Optical module and method for manufacturing same

An optical module and molding technology, applied in the field of optical modules, can solve problems such as low production efficiency, high price, and modules not suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

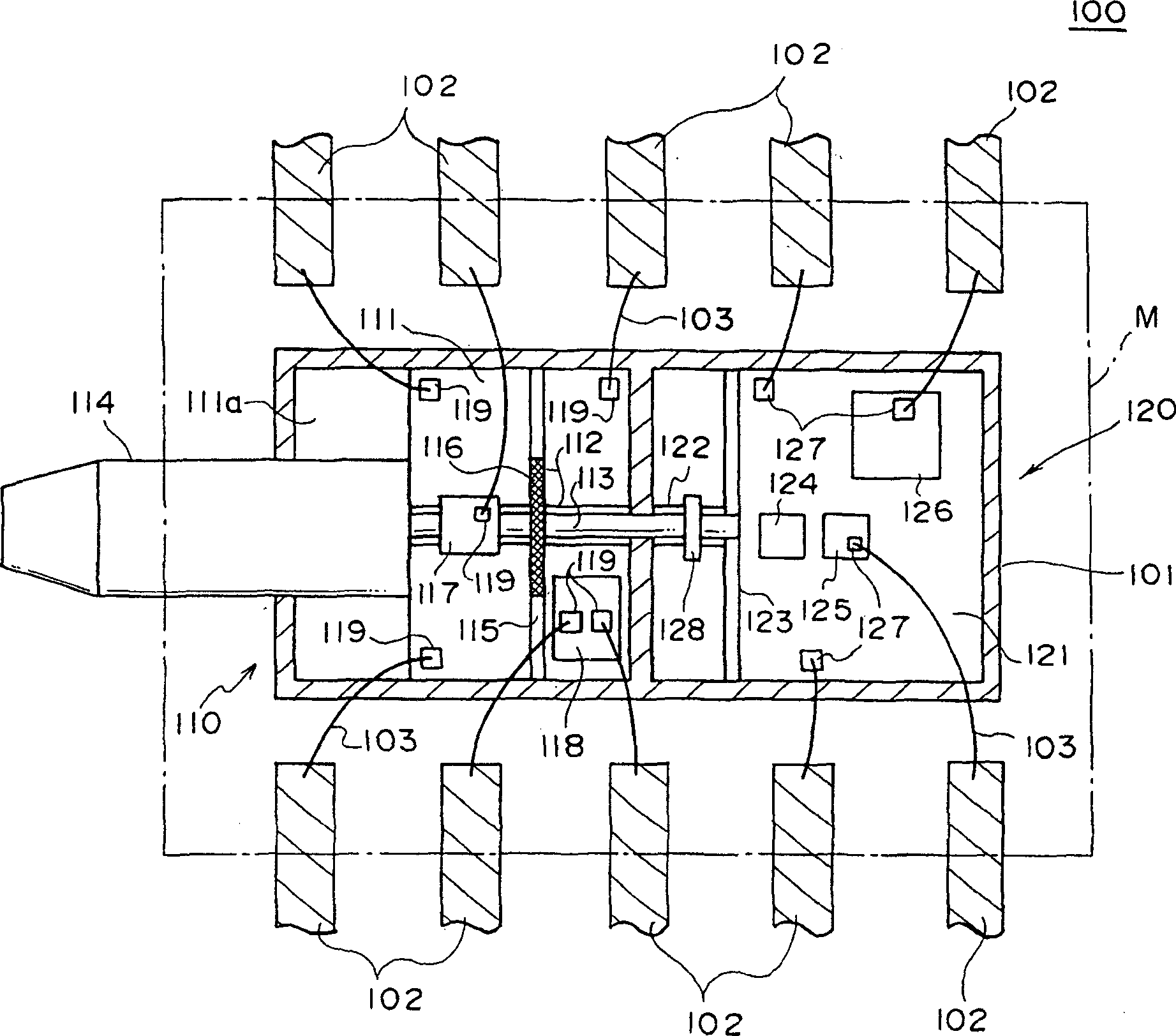

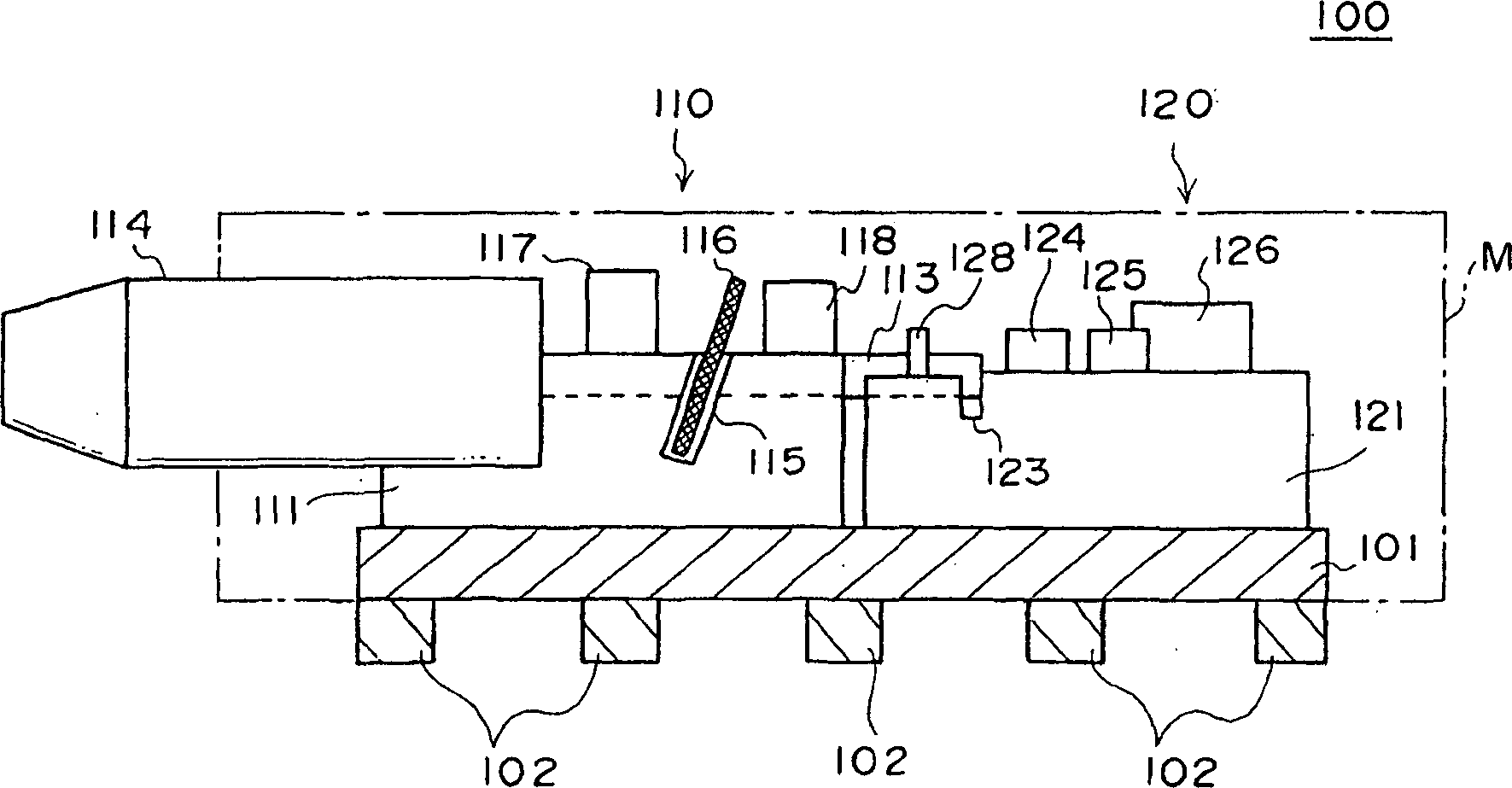

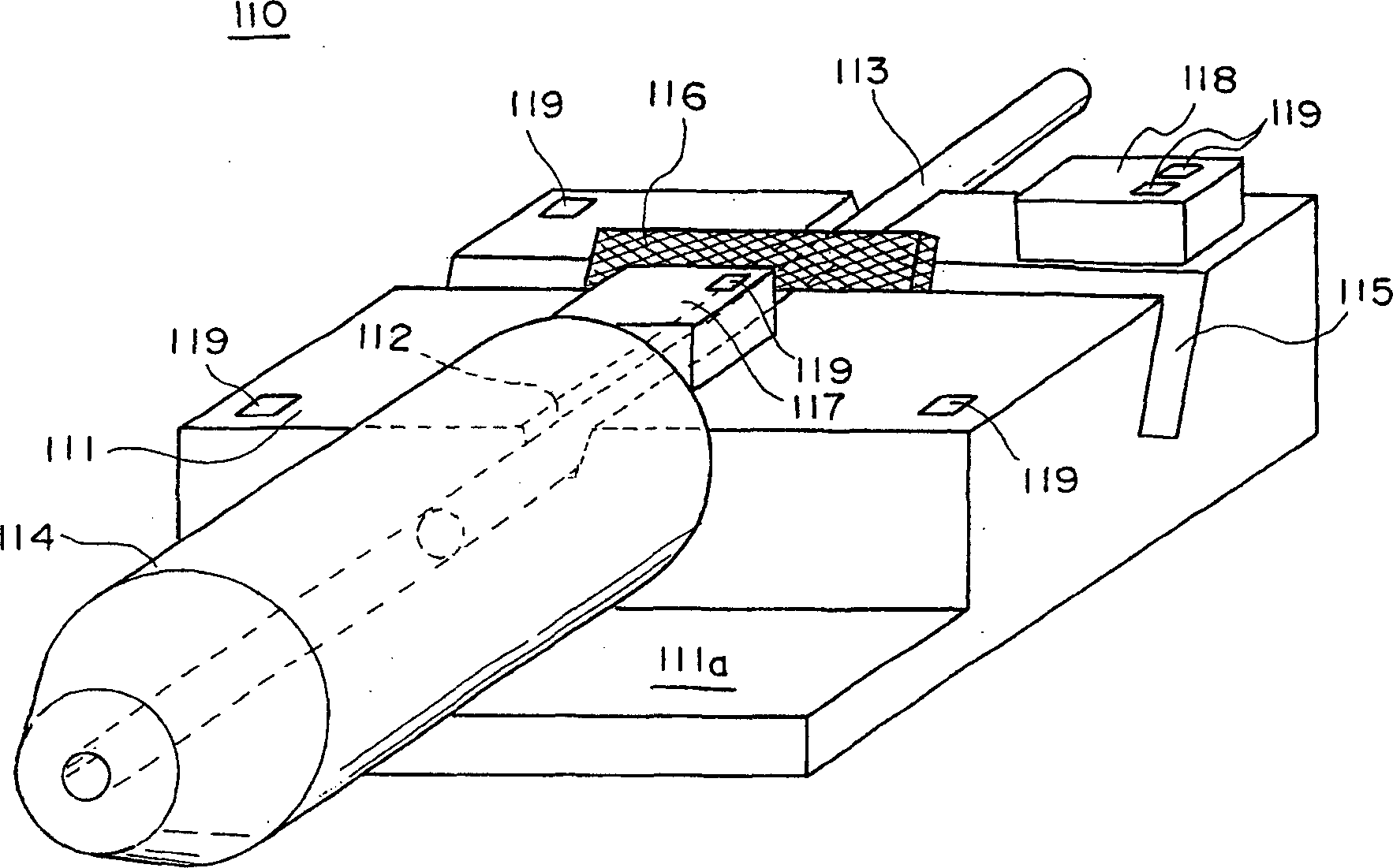

[0057] figure 1 It is a plan view of the structure of the main part of the optical module 100 described in a preferred embodiment of the present invention, figure 2 It is a side view of the structure of the main part of the optical module 100. Although, as will be described below, the optical module 100 described in this embodiment will be finally packaged, and its main part will be covered by resin, figure 1 Shown is the optical module 100 without resin encapsulation. figure 1 and figure 2 The area indicated by M in is the area that will be finally packaged.

[0058] Such as figure 1 and 2 As shown, the optical module 100 according to this embodiment includes: a molding pad 101 , a plurality of leads 102 , a first platform 110 and a second platform 120 mounted on the molding pad 101 .

[0059] The die pads 101 and leads 102 are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com