Low temp high radiation carbon fiber electrothermal radiation tube

An electrothermal radiation and carbon fiber technology, applied in the field of electrothermal radiant tubes, can solve the problems of high surface temperature, low thermal efficiency, and short life of resistance wires, and achieve high electrothermal conversion efficiency, strong thermal radiation ability, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

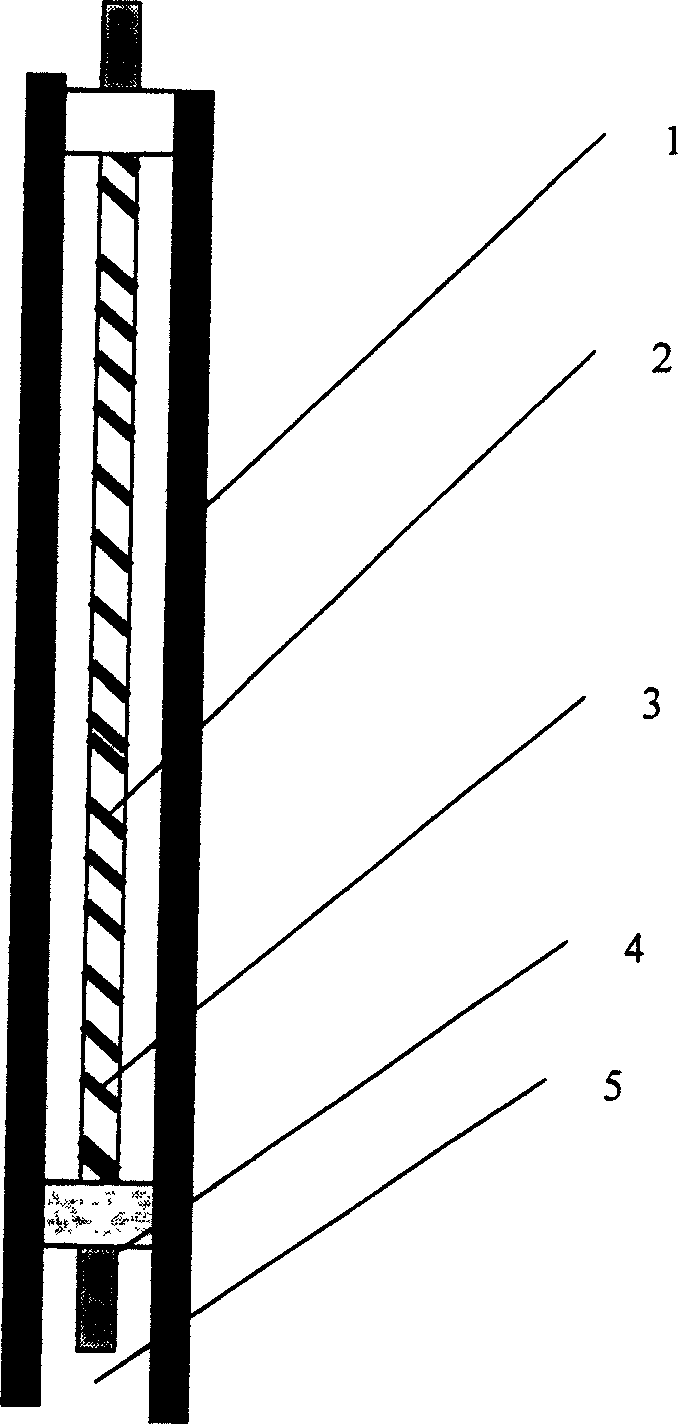

[0015] Example 1: Winding a bundle of 12K carbon fibers on Al with helical grooves 2 o 3 On the insulator frame, the two ends of the insulator frame are inlaid with threaded heat-resistant steel joints, and the two ends of the carbon fiber wound on the insulating frame are wound and fixed on the threaded heat-resistant steel joints, and the outer side is covered with conductive powder and heated and cured to form an electric heating The main body of the element is to coat the surface of the quartz tube with infrared radiation paint, put the prepared carbon fiber electric heating element body into it, fill it with high-purity inert gas helium, and seal the end with a high-temperature adhesive, that is, the low-temperature heating element of the present invention is obtained. High radiation carbon fiber electric heating radiant tube.

Embodiment 2

[0016] Example 2: A bunch of 12K and 6K carbon fibers are mixed and wound on Al with spiral grooves 2 o 3 On the insulator frame, the two ends of the insulator frame are inlaid with threaded heat-resistant steel joints, and the two ends of the carbon fiber wound on the insulating frame are wound and fixed on the threaded heat-resistant steel joints, and the outer side is covered with conductive powder and heated and cured to form an electric heating The main body of the element, the surface of the quartz tube is coated with infrared radiation paint, the main body of the carbon fiber electric heating element is put into it, the end is sealed with a high-temperature adhesive, the inside of the quartz tube is evacuated and then the gas outlet is closed, and the product is obtained. Invented low-temperature high-radiation carbon fiber electric heating radiant tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com