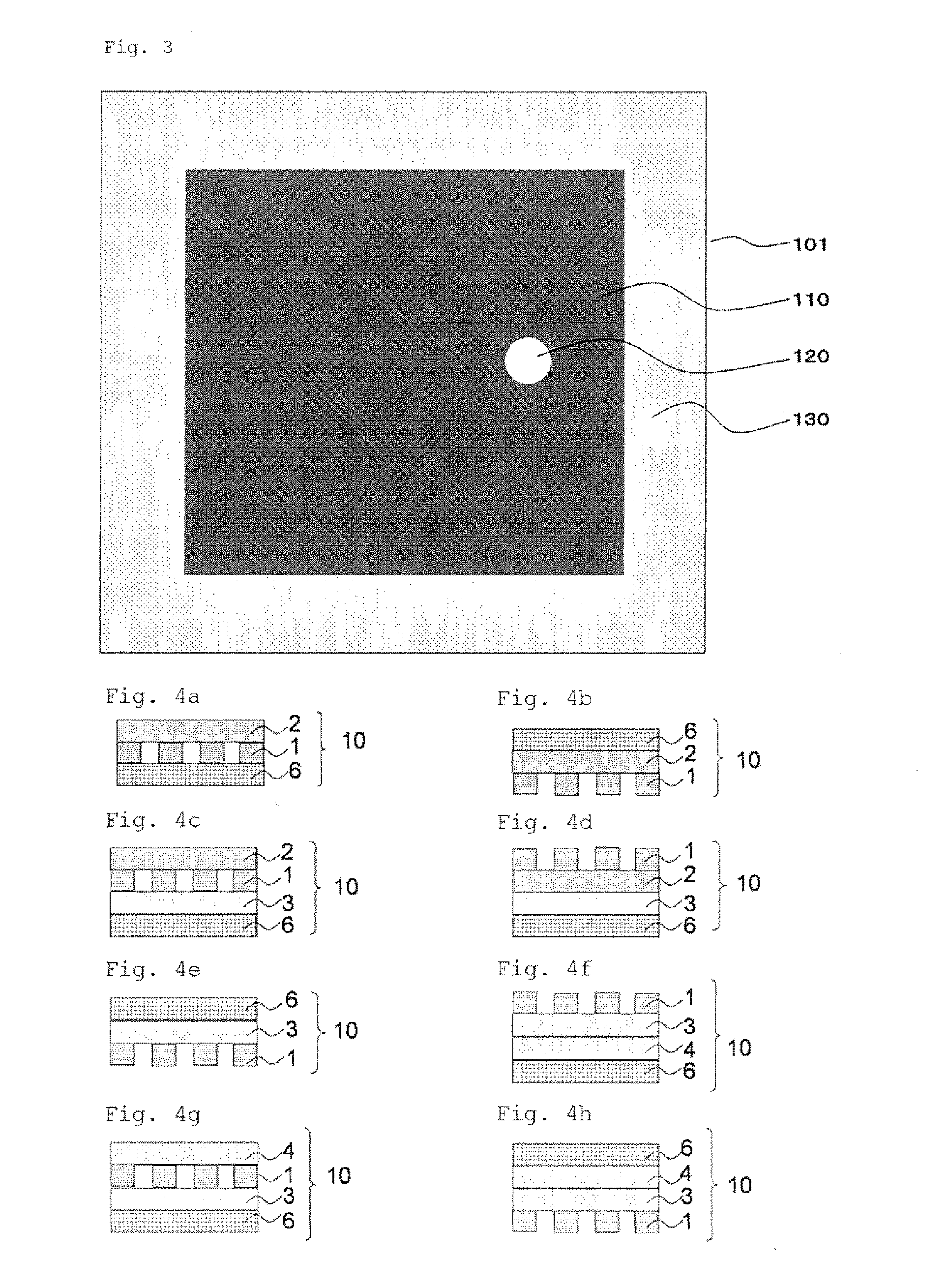

Wire grid polarizer and method for producing same

ActiveUS7220371B2High light transmittanceLow costPolarising elementsOptical articlesLithographic artistWire grid

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

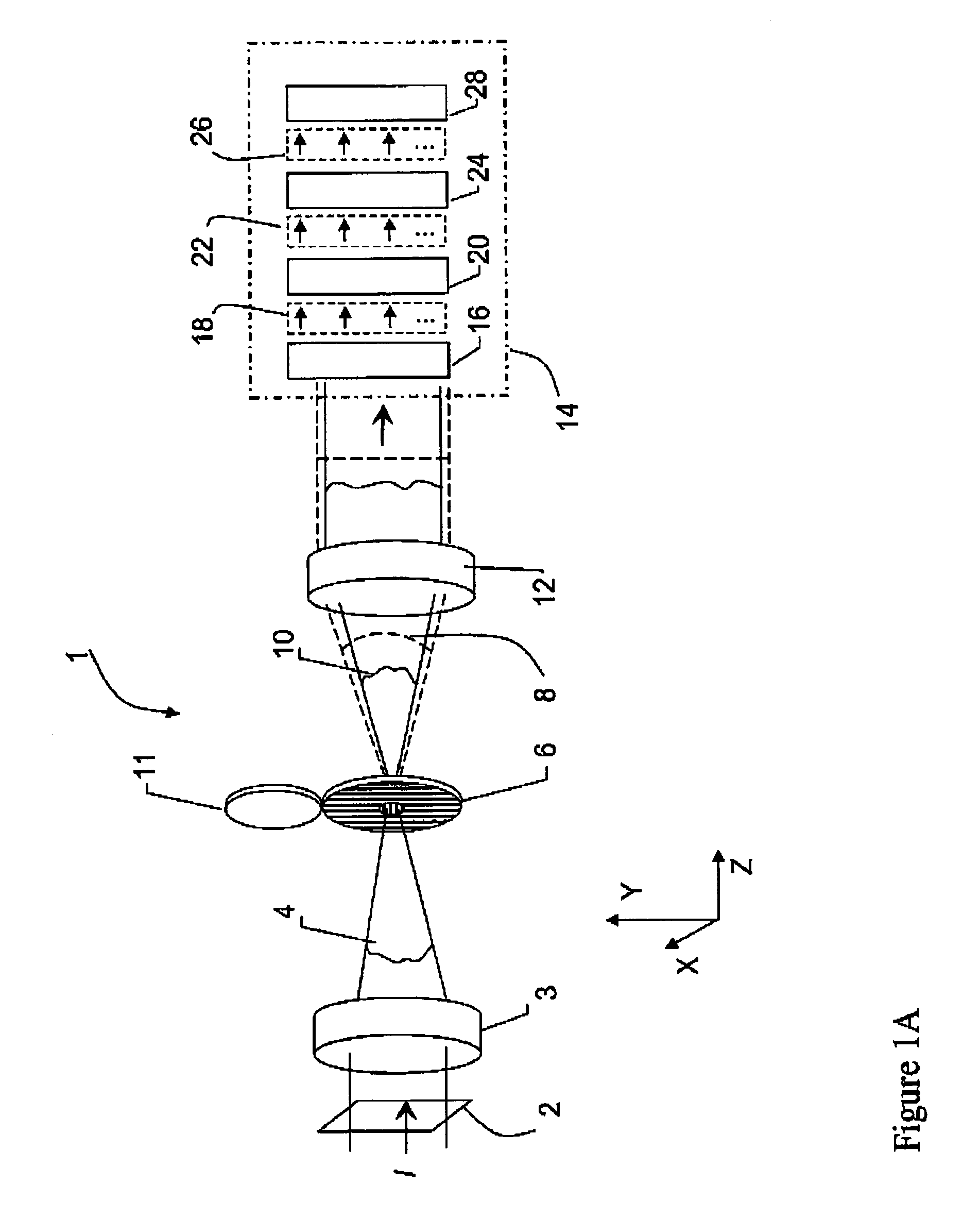

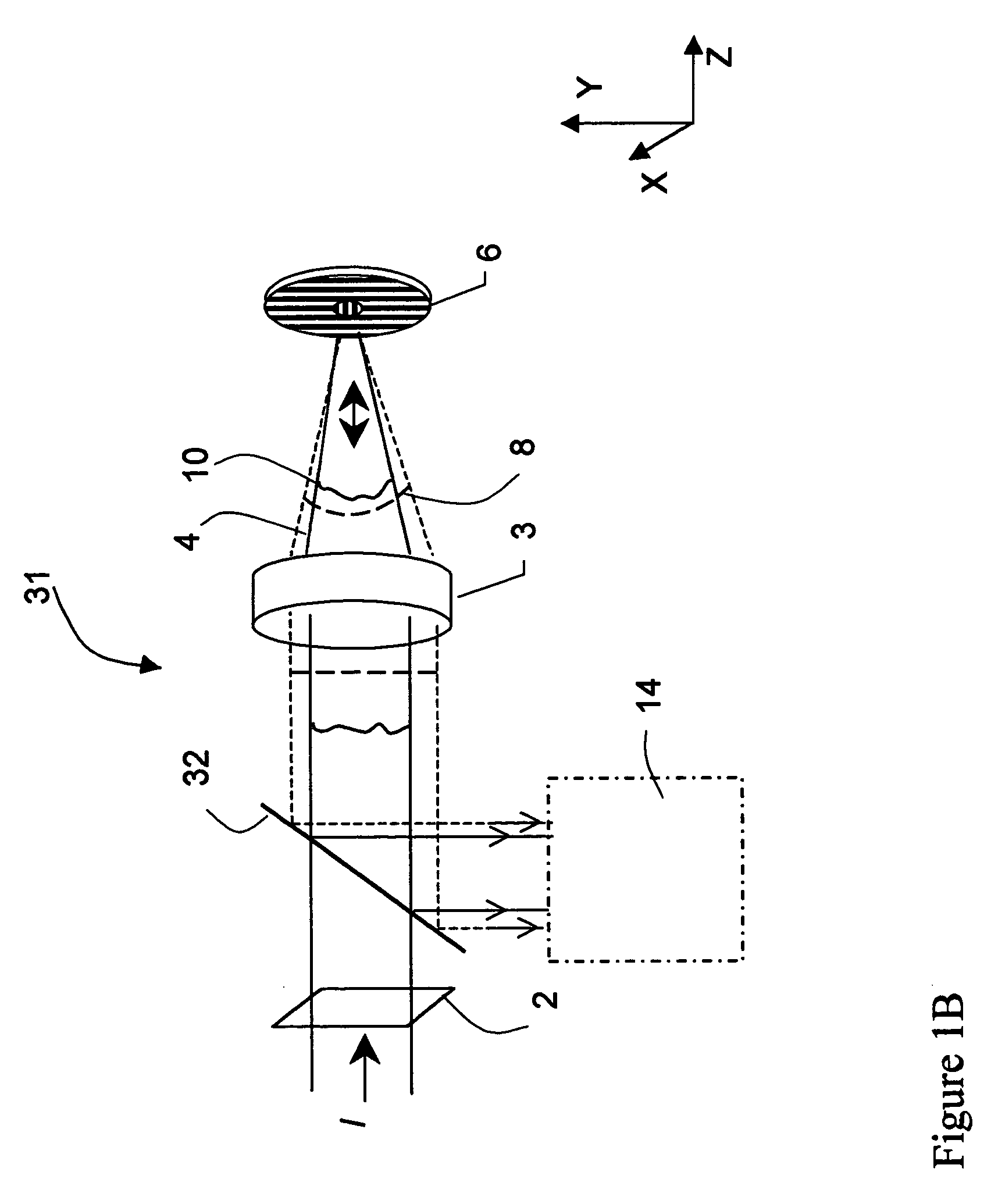

Common optical-path testing of high-numerical-aperture wavefronts

ActiveUS20050046863A1Improve polarizationIncreased Polarization PurityOptical measurementsInterferometersWavefrontPhase shifted

A polarizing point-diffraction plate is used to produce common-path test and reference wavefronts with mutually orthogonal polarizations from an input wavefront. The common-path test and reference wavefronts are collimated, phase shifted and interfered, and the resulting interferograms are imaged on a detector. The interference patterns are then processed using conventional algorithms to characterize the input light wavefront.

Owner:ONTO INNOVATION INC

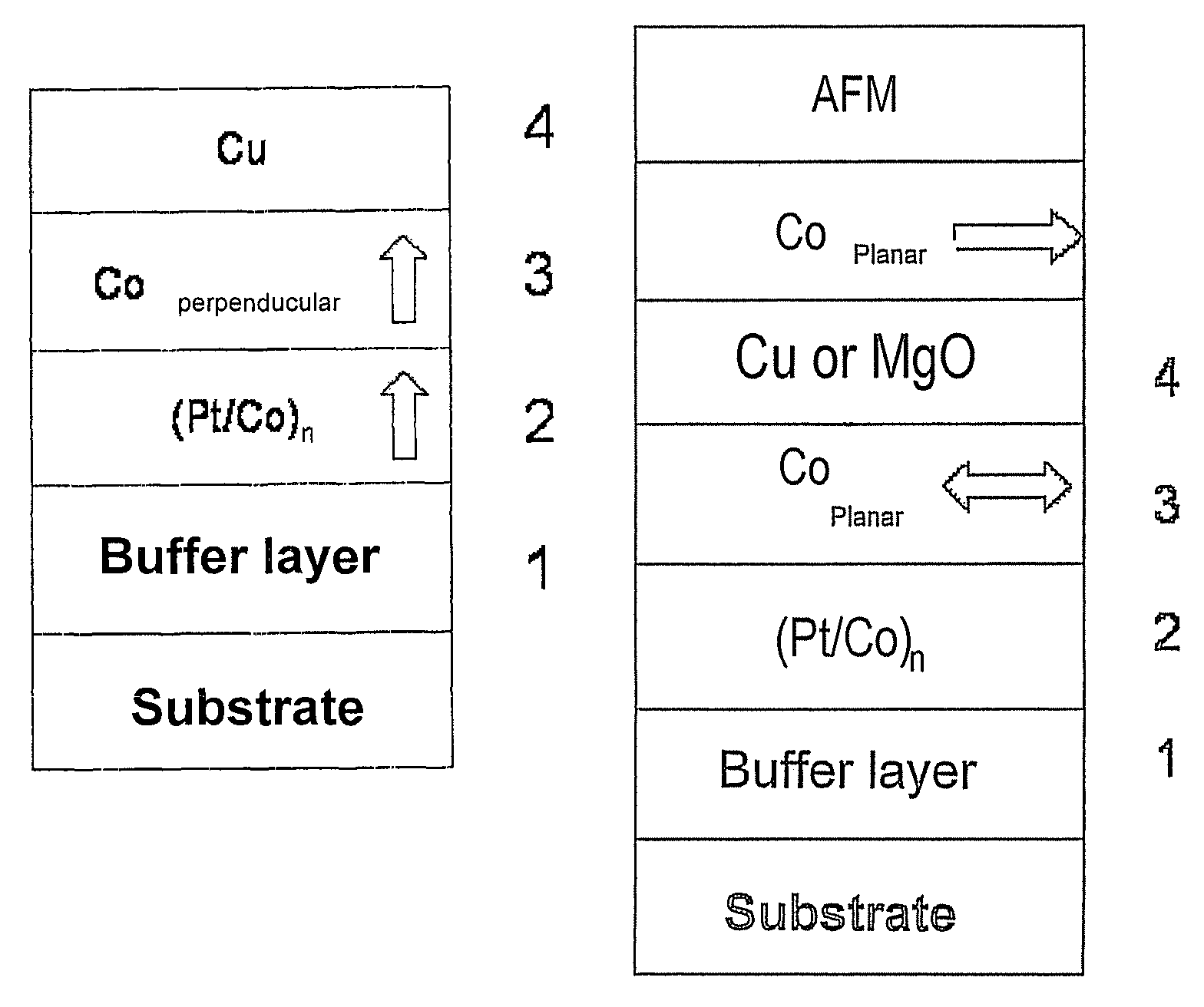

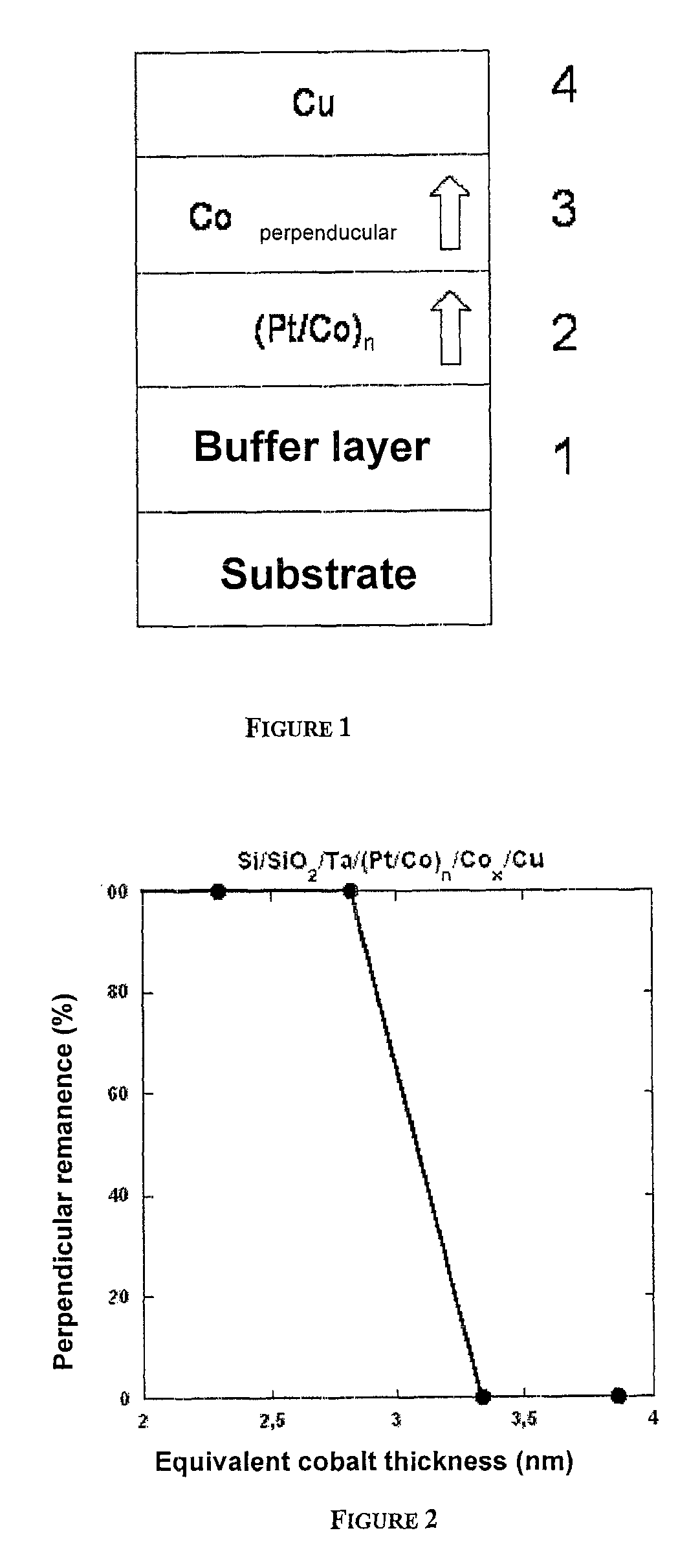

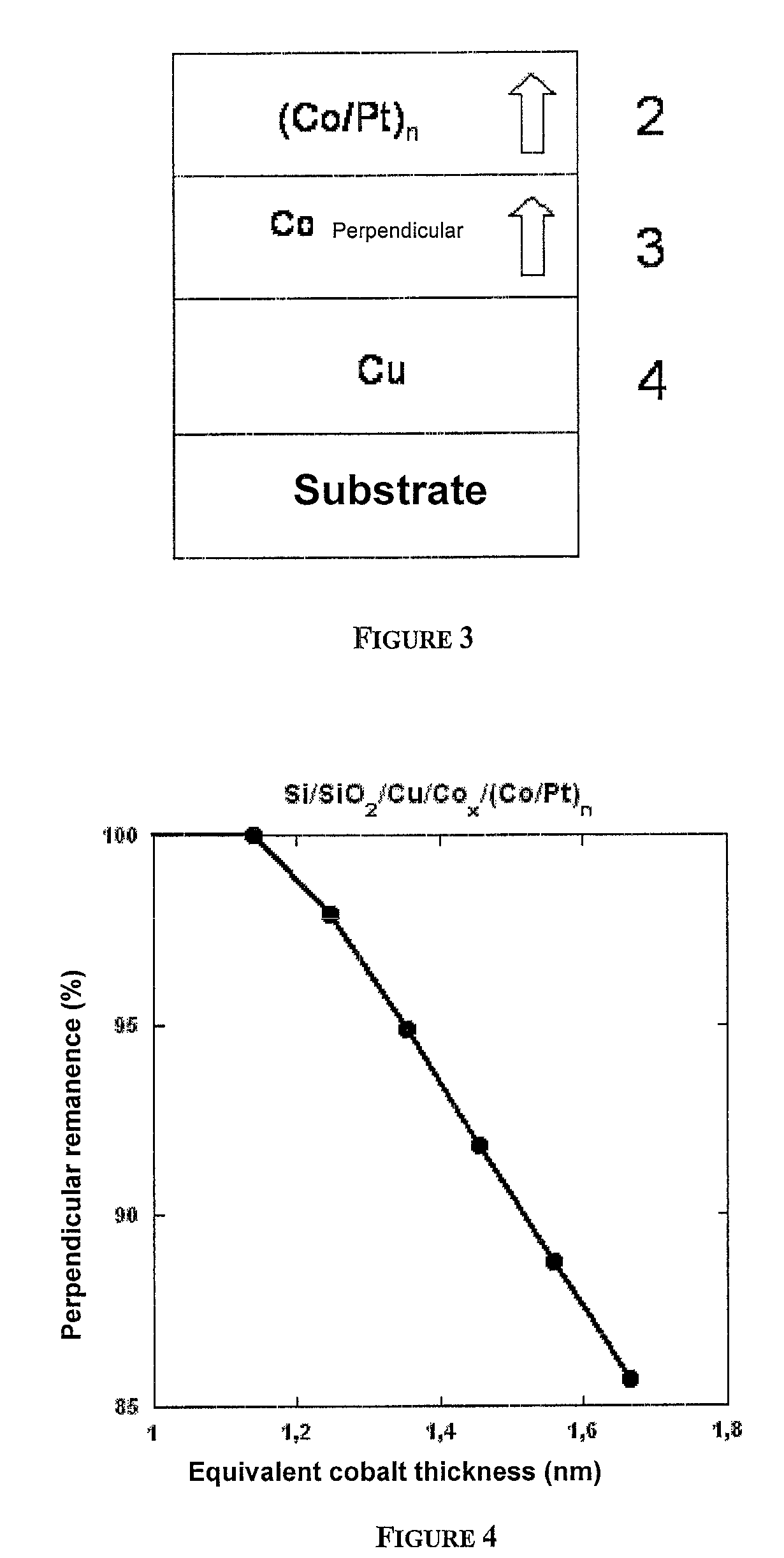

Thin-film magnetic device with strong spin polarization perpendicular to the plane of the layers, magnetic tunnel junction and spin valve using such a device

ActiveUS7813202B2Optimize spin polarizationImprove polarizationNanomagnetismMagnetic measurementsIn planeHigh rate

A thin-film magnetic device comprises, on a substrate, a composite assembly deposited by cathode sputtering and consists of a first layer made of a ferromagnetic material with a high rate of spin polarization, the magnetization of which is in plane in the absence of any electric or magnetic interaction, a second layer made of a magnetic material with high perpendicular anisotropy, the magnetization of which is outside the plane of said layer in the absence of any electric or magnetic interaction, and coupling of which with said first layer induces a decrease in the effective demagnetizing field of the entire device, a third layer that is in contact with the first layer via its interface opposite to that which is common to the second layer and made of a material that is not magnetic and not polarizing for electrons passing through the device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

