Patents

Literature

53results about How to "Good burning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance environment-friendly alcohol-based fuel and preparation method thereof

InactiveCN105670715AHigh calorific valueGood burning effectLiquid carbonaceous fuelsFuel additivesTurpentineEngineering

The invention belongs to the technical field of fuel, and particularly relates to a high-performance environment-friendly alcohol-based fuel and a preparation method thereof. The high-performance environment-friendly alcohol-based fuel is prepared from methyl alcohol, alcohol, butyl octanol, propyl alcohol and turpentine. The alcohol-based fuel has the advantages of being combusted sufficiently, being high in heat value and multiplying heat release, and the requirements for a large amount of released heat, energy conservation and environmental protection are met.

Owner:黄超源

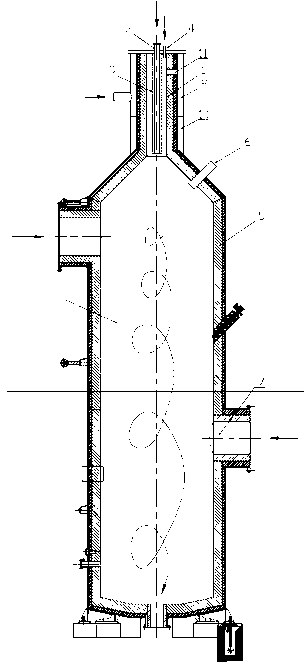

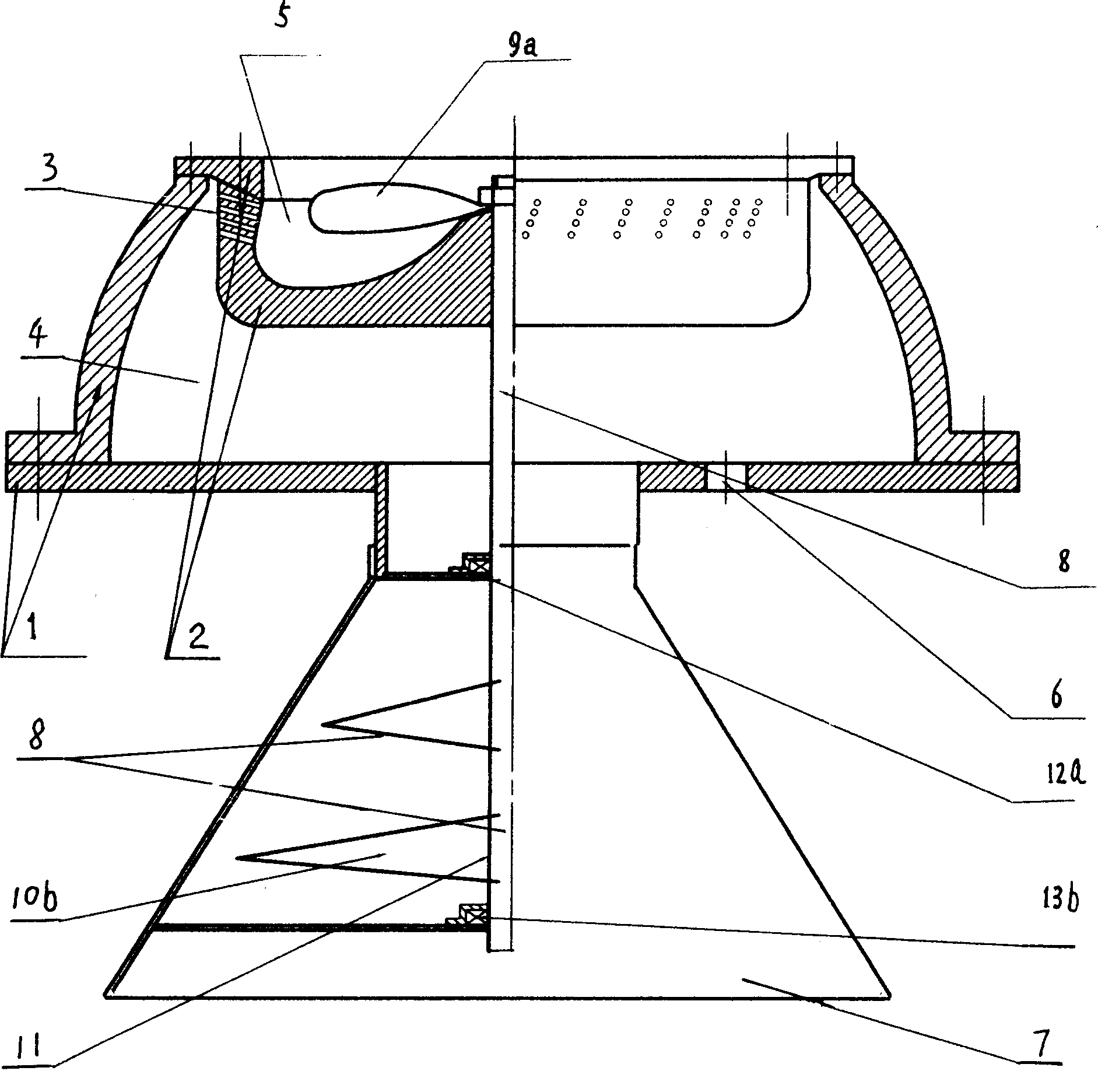

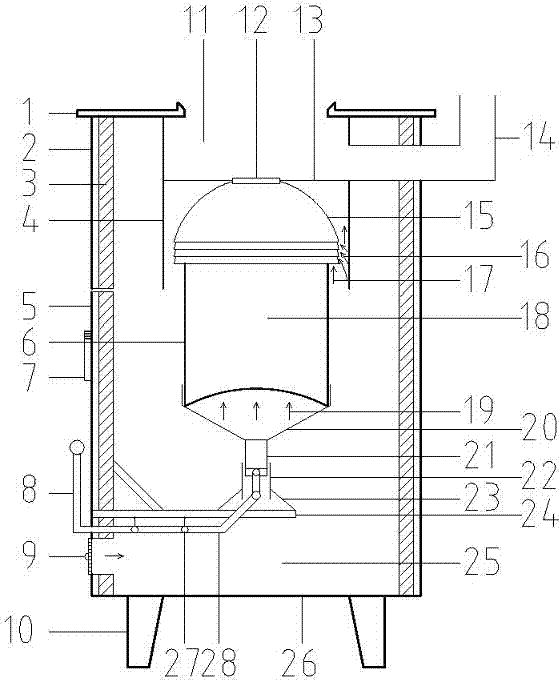

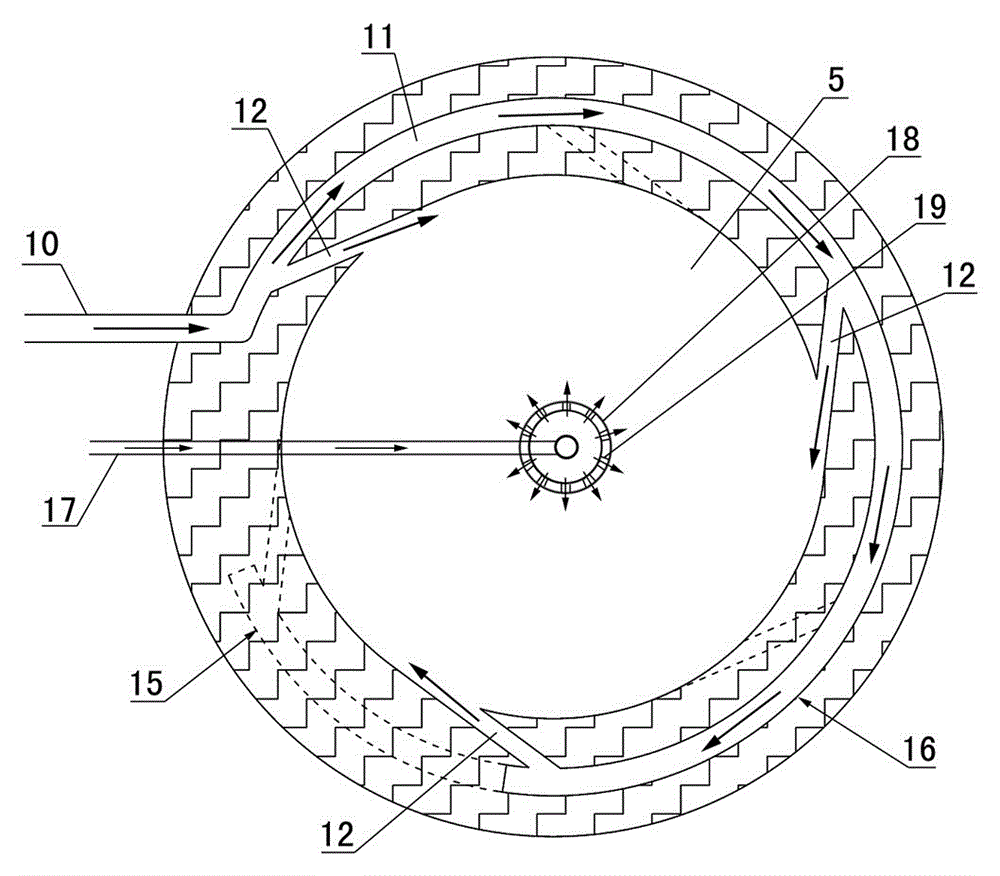

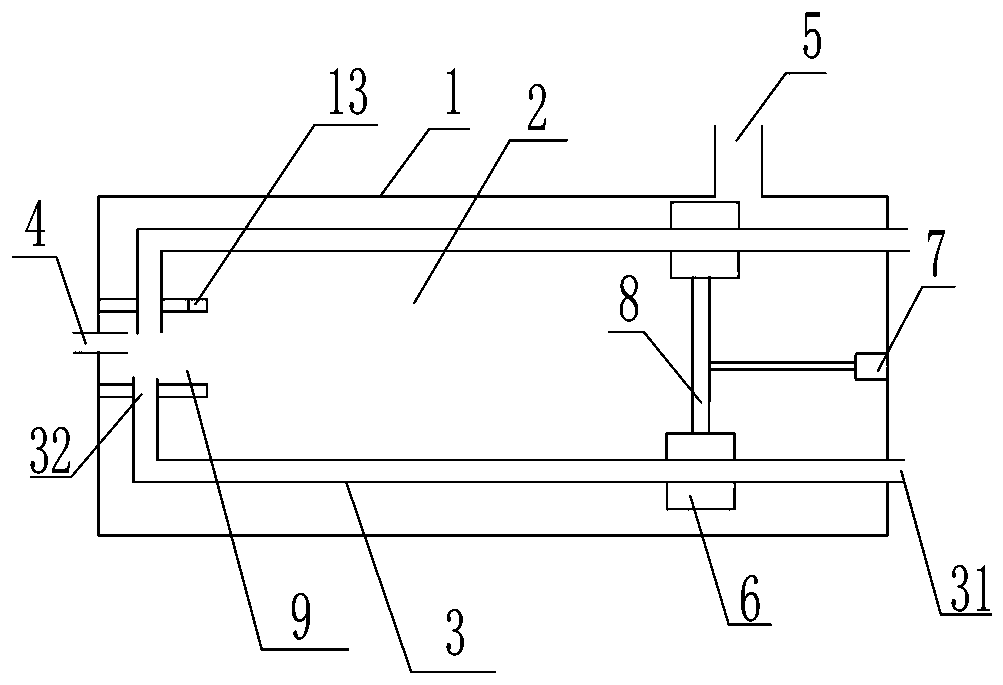

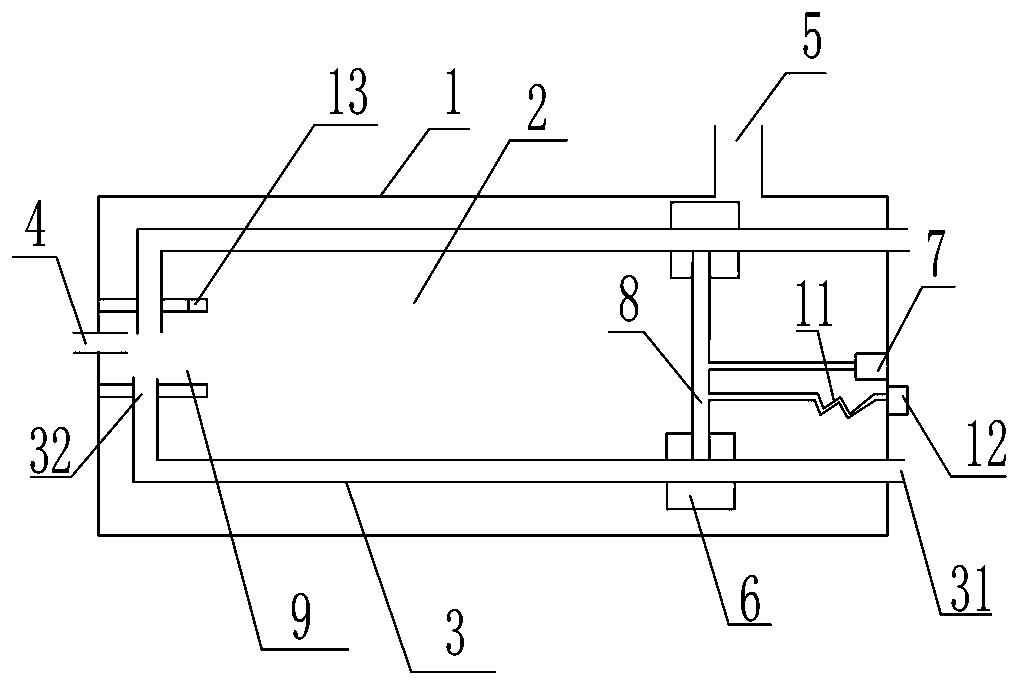

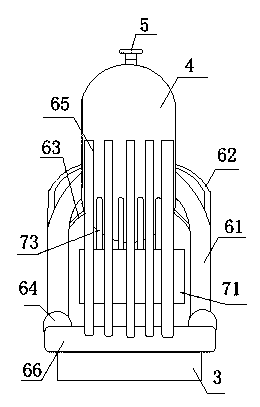

Incinerator

InactiveCN103322576AReduce rangeGood burning effectIncinerator apparatusWaste treatment technologiesCombustion chamber

The invention discloses an incinerator, and belongs to the technical field of waste processing. The incinerator comprises an air chamber and a combustion chamber, and is characterized in that the air chamber is communicated with the combustion chamber; a waste adding pipe is arranged in the air chamber; a fuel inlet is formed in the upper portion of the air chamber; an air inlet jacket is arranged on the periphery of the air chamber; a through hole communicated with the air chamber is formed in the air inlet jacket; fire-resistant materials are arranged on the wall of the combustion chamber; a fuel inlet is formed in the upper portion of the combustion chamber; an air inlet is formed in the combustion chamber; the waste adding pipe is communicated with the combustion chamber, and covers a cooling water jacket arranged on the periphery of the air chamber in the connection position of the combustion chamber. According to the incinerator, fuel, combustion air and waste to be processed are adequately mixed to form a high-speed cyclone, the high-speed cyclone adequately combusts in a high-speed rotating state; because a big-diameter feed pipe can be adopted, the incinerator is not blocked, does not corrode, and is long in service life, capable of simultaneously processing various waste liquids and high-viscosity waste liquids, and good in combustion effect.

Owner:NANJING HAOYANG CHEM EQUIP

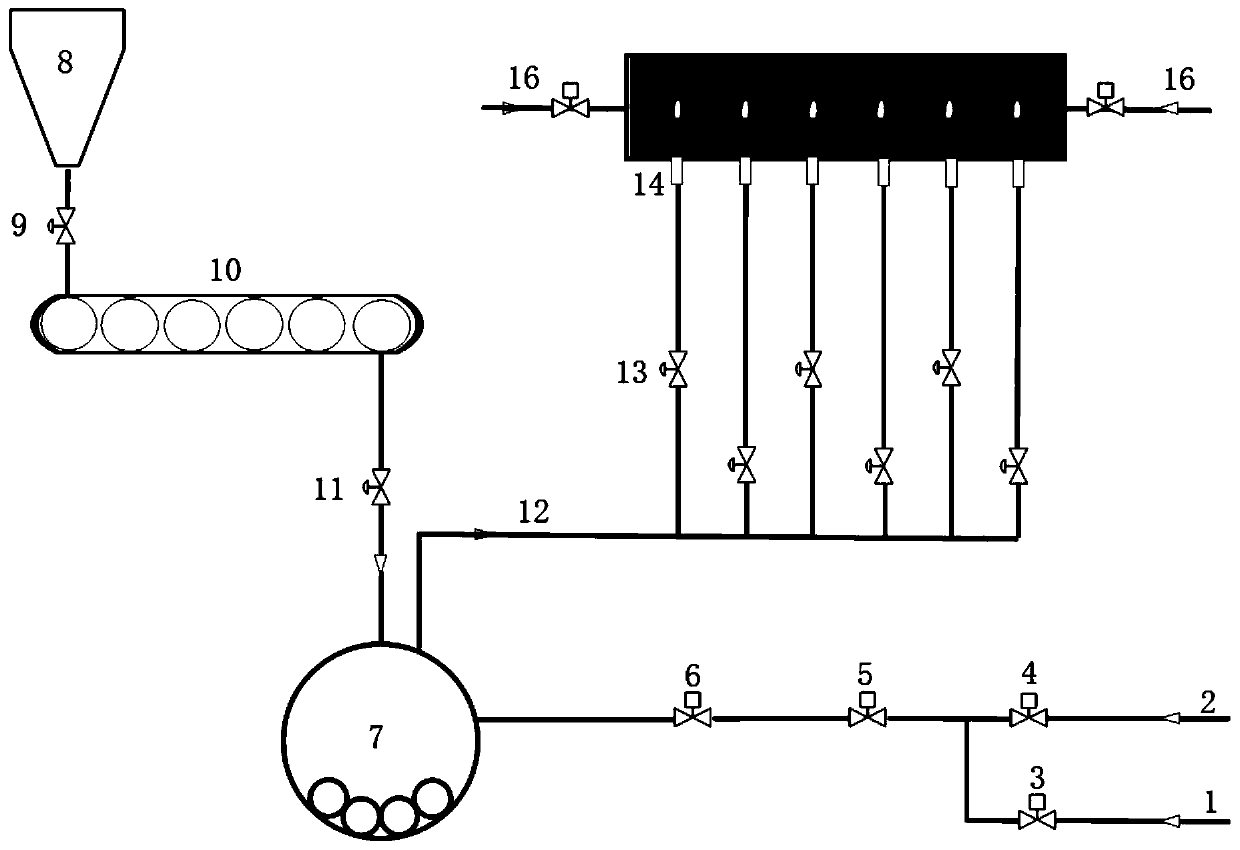

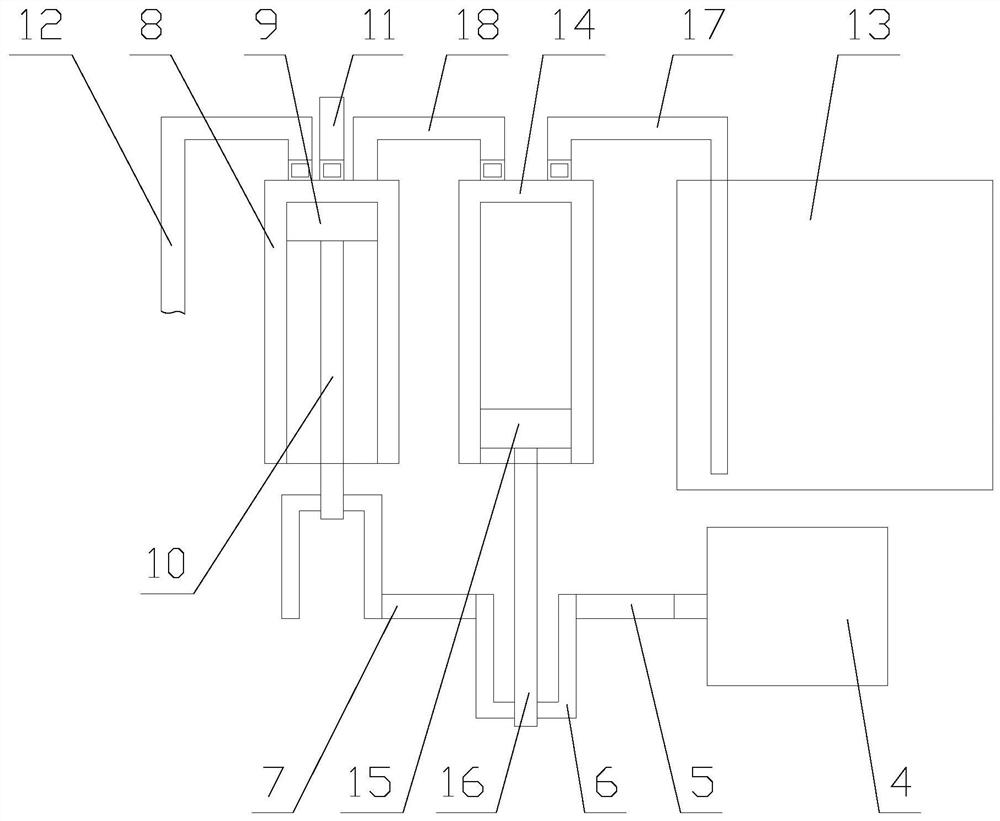

Medium-speed mill self-starting and self-stopping control system suitable for deep peak regulation of direct blowing type coal-fired unit

PendingCN111486472AGood burning effectGood energy saving effectFuel supply regulationSolid fuel pretreatmentAutomatic controlNitrogen oxides

The invention discloses a medium-speed mill self-starting and self-stopping control system suitable for deep peak regulation of a direct blowing type coal-fired unit, belongs to the field of automaticcontrol of clean and efficient coal-fired power generation, and aims to improve the running flexibility of the unit for adapting to power grid dispatching. The system relates to automatic control ofa whole-course fuel and pulverizing system in a deep peak regulation process; two coal mills operate under the working condition of deep peak regulation at 30%; in the starting / stopping automatic control of the coal mills, an intermediate staying control and actual coal quantity delay calculation strategy is added, so that the large fluctuation of coal quantity change on the superheated steam temperature and reheated steam temperature of a boiler and nitric oxide at an inlet of a denitration system is inhibited, and the impact of starting / stopping mills on the boiler system is reduced; in thestarting / stopping automatic control of the coal mills, an override control strategy for the temperature of a mill outlet is added, so that the abnormities of high temperature of the coal mill outletsduring mill stop and low temperature of the coal mill outlets during mill start are avoided; and after the coal mills are sequentially controlled and stopped, the coal mills are in a hot standby state, flexible restart of the coal mills is facilitated, and the start time is saved.

