Laminated optical film and production method thereof

A production method and technology for optical films, applied in chemical instruments and methods, optics, lamination, etc., can solve the problems of reduced transmittance and polarization degree, inability to attach polarizers to optical compensation films, and lack of elasticity of polarizers. Excellent effect of transmittance and polarization degree

Inactive Publication Date: 2008-10-15

NITTO DENKO CORP

View PDF19 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is a problem that the polarizer itself has no elasticity, so that the polarizer and the optical compensation film cannot be easily attached to each other

Therefore, there arises a problem that the entering impurities cause trouble, and the transmittance and the degree of polarization decrease

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Login to View More

Abstract

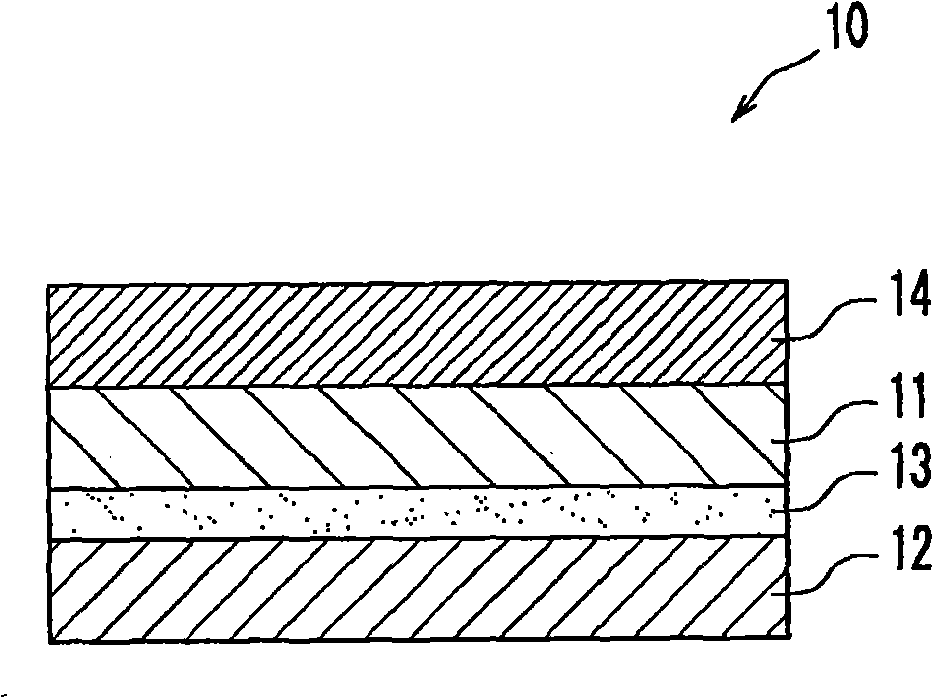

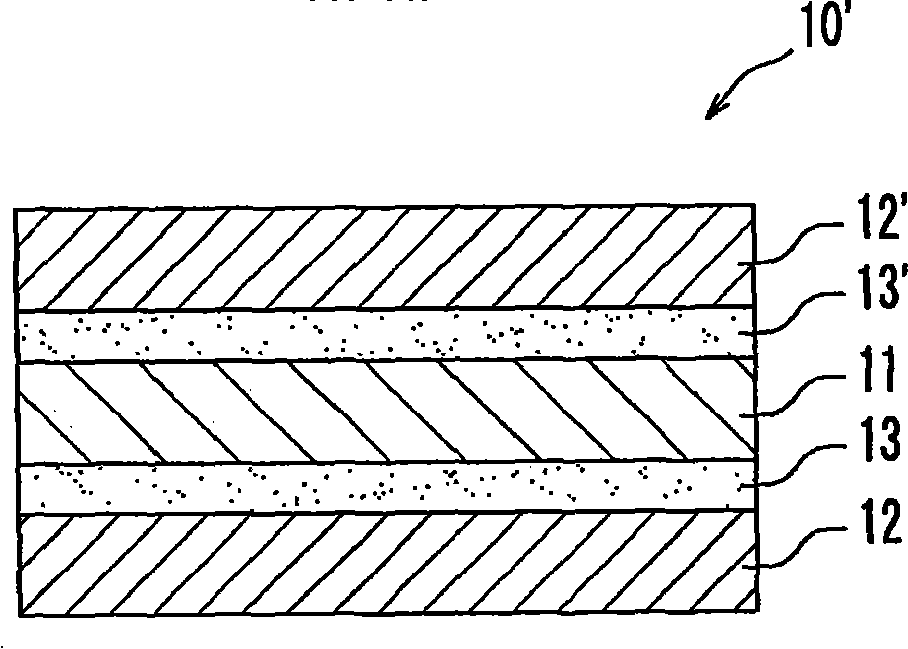

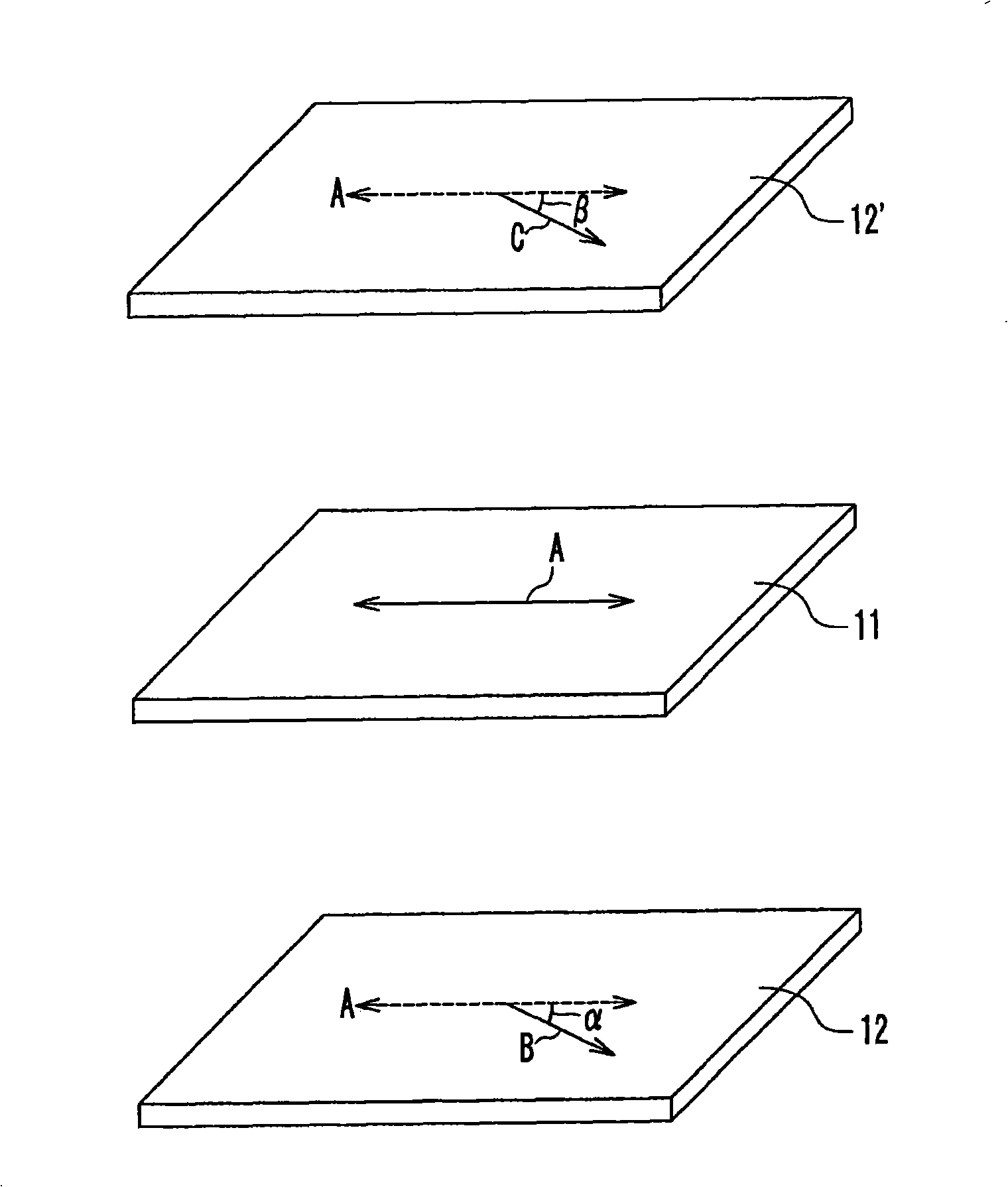

A laminated optical film according to an embodiment of the present invention includes a long polarizer having an absorption axis in a lengthwise direction and a long optical compensation film. An angle formed by a slow axis of the optical compensation film and the absorption axis of the polarizer is 5 to 85 DEG .

Description

Laminated optical film and production method thereof This application requires Japanese patent application 2007-103800 submitted on April 11, 2007, Japanese patent application 2007-288449 submitted on November 6, 2007, and Japanese patent application 2007-315433 submitted on December 6, 2007 at 35U. Priority under S.C. Section 119, said Japanese patent application is hereby incorporated by reference. technical field The present invention relates to a laminated optical film and its production method. More particularly, the present invention relates to a laminated optical film for an image display device such as a liquid crystal display device and a method for producing the same. Background technique In a liquid crystal display device, due to its imaging system, it is necessary to arrange polarizers on both sides of a glass substrate (liquid crystal cell) forming the surface of a liquid crystal panel. In addition, for optical compensation of the liquid crystal panel, an o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02F1/1335G02F1/13363G02F1/1333B32B7/12B32B37/12

Inventor 平井真理子加藤芽实池田哲朗

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com