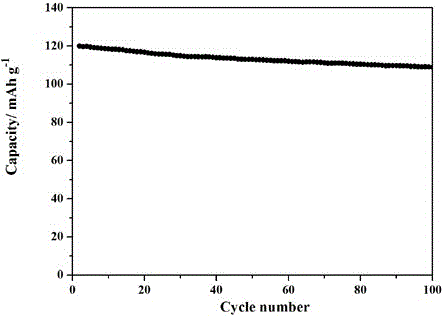

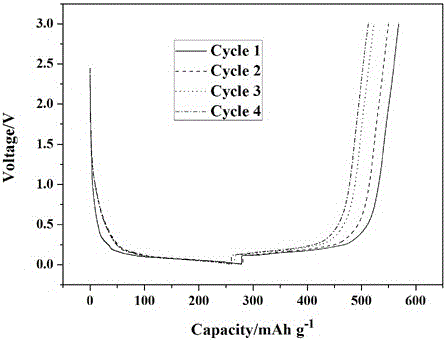

Lithium battery electrode preparation method including polymer material with stable interface and application of lithium battery electrode in solid lithium battery

ActiveCN105702919AImprove discharge capacityReduce discharge capacityCell electrodesLi-accumulatorsSolid state electrolyteDecomposition

The invention discloses a lithium battery electrode preparation method including polymer material with a stable interface and the application of a lithium battery electrode in a solid lithium battery. The preparation method is characterized in that the polymer material with the stable interface is poly-vinylene carbonate (PVCA) or copolymers thereof. The free radical triggers the monomer to perform mass polymerization to obtain a polymer, the polymer material with the stable interface can form a cover film on the surface of the electrode, thus destruction on the electrode material and decomposition of the solid electrolyte on the surfaces of the positive and negative electrodes can be effectively restrained. Meanwhile, the polymer material can form a stable protection layer on the surface of lithium metal to inhibit the growth of the lithium dendrites, thus the cycle performance of the solid lithium battery is improved. The invention also provides a preparation method of the electrochemical stable polymer material, and the solid lithium battery assembled by using the polymer material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

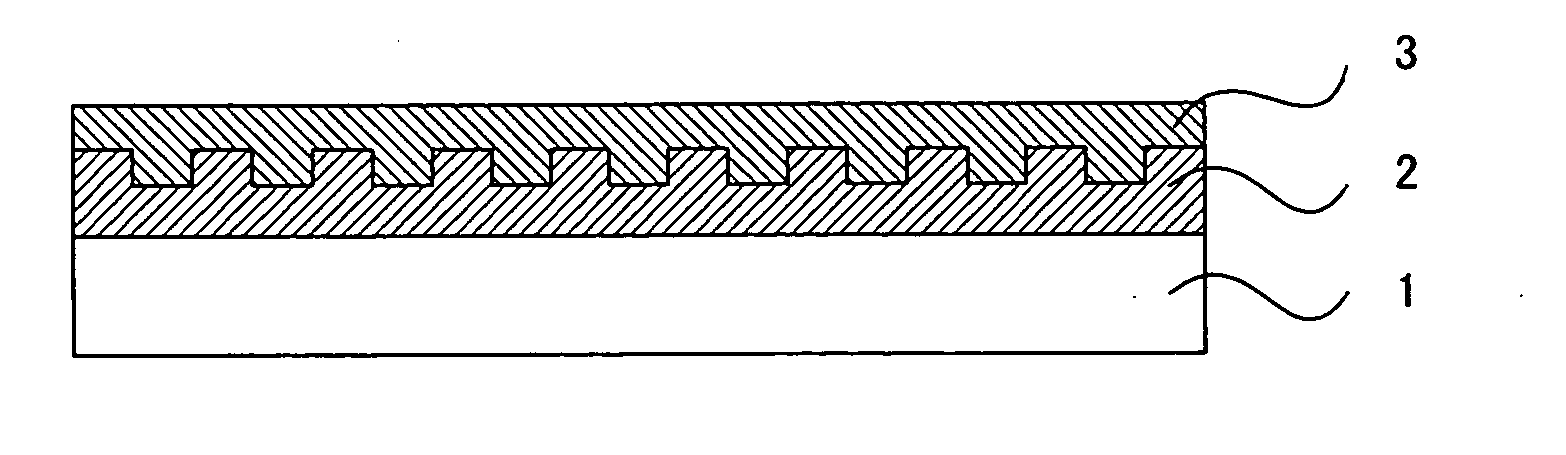

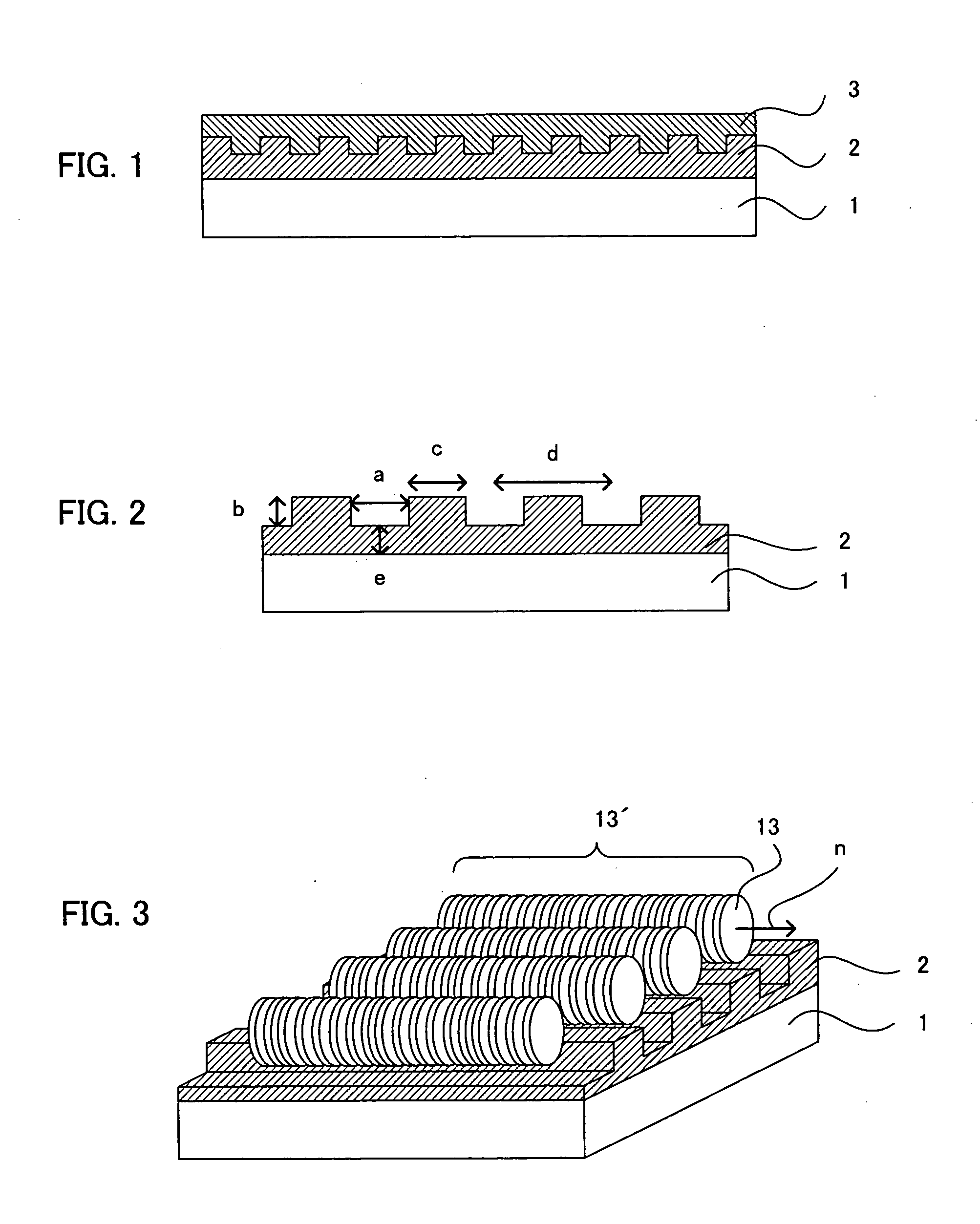

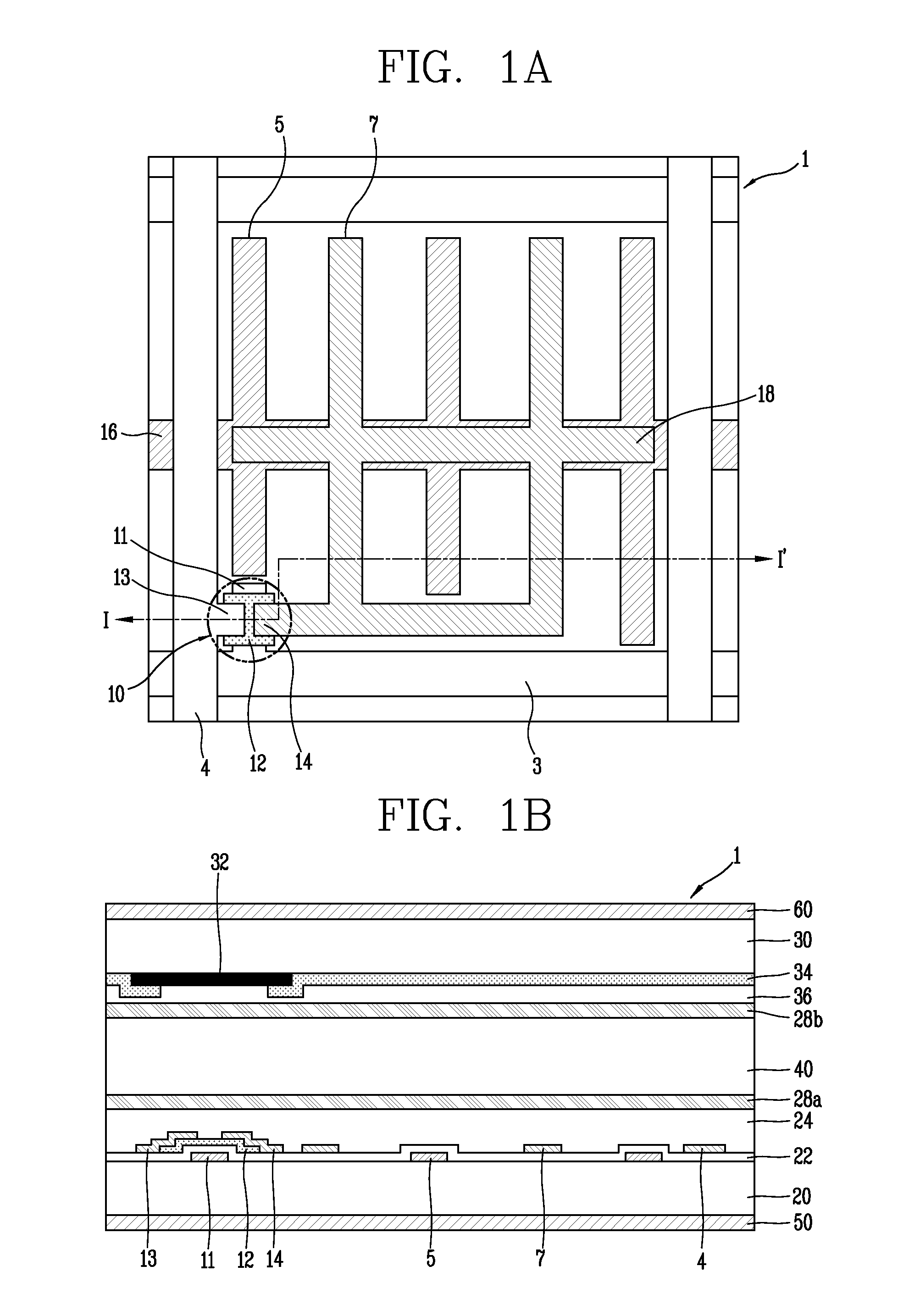

Polarizing plate, liquid crystal display using the same and method for manufacturing polarizing plate

InactiveUS20050068476A1Improve polarization performanceReduce thicknessLamination ancillary operationsLaminationLiquid-crystal displayEngineering

A main object of the present invention is to provide a polarizing plate having a good polarization performance, capable of being reduced in thickness, and showing excellent manufacturing efficiency. To attain the above mentioned object, the present invention provides a polarizing plate comprising: a base material; a resin layer formed on the base material and having concave portions or convex portions formed in a pattern on its surface; and a polarizing layer formed on the resin layer and comprising a tabular dye.

Owner:DAI NIPPON PRINTING CO LTD

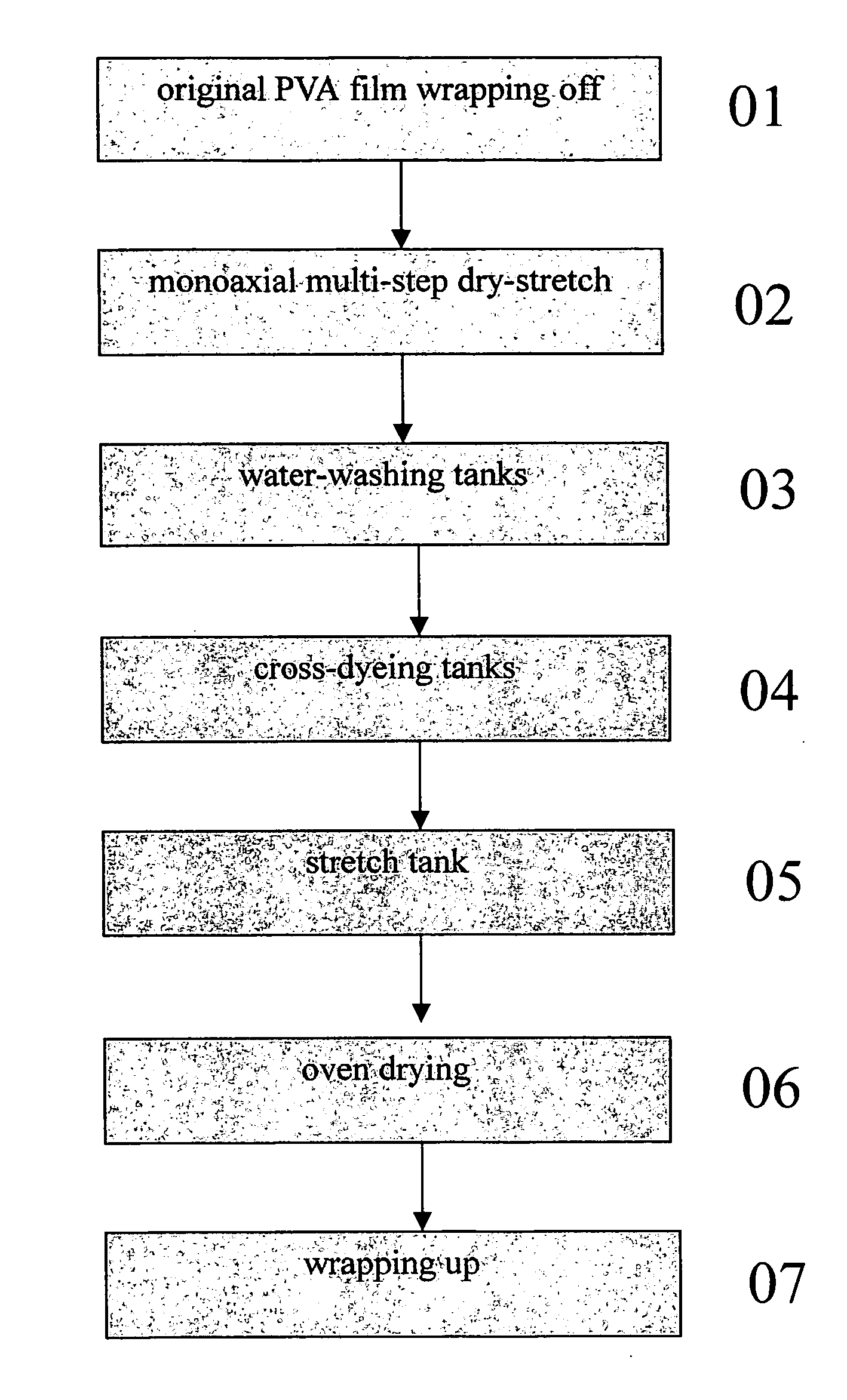

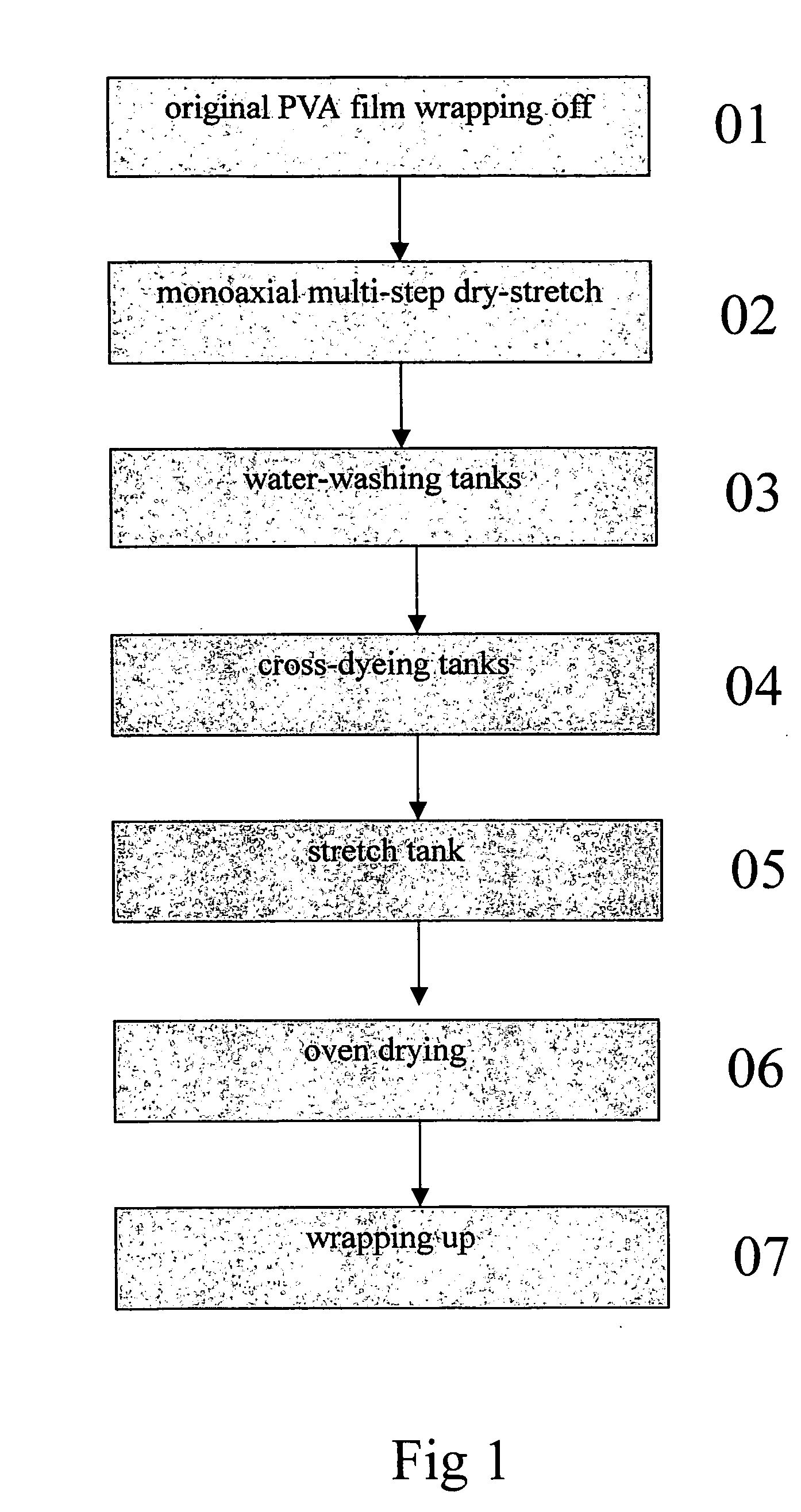

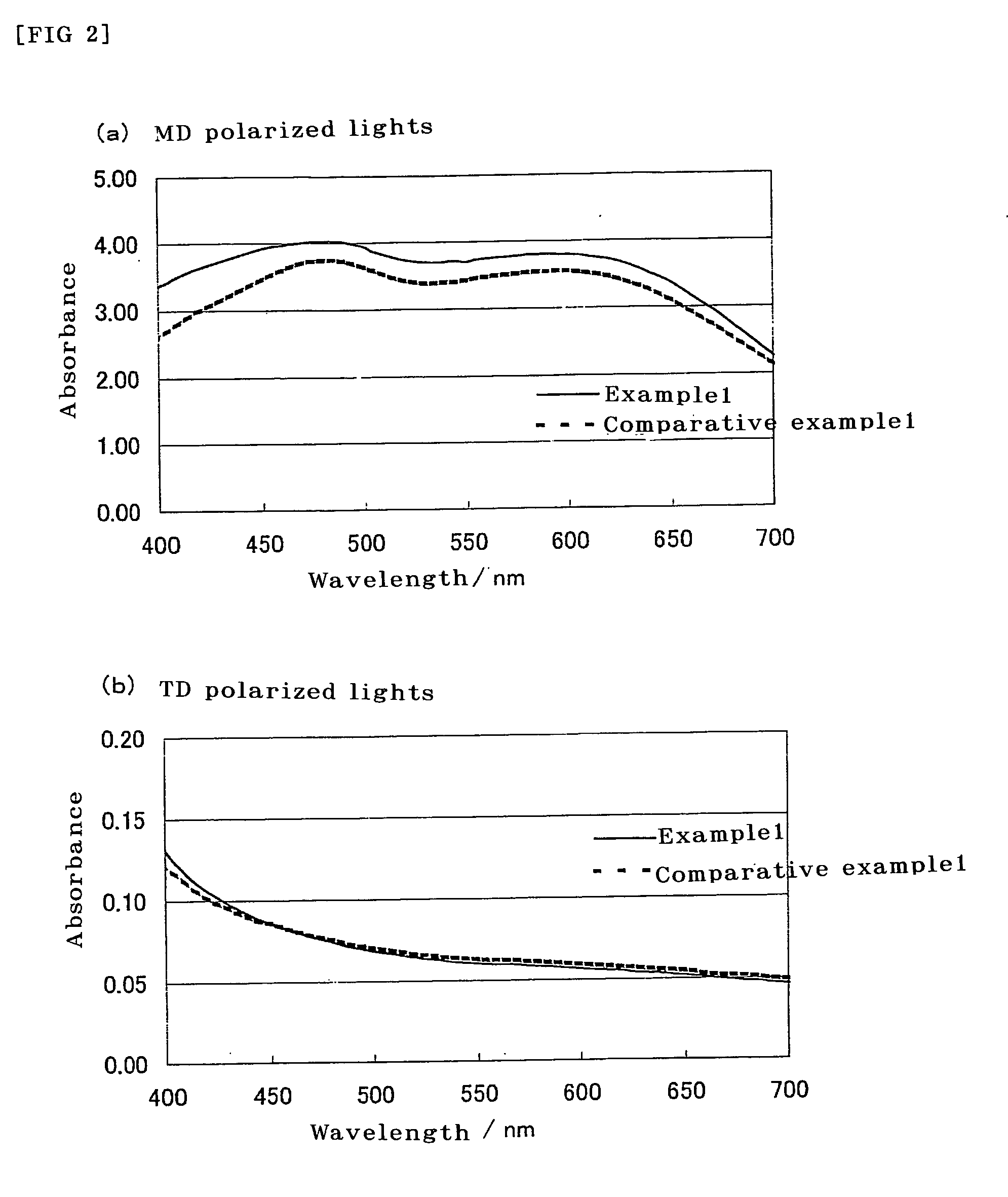

Polarizing film and producing method thereof, and optical component using the same

InactiveUS20060177606A1Improve polarizationHigh light transmittanceLiquid crystal compositionsOptical articlesPolarizerPVA - Polyvinyl alcohol

The present invention provides a polarizing film with high polarization degree and high transmittance, which is directed to the use of polyvinyl alcohol (PVA)-based film by subjecting to a monoaxial multi-step dry-stretch process, thereafter conducting a swelling process in a water-washing tank, cross-dyeing in a dyeing-crosslinking tank comprising an aqueous iodine containing solution, then subjecting to a post stretch process in an stretch tank 05 comprising PVA crosslinking agent, as to obtaining a polarizing film with a transmittance of at least 43% and a polarization degree of at least 98%; and the producing method thereof, a polarizing plate and an optical component produced from the same.