Owner:扬州第二发电有限责任公司

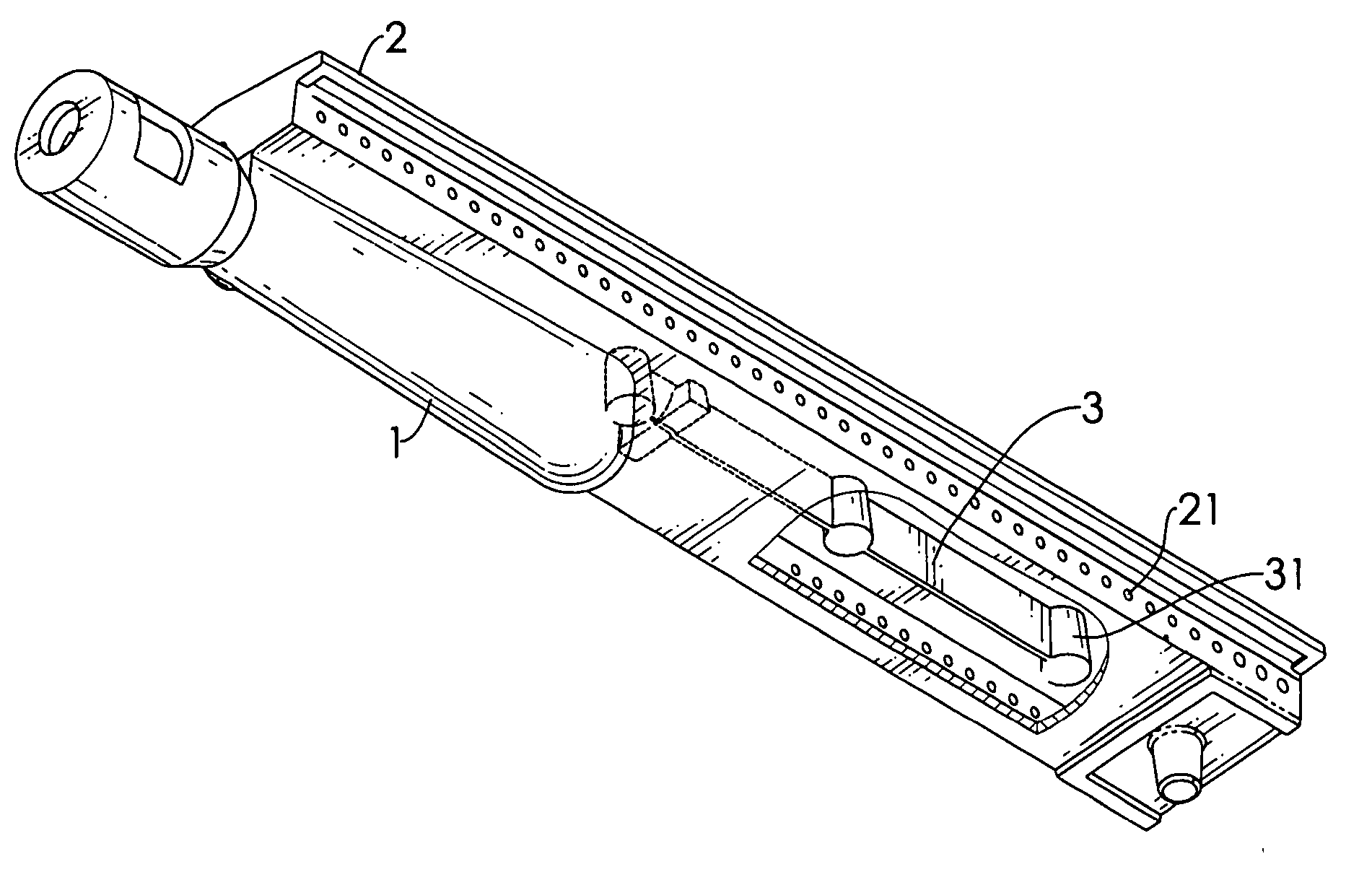

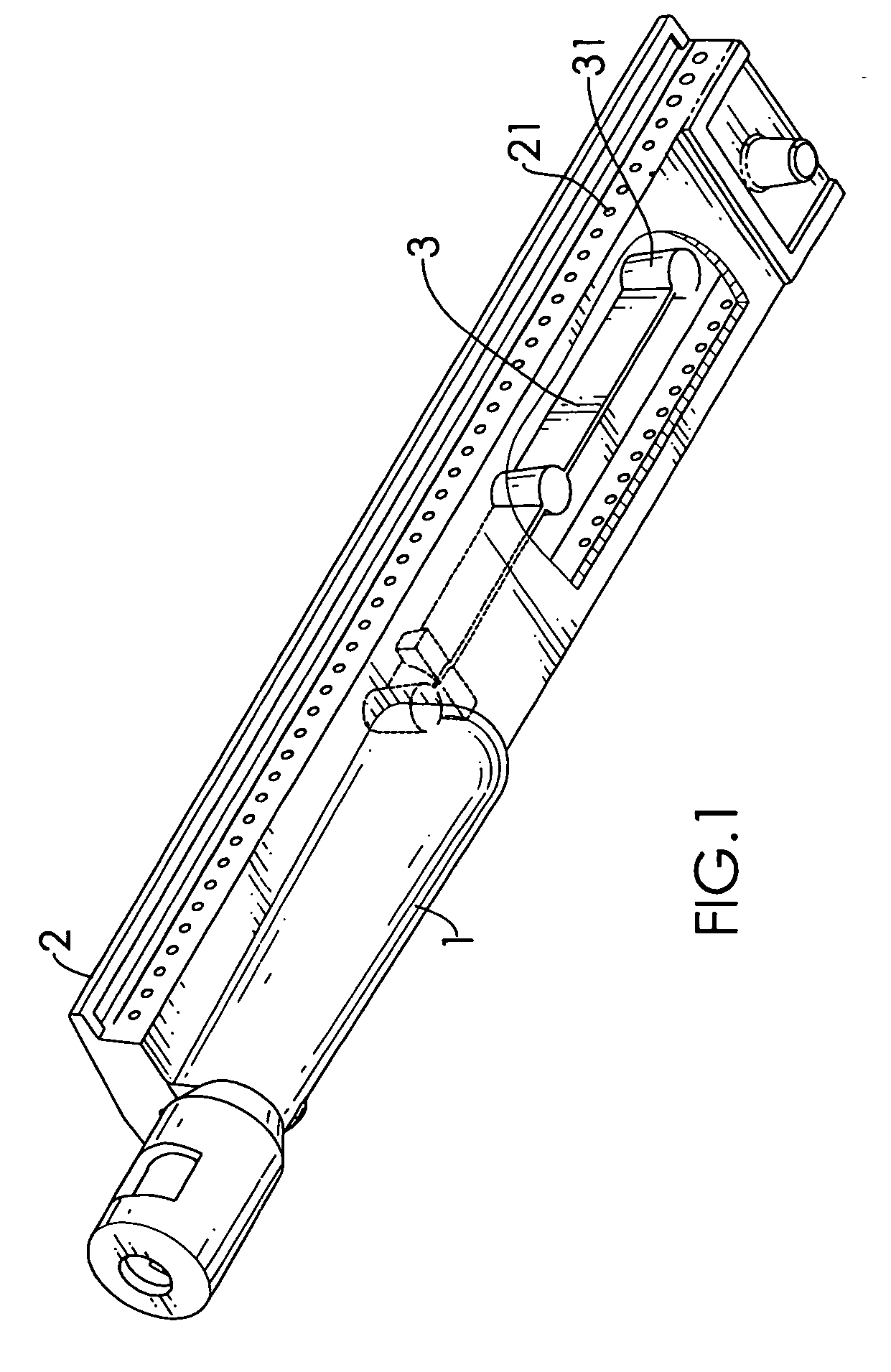

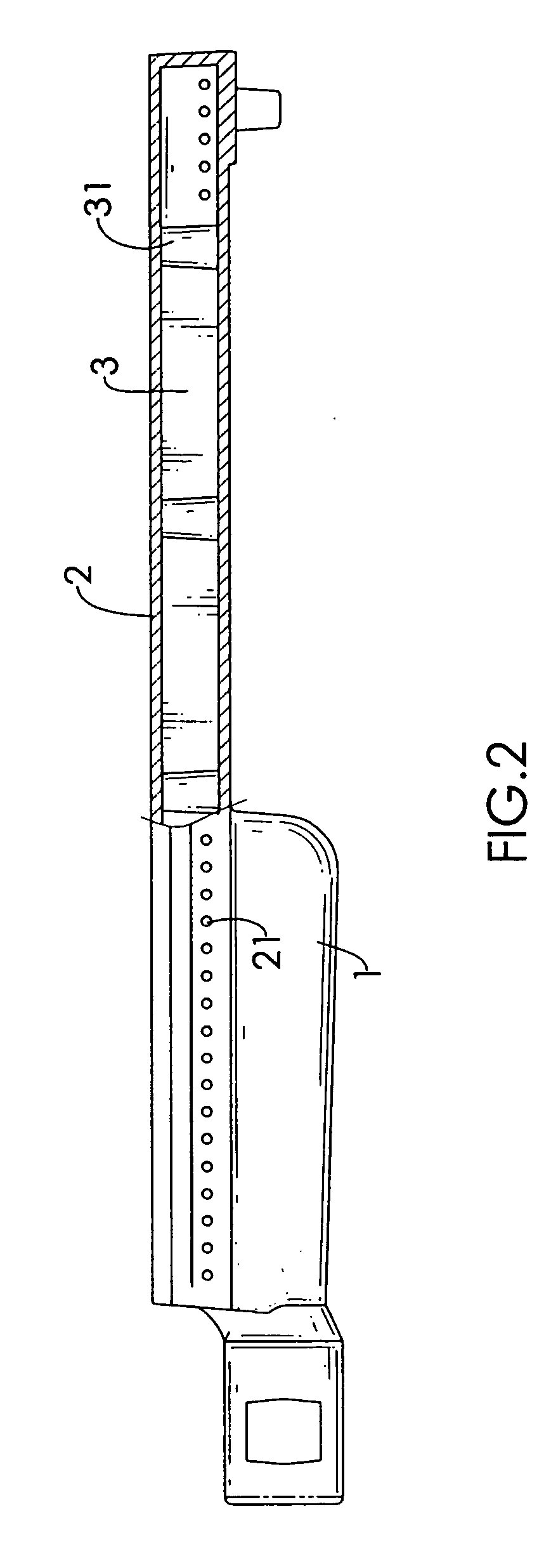

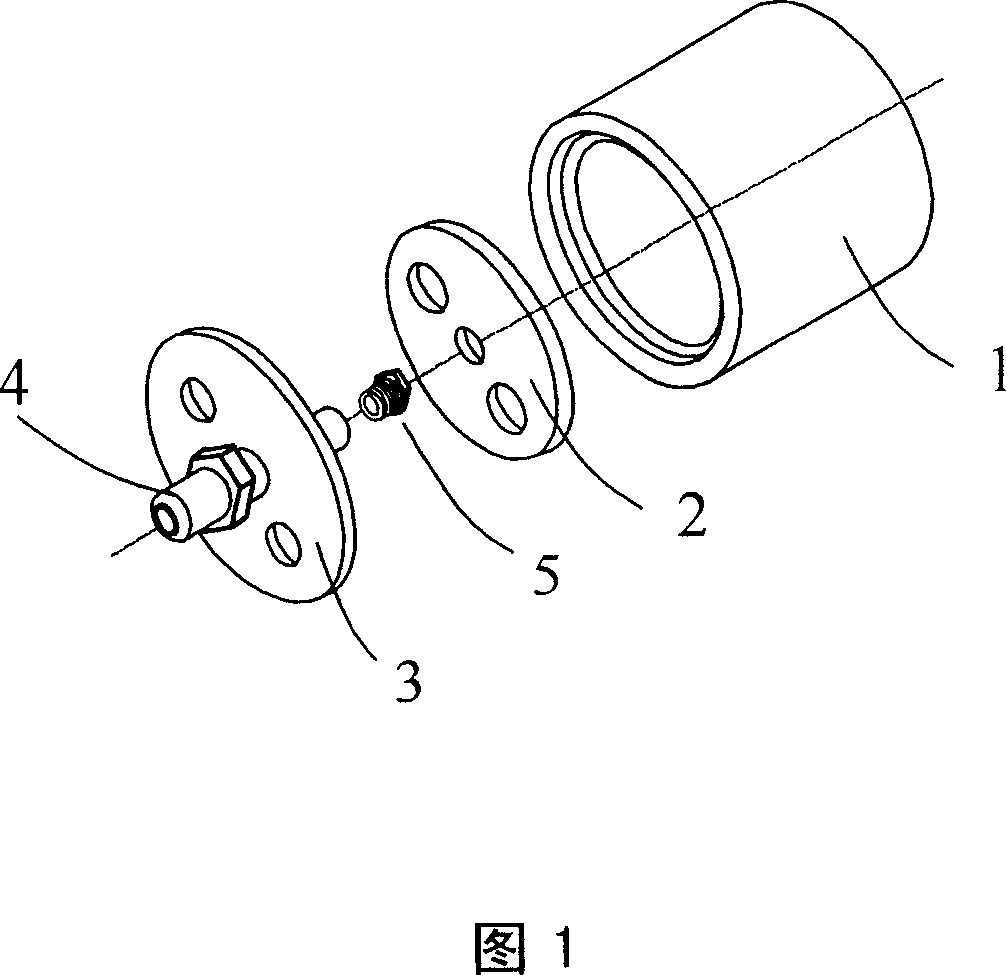

Gas burner

InactiveUS20070009847A1Good burning effectGood effectGaseous fuel burnerMechanical engineeringFuel gas

A gas burner includes a cylindrical hollow body, a top casing integrally mounted on top of the body and having multiple through holes defined in two opposed side faces of the top casing to communicate with an interior of the body and a supporting baffle formed inside the top casing to engage with a bottom face and a top face of the top casing so as to increase rigidity of the top casing so that distortion of the top casing is avoided.

Owner:WU TSEN TUNG

Lead-free borosilicate glass-based ceramic composite material and preparation method thereof

ActiveCN114315162ALow temperature sinteringGood burning performanceGlass furnace apparatusGlass shaping apparatusThermal dilatationCeramic composite

The invention discloses a lead-free borosilicate glass-based ceramic composite material and a preparation method thereof. The lead-free borosilicate glass-based ceramic composite material is prepared from the following components in percentage by weight: 40 to 60 percent of SiO2-B2O3-AlF3-SrO glass which is used as a matrix and 40 to 60 percent of ceramic. The glass-based ceramic composite material is obtained by uniformly mixing ceramic powder and glass powder with proper particle sizes, granulating, tabletting and sintering. The prepared glass-based ceramic composite material has the characteristics of excellent microwave dielectric property, high bending strength, low thermal expansion coefficient, relatively high heat conductivity coefficient, good matching property with silver electrodes and the like, and has an application prospect in the field of low-temperature co-fired ceramic (LTCC) packaging.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

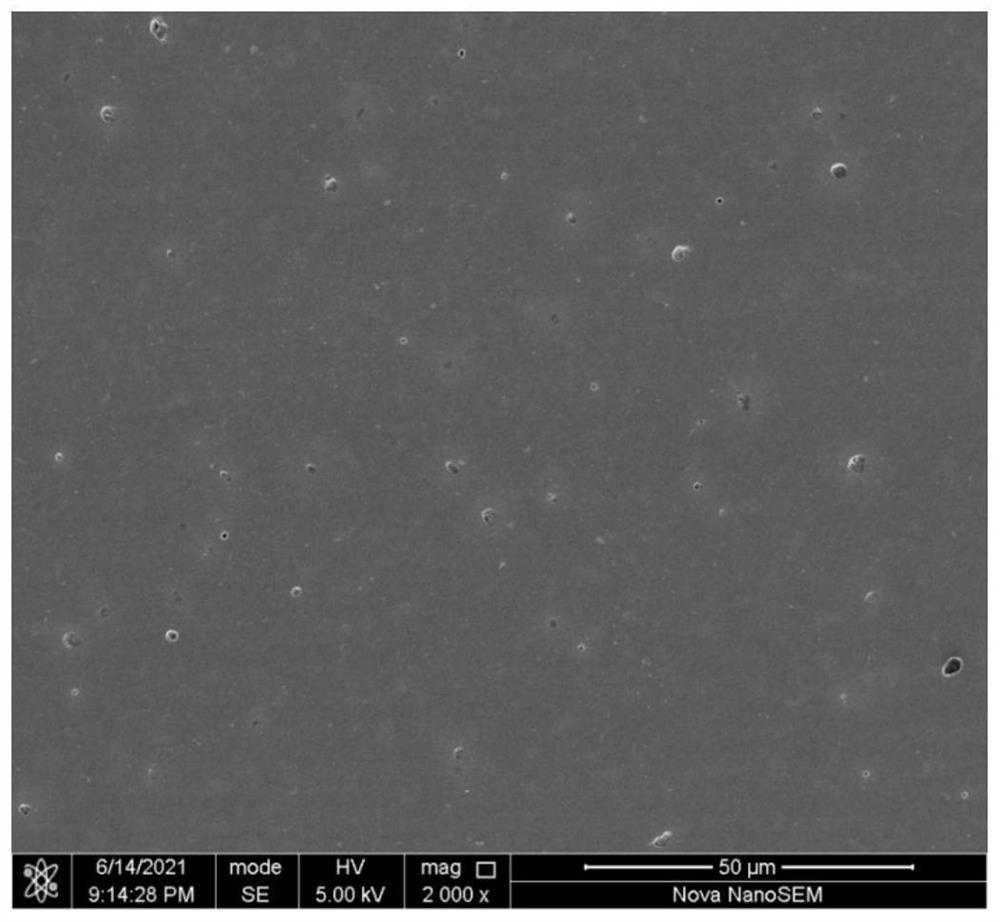

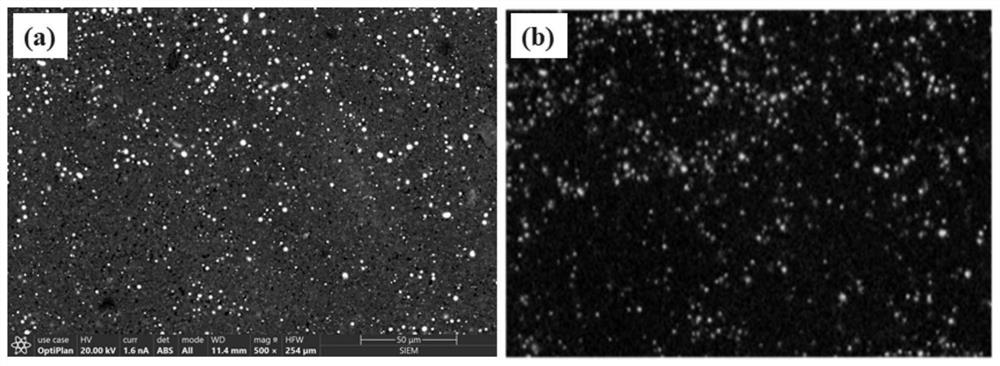

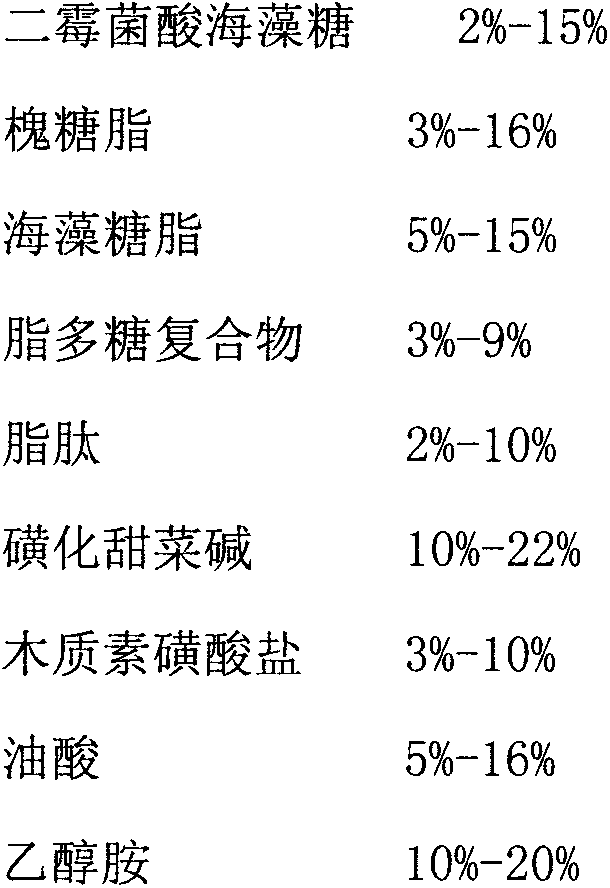

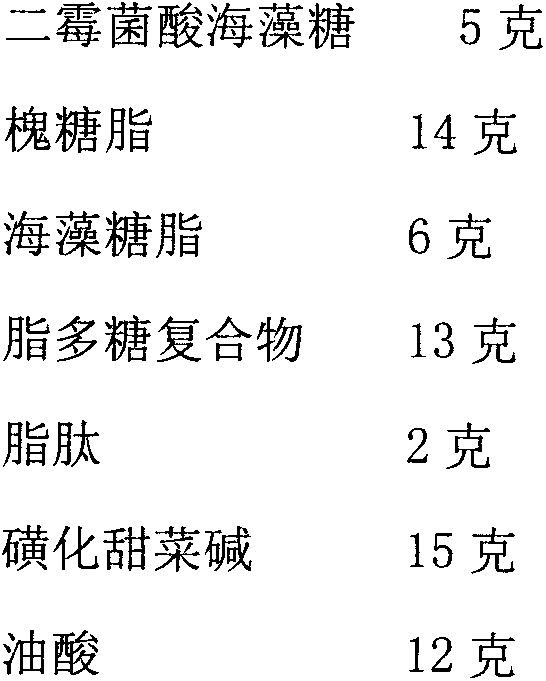

Microemulsion diesel oil with good thermodynamic stability

InactiveCN103409182AEasy to gatherHigh thermodynamic stabilityLiquid carbonaceous fuelsBetaineMycolic acid

The invention discloses microemulsion diesel oil with good thermodynamic stability and belongs to the field of energy chemistry. The formula is characterized by consisting of diesel oil, water and a total assistant, wherein the total assistant is composed of di-mycolic acid fungal acid trehalose, sophorolipid, trehalose glycolipid, lipopolysaccharide complex, lipopeptide, sulfonated betaine, lignin sulfonate, oleic acid, cholamine and amyl nitrate. The microemulsion diesel oil disclosed by the invention is good in thermodynamic stability, good in combustion effect, small in viscosity and free of oil-water stratification phenomenon after long-term storage. Moreover, the microemulsion diesel oil disclosed by the invention can be used for stably improving the vaporization rate of diesel fuel, and the secondary atomization effect of the microemulsion diesel oil ensures more full contact between the diesel fuel and the oxygen, so that the combustion of the diesel fuel is more full; compared with common diesel oil, the oil saving rate of the microemulsion diesel oil disclosed by the invention is larger than 10%, and the tail gas emission is excellent superior than that of national standard diesel oil.

