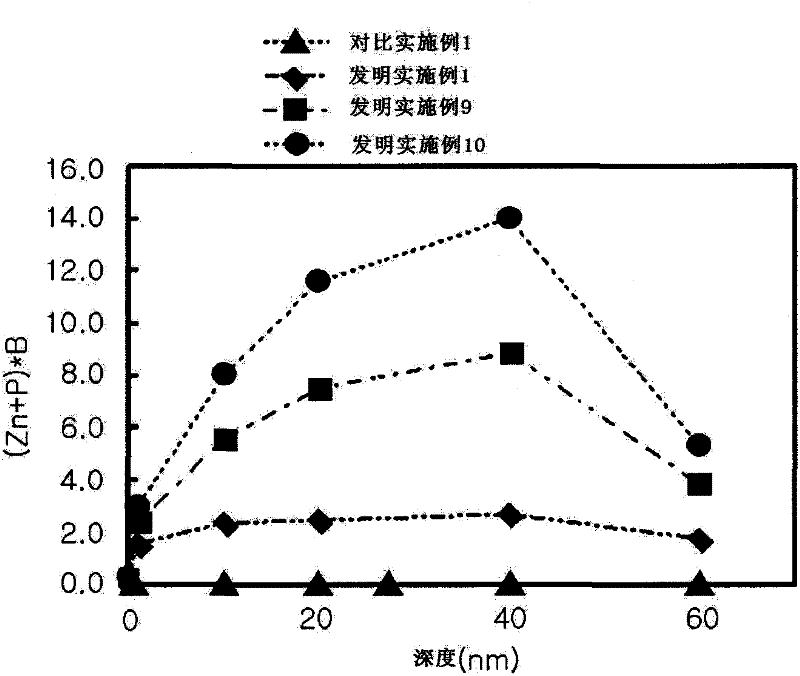

Polarizing element having excellent durability and heat resistance, polarizing plate and image display device, and method of manufacturing polarizing element

A polarizer, a range of technology, applied in polarizing elements, optical elements, instruments, etc., can solve the problems of reduced polarization degree, difficult to control orientation, and reduced transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

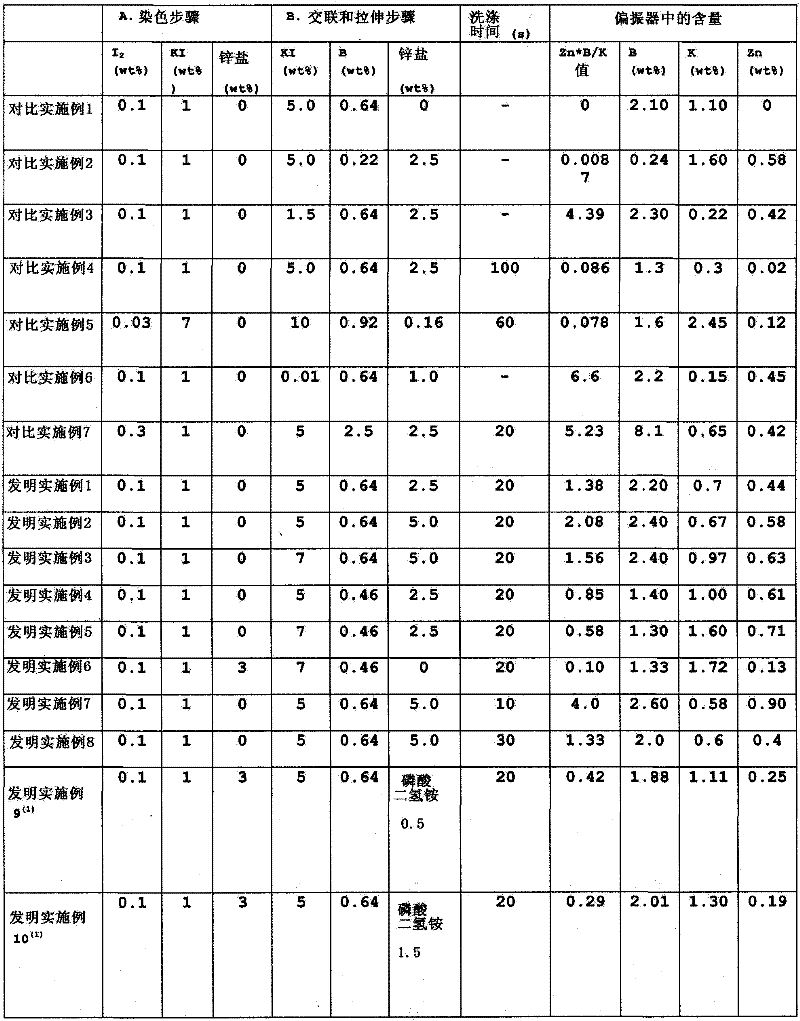

Embodiment 1

[0091] In addition to adding 2.5 wt.% zinc nitrate to the cross-linking and stretching step (B), and then immersing the polyvinyl alcohol film in distilled water at 25° C. (degrees Celsius) for 20 seconds in the washing step (C), A polarizer and a polarizing plate were produced in the same manner as in Comparative Example 1.

Embodiment 2

[0093] Except adding 5 wt.% zinc nitrate to the cross-linking and stretching step (B), and then immersing the polyvinyl alcohol film in distilled water at 25°C (Celsius) for 20 seconds in the washing step (C), according to A polarizer and a polarizing plate were manufactured in the same manner as in Comparative Example 1.

Embodiment 3

[0095] In addition to adjusting the concentration of potassium iodide to 7.0wt.%, and adding 5wt.% of zinc nitrate into the cross-linking and stretching step (B), and then washing the polyvinyl alcohol film at 25 ° C (C) degrees Celsius) in distilled water for 20 seconds, a polarizer and a polarizing plate were manufactured in the same manner as in Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com