Owner:OPTIMAX TECHNOLOGY CORPORATION

Method for producing polarizer

InactiveUS20120052197A1Improve polarizationIncrease volumeLayered productsPretreated surfacesPolyvinyl alcoholIodine

A method for producing a polarizer comprises the steps of: (A) stretching a polyvinyl alcohol-based resin layer to obtain a stretched layer; (B) immersing the stretched layer in a dyeing liquid containing iodine to obtain a dyed layer in which absorbance thereof determined from a tristimulus value Y is from 0.4 to 1.0 (transmittance T=40% to 10%); and (C) removing a part of iodine adsorbed in the dyed layer so that the absorbance of the dyed layer decreases by 0.03 to 0.7, provided that the absorbance of the dyed layer is controlled so that it does not become less than 0.3.

Owner:NITTO DENKO CORP

Common optical-path testing of high-numerical-aperture wavefronts

ActiveUS7057737B2Improve polarizationIncreased Polarization PurityOptical measurementsInterferometersWavefrontPhase shifted

Owner:ONTO INNOVATION INC

Wire grid polarizer and method for producing same

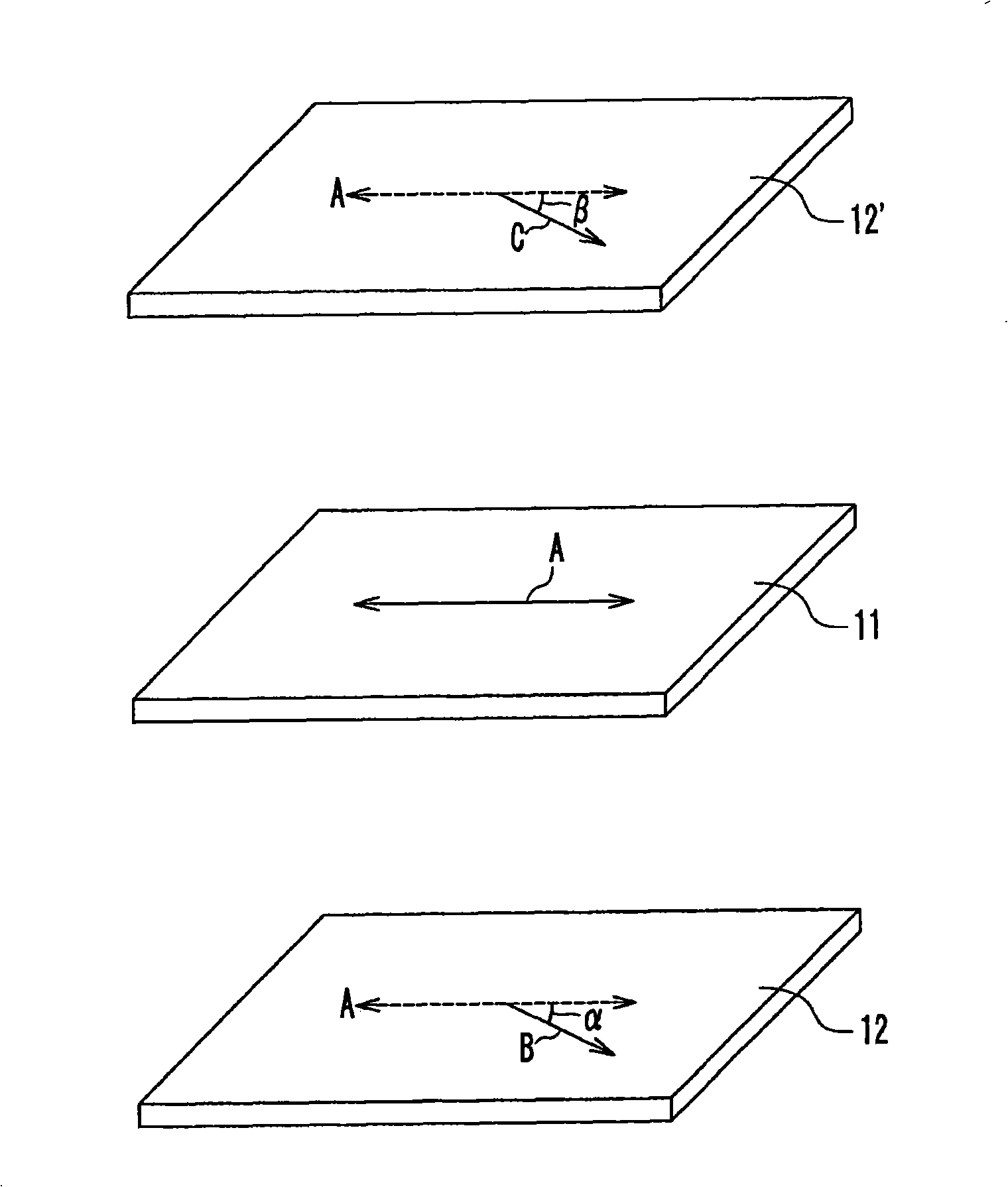

InactiveUS20070152358A1High light transmittanceLow costPolarising elementsOptical articlesWire gridNanoimprint lithography

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:SUGANUMA TAKAYOSHI

Substantially colorless and optically anisotropic material

InactiveUS6881454B2Slim shapeDisplay thinner and lighterLiquid crystal compositionsPolarising elementsMicelleChemistry

A substantially colorless and optically anisotropic material is obtained from substantially colorless and optically anisotropic micelles. The micelles are oriented in a definite direction. The optically anisotropic material is usable in optical films and polarization elements.

Owner:FUJIFILM CORP

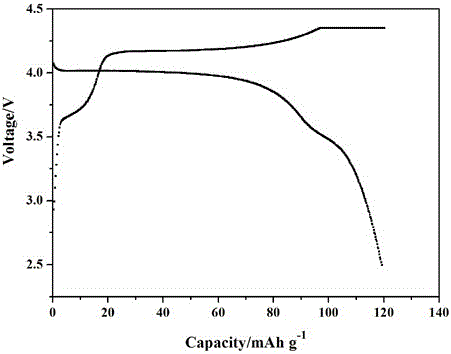

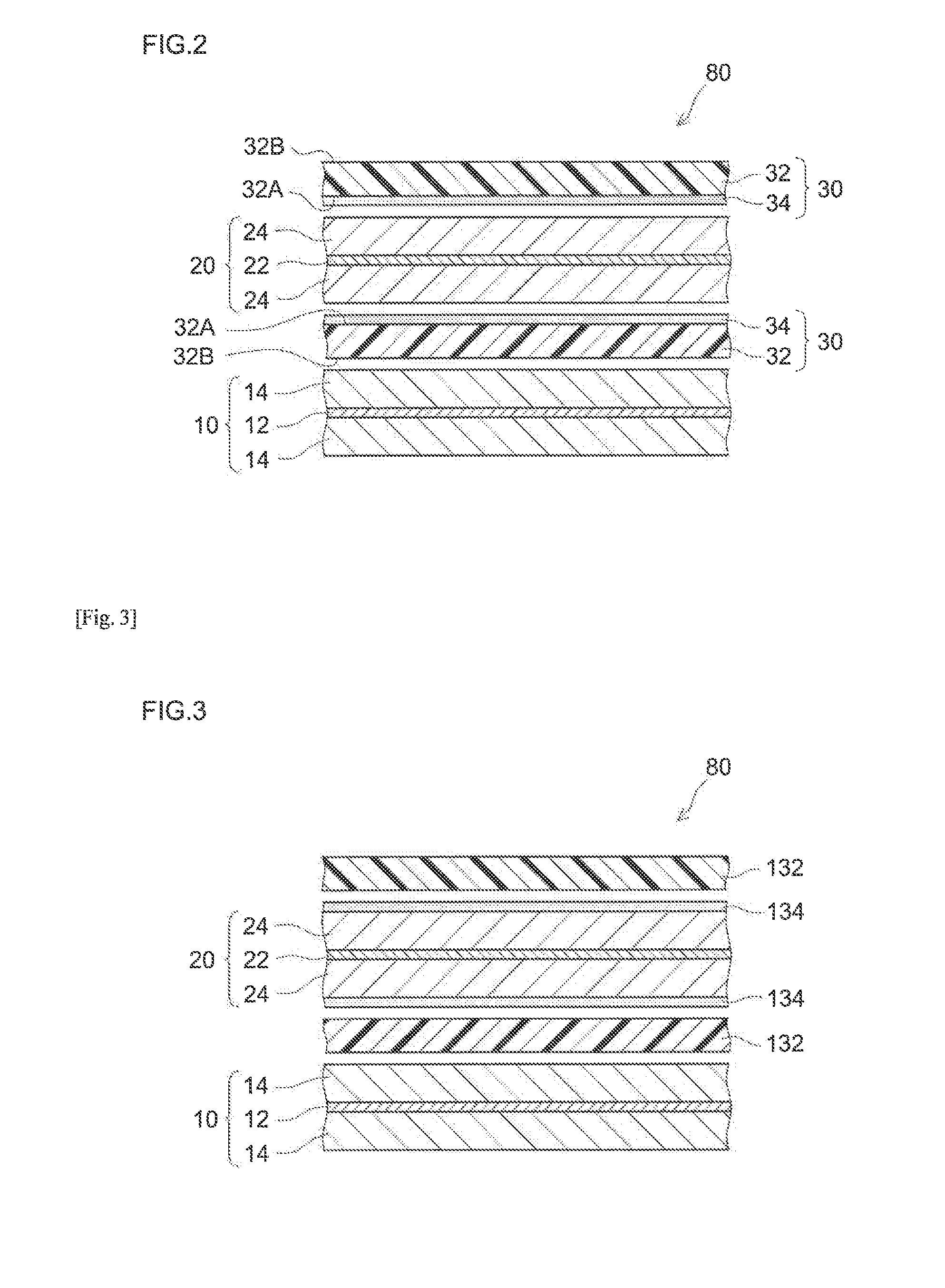

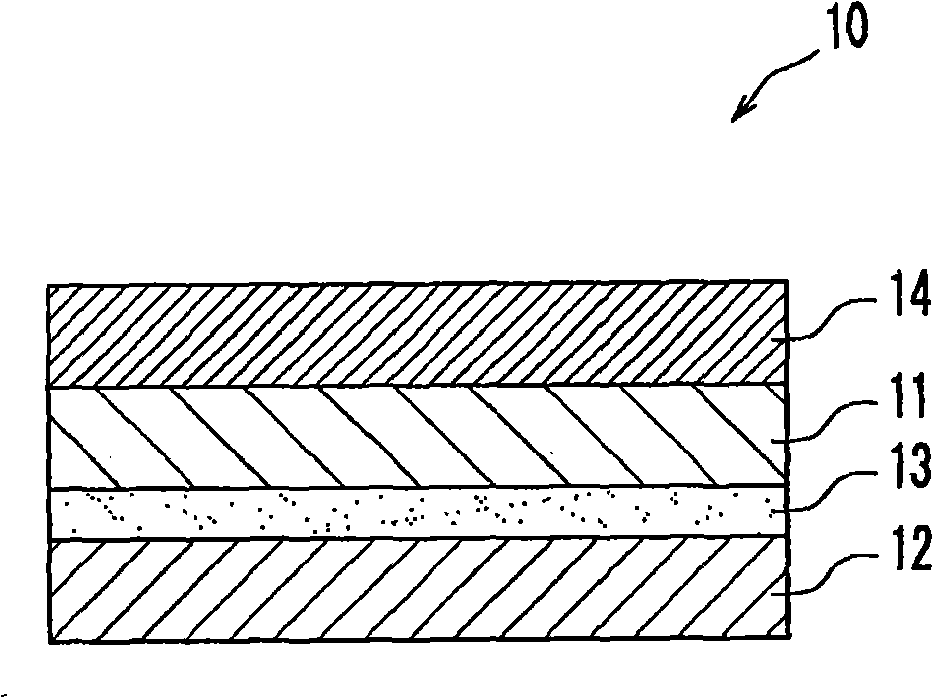

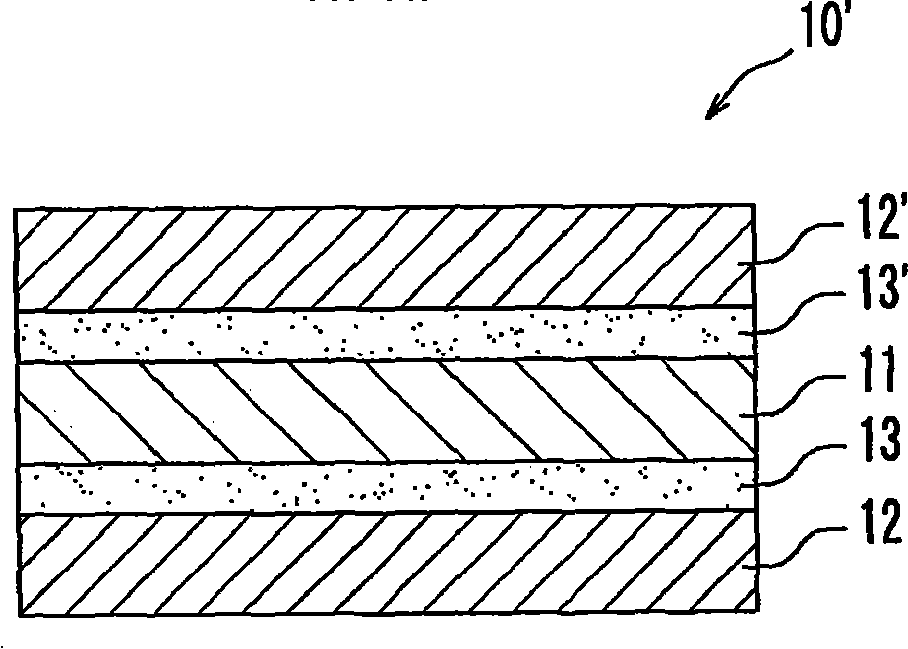

Lithium secondary battery

ActiveUS20150050541A1Improve polarizationHigh overvoltageCell electrodesFinal product manufactureHigh rateEngineering

This invention provides a lithium secondary battery which degrades less upon high-rate charge / discharge cycles (thus durable). The lithium secondary battery comprises positive electrode 10 having positive electrode active material layer 14, negative electrode 20 having negative electrode active material layer 24, organic porous material layer 32 placed between positive electrode active material layer 14 and negative electrode active material layer 24, inorganic porous material layer 34 placed between organic porous material layer 32 and negative electrode active material layer 24. Inorganic porous material layer 34 comprises an inorganic filler that does not store lithium at a potential higher than the lithium-storing potential of the negative electrode active material layer, and a Li absorber that irreversibly stores lithium at a potential higher than the lithium storing potential.