Owner:朱光银

Automatic-regualting burner for gas furnace

InactiveCN1815081AGood burning effectSave electricity or gasGaseous fuel burnerAutomatic controlIntake pressure

A gas furnace self-adjustment type burner includes shell, ejector, gas mixture chamber, combustion chamber, gas distribution hole, gas inlet and air inlet. It features linkage fan set in combustion chamber and air inlet, said linkage fan set vane a and b a and b respectively on combustion chamber and air inlet central shaft. Linkage rotation is realized by thermal current impulsion of vane whose speed depending on air inlet pressure and flow rate variation, Linkage fan rotational velocity automatically controlling fuel gas with air mixing ratio in mixing chamber, therefore having good firing effect, saving fire gases, avoiding gas mixture backfire detonation combustion, safety use etc advantages.

Owner:杜英玮

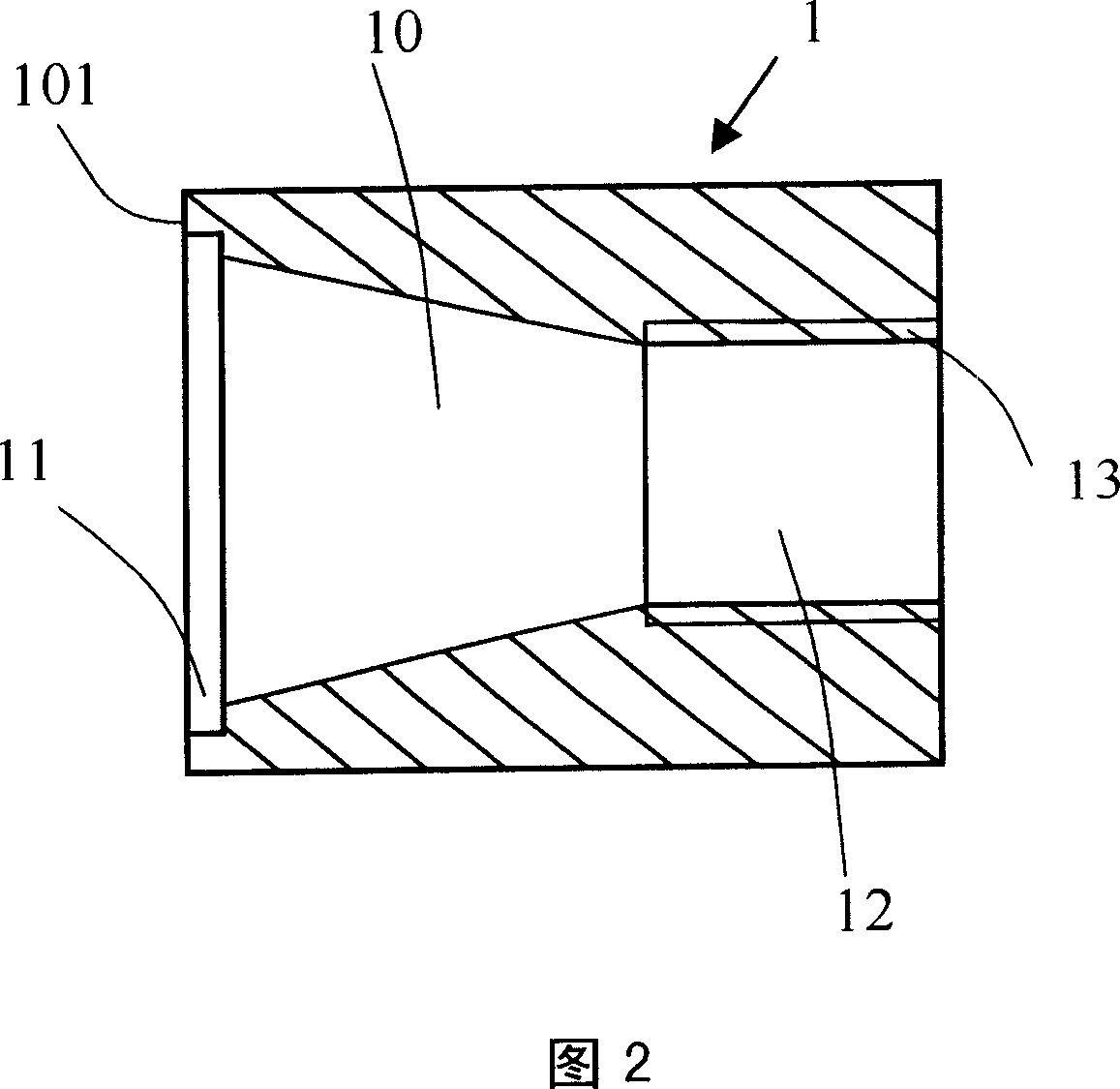

Fuel jet device

The present invention discloses one kind of fuel injecting device and relates to fuel gas providing technology for combustion apparatus. The fuel injecting device includes one injection valve, one nozzle element and one bonnet to the injection valve. The injection valve includes one valve body, one inlet end, one outlet end and one central passage between the inlet end and the outlet end; and the nozzle element set to the outlet end of the injection valve has one jet hole in the middle part with inner diameter smaller than that of the central passage in the injection valve. The size of the jet hole is proper for jetting the fuel through the outlet end of the injection valve to the mixing chamber inside the bonnet to control the fuel consumption. Several nozzle elements of different sizes of jet hole are provided for the user to select and to reach clean efficient combustion effect.

Owner:小霍华德·C·奥利弗

Self-preheating temperature adjusting gas burner

PendingCN108469024ABurn fullyGood burning effectGaseous fuel burnerIndirect carbon-dioxide mitigationGas burnerEngineering

The invention relates to the technical field of combustion equipment, in particular to a self-preheating temperature adjusting gas burner. The self-preheating temperature adjusting gas burner comprises a gas pipe, a primary air flowing guiding pipe and a secondary air flowing guiding pipe, a shell is internally provided with the primary air flowing guiding pipe, the primary air flowing guiding pipe is coaxially arranged on the outside of the gas pipe in a sleeving mode, and the secondary air flowing guiding pipe communicates with the gas outlet end of the gas pipe. According to the self-preheating temperature adjusting gas burner, the flame temperature is adjusted by controlling the air inlet amount of the secondary air flowing guiding pipe, meanwhile, secondary air and flue gas are mixed,the temperature of the flue gas is reduced, thus the flame temperature is adjustable, and heat carried by the flue gas can exchange with primary air, so that the primary air is more suitable for combustion supporting, meanwhile, the heat of the flue gas is reduced, the temperature of combustion supporting air is increased, and energy sources are saved.

Owner:北京兴达奇热工控制设备有限公司

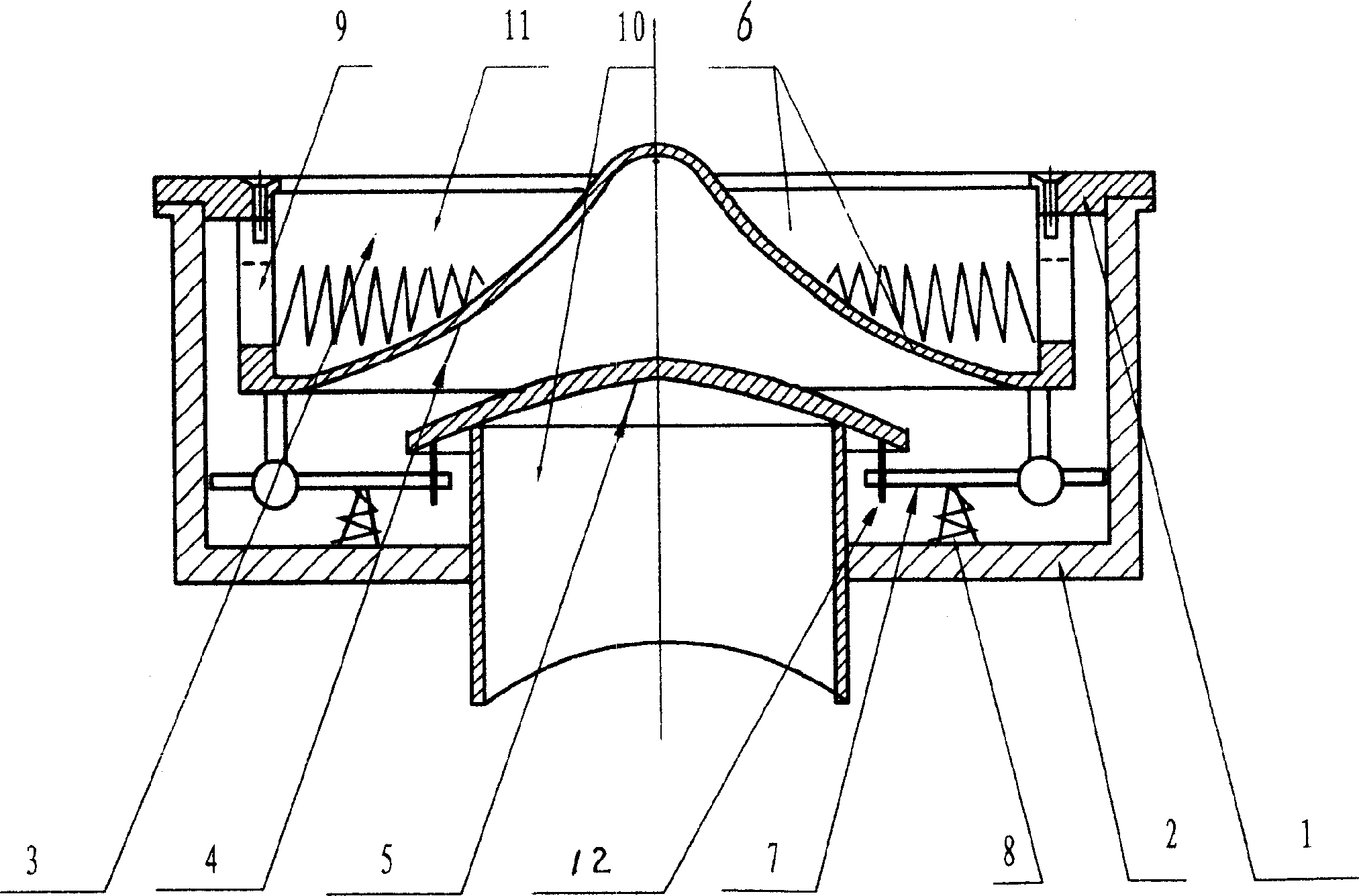

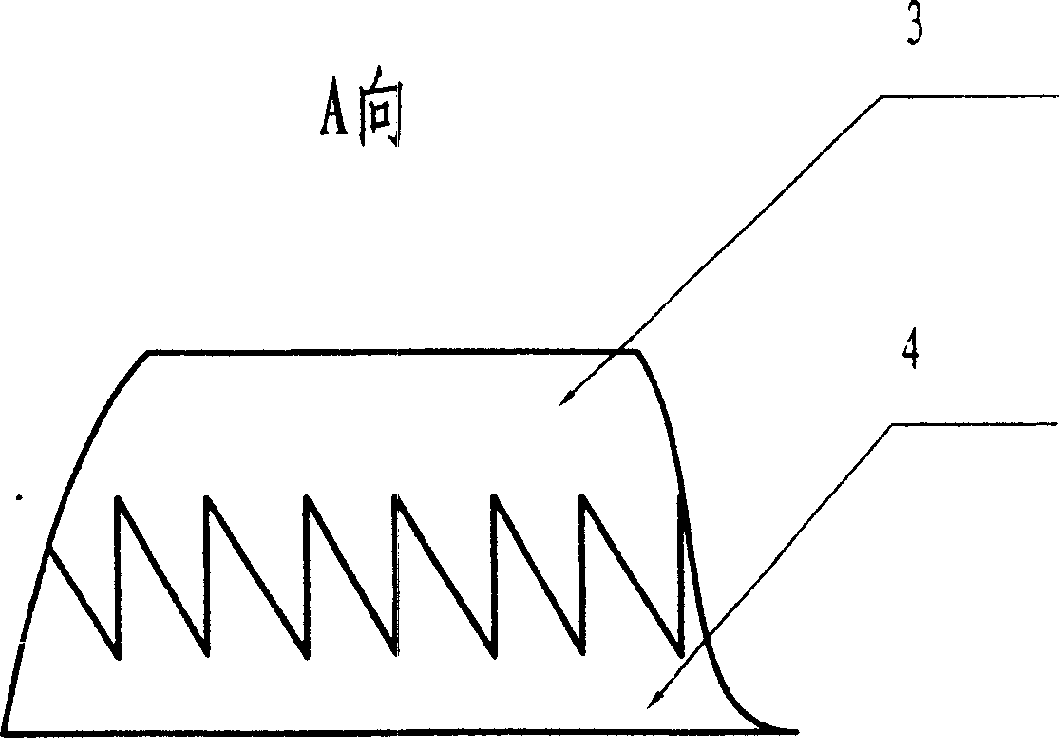

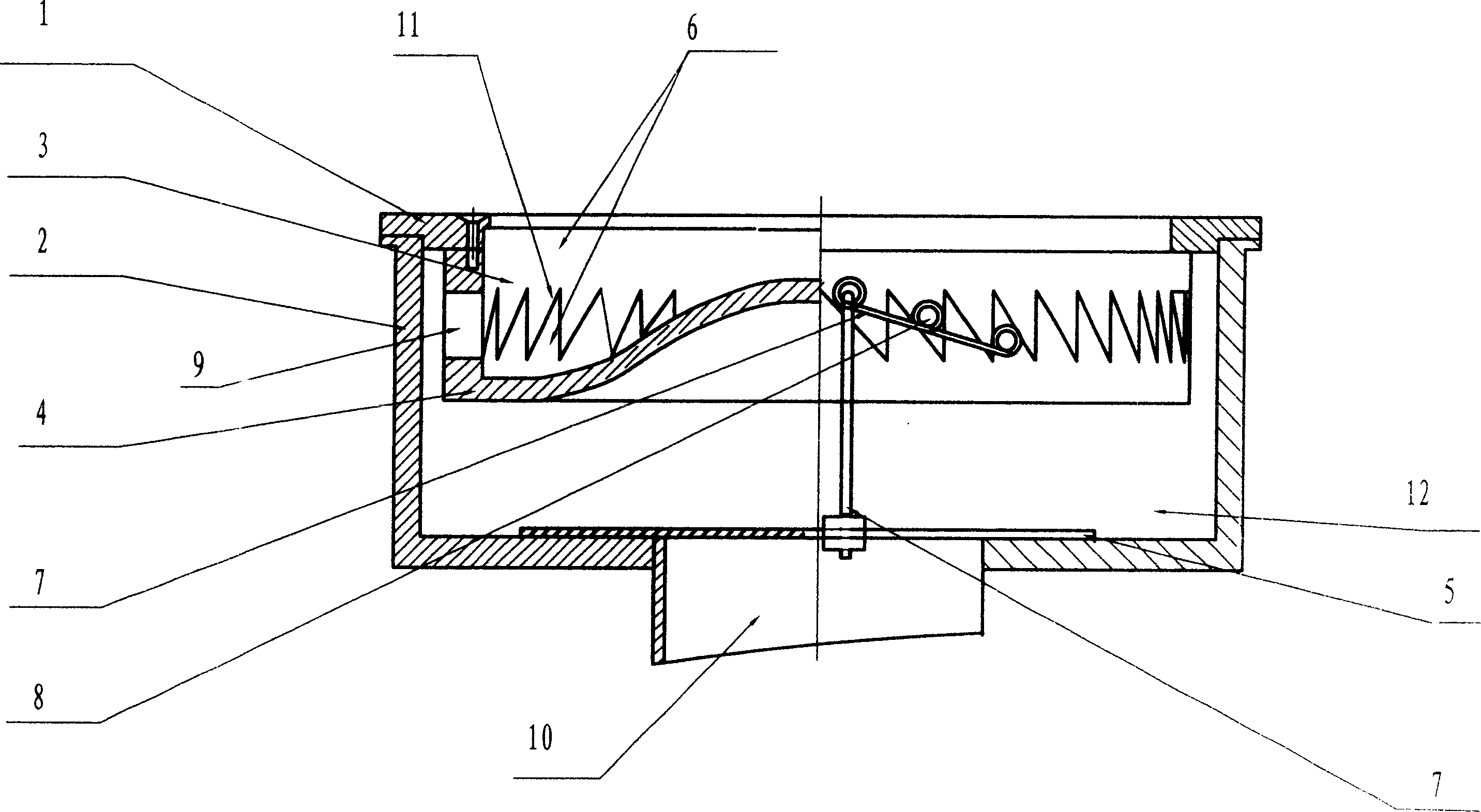

Biomass burning furnace and air intake method

InactiveCN103047686AGood burning effectImprove efficiencyDomestic stoves or rangesLighting and heating apparatusTarAutomotive engineering

A biomass burning furnace which is clean, energy-saving and convenient to use comprises a casing, a combustion system and a lifter. The combustion system uses a multiple-layer air intake cover and is provided with a lower combustion barrel bottom air inlet, a lower combustion barrel upper edge air inlet and a multiple-layer air inlet. An upper combustion barrel is fixedly connected with a furnace base and an inner lateral wall of the casing, a lower combustion barrel is placed on a support of the lifter and can lift vertically, the lower combustion barrel and the multiple-layer air intake cover form a movable type embedded structure, and the lifter is of a door curtain structure, charging of the lower combustion barrel is performed through a switch of a door. The multiple-layer air intake cover has the effects of brightening fire, gathering energy and achieving pyrolysis combustion of tar and steam. The biomass burning furnace adopts direct-ignition combustion and natural air feeding, and is clean, hygienic, free of smoke in ignition and quick in fire exchange. Biomass sources required by the biomass burning furnace are wide and include core woods and various by-products of agriculture and forestry, processed biological rids can serve as fuel, and the biomass burning furnace is suitable for agricultural production and rural families.

Owner:黄爱国

Biomass fuel for firing shale ceramsite and preparation method thereof

InactiveCN110129107AImprove combustion efficiencyGood burning effectBiofuelsSolid fuelsMagnesium nitrateEngineering

The invention relates to a biomass fuel for firing shale ceramsite and a preparation method thereof. The biomass fuel includes rice husk, sawdust and a combustion improver. The biomass fuel comprisesthe following components in percentage by mass: 70-85% of the rice husk, 10-25% of the sawdust and 2-5% of the combustion improver. The rice husk and the sawdust adopt powdery particles with the particle size below 5 mm, and the combustion improver comprises at least 15-25% magnesium nitrate and 15-20% magnesium oxide. The preparation method of the biomass fuel comprises the steps of raw materialdrying, primary crushing, secondary crushing after mixing, high-temperature steam heat treatment, addition of the combustion improver, mixing and the like. The biomass fuel not only has low cost, highheat value and combustion efficiency, but also has the advantages of difficult slagging, less harmful gas emission and the like.

