Functional nanometer heat dissipation coating and preparation method and application thereof

A heat-dissipating coating and nano-functional technology, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor heat radiation ability on metal surfaces, difficult metal heat dissipation, and large space occupation, so as to improve heat radiation. Ability, heat dissipation effect is obvious, the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the second aspect, the present invention provides a method for preparing the functional nano heat-dissipating coating as described in the first aspect, comprising the following steps:

[0048] (1) Add nano-carbon material, water, and additives into the stirring tank, stir and mix for 1-3 hours, and obtain material A;

[0049] (2) Add water-soluble resin, water-soluble curing agent, and leveling agent to the material A obtained in step (1), and continue stirring and mixing for 0.5-2 hours to obtain material B;

[0050] (3) Add a defoamer to the material B obtained in step (2), and finally add a thickener in batches, and continue stirring for 2-6 hours to obtain a functional nano heat-dissipating coating.

[0051] In the embodiment of the present invention, the stirring speed in step (1) is 300-1000 rpm.

[0052] In the embodiment of the present invention, the stirring speed in step (2) is 300-1000 rpm.

[0053] In the embodiment of the present invention, the stirrin...

Embodiment 1

[0064] A preparation method of a functional nano heat dissipation coating provided in this embodiment comprises the following steps:

[0065] (1) Add 0.7g carbon black, 0.3g graphite, 50g deionized water, 10g ethanol, and 3g diacetone alcohol into the stirring tank, stir and mix at 500 rpm for 1 hour to obtain a uniform material;

[0066] (2) Add 30g water-soluble acrylic resin, 3g water-soluble amino resin curing agent, 1.7g polyacrylic acid leveling agent, and continue stirring and mixing for 1 hour at 500 rpm;

[0067] (3) Then add 0.3g of silicone oil, first add 0.5g of sodium carboxymethyl cellulose, and then add 0.5g of sodium carboxymethyl cellulose after it is completely dissolved, and continue stirring at 700 rpm for 4 hours to obtain a functional nano heat dissipation coating 1.