Owner:TOYOTA JIDOSHA KK

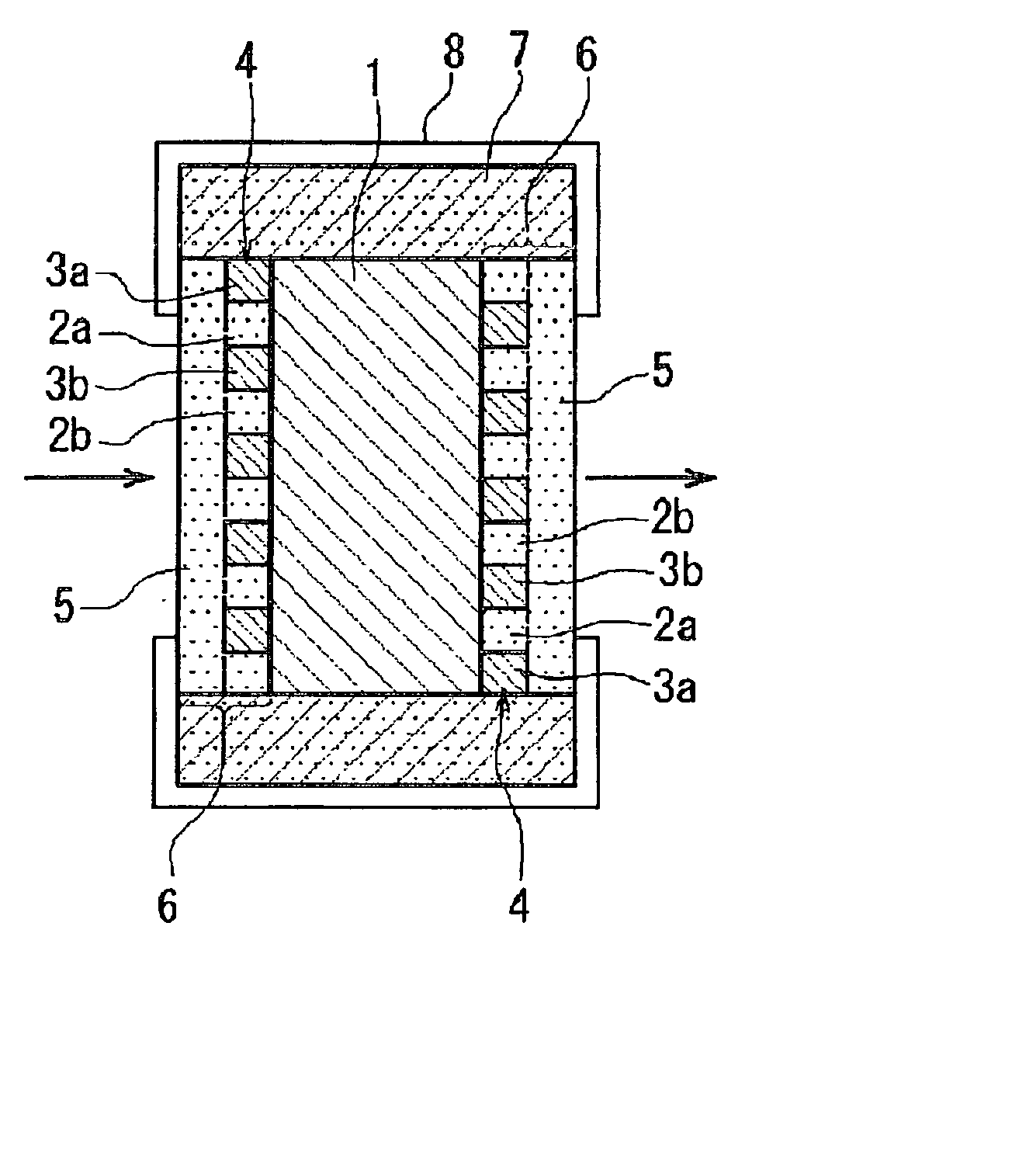

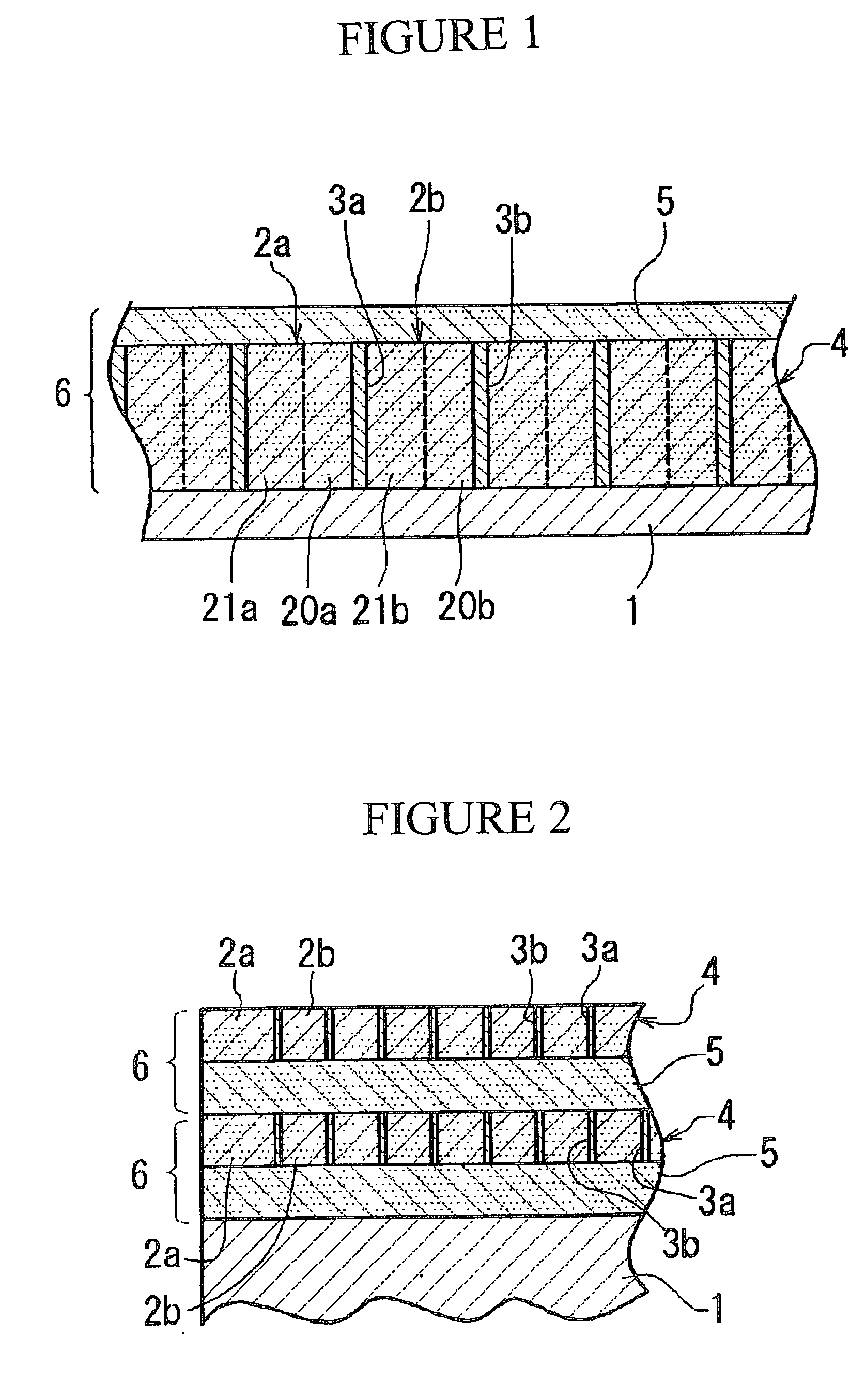

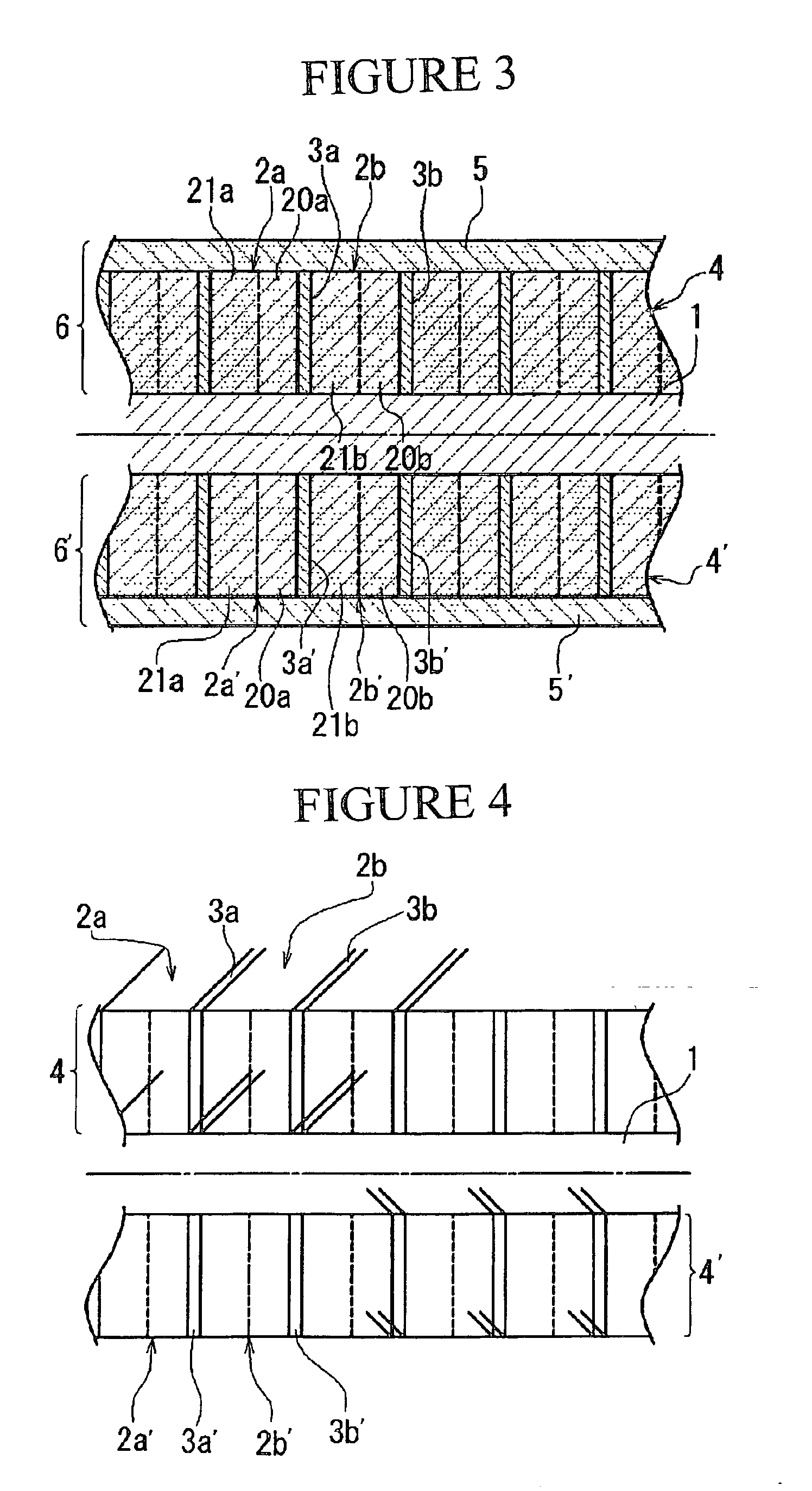

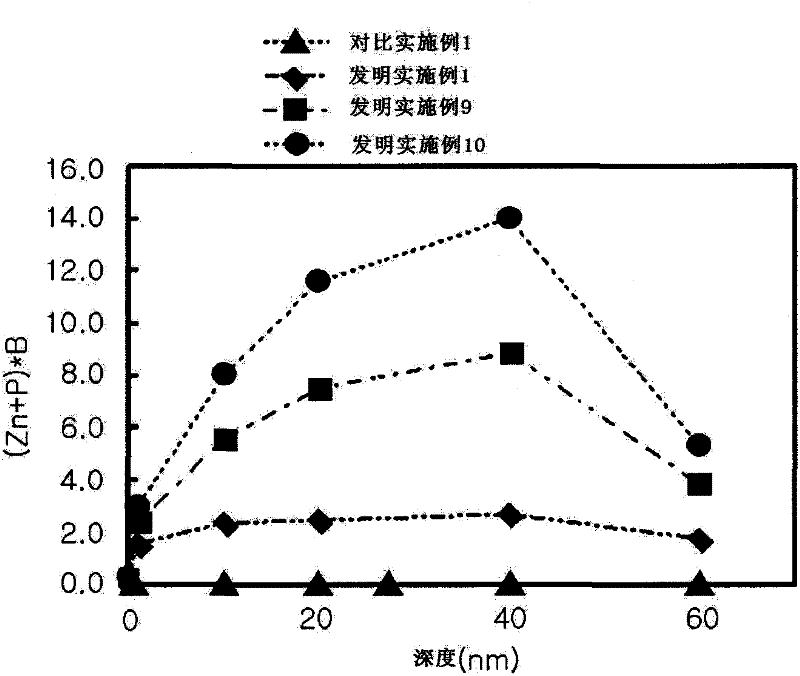

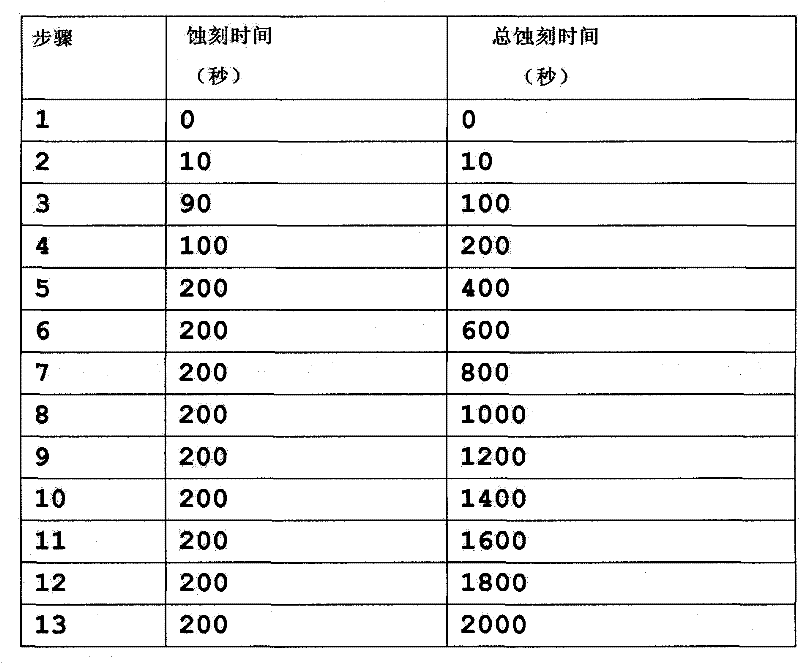

Polarizing function element, optical isolator, laser diode module and method of producing polarizing function element

InactiveUS20030007251A1Improve polarizationSuppresses reflective scattering of the input beamOptical filtersPolarising elementsOptical isolatorLight beam

This invention has the polarizing function of polarizing an input beam and a non-reflecting function of suppressing reflection of the input beam, wherein at least one side of a light-transmissive substrate 1 has a polarizing portion 4 with a striped structure formed by multiple alternating light-transmissive dielectric layers 2a, 2b . . . and metallic film layers 3a, 3b . . . . Its characteristics are improved if the metallic film layers are very thin and flat, with a target thickness in the range from 5 to 20 nm and variation of film thickness within the range of ±10%.

Owner:NAMIKI PRECISION JEWEL CO LTD

Bulk production and usage of hyperpolarized 129Xenon

InactiveUS6125654AEnhanced magnetic resonance imagingHigh sensitivitySolidificationLiquefactionSpin relaxationSpins

The production and usage of hyperpolarized 129Xenon which comprises providing solid xenon with either an internal (dissolved) or external (imbedded) nuclear spin relaxant, loading and positioning the solid xenon in a low temperature refrigerator operating in the range of 5 mK to 30 mK with a surrounding magnetic field of between about 10 and 20 Tesla enabling high xenon spin polarizations between about 10% and 50% to be obtained in a time of about 1-3 days owing to the properties of the relaxant, separating the xenon from the relaxant or otherwise rendering the relaxant inoperable after polarizing and thereby switching off further relaxation and insuring preservation of the polarization of the xenon in solid, liquid or gaseous form for storage or external use for long times, ranging from weeks to the order of minutes, depending on the usage conditions.

Owner:SYRACUSE UNIVERSITY

Polarizing element having excellent durability and heat resistance, polarizing plate and image display device, and method of manufacturing polarizing element

ActiveCN102301260AExcellent initial orthogonal transmittanceImprove transmittancePolarising elementsCold-cathode tubesDisplay devicePolarizer

Owner:LG CHEM LTD

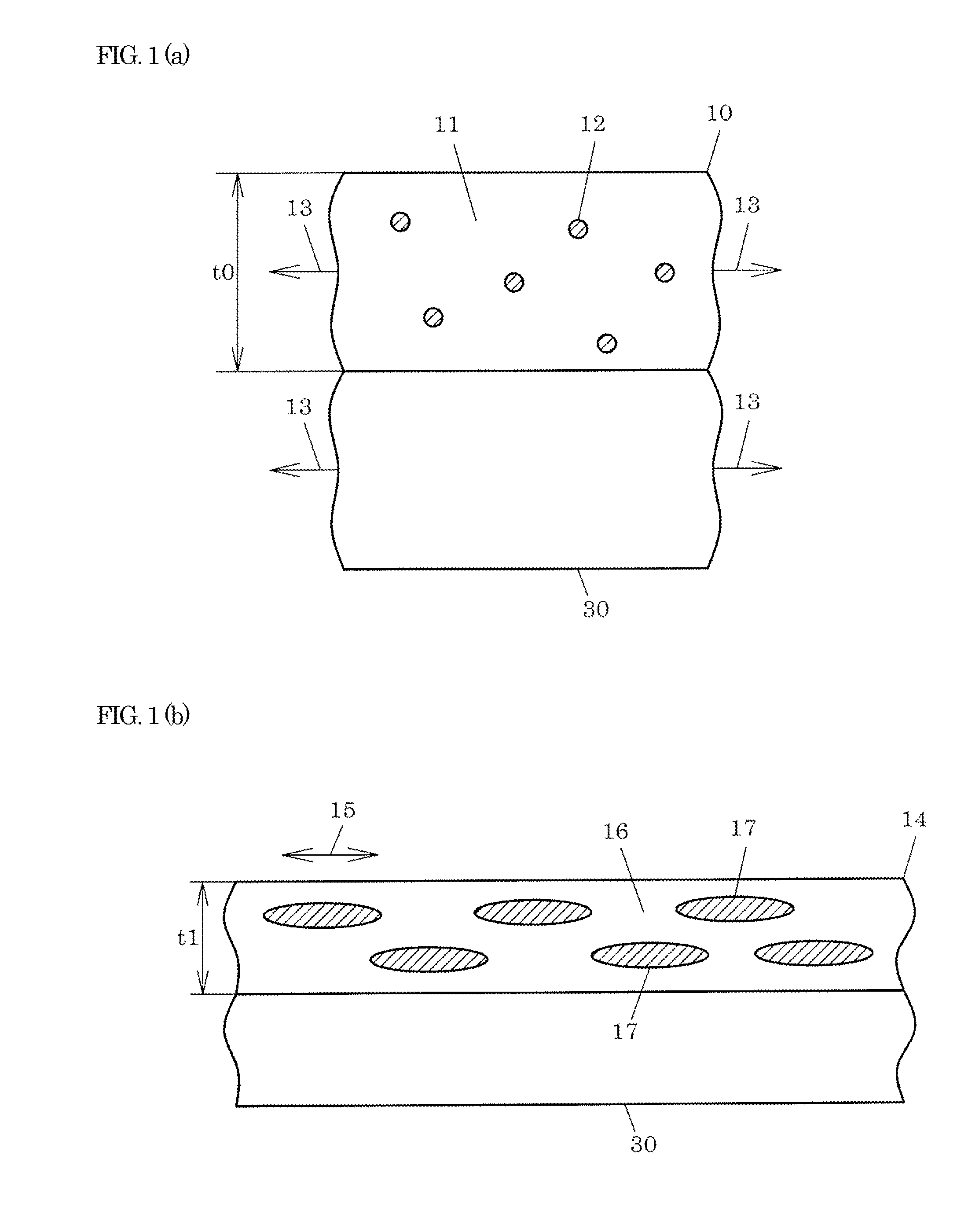

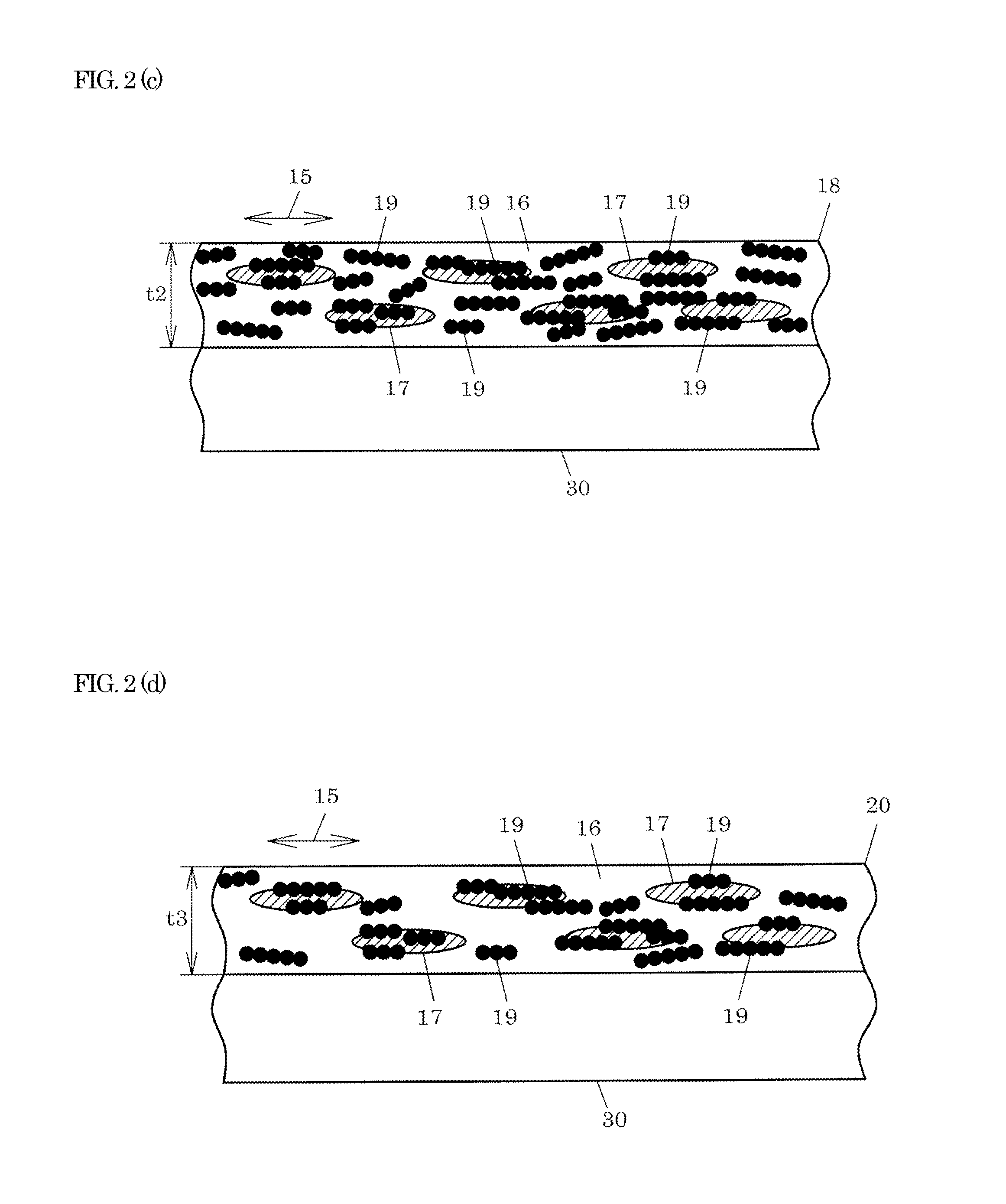

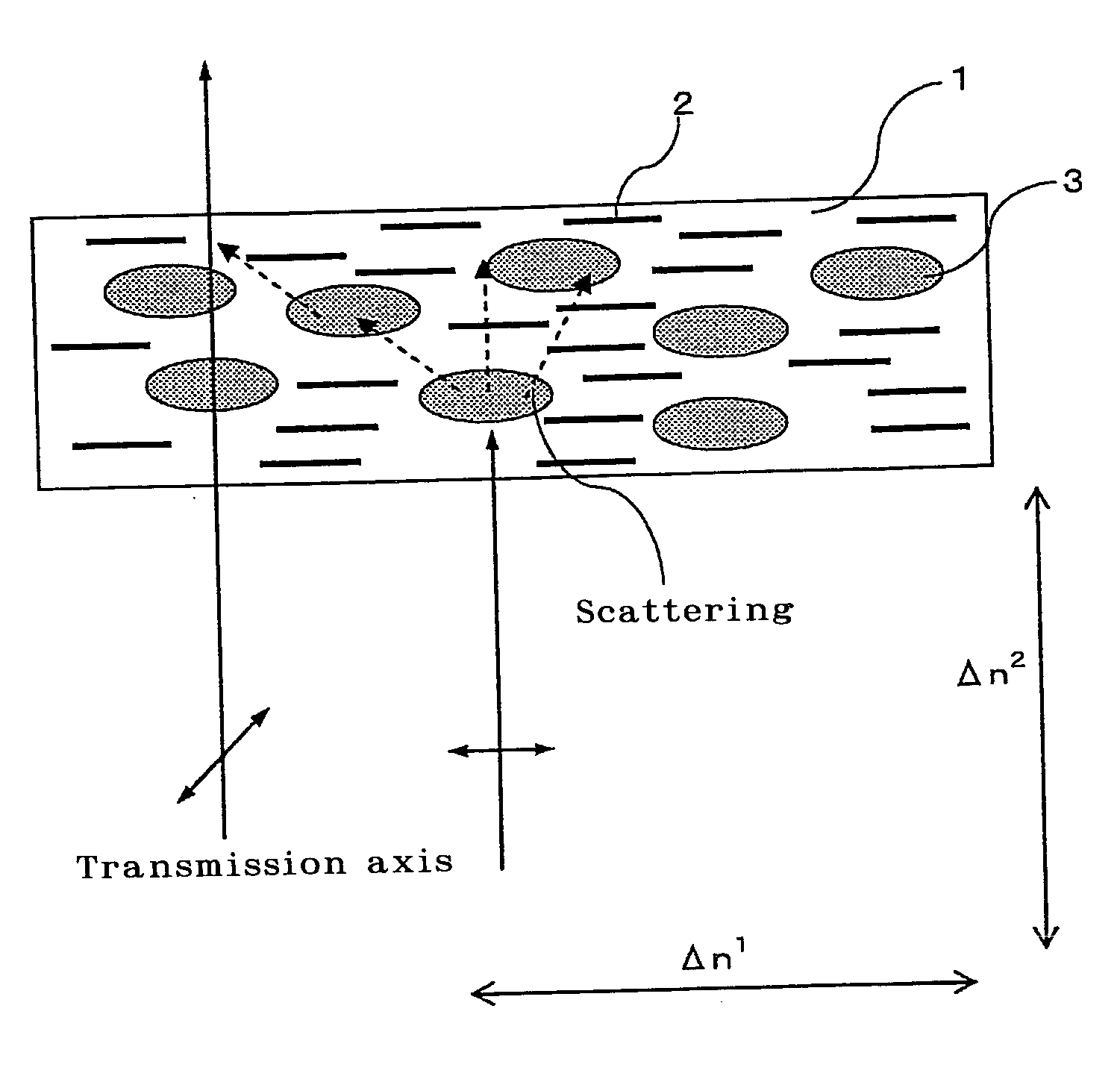

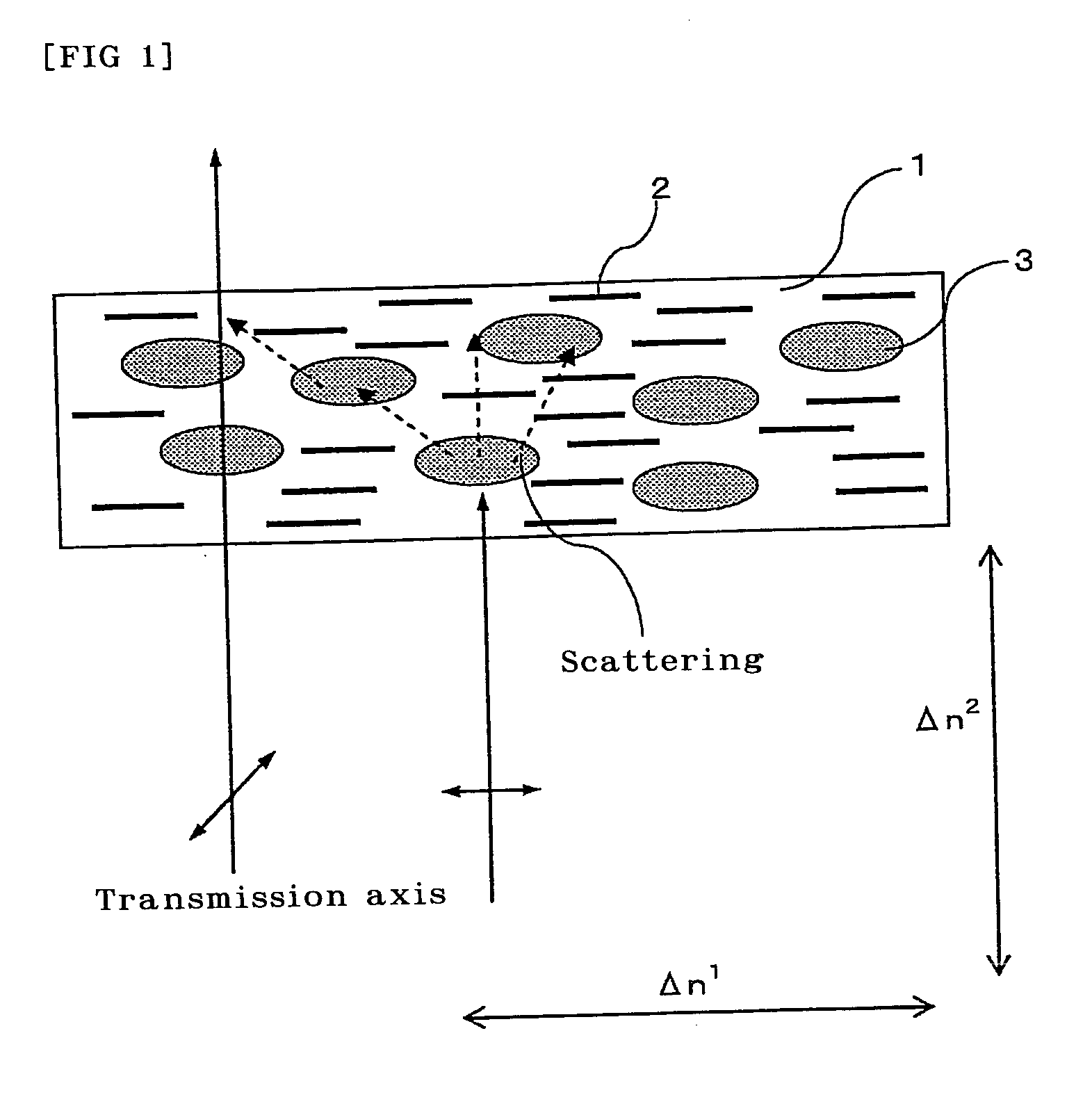

Methods for Manufacturing Polarizers, Polarizing Plates and Laminated Optical Films, and Polarizers, Polarizing Plates, Laminated Optical Films, and Image Displays

InactiveUS20080231793A1Improve polarizationAccuracy meetsLiquid crystal compositionsPolarising elementsLiquid crystallineDisplay device

A method for manufacturing a polarizer of the invention, wherein the polarizer comprises a film that comprises: a matrix made of an optically-transparent resin containing a dichroic absorbing material; and minute domains that are made of an energy ray-curable birefringent material having liquid crystalline properties and are aligned and dispersed in the matrix; and comprising a process of applying energy rays for fixing the alignment of the birefringent material having liquid crystalline properties. A polarizer obtained by the method has a high transmittance and a high polarization degree, and being able to control unevenness of the transmittance in the case of black viewing.