Owner:宜昌朗天新型建材有限公司

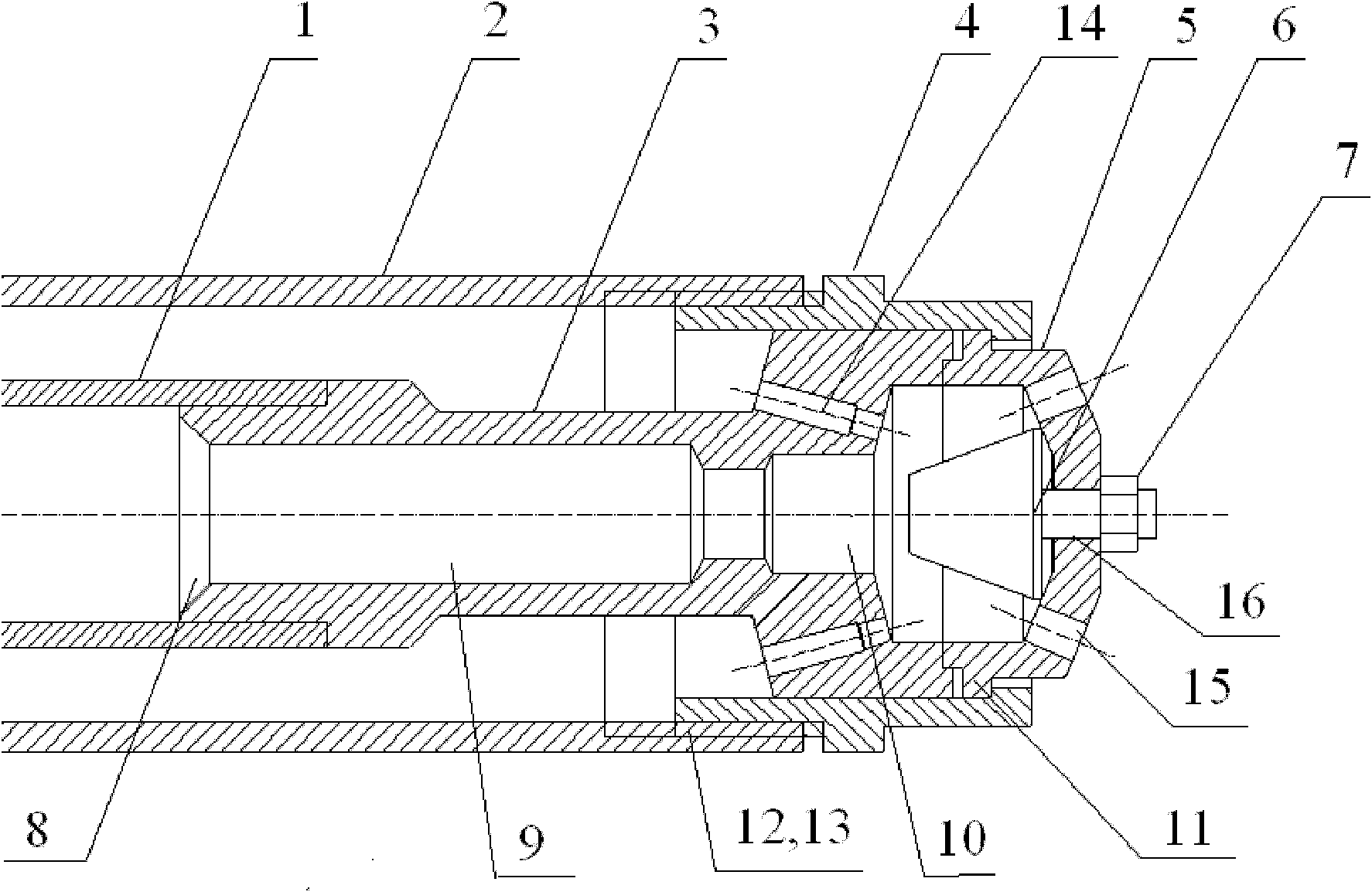

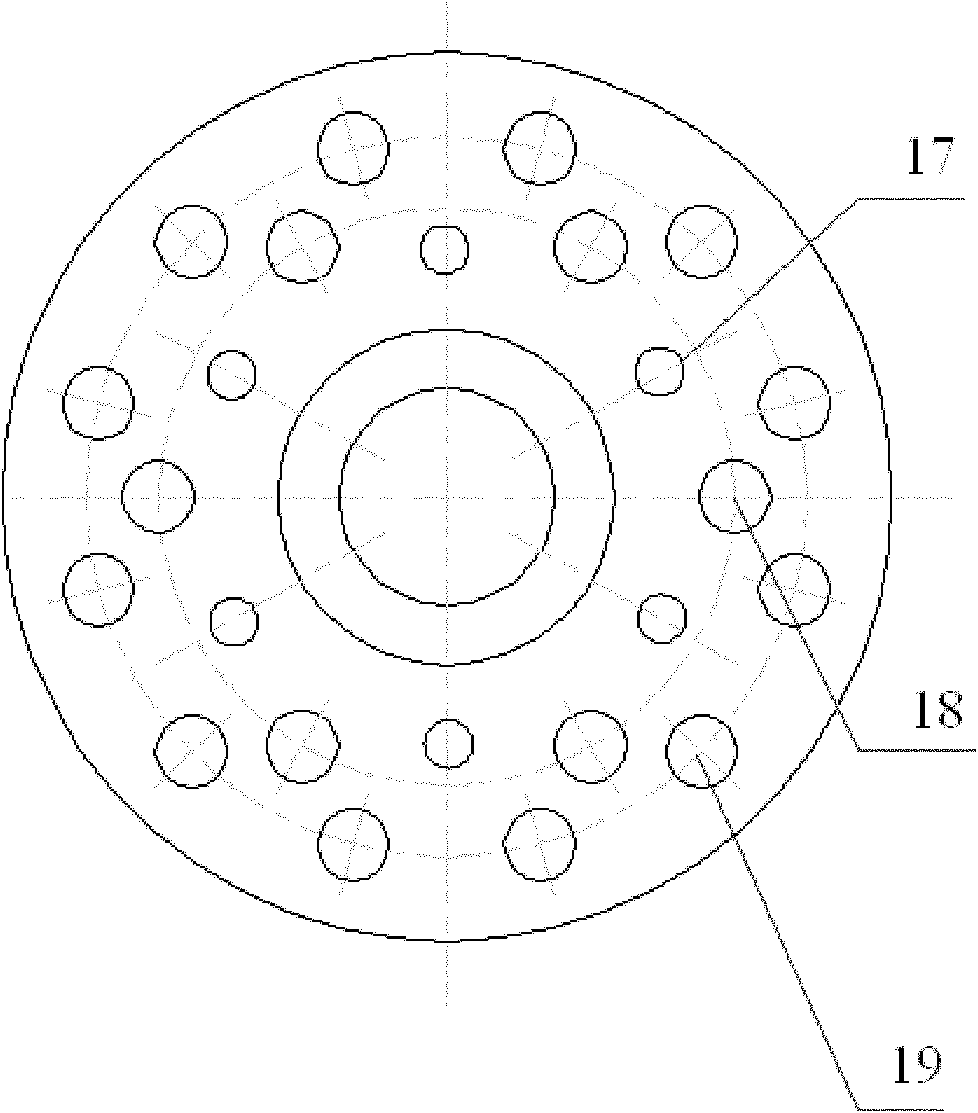

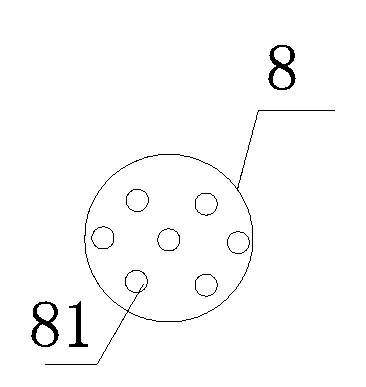

Multi-angle impact atomization coal water slurry nozzle

The invention belongs to the field of combustion of coal water slurry and in particular relates to a multi-angle impact atomization coal water slurry nozzle, which comprises an atomizer; the atomizer is fixedly connected with an outer atomization cover; one end of the atomizer, which is connected with the outer atomization cover, is provided with atomization holes; a spraying hole is arranged in the outer atomization cover; because of the distribution of the atomization holes, coal water slurry is impacted and atomized in multiple angles; pneumatic impact and atomization are concentrated at the outlet of the atomizer and close to the spraying hole; the energy loss of an atomization agent is less; the atomization effect is beneficial to the increase; and, if the multi-angle impact atomization coal water slurry nozzle is tested on a 4-ton boiler, when the flow rate of the coal water slurry is 600 kg / h and the air amount is 3500 Nm<3> / h, the combustion effect is good and the smoke blackness Ringelmann grade is less than 1 under the condition of about 15% of air consumption rate.

Owner:BEIJING AEROSPACE PROPULSION INST

Glass powder applicable to NPO ceramic body as well as preparation method and application of glass powder

The invention discloses glass powder applicable to an NPO ceramic body. The glass powder comprises the following components in percentage by weight: 20-40wt% of B2O3, 15-35wt% of BaO, 10-30wt% of ZnO, 1-10wt% of SiO2, 1-10wt% of CaO, 1-10wt% of ZrO2 as well as 1-5wt% of one or more of TiO2, Co2O3 and SnO2. By virtue of the NPO product matched with copper slurry prepared from the glass powder disclosed by the invention, the problem of internal microcracking during a test can be well solved.

