Electric heating tube

An electric heating tube, tubular technology, applied in the direction of ohmic resistance heating parts, heating element shape, ohmic resistance waterproof/airtight, etc., can solve the problems of reduced service life of heating tube, corrosion and fracture of electric heating tube, affecting normal use, etc. Achieve the effect of enhanced heat dissipation, increased surface area, improved heat transfer and heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

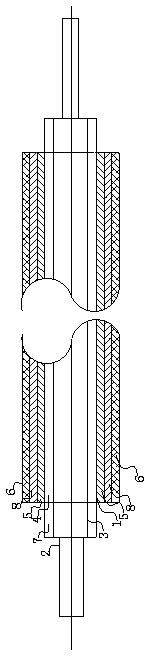

[0017] See attached figure 1 As shown, an electric heating tube of the present invention includes a tubular shell 1, a head set on both sides of the shell 1 for sealing the ends of the shell 1, and a heat generating tube set inside the shell 1 The resistance wire 3 and the crystalline magnesium oxide powder 4 arranged in the gap between the housing 1 and the resistance wire 3 for heat conduction and insulation. The outer surface of the housing 1 is provided with an anti-rust coating 5, and the outer surface of the anti-rust coating 5 is provided There is a far-infrared radiation coating 6, a waterproof layer 7 is provided at the connection between the sealing 2 and the shell 1, and a layer of quartz sand 8 is sprayed between the anti-rust coating 5 and the far-infrared radiation coating 6. An electric heating tube of the present invention is provided with a far-infrared radiation coating 6 on the outer surface of the anti-rust coating 5, which has better heat radiation performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com