Owner:NITTO DENKO CORP

Method for producing polarizer

ActiveUS20140016198A1Improve polarizationIncrease volumeLayered productsPolarising elementsPolyvinyl alcoholIodine

Owner:NITTO DENKO CORP

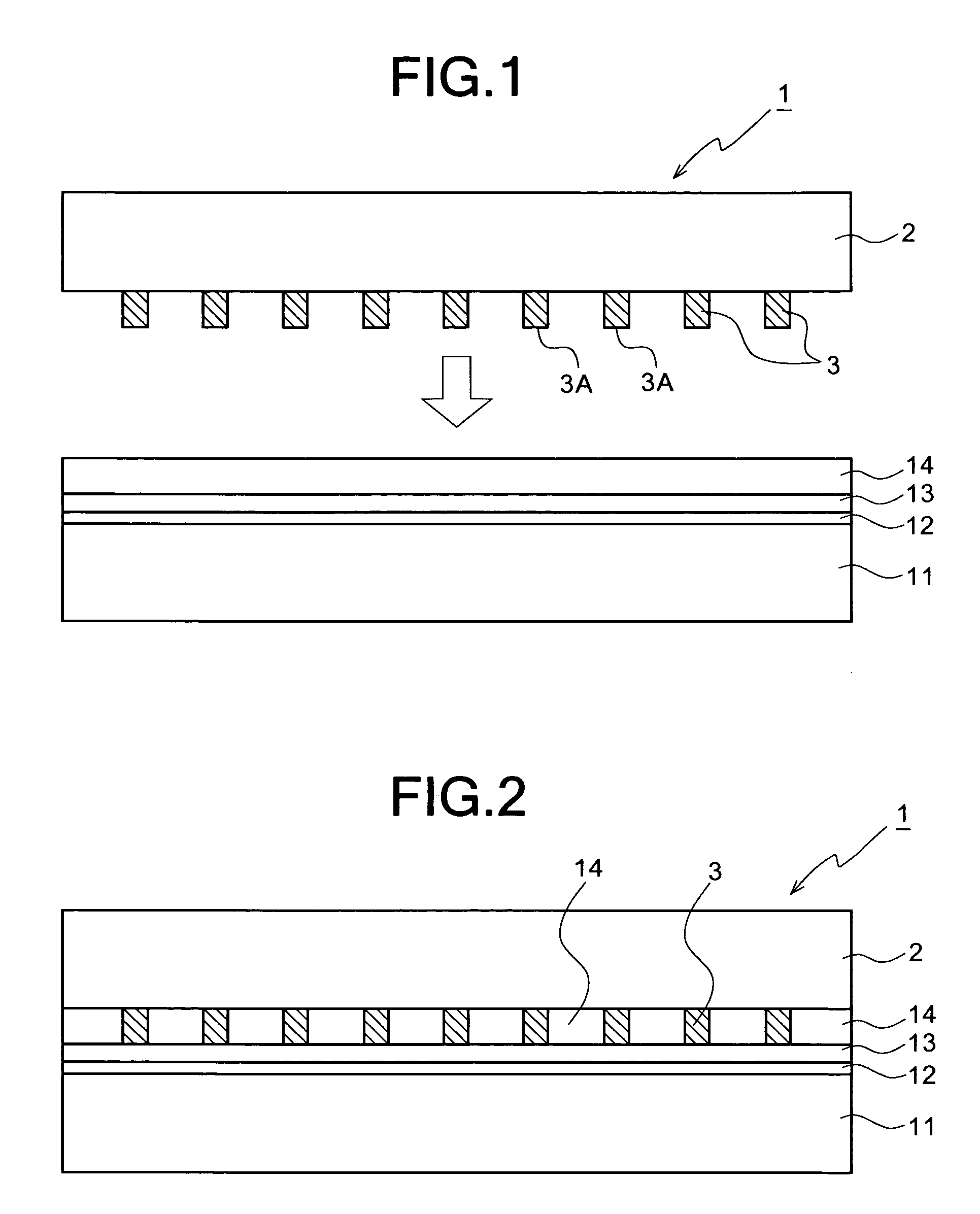

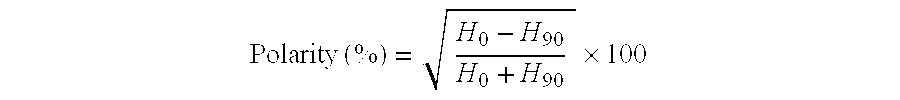

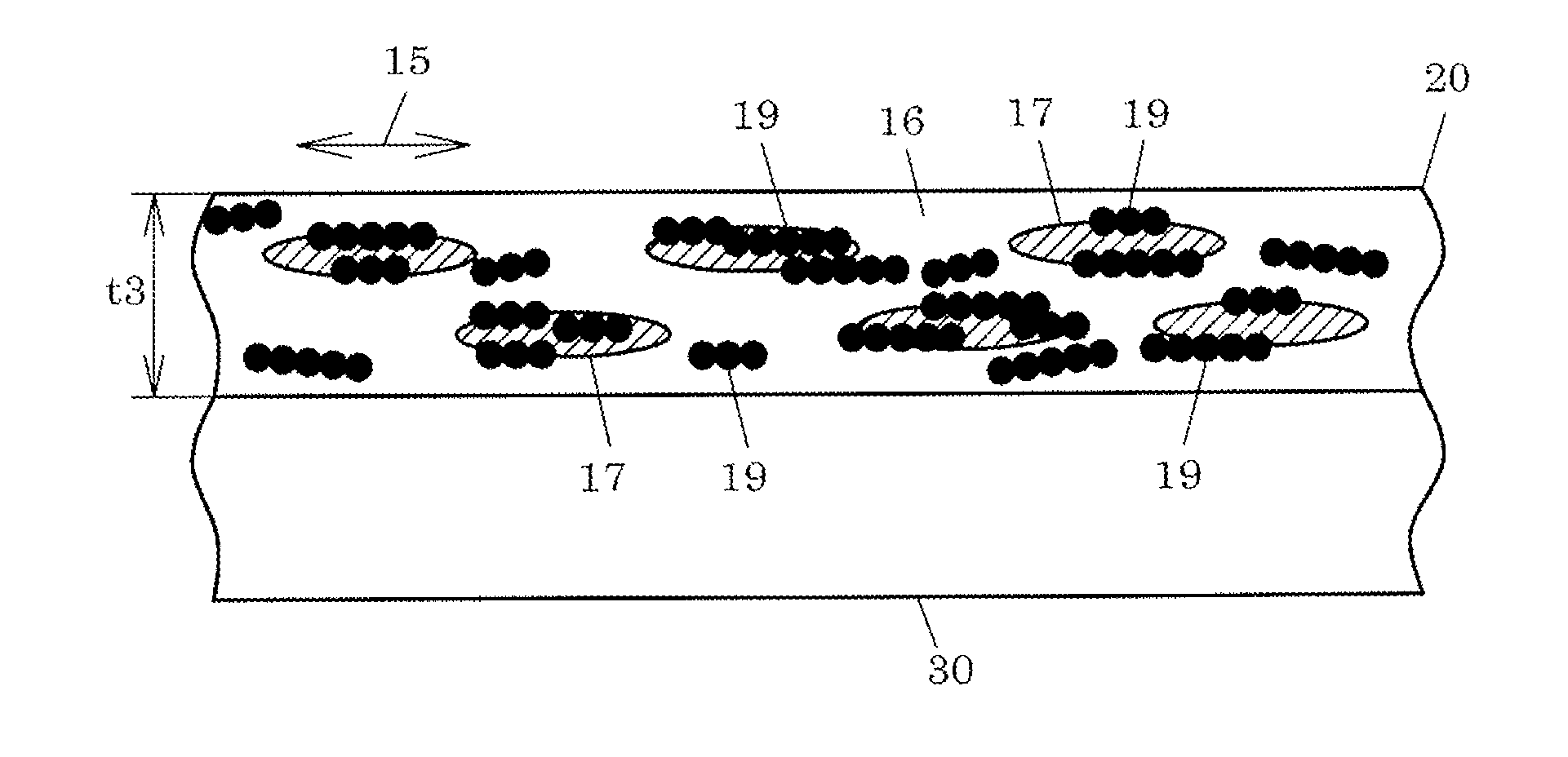

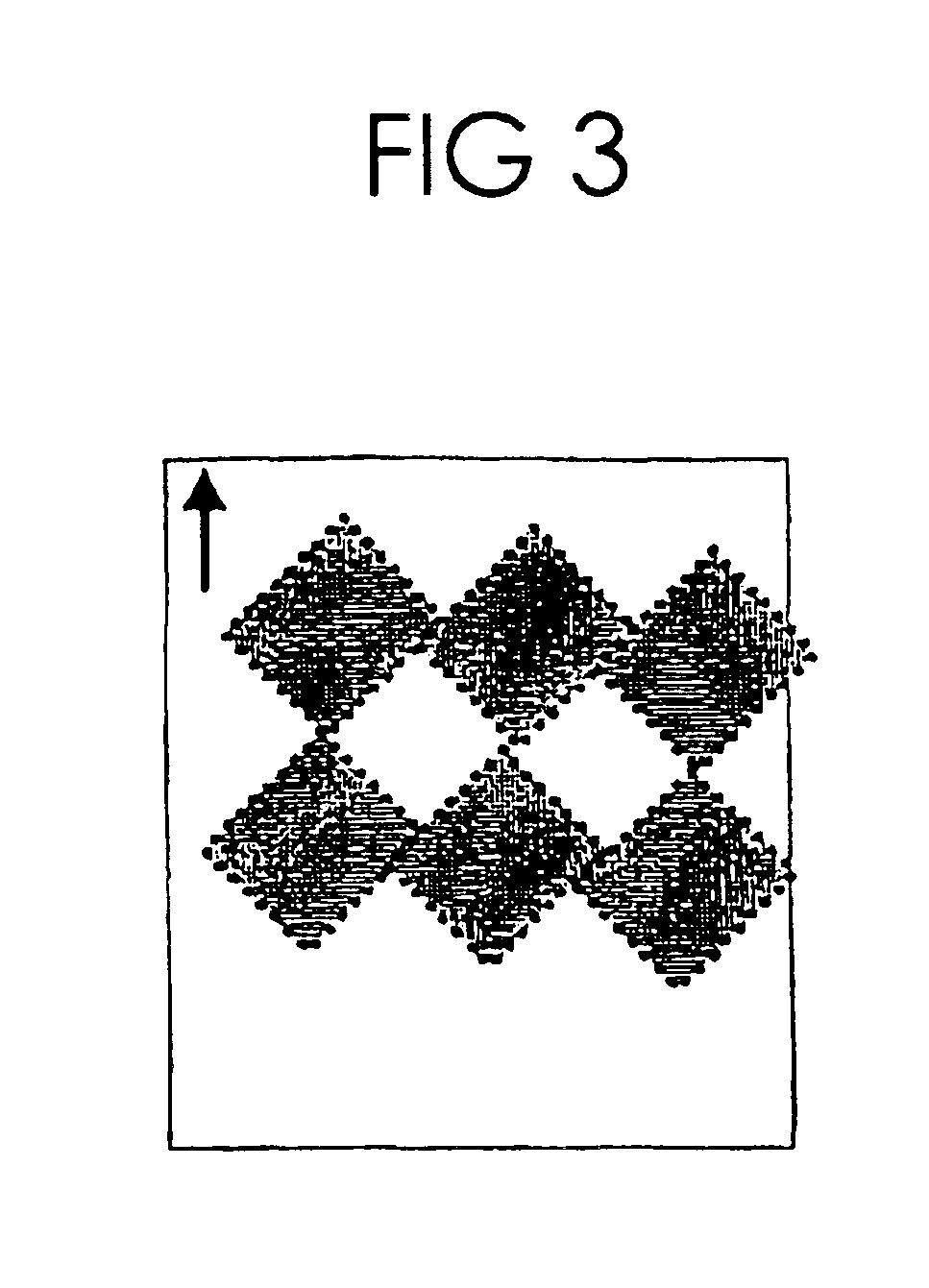

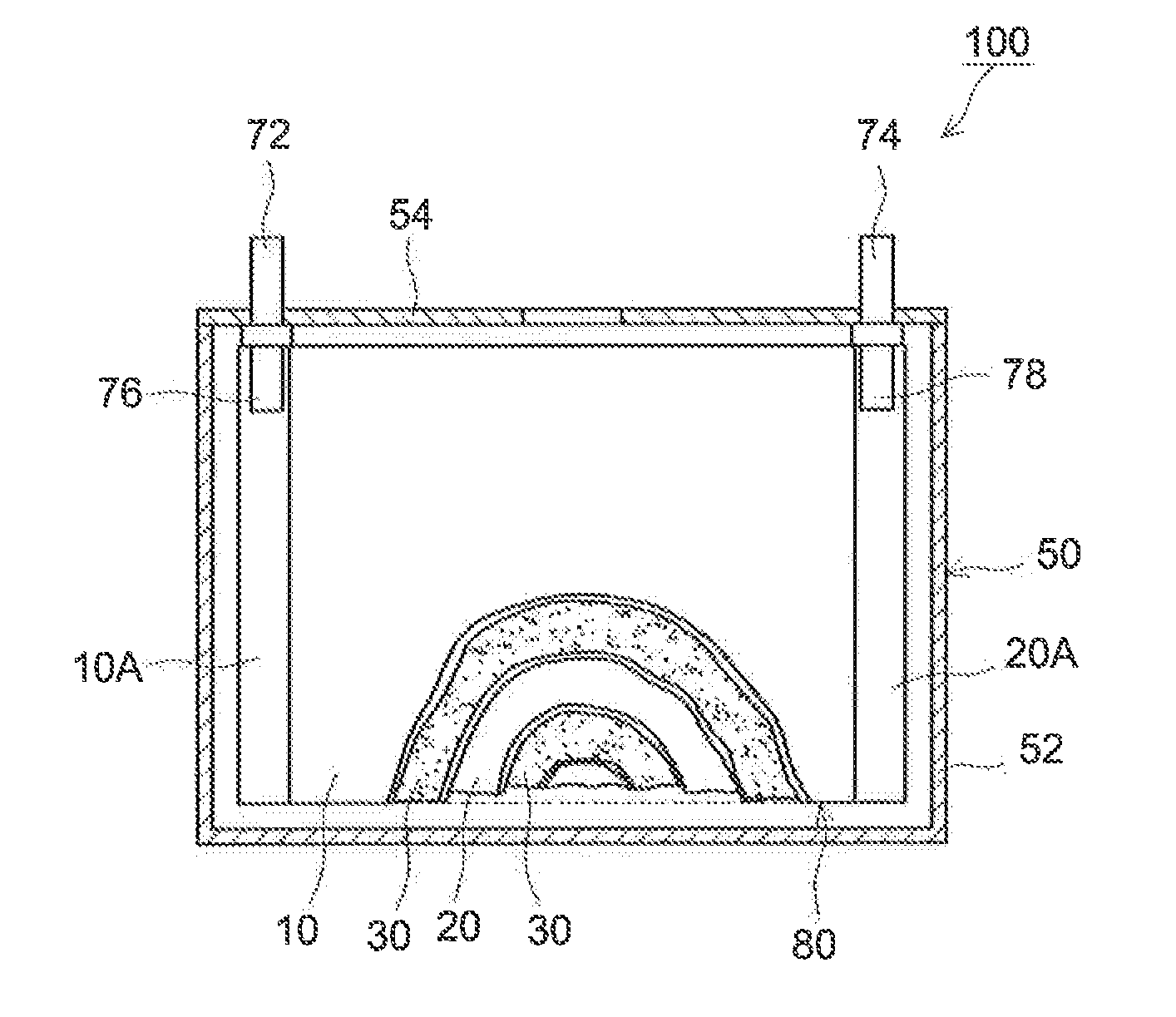

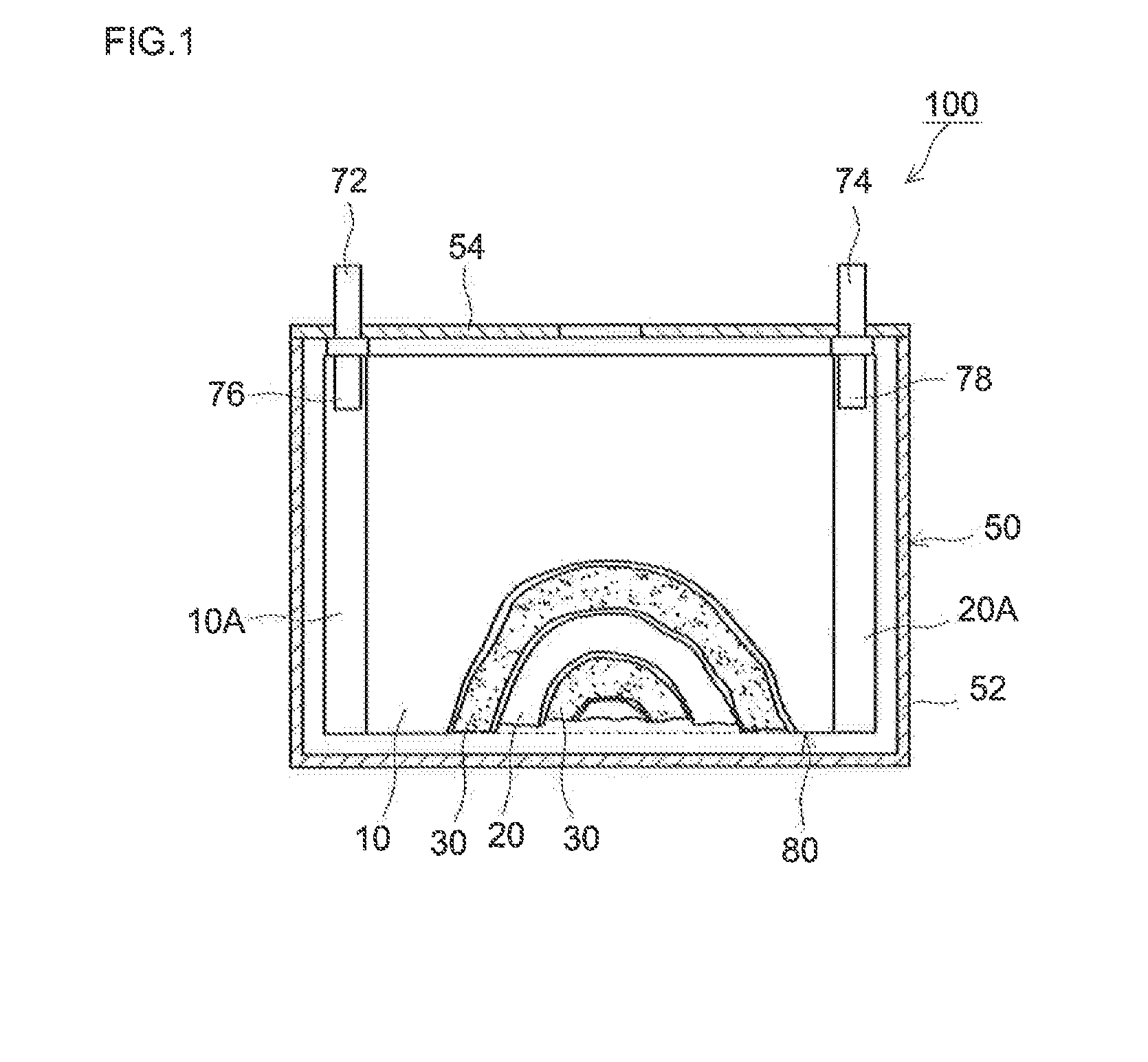

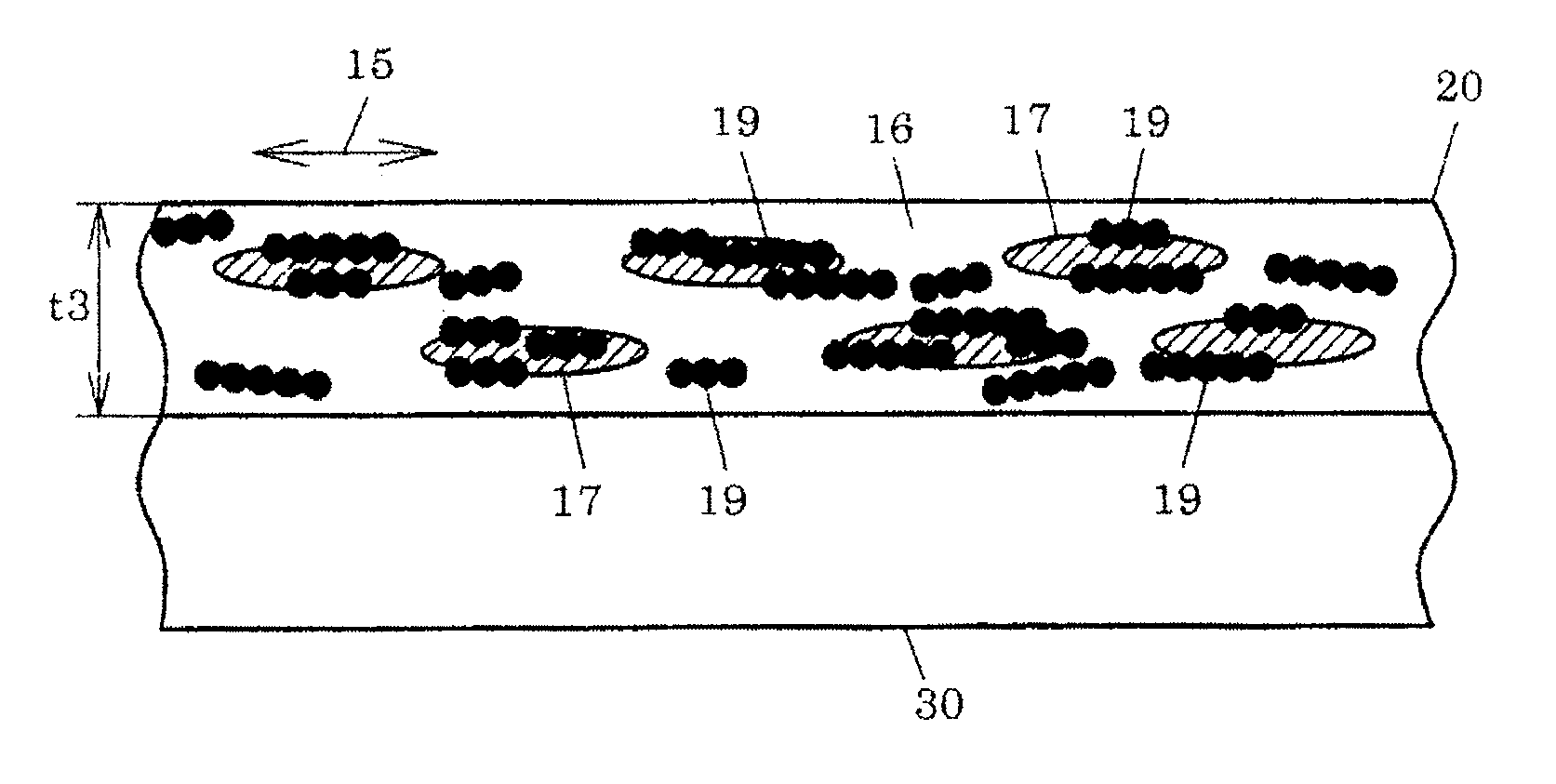

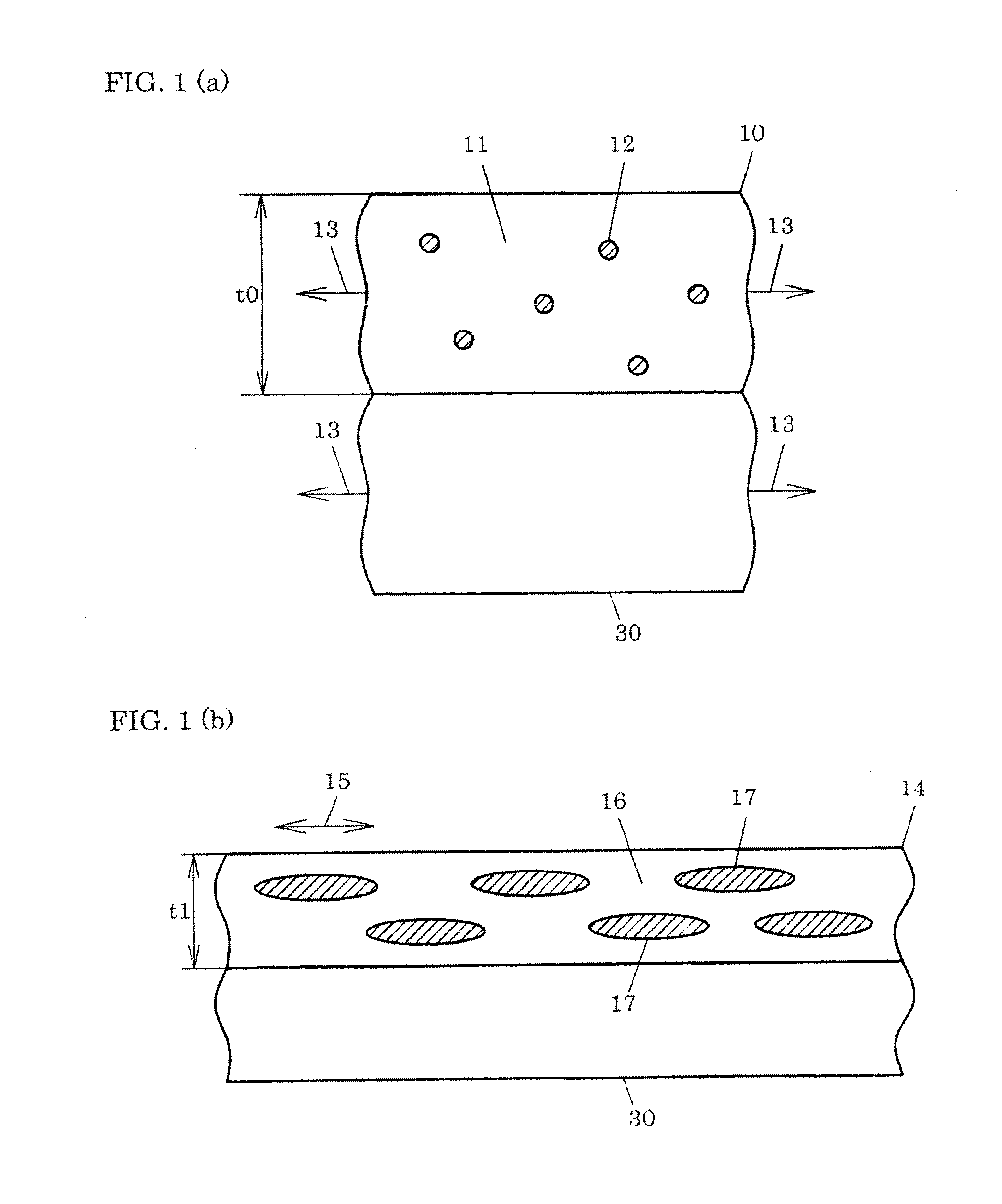

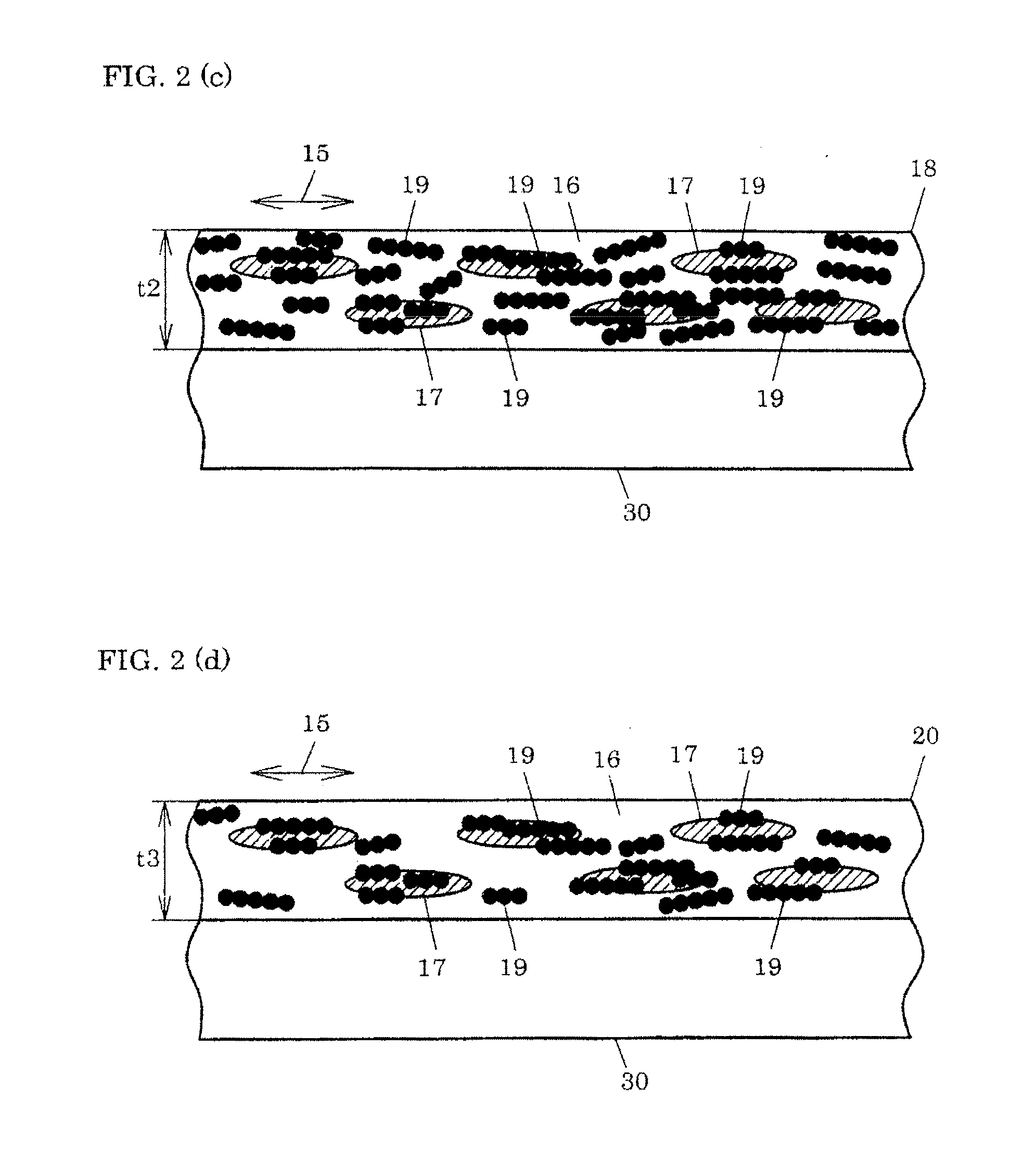

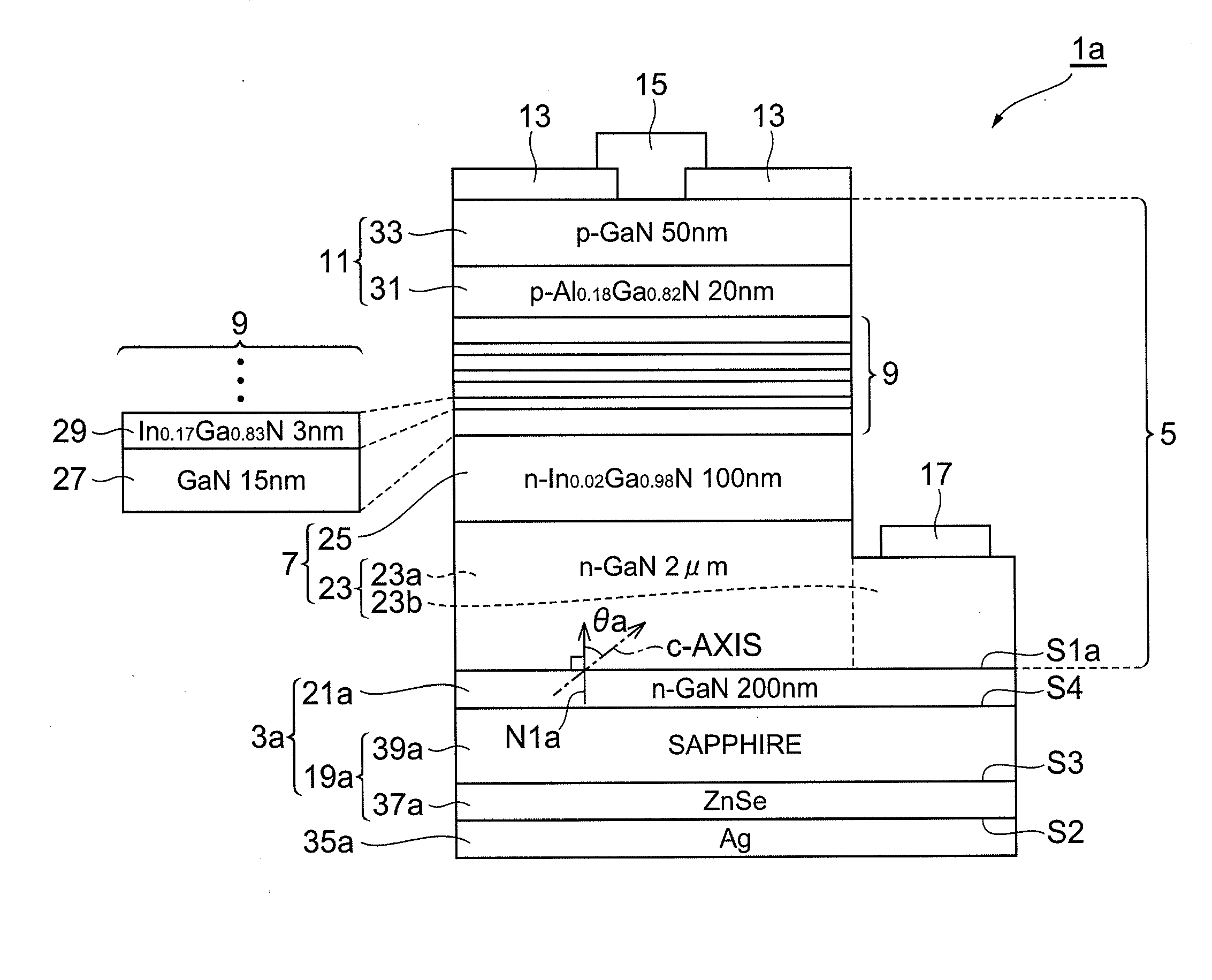

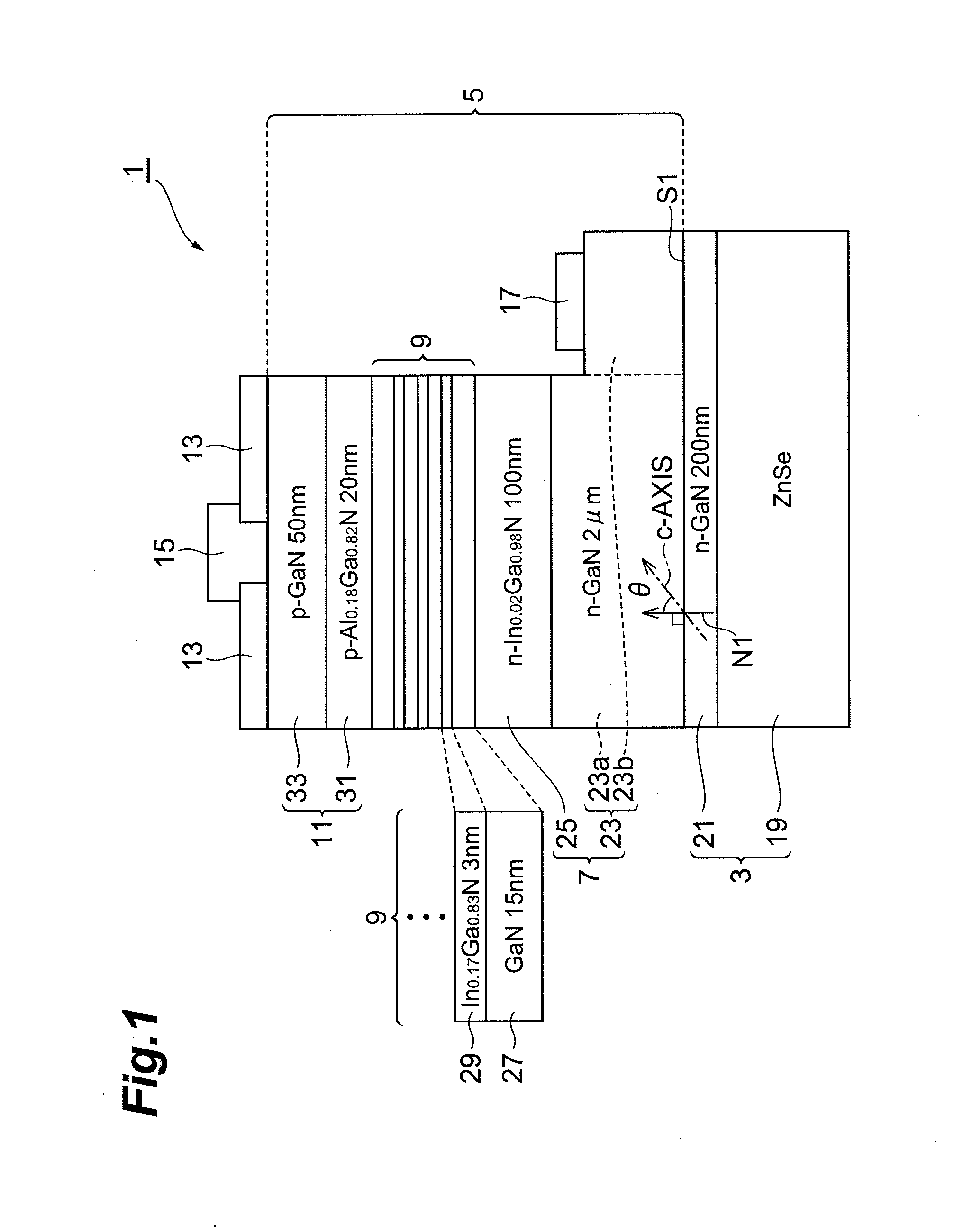

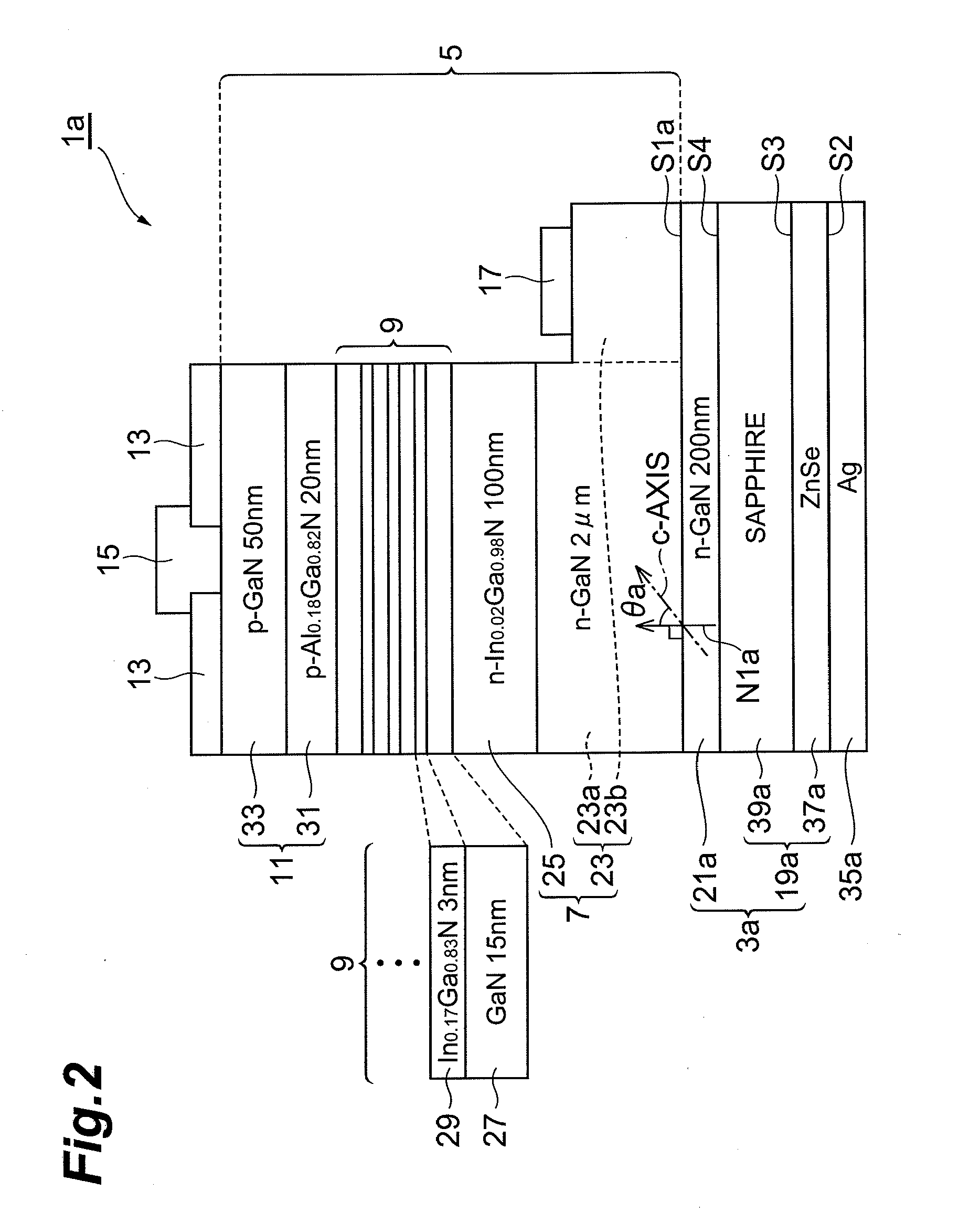

Light emitting device

InactiveUS20110073892A1Improve utilization efficiencyLower substrate costSemiconductor devicesComposite substrateGallium nitride

A light emitting device having a relatively simple configuration is provided that emits stable light having a plurality of wavelengths. The light emitting device 1 comprises, in sequence, a composite substrate 3 and a gallium nitride-based semiconductor layer 5 including a light emitting layer 9. The composite substrate 3 includes a base 19 and a gallium nitride layer, the gallium nitride-based semiconductor layer 5 being disposed on a principal surface of the gallium nitride layer, the angle θ defined by the c-axis of the gallium nitride layer and a normal line N1 to the principal surface S1 of the gallium nitride layer ranging from 50 to 130 degrees, the light emitting layer 9 emitting light with an absolute value of the degree of polarization of 0.2 or more, the base 19 containing a fluorescent material that emits a fluorescent light component induced by irradiation of a light component emitted from the light emitting layer 9. Accordingly, the light emitting device 1 can emit white light produced by superposition of blue light directly emitted from the light emitting layer 9 and yellow light induced by blue light incident on the base 19 from the light emitting layer 9.

Owner:SUMITOMO ELECTRIC IND LTD

Laminated optical film and production method thereof

InactiveCN101285958AAvoid enteringImprove transmittanceLaminationLamination apparatusEngineeringPolarizer

A laminated optical film according to an embodiment of the present invention includes a long polarizer having an absorption axis in a lengthwise direction and a long optical compensation film. An angle formed by a slow axis of the optical compensation film and the absorption axis of the polarizer is 5 to 85 DEG .