Owner:JIANGSU HOYI TECH

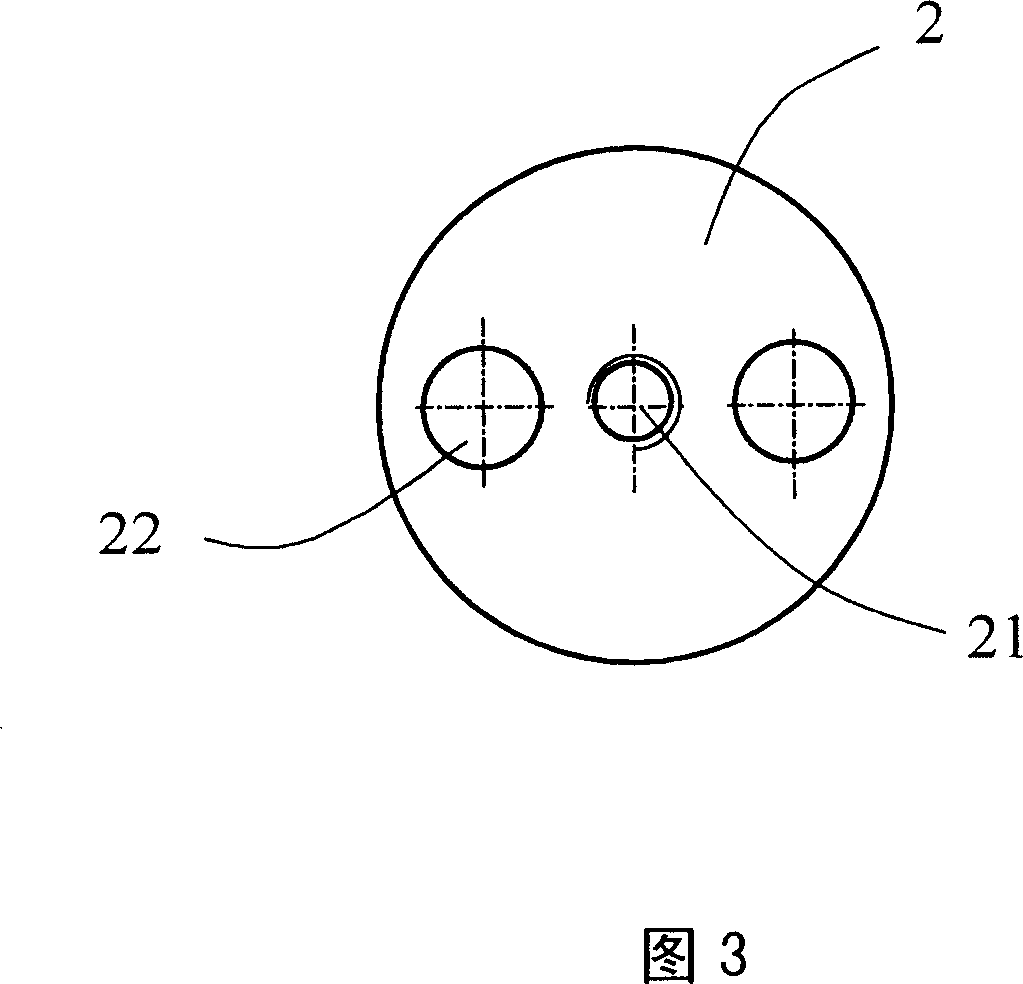

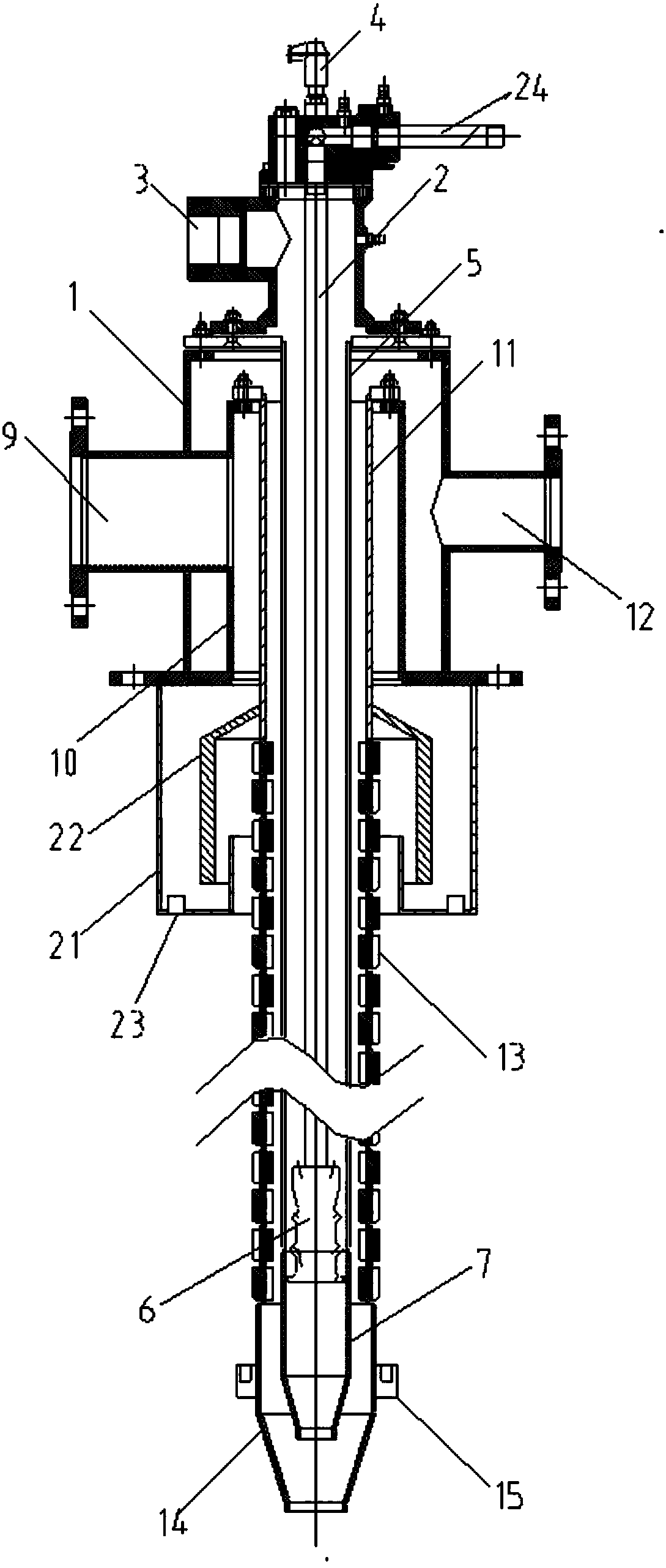

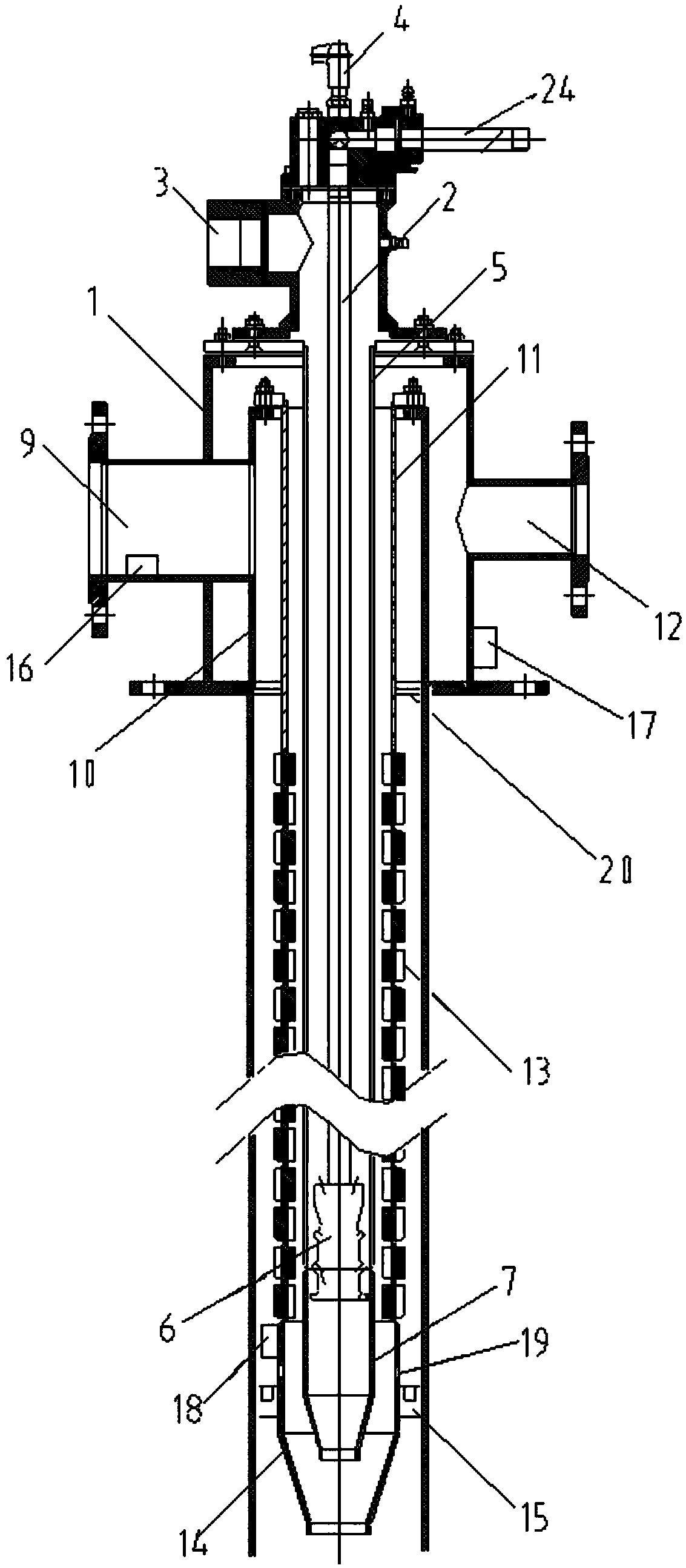

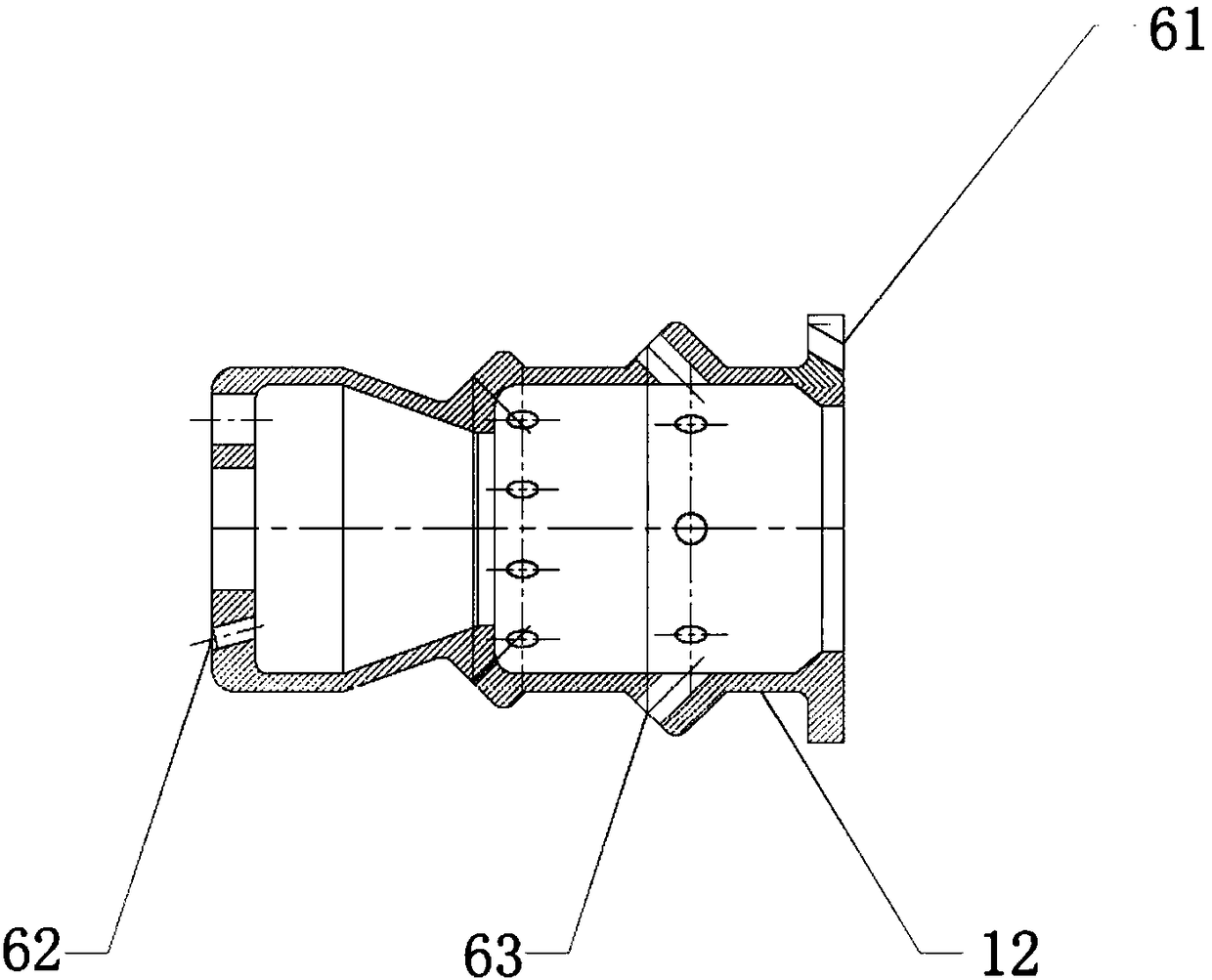

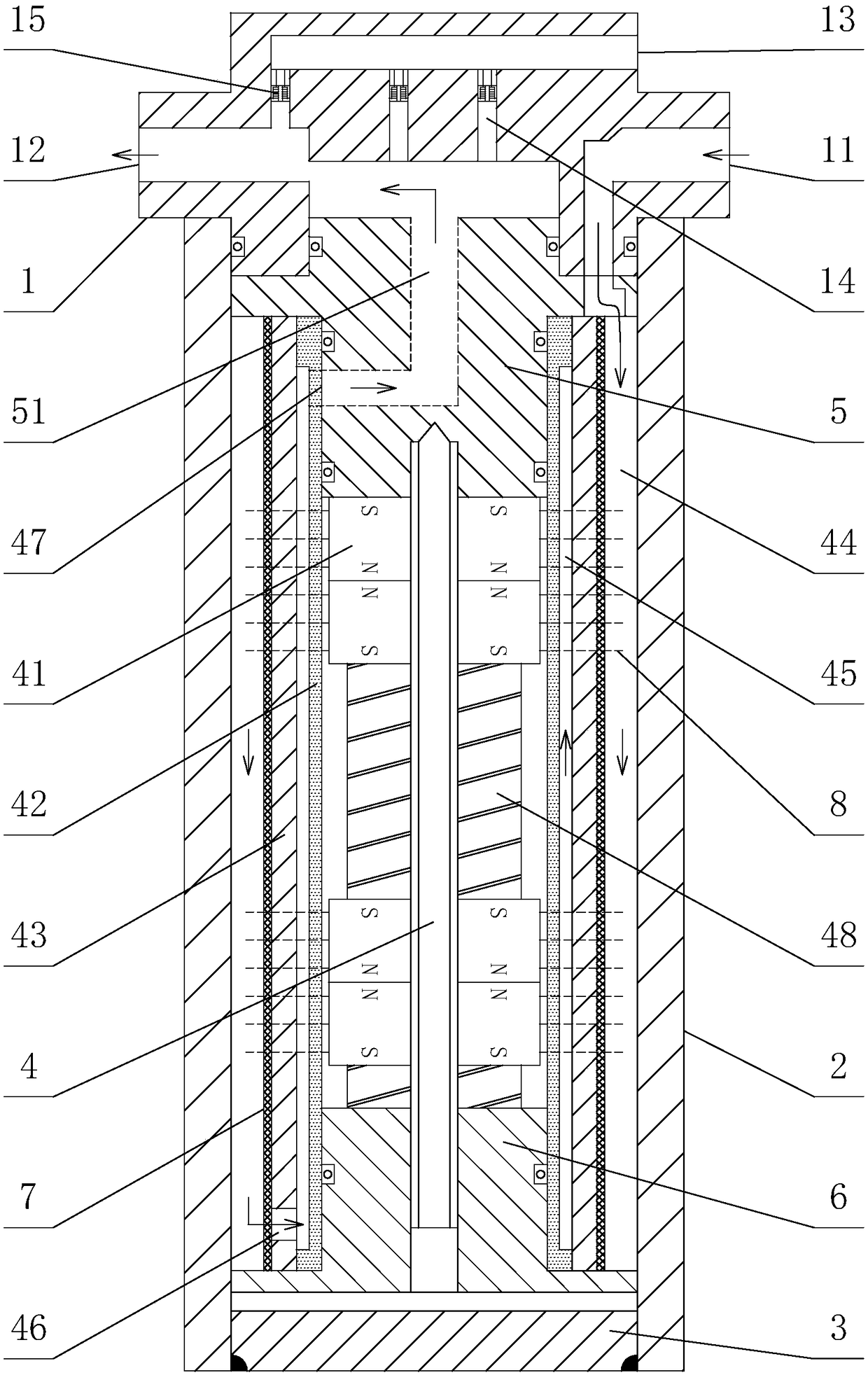

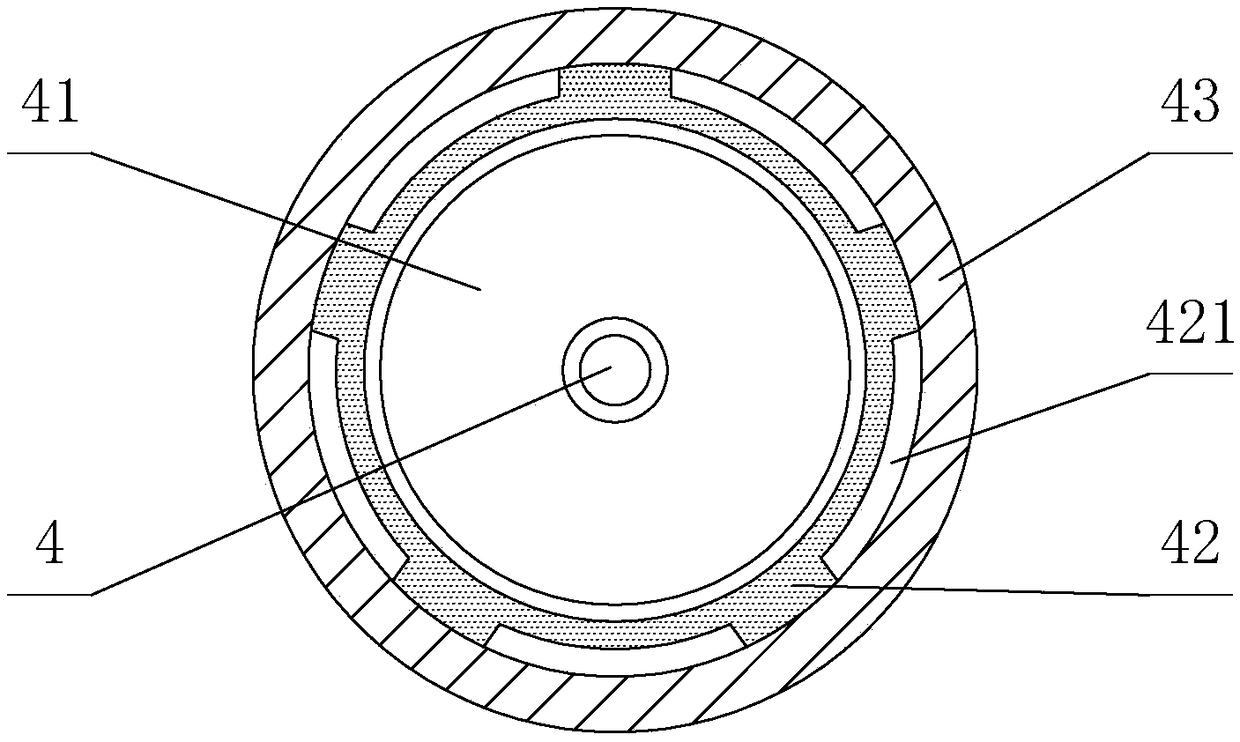

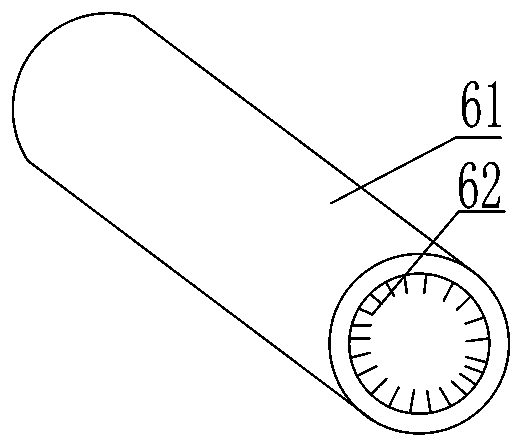

Multifunctional fuel magnetizer

PendingCN109139310AStrong magnetizationAvoid corrosionInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionMagnetic energy

A multifunctional fuel magnetizer comprises an end cover, an outer barrel, an outer barrel rear cover and a magnetizing device arranged in the outer barrel; the upper end of the magnetizing device isconnected to the end cover through a core cover connecting body; the lower end of the magnetizing device is tightly pressed into the outer barrel through a core body rear cover; the magnetizing devicecomprises a central screw, a magnetic energy core body, a magnetic permeable core body tube and a core body protection sleeve which are sequentially connected from inside to outside in a nesting mode; a cavity between the core body protection sleeve and the outer barrel forms a dirt intercepting cavity; the magnetic permeable core body tube and the core body protection sleeve are in close fit andare magnetically permeable; and the outer surface of the magnetic permeable core body tube is provided with a groove which is repeatedly circuitous up and down, and a magnetizing cavity is formed. Apermanent magnet ring body is isolated from fuel, the permanent magnet ring body is effectively prevented from being corroded by the fuel, the large-sized permanent magnet ring body can be arranged, the fuel passes through the magnetizing cavity and is repeatedly cut through magnetic lines of force, the oil channel passing cross-sectional area is adjusted by controlling the depth and width of thegroove, the fluid flow rate is increased, and the high magnetic strength and high flow rate are both achieved, so that the best magnetizing effect and combustion effect are achieved.

Owner:梁严

Preparation method for porous bionic wood ceramics

The invention discloses a preparation method for porous bionic wood ceramics, and belongs to the technical field of bionic materials. The method comprises the following steps that wood is cut into blocks and is subjected to vacuum freeze drying to constant weight so as to obtain dry blocks; the dry blocks are fixed to the bottom of a water tank, are soaked in a saturated salt solution, are subjected to ultrasonic impregnation, are naturally cooled to the room temperature, then are taken out from the water tank and are subjected to vacuum freeze drying so as to obtain blocks subjected to salt solution impregnation; then the blocks subjected to salt solution impregnation are transferred into a reaction kettle, and nitrogen loaded with trimethylaluminum is introduced into the reaction kettleunder the condition that the temperature is 39 DEG C, pressure maintaining is carried out for reaction for 6-8 hours, and then the pressure is released to normal pressure so as to obtain fumigated blocks; and the obtained fumigated blocks is mixed with resin and impregnated, and then subjected to compression molding, calcining at an inert gas protection state, and cooling so as to obtain the porous bionic wood ceramics. The porous bionic wood ceramics obtained through the preparation method has excellent mechanical properties.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

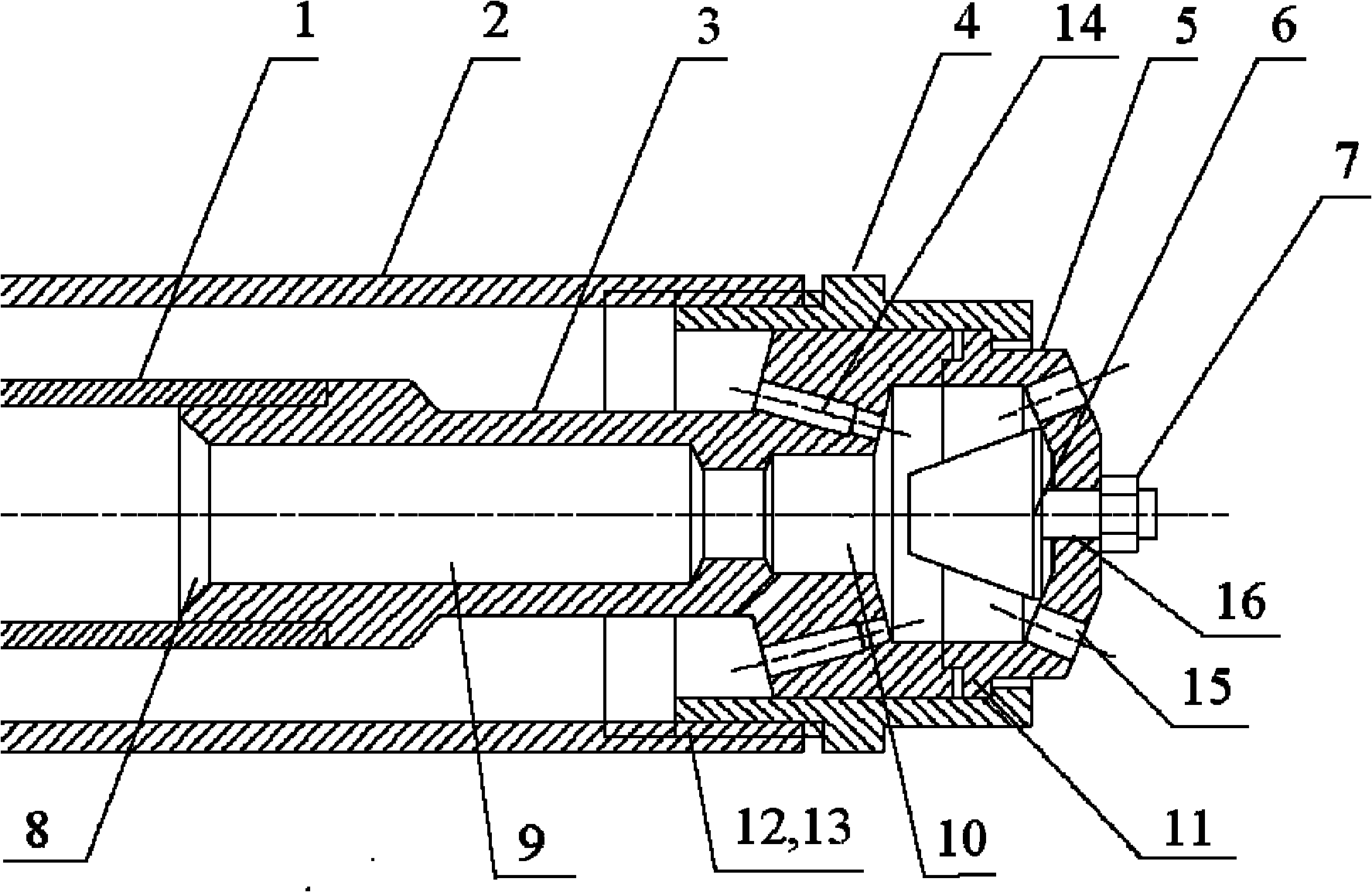

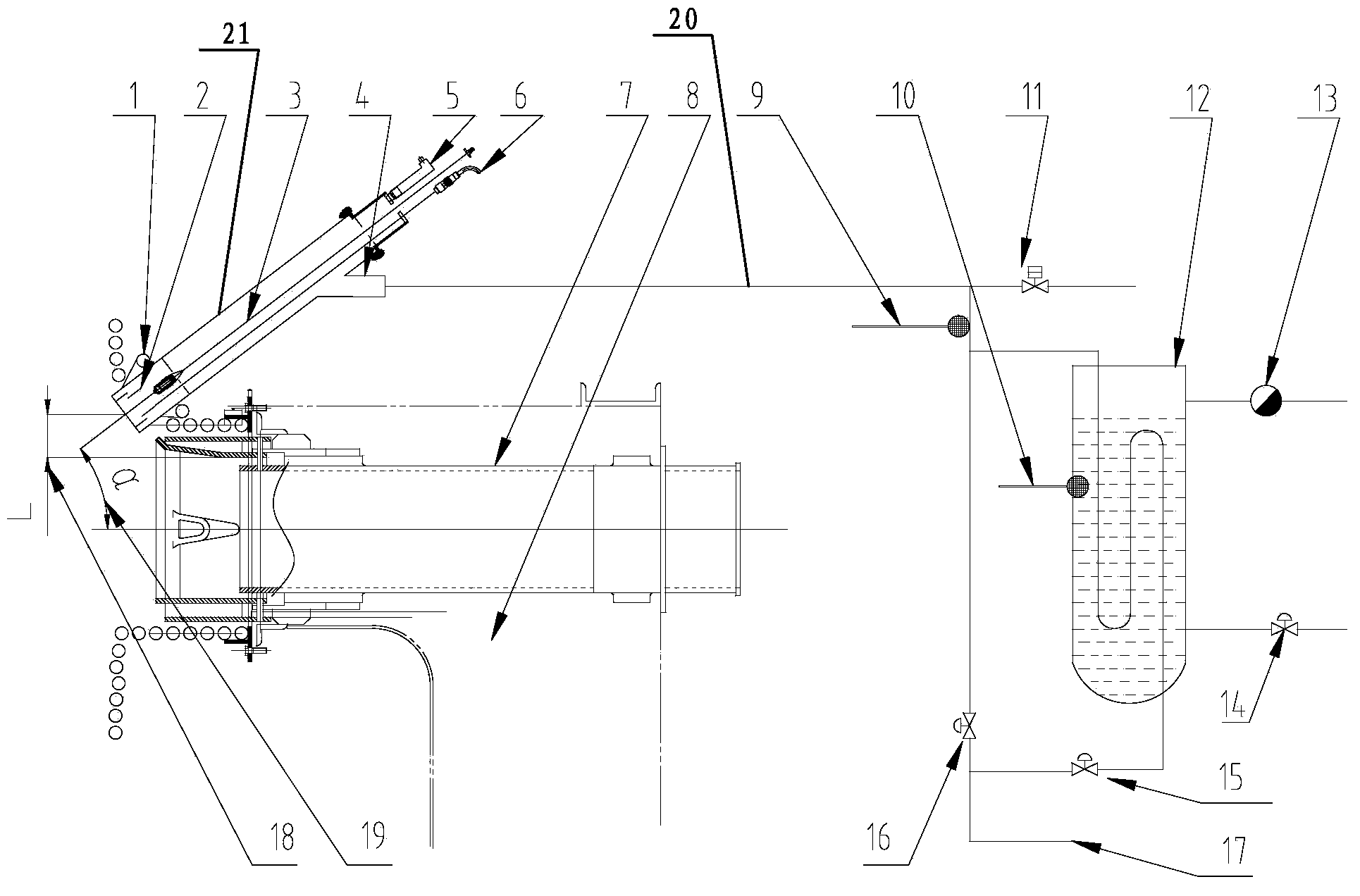

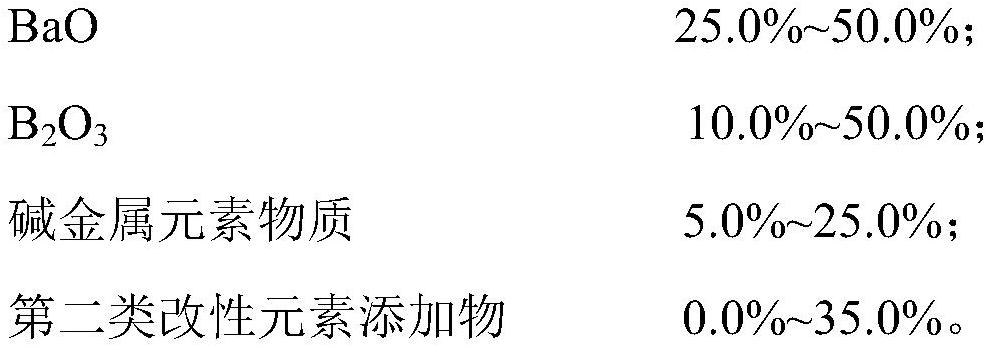

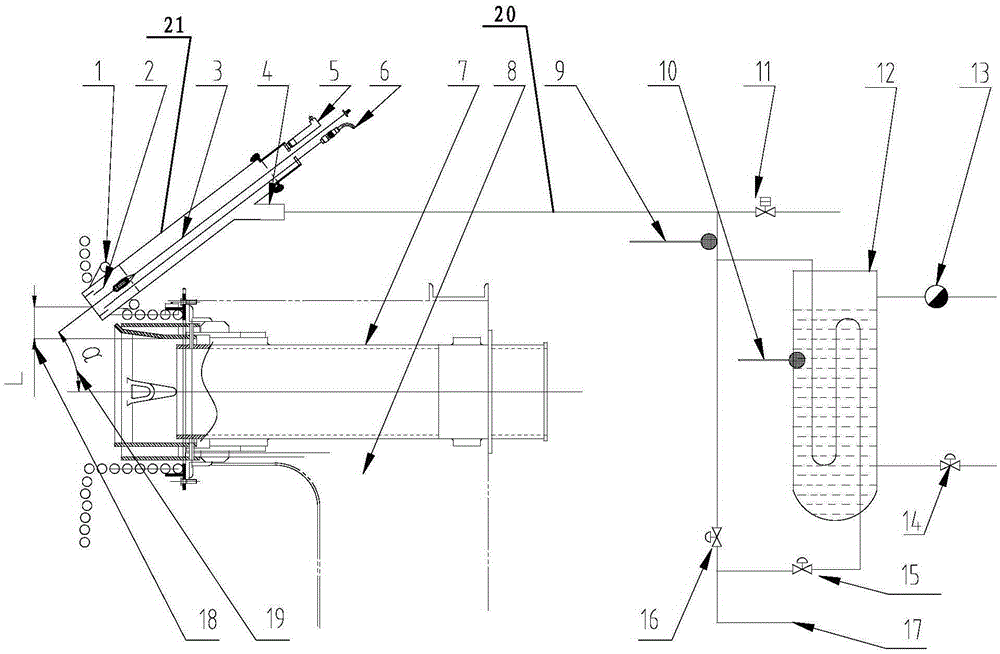

High-temperature pure oxygen oil gun device for utility boiler automatic stable combustion

ActiveCN103868059AGood burning effectGuarantee safe and reliablePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustionFuel oil

The invention relates to a high-temperature pure oxygen oil gun device for utility boiler automatic stable combustion. The high-temperature pure oxygen oil gun device comprises a water wall pipe, a high-temperature pure oxygen oil gun assembly, a pulverized coal burner, a hot air box, an oxygen heater, an oxygen mother pipe and an oxygen pipeline. The pulverized coal burner is installed on the hot air box, a hole is formed between the water wall pipe and the pulverized coal burner, the high-temperature pure oxygen oil gun assembly is connected with the water wall pipe and the pulverized coal burner in the mode that the bottom of the high-temperature pure oxygen oil gun assembly is arranged into the hole in a sleeved mode, the high-temperature pure oxygen oil gun assembly is connected with the oxygen mother pipe through the oxygen pipeline, the oxygen mother pipe is connected with the oxygen heater, and the top of the oxygen heater is open. According to the high-temperature pure oxygen oil gun device for utility boiler automatic stable combustion, high-temperature pure oxygen is utilized for combustion supporting for fuel oil, white flame at the temperature higher than 2000 DEG C is obtained, oxygen is heated further through the high-temperature flame, the oxygen temperature can reach or exceed the temperature needed by pulverized coal ignition, finally, pulverized coal is ignited by high-temperature oxygen-enriched oil flame, and the excellent stable combustion effect is achieved.