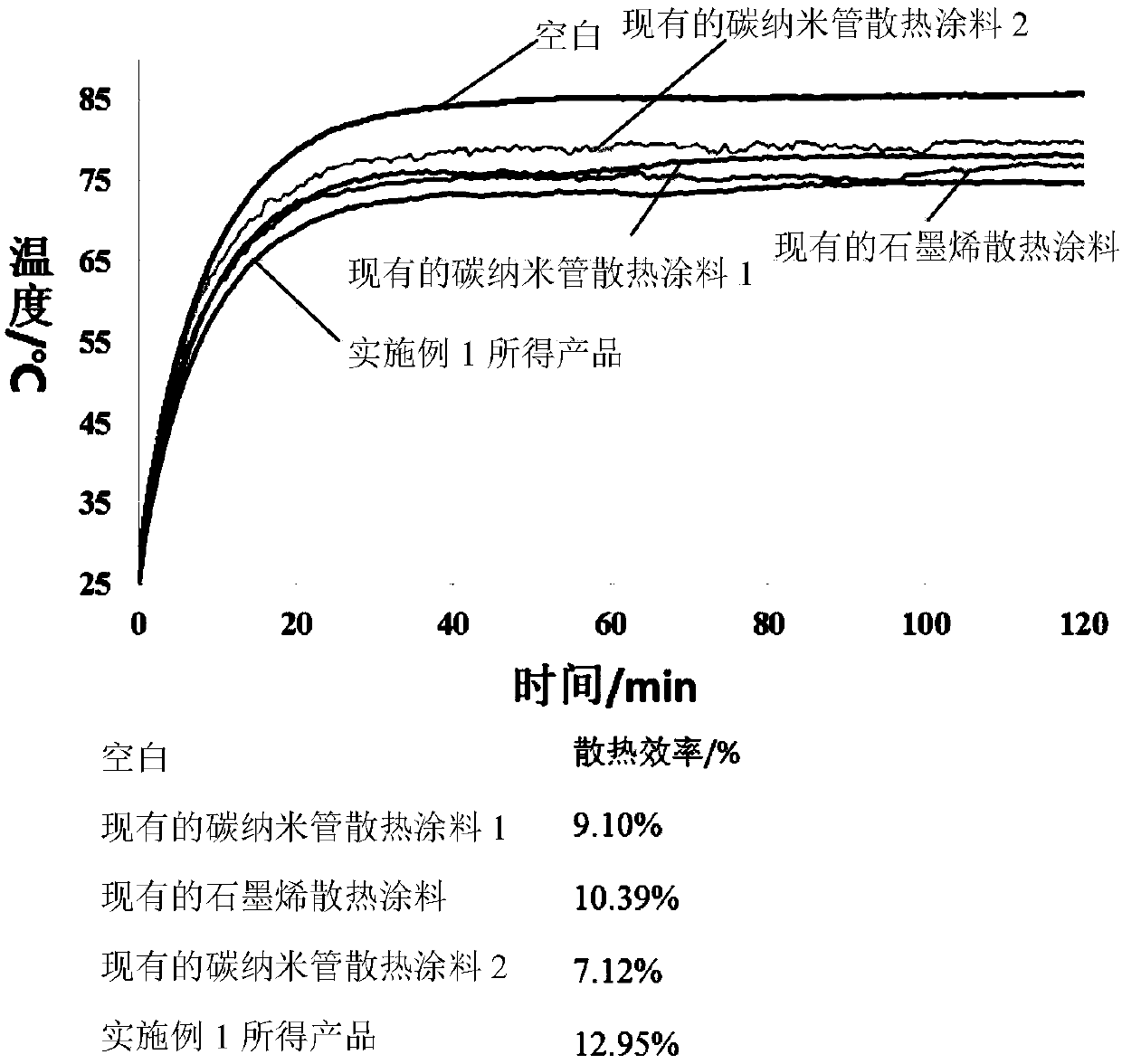

[0068] Apply this paint evenly on the surface of the radiator by dipping (such as figure 1 A certain brand of LED lighting radiator), baked at 120°C for 30 minutes, and tested the perform...

Embodiment 2

[0073] A preparation method of a functional nano heat dissipation coating provided in this embodiment comprises the following steps:

[0074] (1) Add 0.8g carbon black, 0.2g graphite, 50g deionized water, 10g isopropanol, and 2g diacetone alcohol into the stirring tank, stir and mix at 300 rpm for 2 hours to obtain a uniform material;

[0075] (2) Add 30g of water-soluble acrylic resin, 3g of water-soluble amino resin curing agent, and 1g of polyacrylic acid leveling agent, and continue stirring and mixing for 1 hour at 500 rpm;

[0076] (3) Add 0.3 g of silicone oil, first add 0.5 g of polyacrylamide, and then add 0.5 g of polyacrylamide after it is completely dissolved, and continue stirring at 700 rpm for 4 hours to obtain functional nano heat dissipation coating 2.

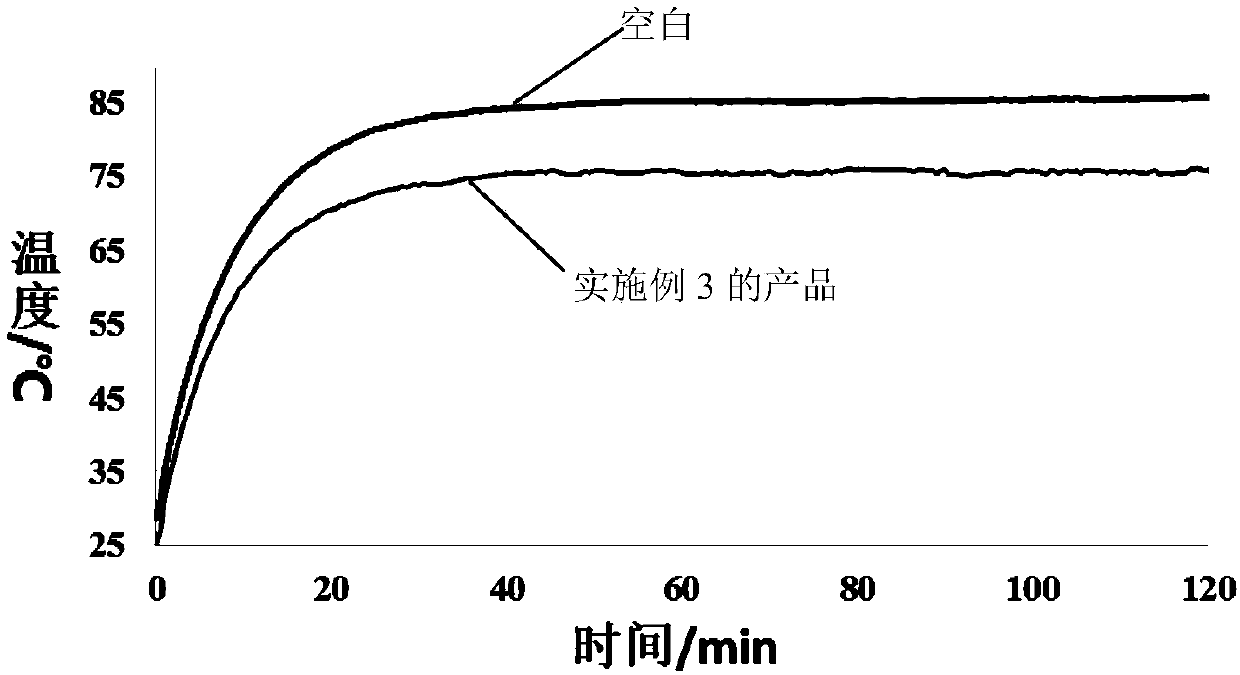

[0077] In order to better illustrate the implementation effect of the present invention, the functional nano heat dissipation coating 2 obtained in step (3) is evenly coated on the surface of the heat sink, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com