Owner:NITTO DENKO CORP

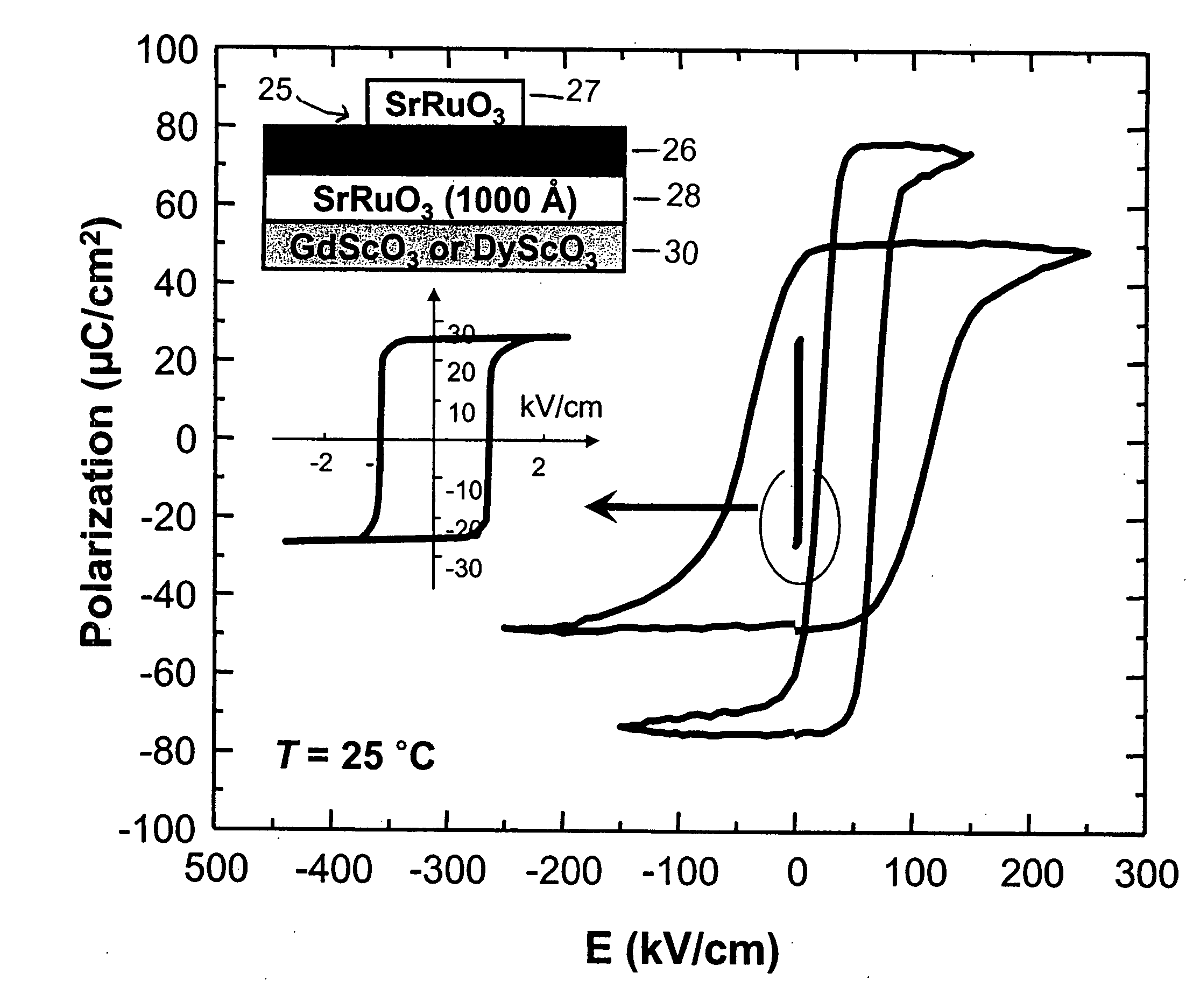

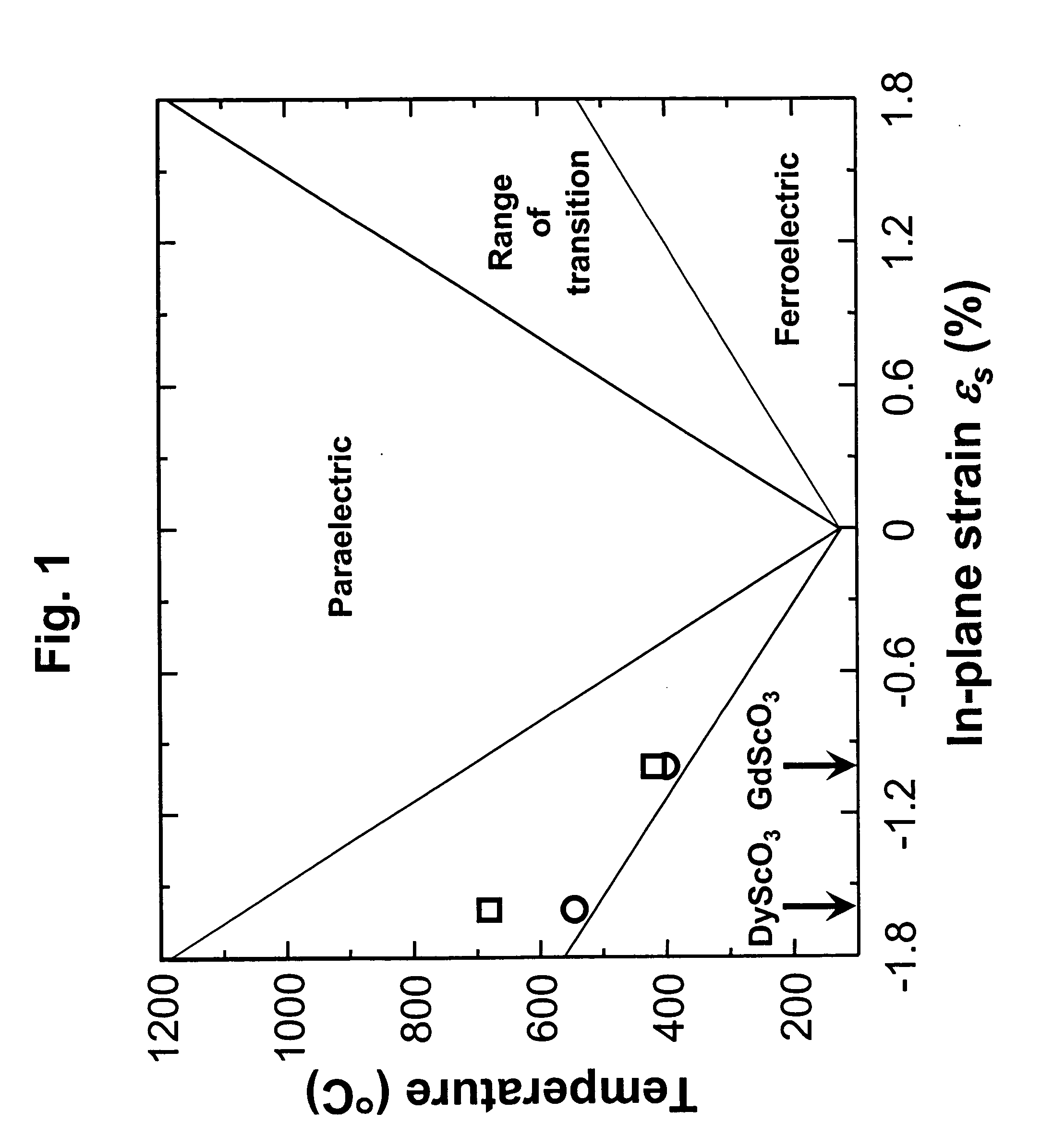

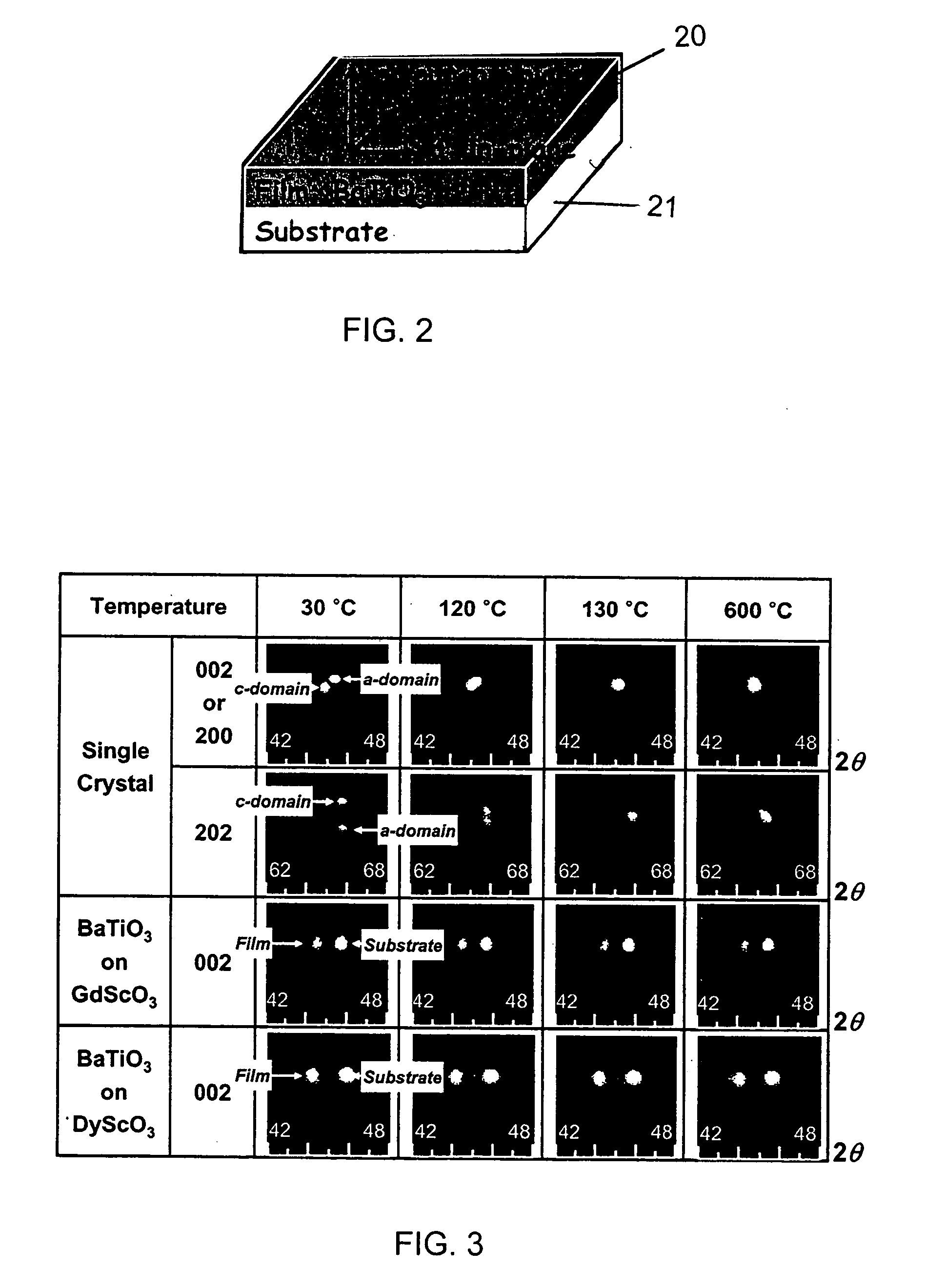

Strain-engineered ferroelectric thin films

ActiveUS20060091434A1Improve ferroelectric propertiesRaise the transition temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesInter layerFerroelectric thin films

A strained thin film structure includes a substrate layer formed of a crystalline scandate material having a top surface, and a strained layer of crystalline ferroelectric epitaxially grown with respect to the crystalline substrate layer so as to be in a strained state and at a thickness below which dislocations begin to occur in the crystalline ferroelectric layer. An intermediate layer may be grown between the top surface of the substrate layer and the ferroelectric layer wherein the intermediate layer carries the lattice structure of the underlying substrate layer. The properties of the ferroelectric film are greatly enhanced as compared to the bulk ferroelectric material, and such films are suitable for use in applications including ferroelectric memories.

Owner:PENN STATE RES FOUND +1

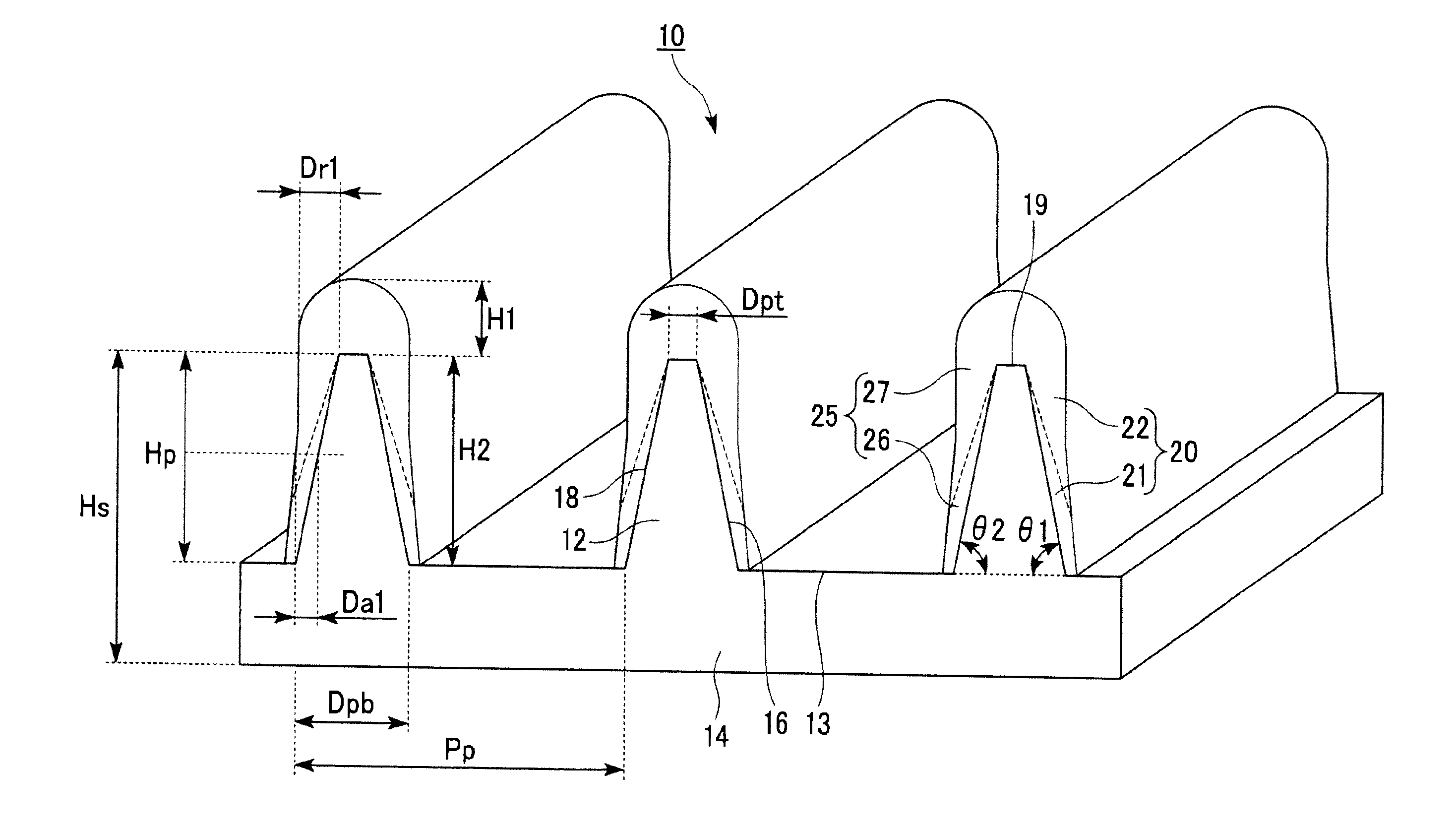

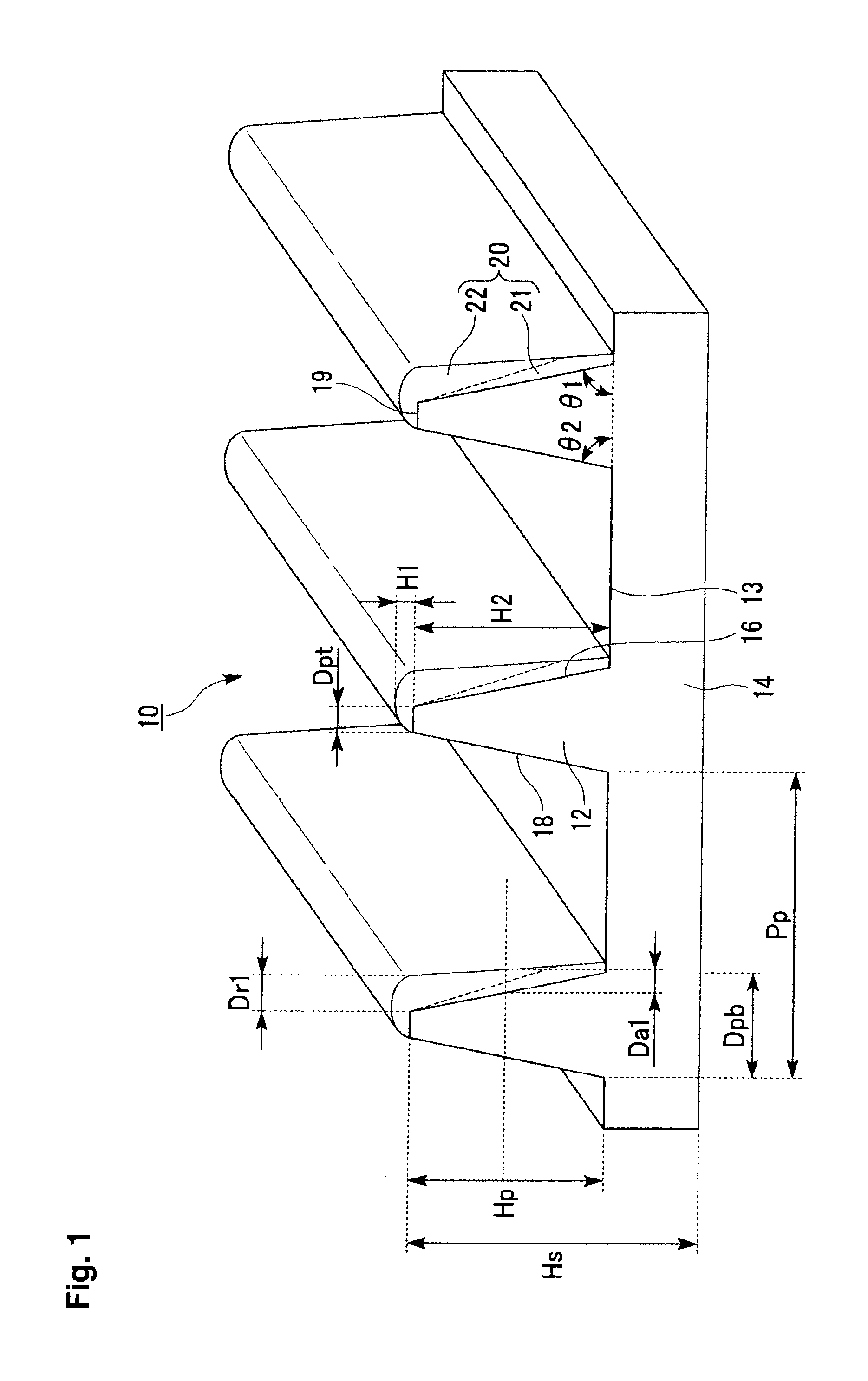

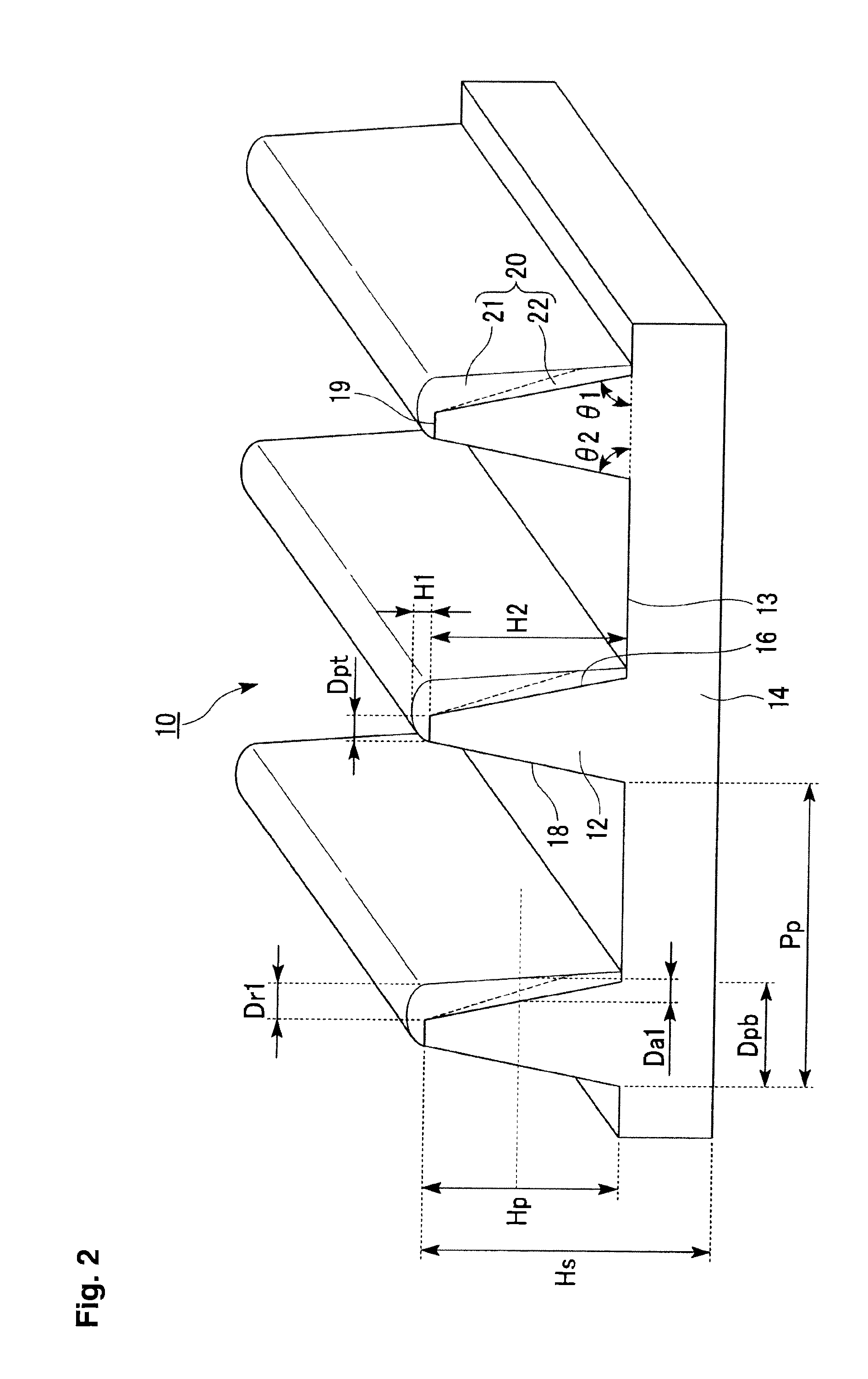

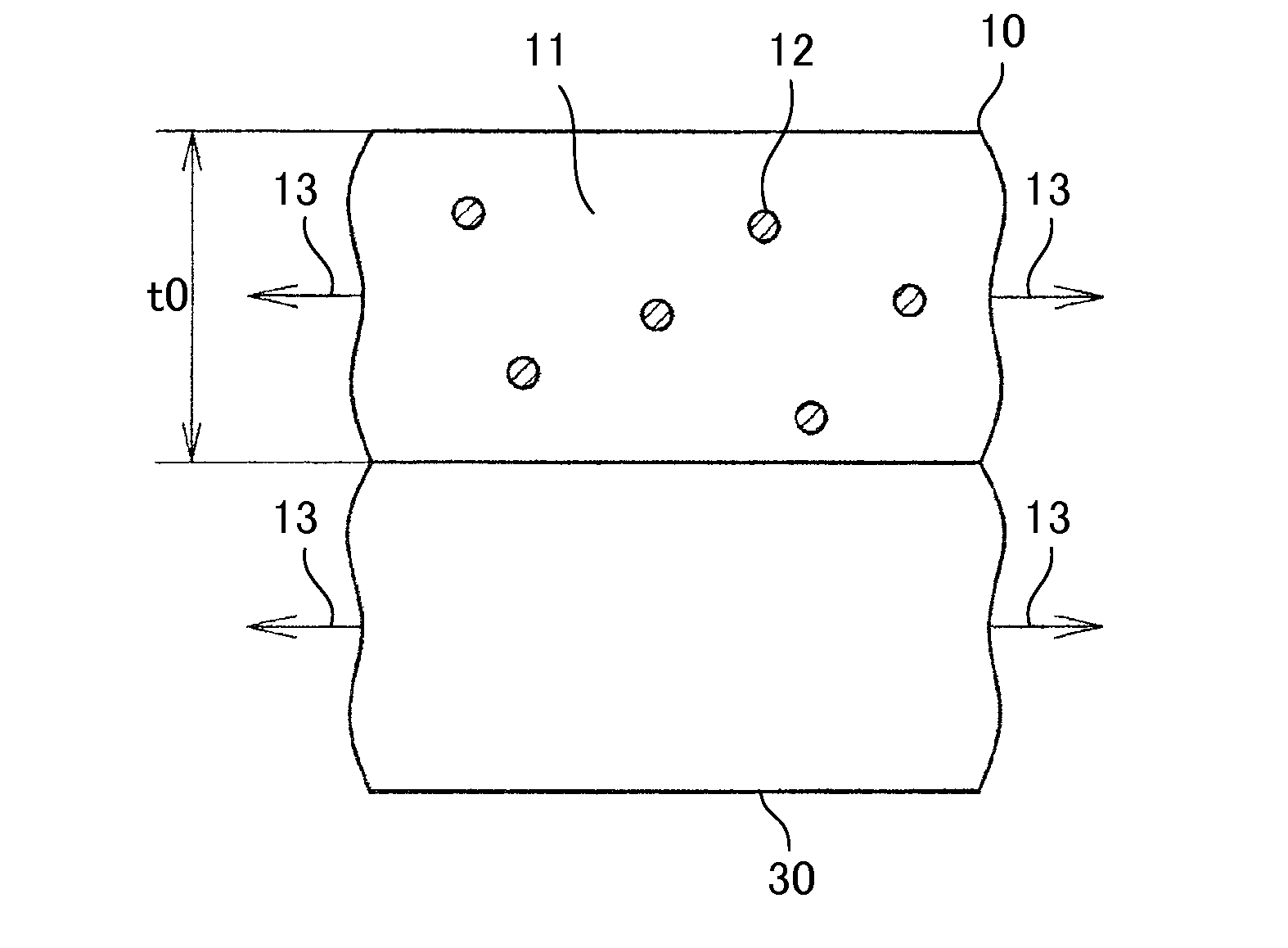

Process for producing wire-grid polarizer, and liquid crystal display device

InactiveUS20130040052A1Improve productivityImprove polarizationVacuum evaporation coatingSputtering coatingWire gridLiquid-crystal display

A process for producing a wire-grid polarizer; the wire-grid polarizer comprising: a light-transmitting substrate 14 having a surface on which a plurality of ridges 12 are formed in parallel with one another at a predetermined pitch; and a first cover layer 20 comprising a metal layer 22 and a metal oxide layer 21 and covering a first side surface 16 of each ridge 12, the maximum covering thickness of the cover layer 20 in a lower region of the ridge 12 being smaller than the maximum covering thickness of the cover layer 20 in an upper region of the ridge 12; the process comprising: forming the metal layer 22 by vapor-depositing aluminum so that no oxide is formed in the metal layer; and forming the metal oxide layer 21 by vapor-depositing aluminum under the presence of oxygen so that oxygen defects are formed in the metal oxide layer 21.

Owner:ASAHI GLASS CO LTD

Method for producing polarizer

InactiveUS20160025910A1High degree of polarizationImprove polarizationSynthetic resin layered productsLaminationPolarizerTransmittance

A method for producing a polarizer comprises the steps of: (A) forming a polyvinyl alcohol-based resin layer on a support made of an optically transparent thermoplastic resin; (B) stretching a polyvinyl alcohol-based resin layer together with the support to obtain a stretched layer; (C) immersing the stretched layer in a dyeing liquid containing iodine to obtain a dyed layer in which absorbance thereof determined from a tristimulus value Y is from 0.4 to 1.0 (transmittance T=40% to 10%); and (D) removing a part of iodine adsorbed in the dyed layer so that the absorbance of the dyed layer decreases by 0.03 to 0.7, provided that the absorbance of the dyed layer is controlled so that it does not become less than 0.3. The support may be used as an optical film laminated to the polarizer.