Owner:重庆高新技术产业研究院有限责任公司

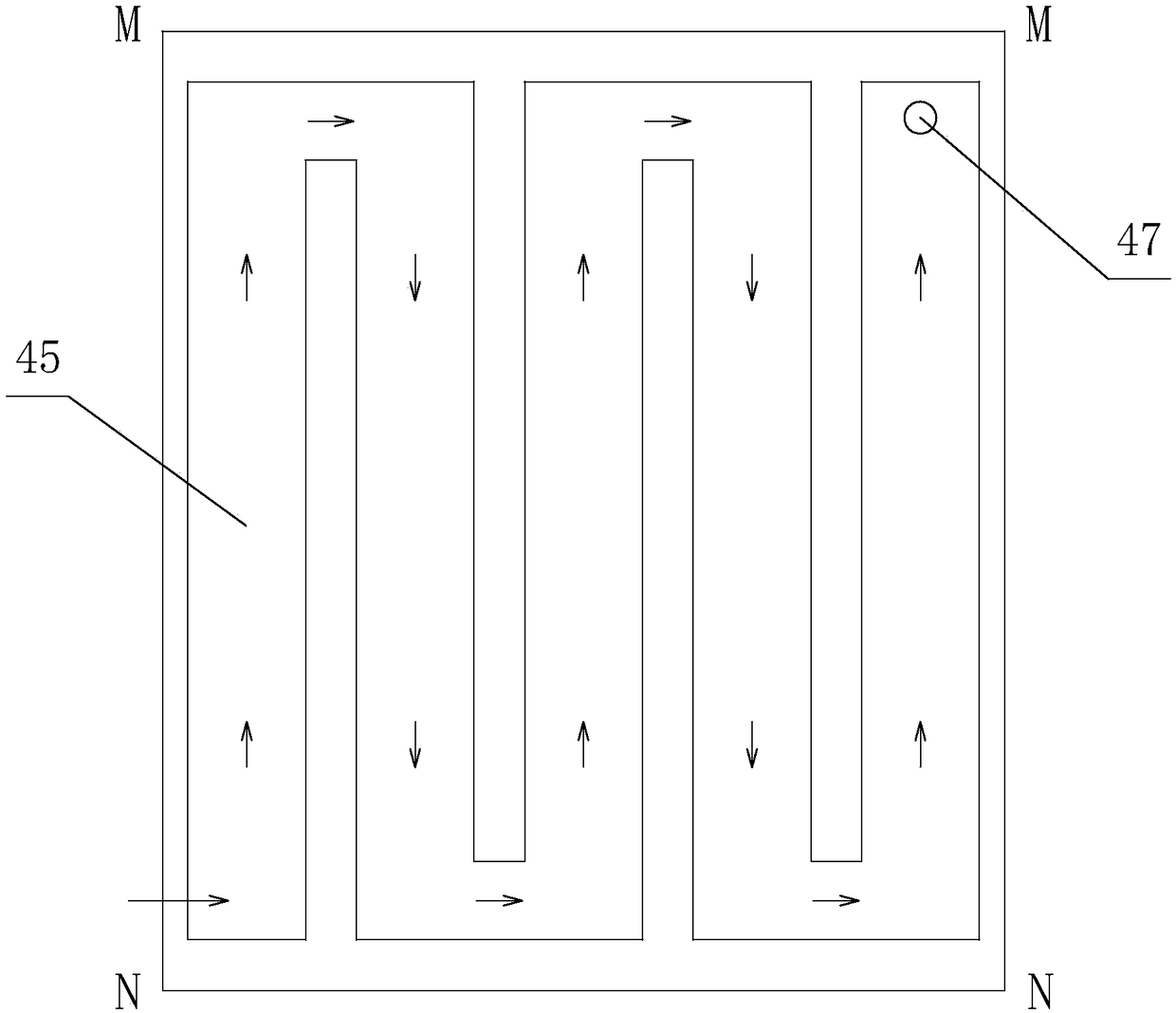

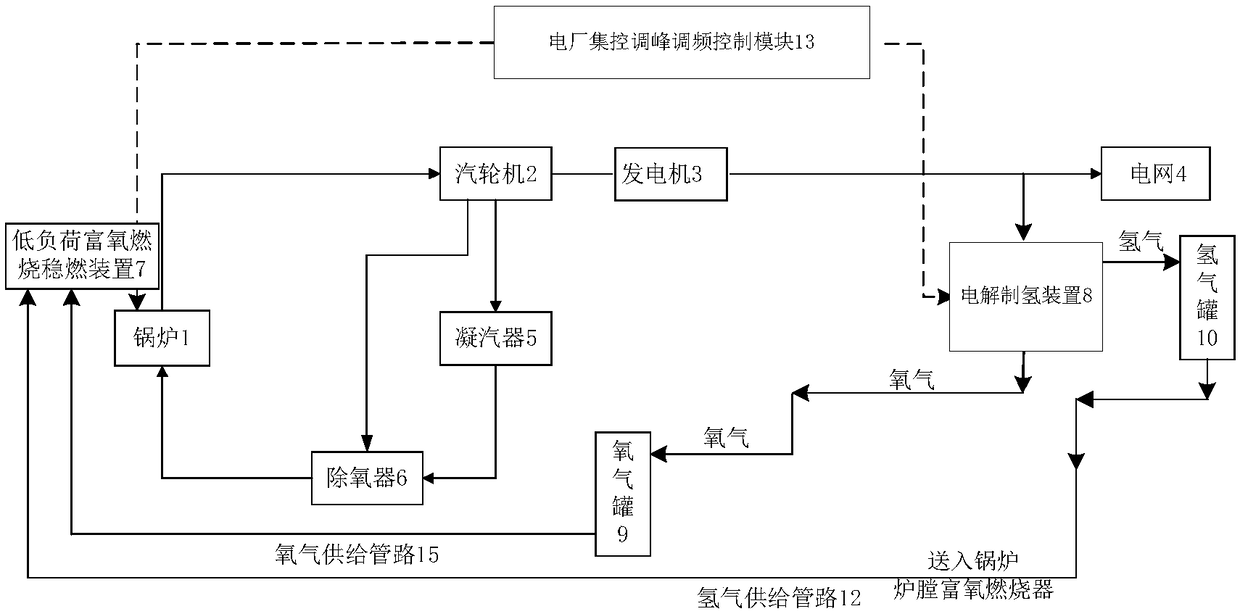

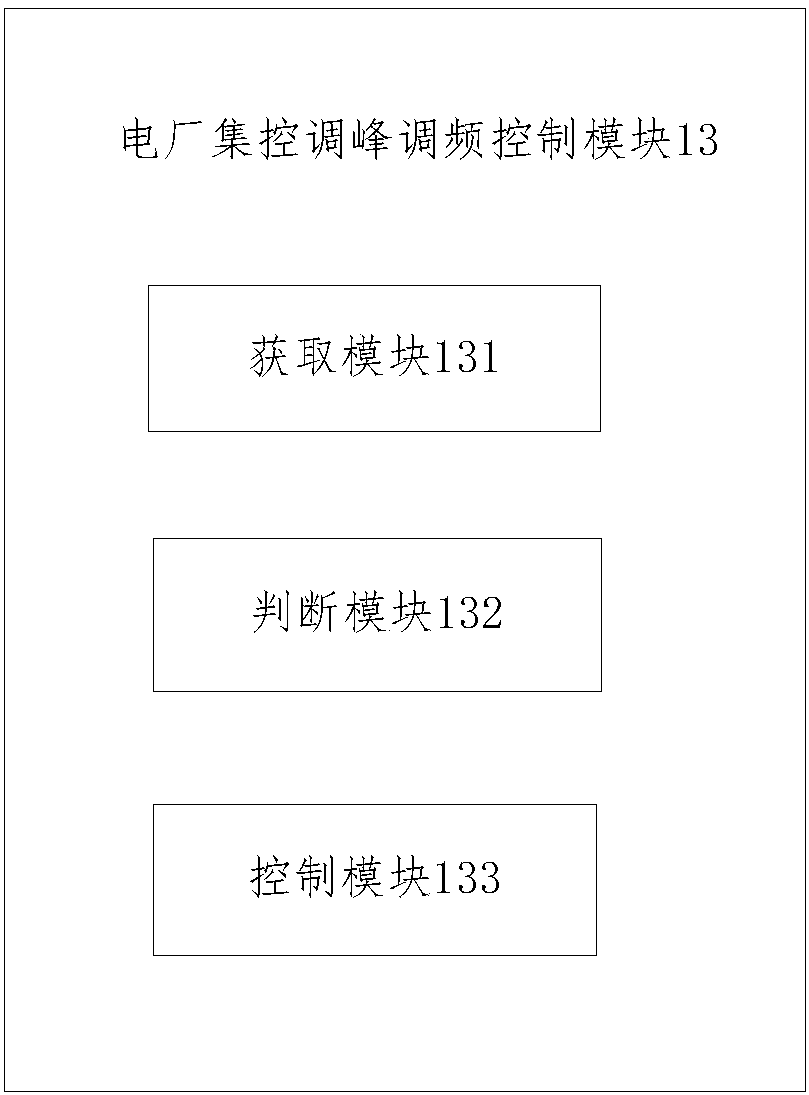

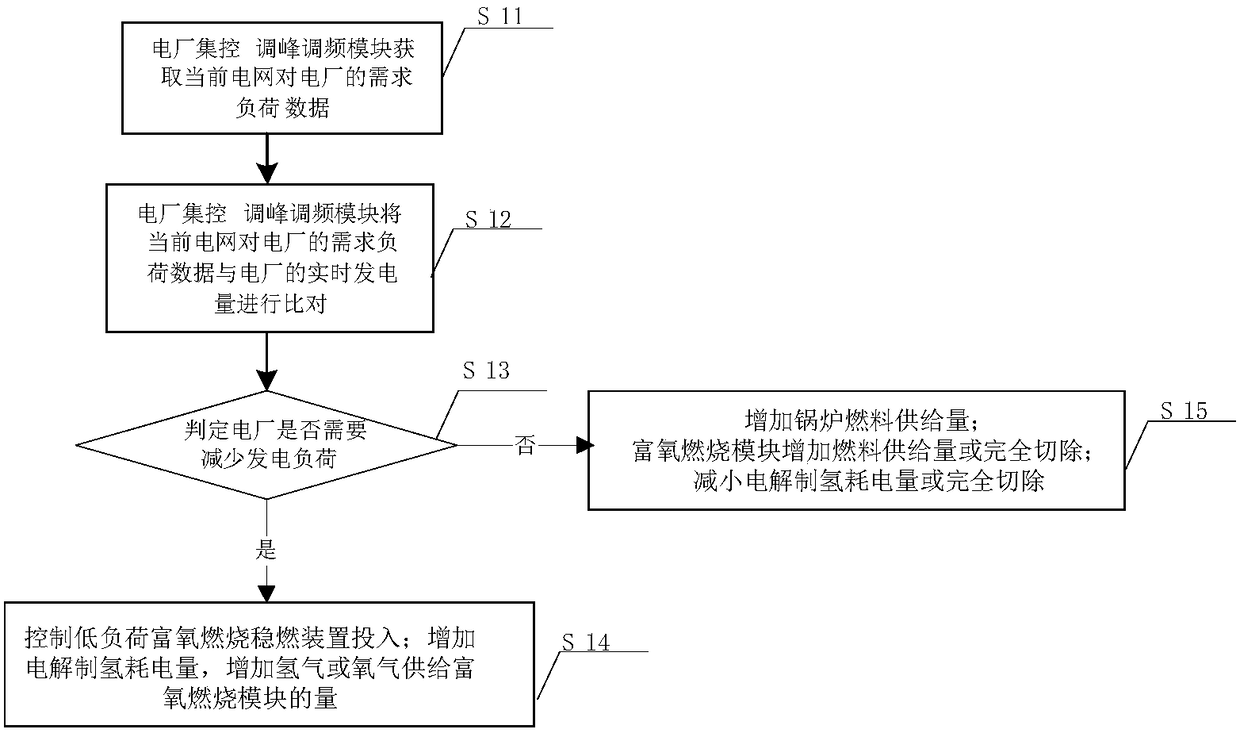

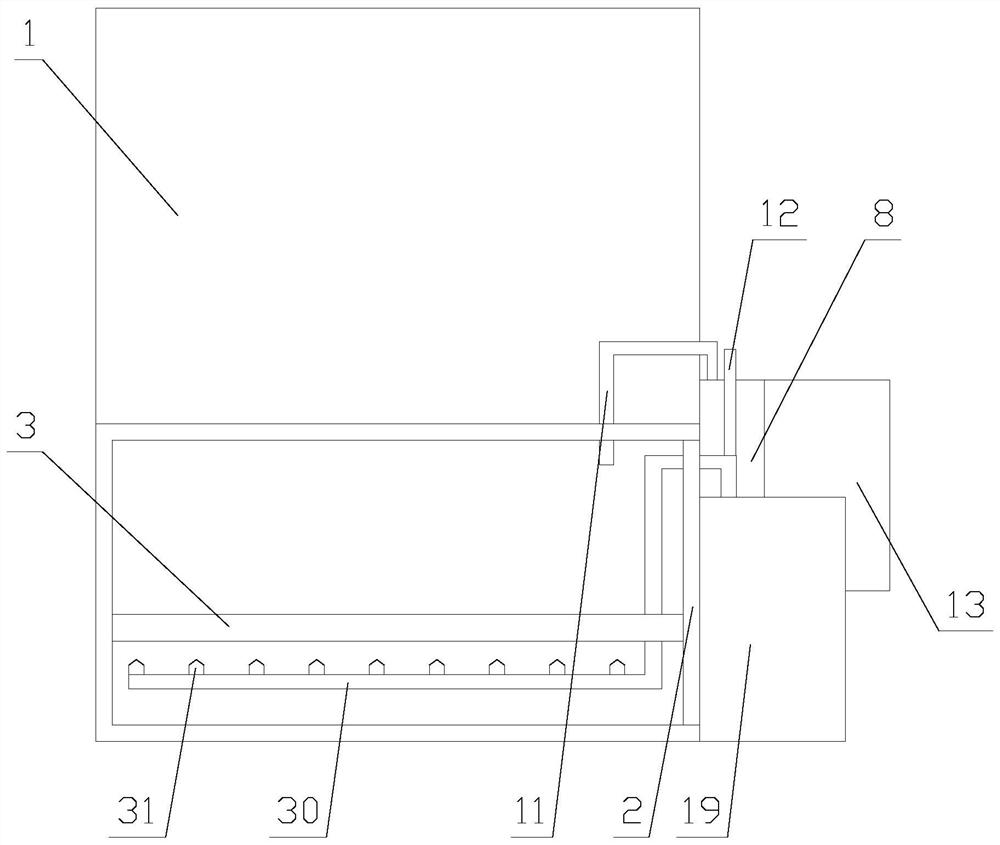

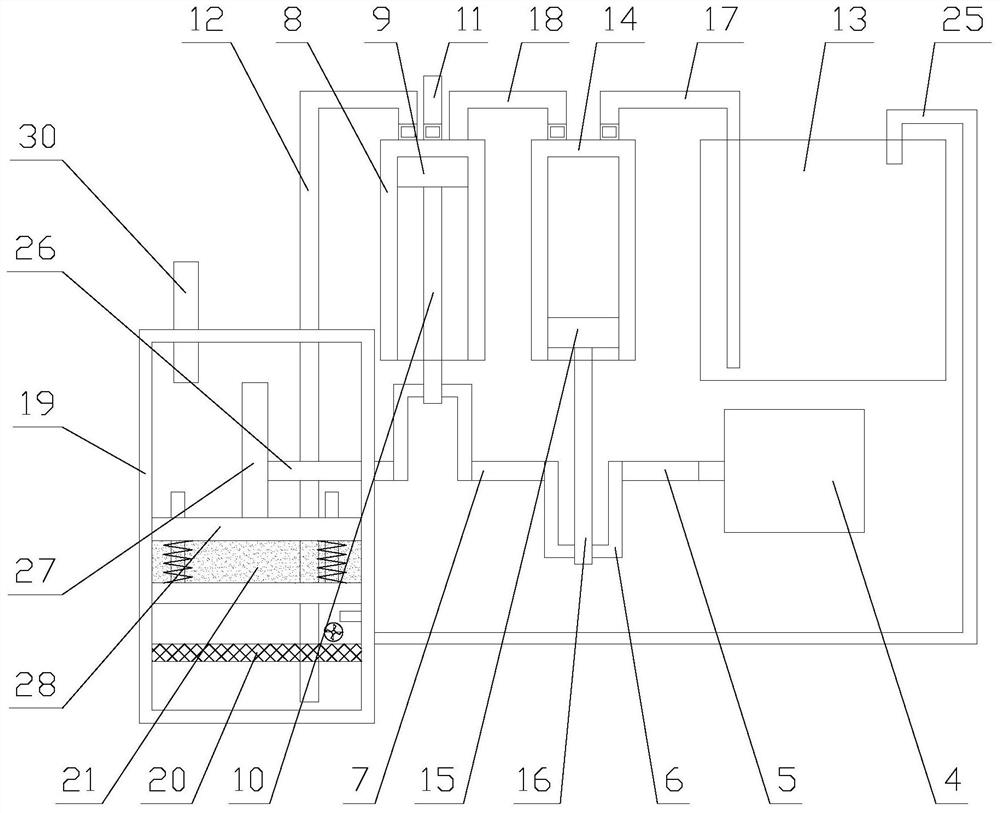

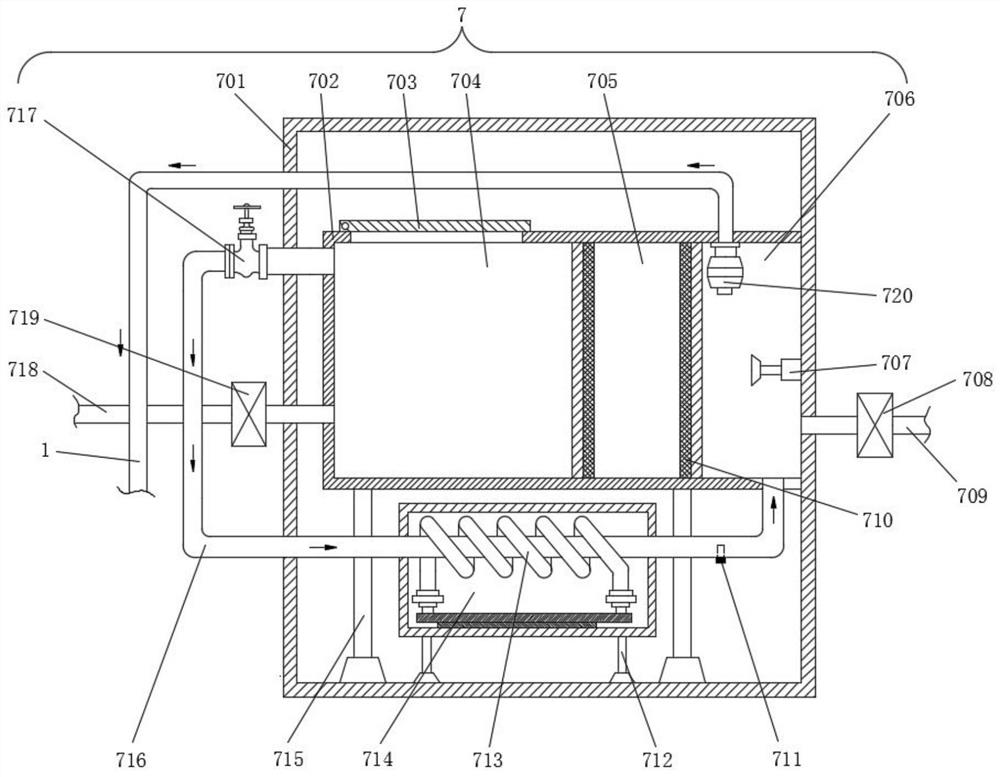

System enabling boiler oxygen-rich combustion to be combined with electrolytic hydrogen production peak and frequency regulation apparatus

PendingCN108183495ALow running costImprove economyFuel supply regulationEnergy storageCombustionElectrolysis

The invention discloses a system enabling boiler oxygen-rich combustion to be combined with an electrolytic hydrogen production peak and frequency regulation apparatus. The system comprises a power plant centralized control peak and frequency regulation control module, a boiler oxygen-rich combustion module, and an electrolytic hydrogen production peak and frequency regulation apparatus. The system improves the load reducing capability of a boiler itself and also enables a set to carry out in-depth peak and frequency regulation operations anytime during four seasons, so the flexibility of thethermal power set can be greatly improved. The system is widely applied to combined heat and power sets or pure condensing set. Moreover, environment pollution is low since clean fuels are provided bya power plant, power plant resources are utilized effectively, and the economical efficiency of the power plant is improved.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

Waste gas combustion device with soot treatment function

InactiveCN112413612AGood burning effectAvoid secondary pollutionDispersed particle separationAir/fuel supply for combustionExhaust fumesCoal

The invention relates to a waste gas combustion device with a soot treatment function. The waste gas combustion device comprises a main body, a cover plate, a bottom plate, a dust removal mechanism and a drying mechanism, wherein the dust removal mechanism and an air blowing mechanism are both arranged on the cover plate. The waste gas combustion device with the soot treatment function achieves combustion treatment of waste gas by combusting coal and combusting the waste gas in the main body. Absorption treatment of soot is achieved through the dust removal mechanism, purified air is dried andblown through the drying mechanism, a better combustion effect is achieved, and meanwhile, filtering and cyclic utilization of water are achieved. Compared with an existing waste gas combustion treatment device, secondary pollution generated by soot is avoided through treatment of soot. Compared with an existing soot treatment device, a rotating shaft achieves online purification and dry air blowing of soot through linkage of the dust removal mechanism and the drying mechanism, so that a better combustion effect is achieved. Compared with an existing water purification mode, the device achieves cyclic utilization of water and saves water resources.

Owner:南京伊都锦环保科技有限公司

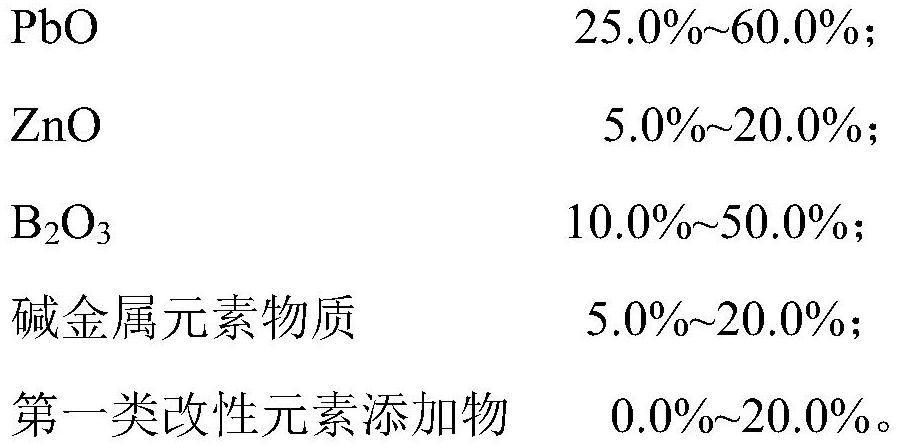

Conductive silver aluminum paste, preparation method, electrode and battery

ActiveCN114822910AStrong burning abilityIncrease the output voltageNon-conductive material with dispersed conductive materialCable/conductor manufactureAluminium powderSilicon solar cell

The invention discloses conductive silver-aluminum paste, a preparation method, an electrode and a battery, the conductive silver-aluminum paste comprises the following components in percentage by weight: 80.0-90.0% of silver powder, 0.1-1.0% of aluminum powder, 0.1-1.0% of silicon powder, 0.1-1.0% of first glass powder, 0.1-1.0% of second glass powder and 0.1-1.0% of organic carrier, and the total weight of the conductive silver-aluminum paste is 100%. 0.3%-2.5% of aluminum powder; 0.0%-1.5% of silicon powder; 1.0%-6.0% of first glass powder; 0.5%-4.0% of a second type of glass powder; 7.0%-15.0% of an organic carrier; the first type of glass powder is Pb-Zn-B-O-M series glass powder, the second type of glass powder is Ba-B-O-M series glass powder, and M is at least one of alkali metal elements; the organic carrier is a carrier containing organic resin and / or cellulose, and the content of the organic resin and / or cellulose in the organic carrier does not exceed 10.0% of the total mass of the organic carrier. By introducing two different types of glass powder, the contact resistance between the metal grid line and the PN junction is reduced, and the high-performance silver-aluminum paste for the N-type Topcon monocrystalline silicon cell and the high-efficiency electrode metallization of the N-type silicon solar cell are realized.

Owner:上海银浆科技有限公司

Multifunctional multi-level turbulence strong combustion device

InactiveCN105157037ASolve uneven oxygen supplyGood burning effectIncinerator apparatusAir volumeCombustion chamber

A multifunctional multi-level turbulence strong combustion device comprises a strong combustion chamber wall, a vertical cylindrical strong combustion chamber located on the inner side of the strong combustion chamber wall, and an air blower located on the outer side of the strong combustion chamber wall. The strong combustion chamber wall is internally provided with an upper turbulence oxygen conveying channel, a middle turbulence oxygen conveying channel and a lower turbulence oxygen conveying channel. Air outlets of the turbulence oxygen conveying channels which are vertically adjacent are arranged in a dislocation manner. Air inlets of the turbulence oxygen conveying channels are communicated with branch oxygen supply pipelines on the outer side of the strong combustion chamber wall. The branch oxygen supply pipelines are communicated with a master oxygen supply pipeline. The master oxygen supply pipeline is communicated with an air outlet of the air blower. The branch oxygen supply pipelines are provided with single-layer air volume adjusters. The air blower is connected with an air blower frequency converter. The strong combustion chamber wall is provided with a smoke flow measuring instrument and a smoke oxygen content measuring instrument which are inserted in the cylindrical strong combustion chamber. When an incinerator with the device combusts different substances, the oxygen inlet manners and the oxygen inlet amount can be adjusted and controlled according to specific situations, and accordingly sufficient combustion of the incinerator is guaranteed.

Owner:王红卫

Waste gas combustion treatment device with turn-back type multi-stage rotational flow oxidation function

ActiveCN111828991ATake advantage ofDesign scienceIndirect carbon-dioxide mitigationIncinerator apparatusThermodynamicsCombustion chamber

The invention discloses a waste gas combustion treatment device with a turn-back type multi-stage rotational flow oxidation function, and relates to the technical field of combustion treatment. The device comprises a garbage combustion treatment module. The garbage combustion treatment module comprises a combustion box and an inner shell. A garbage combustion chamber, a garbage storage chamber anda waste gas pretreatment chamber are arranged in the inner shell. Waste gas is generated by combustion of garbage in the garbage storage chamber and is conveyed to the waste gas pretreatment chamberthrough a conveying pipeline. A heating chamber is arranged on the outer portion of the conveying pipeline. A waste gas conveying pipeline is arranged above the waste gas pretreatment chamber and penetrates through an insulation chamber body module to be connected with one end of a rotational flow shell in a rotational flow module. An inner spray head is arranged at the top of the rotational flowshell, an oxygen supply module is arranged on one side of the rotational flow shell, and an ignition chamber is arranged on one side of the rotational flow shell. By means of the device, waste gas generated by garbage combustion can be fully decomposed, the actual production requirements of enterprises for waste gas treatment after garbage combustion treatment can be met, and the treatment effectto garbage combustion waste gas is good.

Owner:湖南未名环保科技有限公司

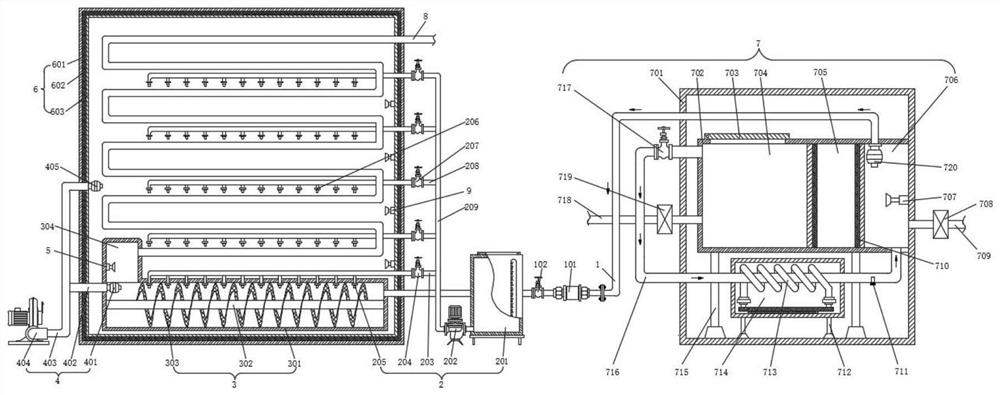

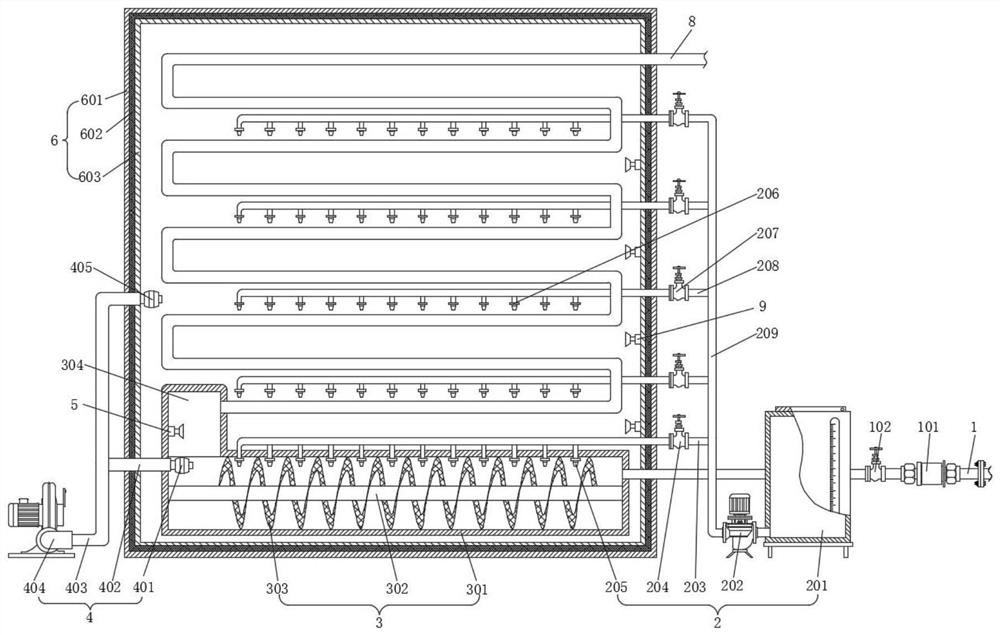

Environment-friendly waste gas combustion furnace

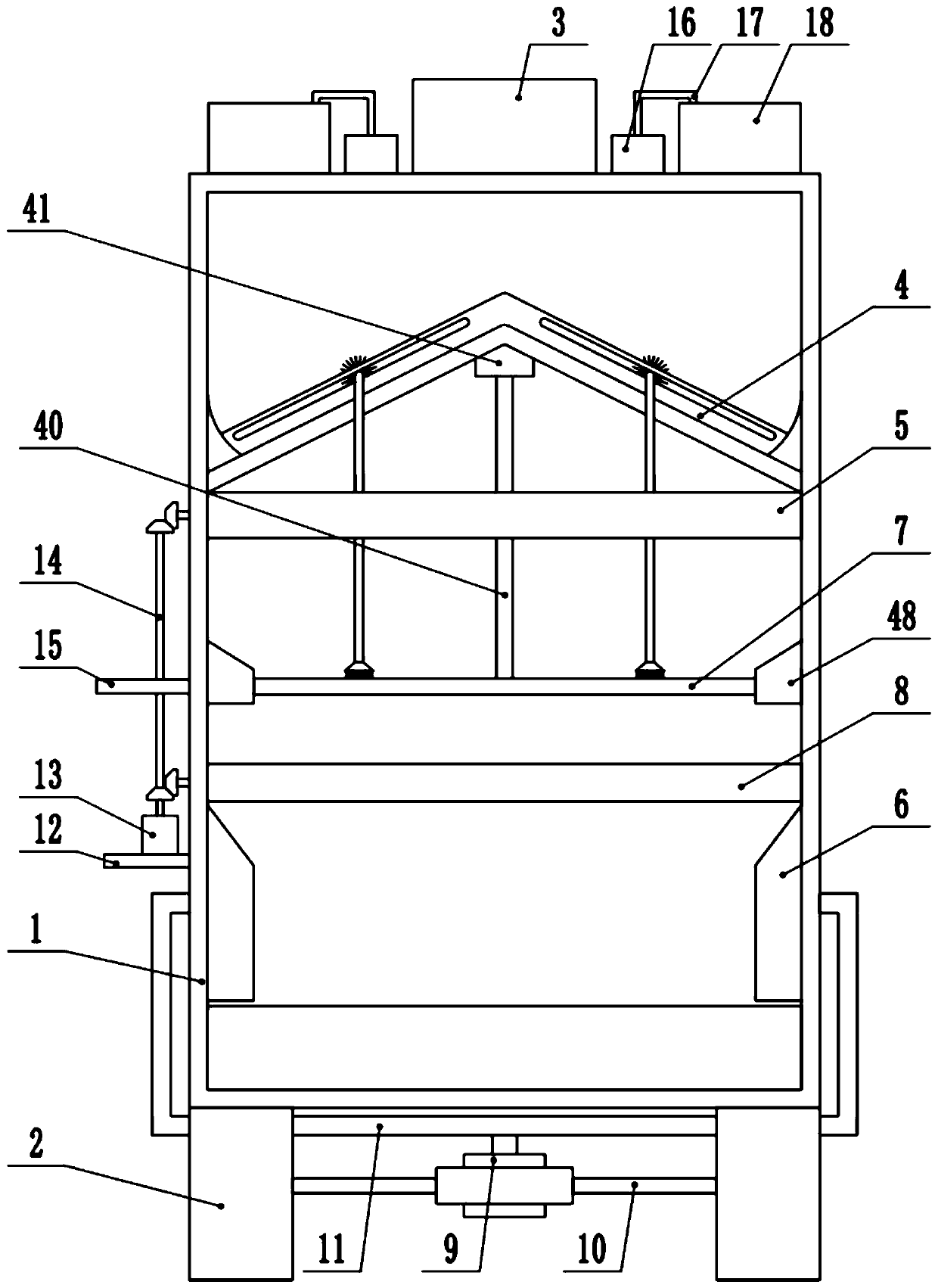

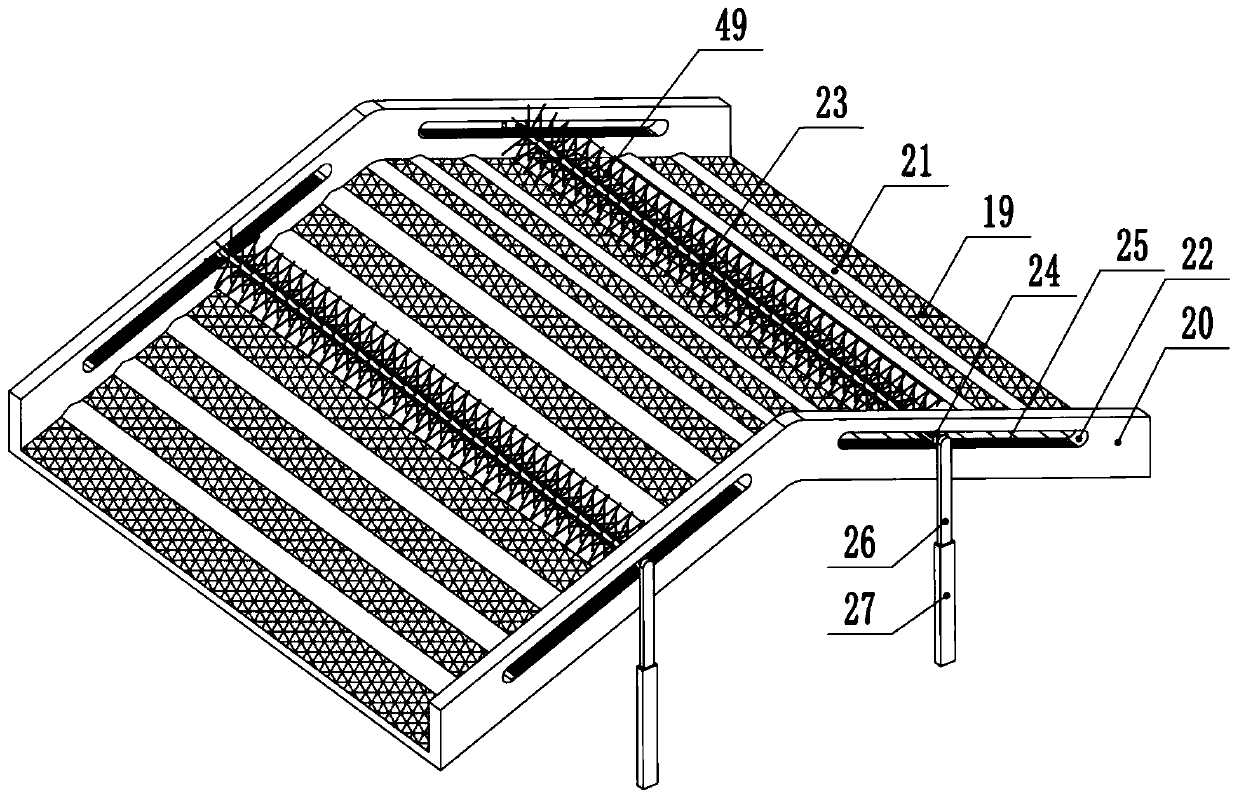

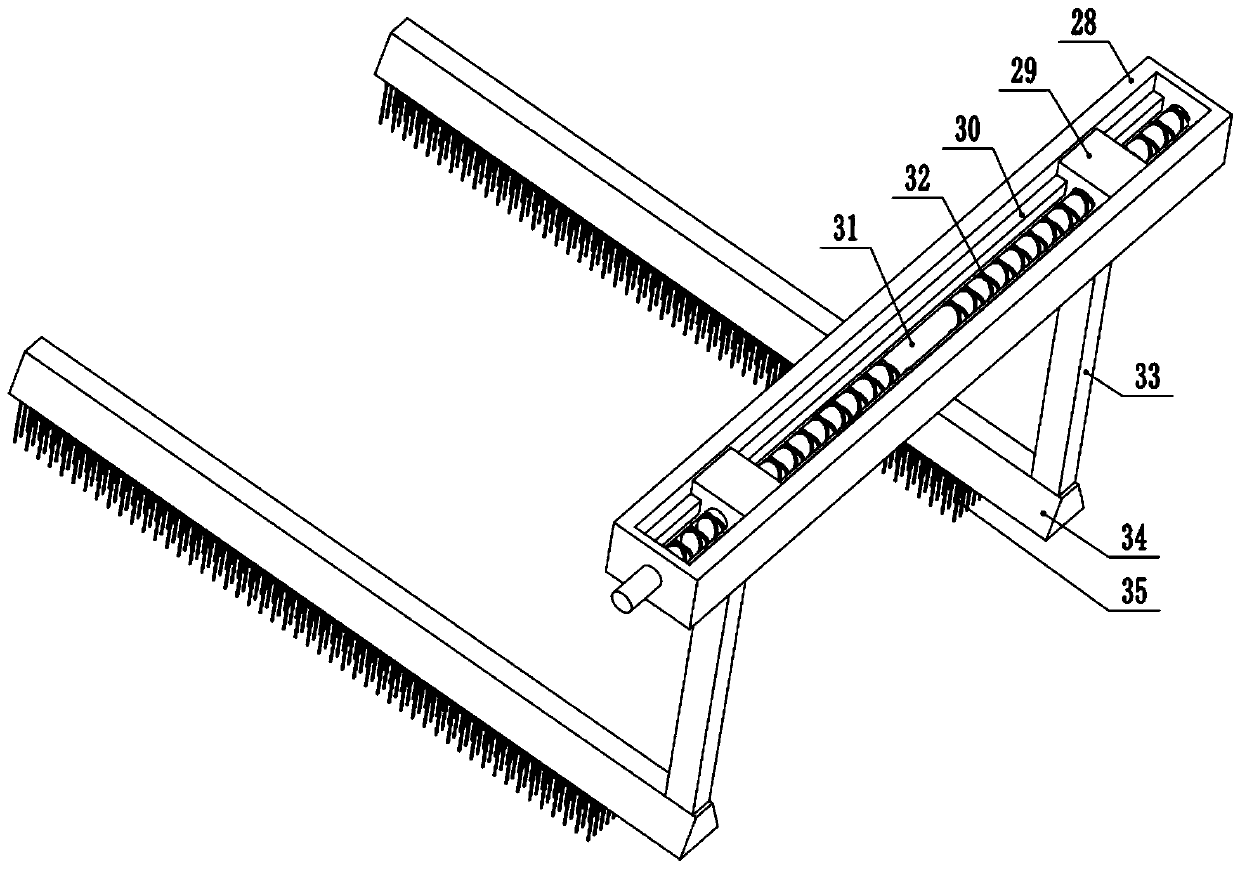

InactiveCN111351059AGood burning effectBest combustion temperatureIncinerator apparatusExhaust fumesProcess engineering

The invention discloses a waste gas combustion furnace. The waste gas combustion furnace comprises a combustion chamber defined by a furnace body, waste gas preheating pipes are arranged in the combustion chamber, the waste gas preheating pipes are provided with waste gas inlets and waste gas outlets, dust removal brushes capable of sliding along the waste gas preheating pipes are arranged on thewaste gas preheating pipes, the dust removal brushes are arranged on the waste gas preheating pipes in a sleeving mode, and a smoke guide device is further arranged in the combustion chamber. According to the waste gas combustion furnace, waste gas is preheated through heat generated by the combustion chamber so that the waste gas can obtain the optimal combustion temperature, the waste gas and fuel gas are fully mixed, and the combustion effect is better; and the dust removal brushes can clean the waste gas preheating pipes in time, and the situation that smoke dust generated after the fuel gas and the waste gas in the combustion chamber are mixed gathers on the waste gas preheating pipes, and consequently the preheating effect of the waste gas preheating pipes is affected is avoided.