Owner:NITTO DENKO CORP

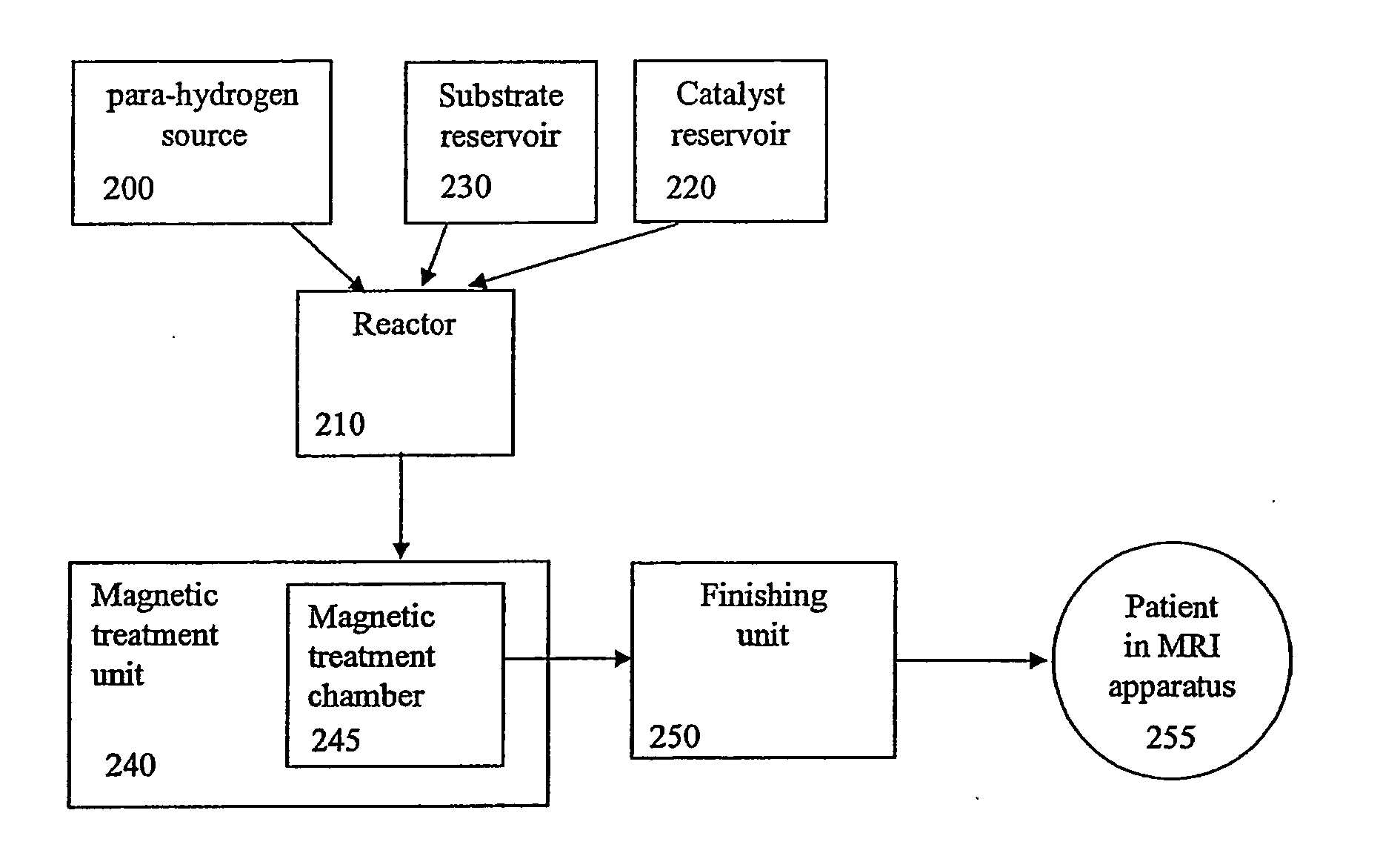

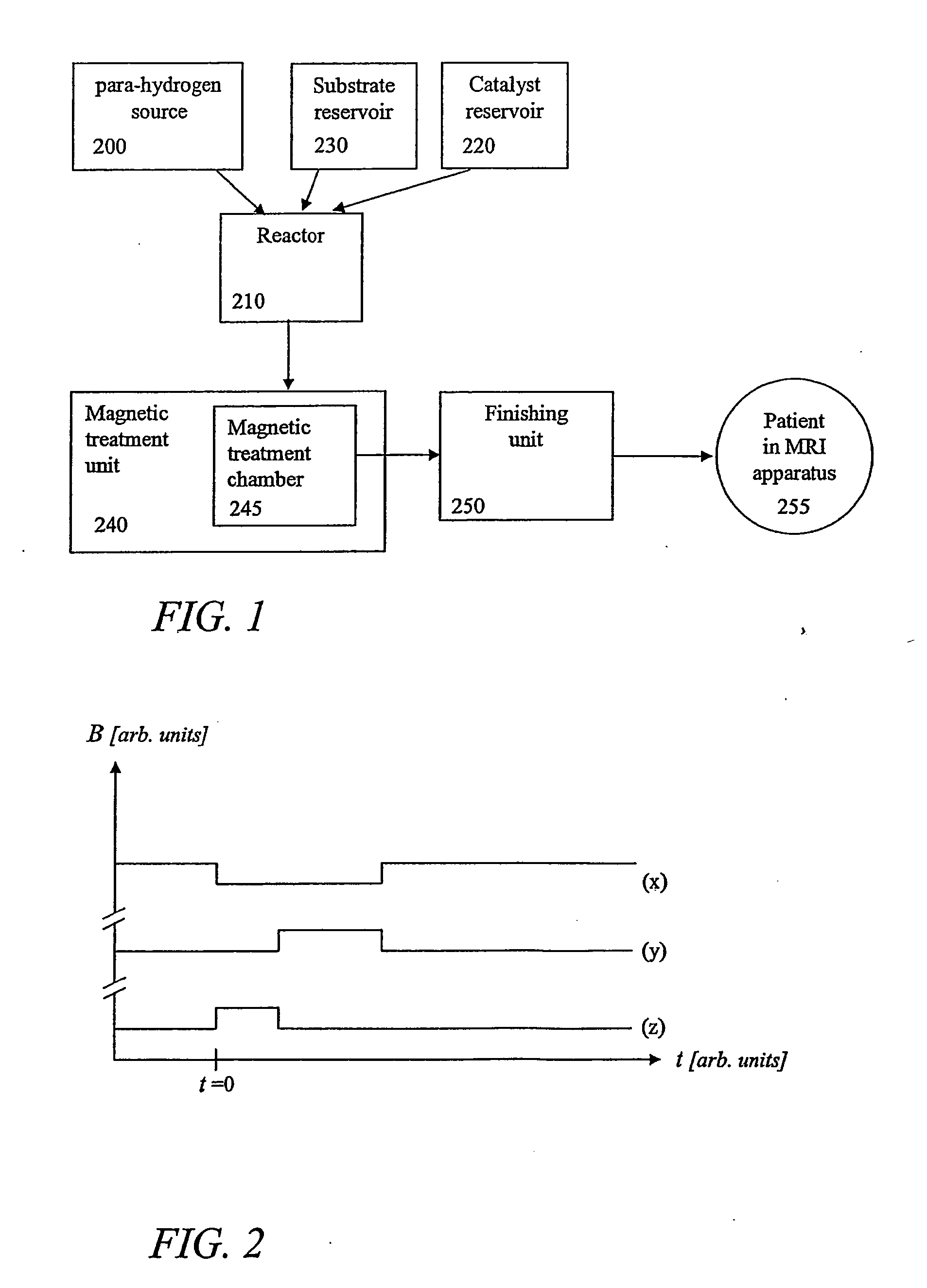

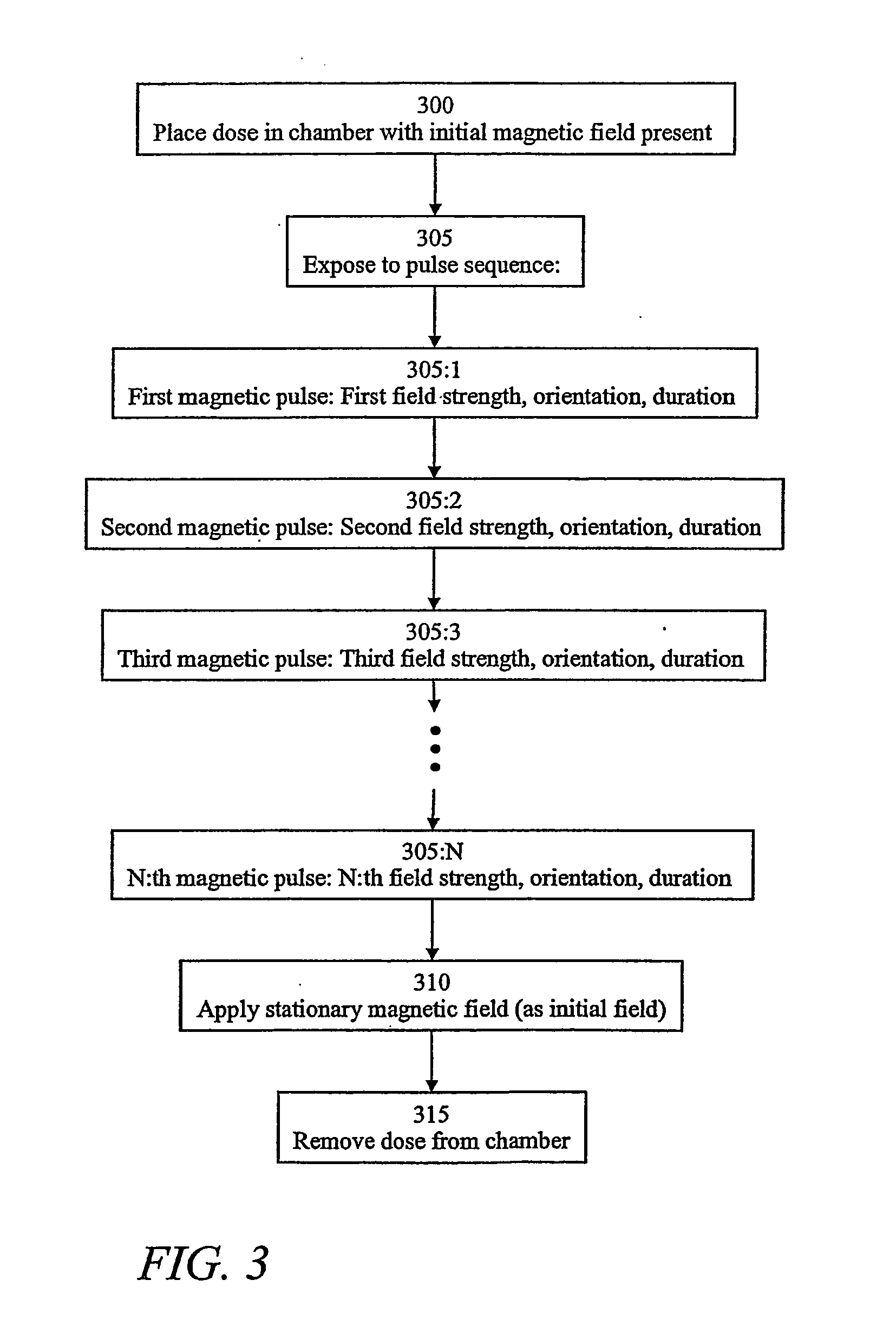

Method and apparatus for producing contrast agents for magnetic resonance imaging

InactiveUS20060104906A1Improve image qualityImprove analysis performanceDispersion deliveryDiagnostic recording/measuringSolventNMR - Nuclear magnetic resonance

The present invention relates to an arrangement and a method for providing contrast agent for e.g. MRI (Magnetic Resonance Imaging) and NMR (Nuclear Magnetic Resonance) applications. The method according to the invention comprises the steps of obtaining (100) a solution in a solvent of a hydrogenatable, unsaturated substrate compound and a catalyst for the hydrogenation of a substrate compound, hydrogenating (110) the substrate with hydrogen gas (H2) enriched in para-hydrogen (p-1H2) to form a hydrogenated contrast agent and exposing (120, 305) the contrast agent to a sequence of pulses of magnetic field. The apparatus comprises a magnetic treatment unit (240) equipped with means for producing pulses of magnetic field.

Owner:GE HEALTHCARE AS

Patterned polarizing film and its production process

ActiveUS20150301251A1Improve anti-reflection effectImprove polarizationPolarising elementsOptical articlesTransmittanceDichroic dye

A patterned polarizing film is provided for obtaining a thin patterned circular polarizing plate having a superior anti-reflection property. The film includes a substrate and a patterned liquid crystal cured layer laminated thereon. The layer contains a polymer of a polymerizable liquid crystal compound(s) and a dichroic dye. The patterned polarizing film includes a region (A) having a degree of polarization of 10% or lower and a single transmittance of 80% or higher, and a region (B) having a degree of polarization of 90% or higher and a single transmittance of 40% or higher.

Owner:SUMITOMO CHEM CO LTD

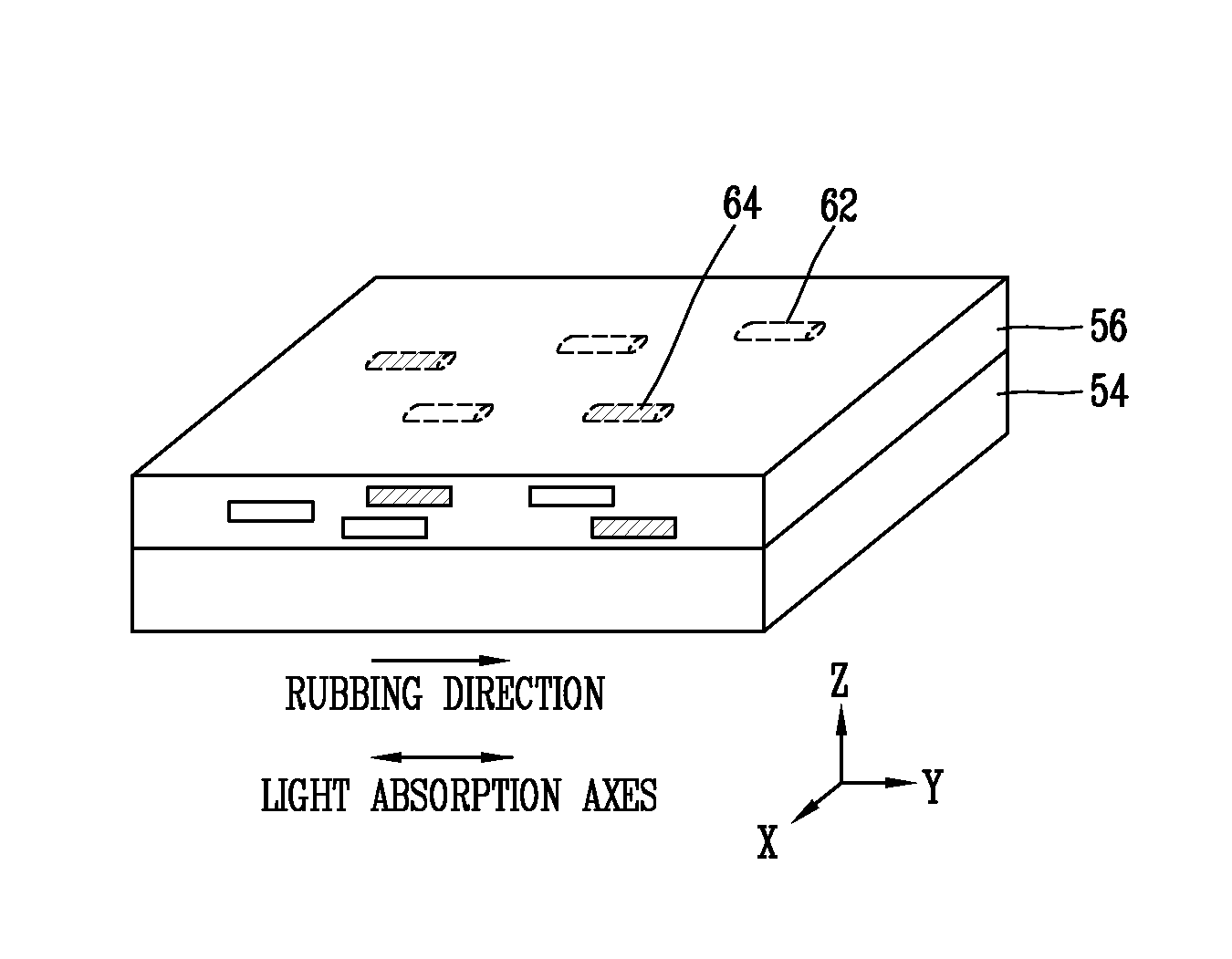

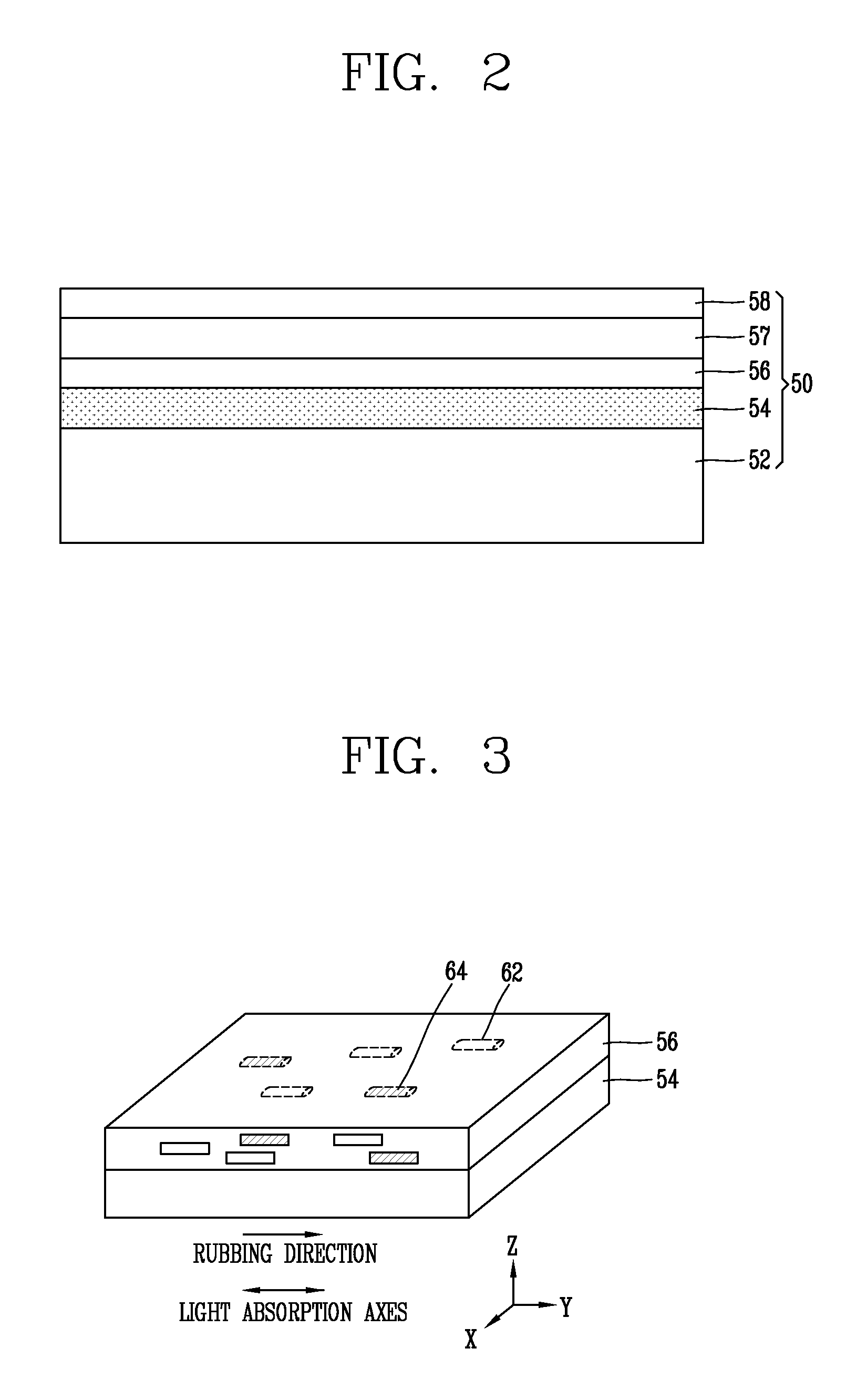

Coatable polarizer and liquid crystal display device having the same

ActiveUS20150362799A1Reduce manufacturing costImprove polarizationPolarising elementsNon-linear opticsLiquid-crystal displayTransmittance

There is provided a coatable polarizer which incurs low manufacturing cost and has an excellent polarization degree and transmittance. A plurality of polarization layers are formed on the coatable polarizer, and each of the polarization layers include about 5 to 7 wt % of dichroic dyes, whereby a light component parallel to an alignment direction of a dichroic dye, among light having a wavelength corresponding to a color, is absorbed to have polarization characteristics.

Owner:LG DISPLAY CO LTD

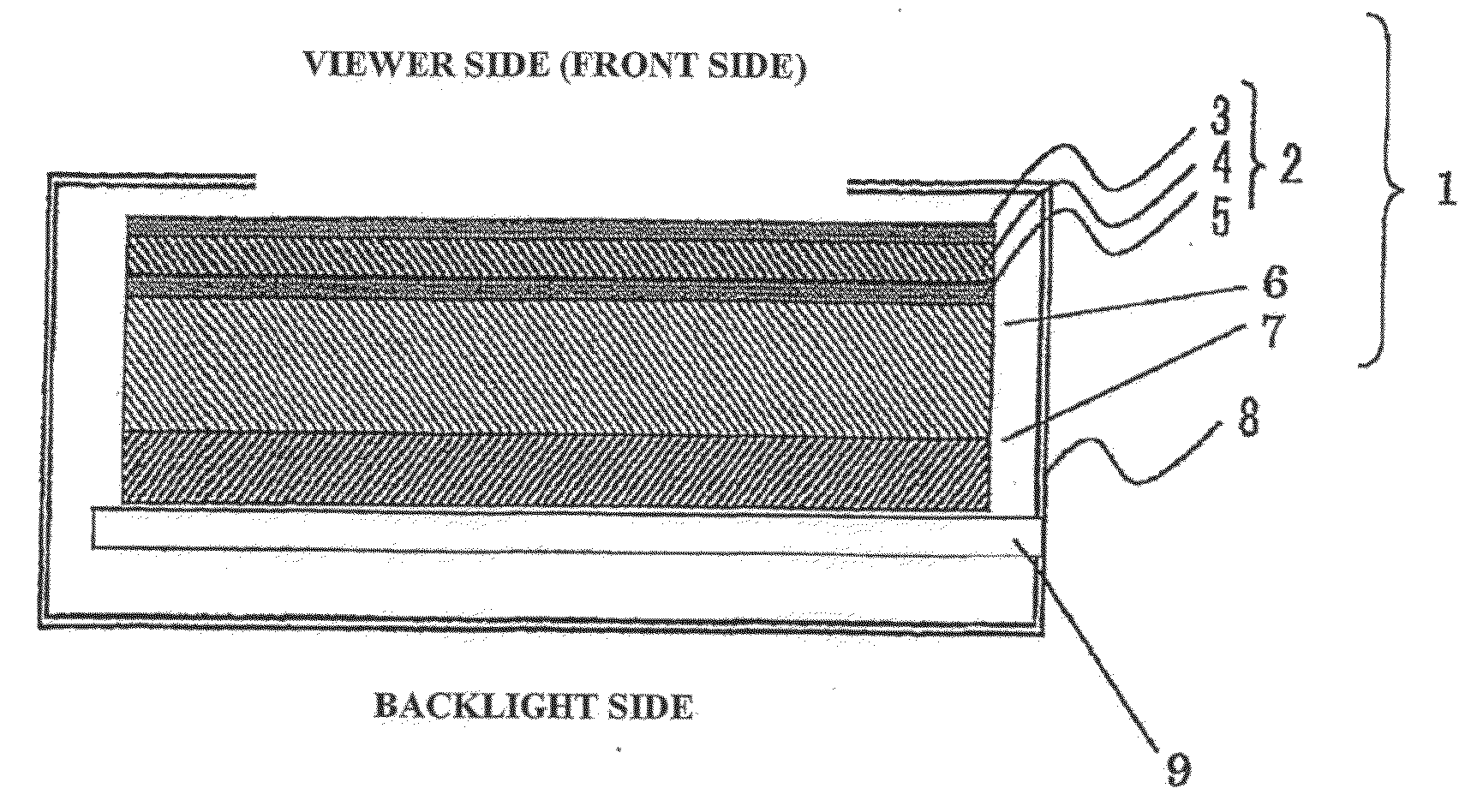

Image display device

ActiveUS20100157216A1Avoid high brightnessContrast lowMountingsNon-linear opticsDisplay deviceEngineering

An image display device provided with a panel comprising a substrate comprising glass or resin, a front side laminated body and a back side laminated body, and an optical member adjacent to the back side laminated body, wherein the surface of the optical member going to contact with the back side laminated body has an arithmetic average roughness (Ra) of 6 μm or more. The image display device can maintain excellent display performance under conditions with significant circumstance variations.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com