Owner:窦义芳

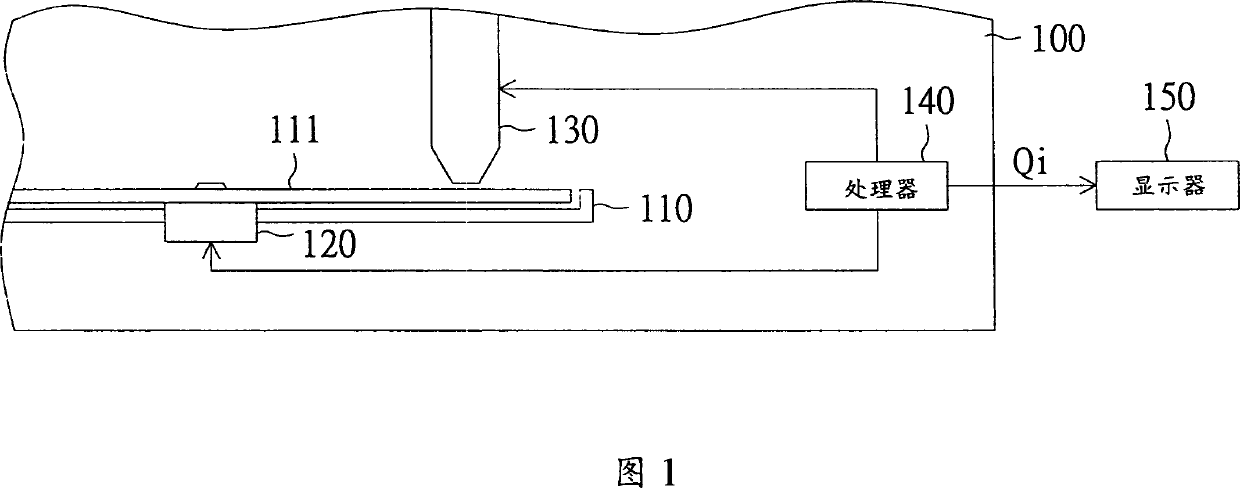

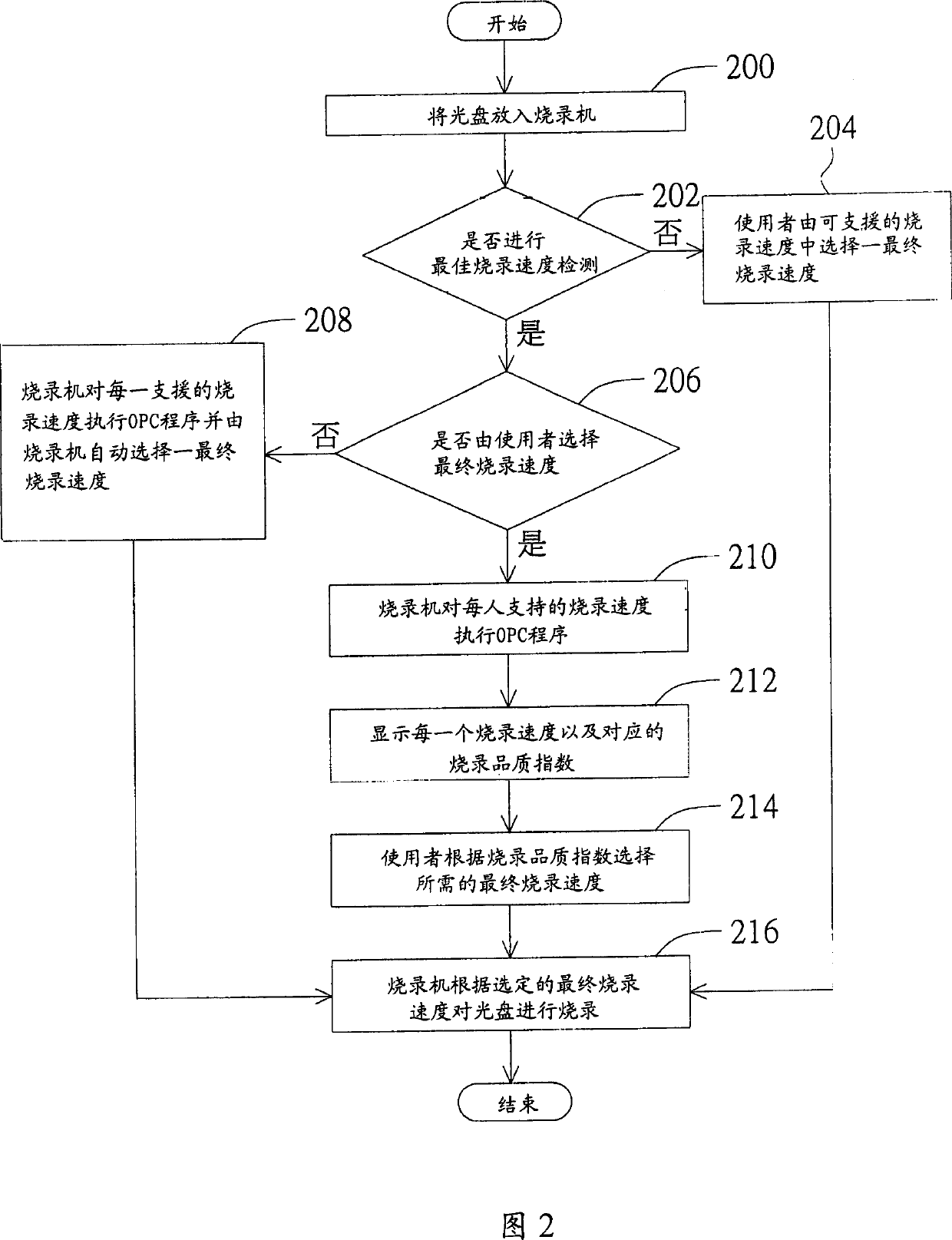

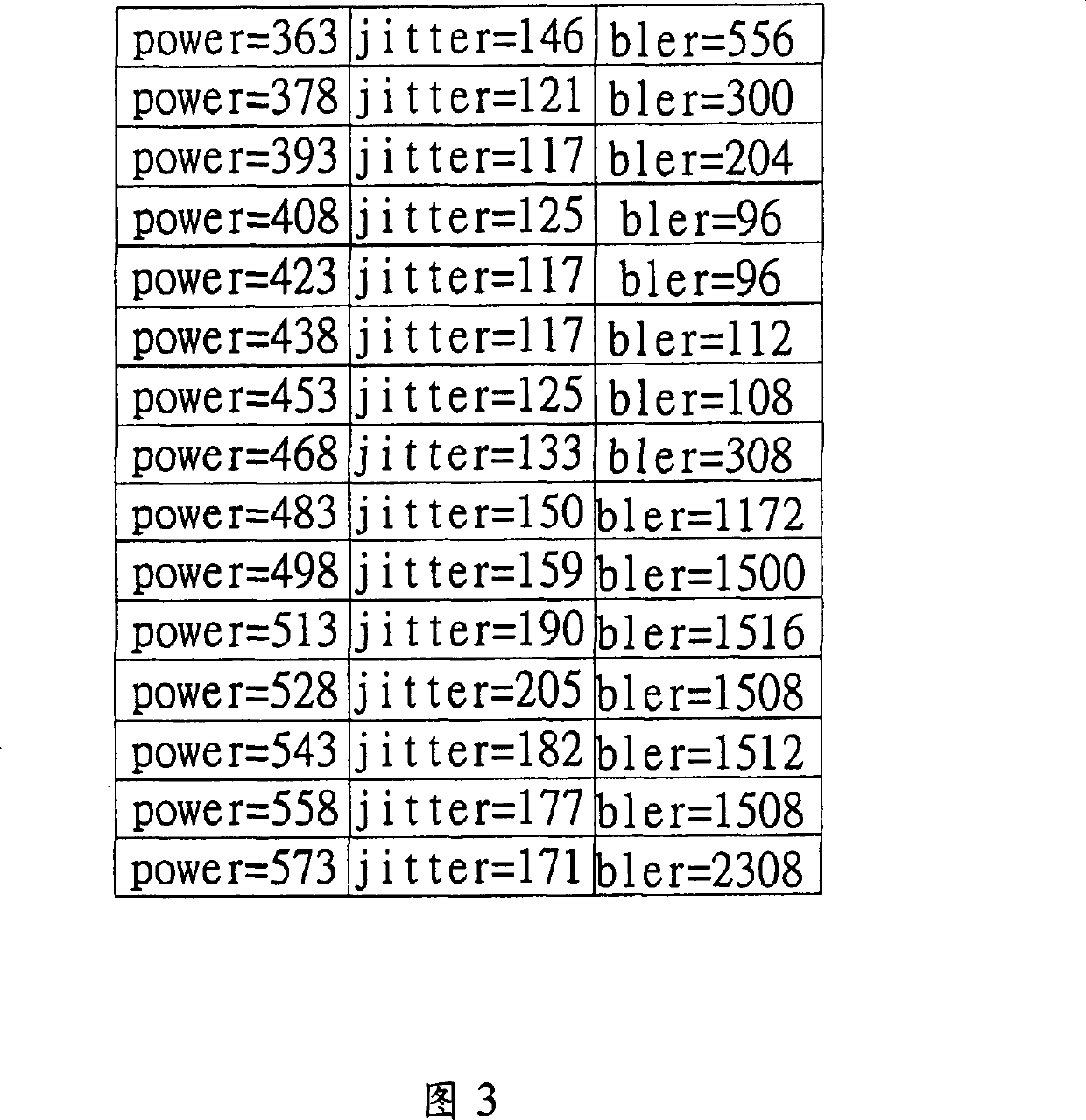

Method for selecting final recording speed and its recording machine

InactiveCN1776811AGood burning effectRecord information storageOptical recording systemsComputer hardwarePower correction

Burning and recording device includes optical picking up head, and processor, providing multiple operation speeds. The optical picking up head is in use for burning and recording optical disk. Based on each burning and recording speed, processor controls the optical picking up head to execute optimal power correction (OPC) program and provides burning and recording qualitative index based on the program. The method for selecting final burning and recording qualitative index includes following steps: placing optical disk sheet into the device, based on each burning and recording speed, the device executes OPC program to obtain corresponding burning and recording qualitative index; based on burning and recording qualitative indexes, selecting a final speed from burning and recording speeds supported, and the device carries out burning and recording operation for optical disk sheet based on the selected final speed.

Owner:BENQ CORP

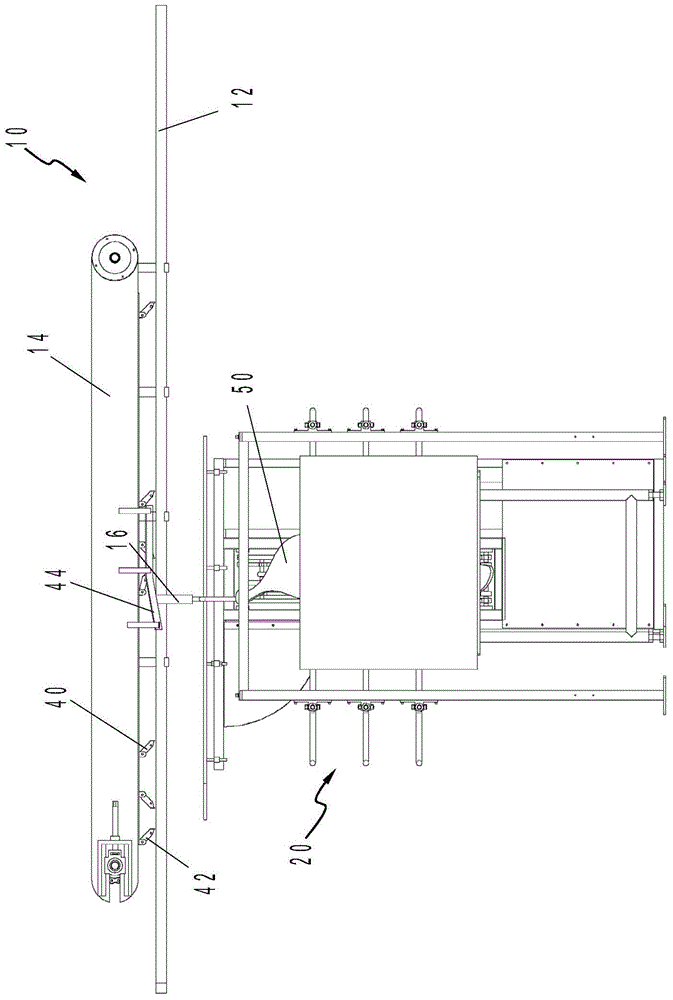

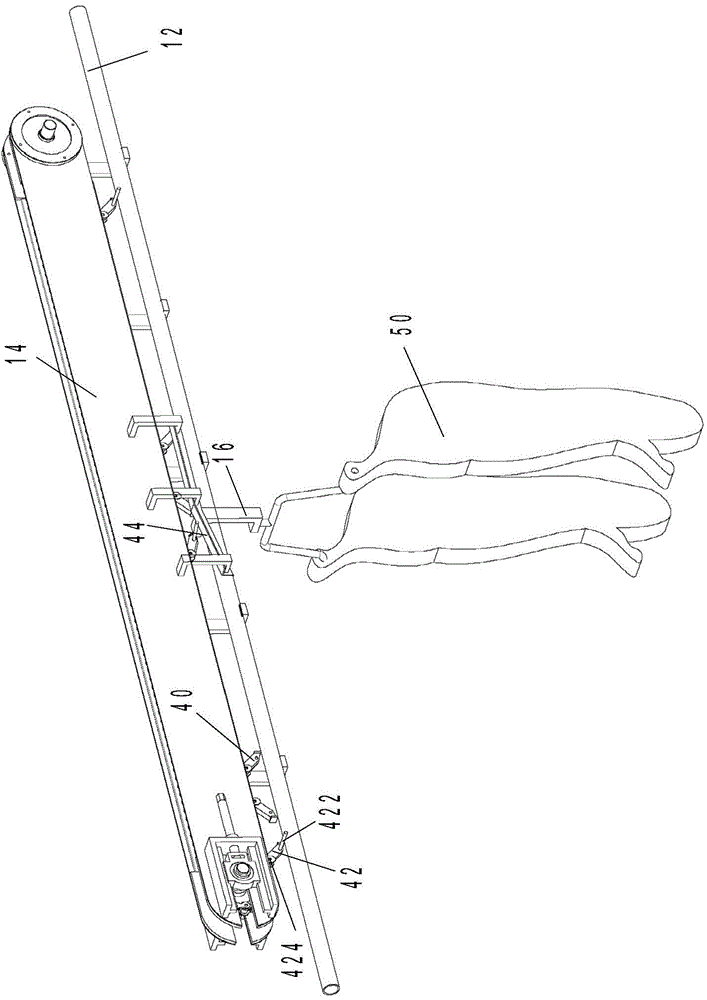

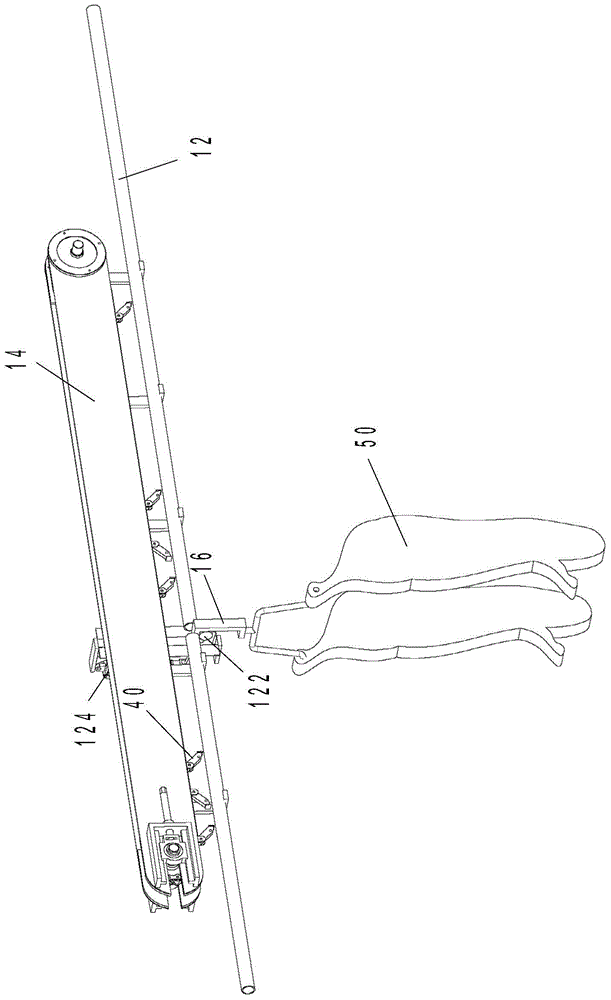

Intermittent laser burning device and intermittent laser burning method

ActiveCN104308373AExtended service lifeGood burning effectTypewritersMeat/sausages markingLaser burnSufficient time

The invention relates to an intermittent laser burning device and an intermittent laser burning method. The intermittent laser burning device comprises a conveying guide rail, a conveying chain, a hook component and a laser burning component, wherein the conveying guide rail is fixedly arranged on a machine frame, the conveying chain is arranged above the conveying guide rail in a way of being approximately parallel to the conveying guide rail, the hook component is glidingly arranged on the conveying guide rail, and the laser burning component is used for carrying out burning processing on a burning object. The intermittent laser burning device provided by the invention also comprises a control mechanism capable of enabling the hook component to intermittently move on the conveying guide rail. The intermittent laser burning device provided by the invention has the advantages that the conveying chain can continuously operate, so a driving mechanism for driving the conveying chain to move does not need to be repeatedly started or stopped, and the service life of the driving mechanism of the conveying chain can be favorably prolonged. In addition, according to the laser burning device, the laser burning component has the sufficient time to carry out laser burning on the etching object, so a good etching effect can be realized. The invention also relates to the intermittent laser burning method.

Owner:BEIJING ZHD LASER SCI TECH

Novel burnt-out knitted fabric and preparation method thereof

InactiveCN112048803AIncrease elasticityGuaranteed StrengthTextile treatment containersDyeing processPolyesterFiber

The invention discloses a novel burnt-out knitted fabric and a preparation method thereof. The fabric is prepared by processing a burnt-out grey fabric; the warp yarns of the burnt-out grey fabric areformed by blending siro compact spinning yarns and polyester fibers, and weft yarns of the burnt-out grey fabric are core-spun yarns formed by blending spandex with bamboo fibers and polyester blended yarns. The siro compact spinning yarns are adopted as the raw material of the fabric, and meanwhile, the spandex is added, so that a good burning effect can be achieved, the bursting strength and compactness of the fabric surface can be guaranteed, and the fabric has good elasticity.

Owner:NINGBO DAQIAN TEXTILE

Self-adjusting burner of gas cooker

An automatic regulating burner of gas ranges comprises a casing, an ejector, an upper gland, a mixed gas inlet, a distributing chamber, a combustion chamber and a distributing port. The ejector structure consists of an upper tooth body and a lower tooth seat engaged each other, and their engaged variable backlash is used as an adjustable distributing port of the ejector. The structure of the automatic regulating mechanism for the adjustable distributing port is that: in the distributing chamber a valve disposed on the mixed gas inlet and a lever set by a support are hinge-jointed, and the lever is connected with the lower tooth seat of the ejector.

Owner:杜英玮

Device capable of using garbage incineration power generation smoke for sludge incineration

The invention discloses a device capable of using garbage incineration power generation smoke for sludge incineration, and relates to the technical field of sludge treatment. The device comprises an incineration box, a primary drying device, a secondary drying device and a smashing device are mounted in the incineration box from top to bottom in sequence, a driving device is mounted between the primary drying device and the secondary drying device, a guide seat is fixedly connected with the bottom end in the incineration box, the lower portion of the incineration box is provided with a gas transmission pump, the output end of the gas transmission pump is fixedly connected with two gas transmission pipes, the two gas transmission pipes penetrate through the two sides of the incineration boxand are fixedly connected with an exhaust cover, the primary drying device and the secondary drying device are arranged in the incineration box, sludge can be dispersed to be sufficiently heated andcombusted, the smashing device is mounted, solid products after sludge combustion can be smashed, recycling is facilitated, and the device is good in sludge combustion treatment effect, ingenious in structure, energy-saving, environment-friendly and low in equipment cost.

Owner:常付连

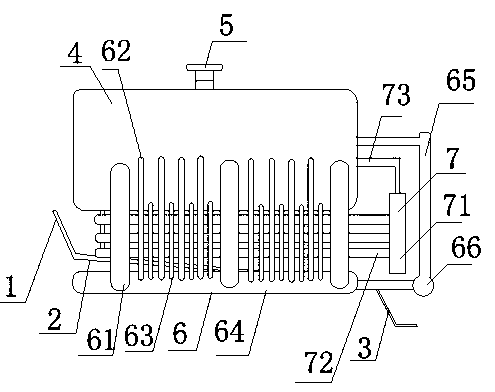

Efficient steam boiler

ActiveCN104180358AUniform heating temperatureGood burning effectSteam generation using pressureCombustion chamberEngineering

Owner:TAICANG CITY LVDIAN INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com