Fuel jet device

A fuel injection device and fuel technology, which are applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of high gas consumption, limited mixing capacity of fuel and air, and inability to adjust and change standard burning appliances, and achieve high efficiency. Burning effect, effect of long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

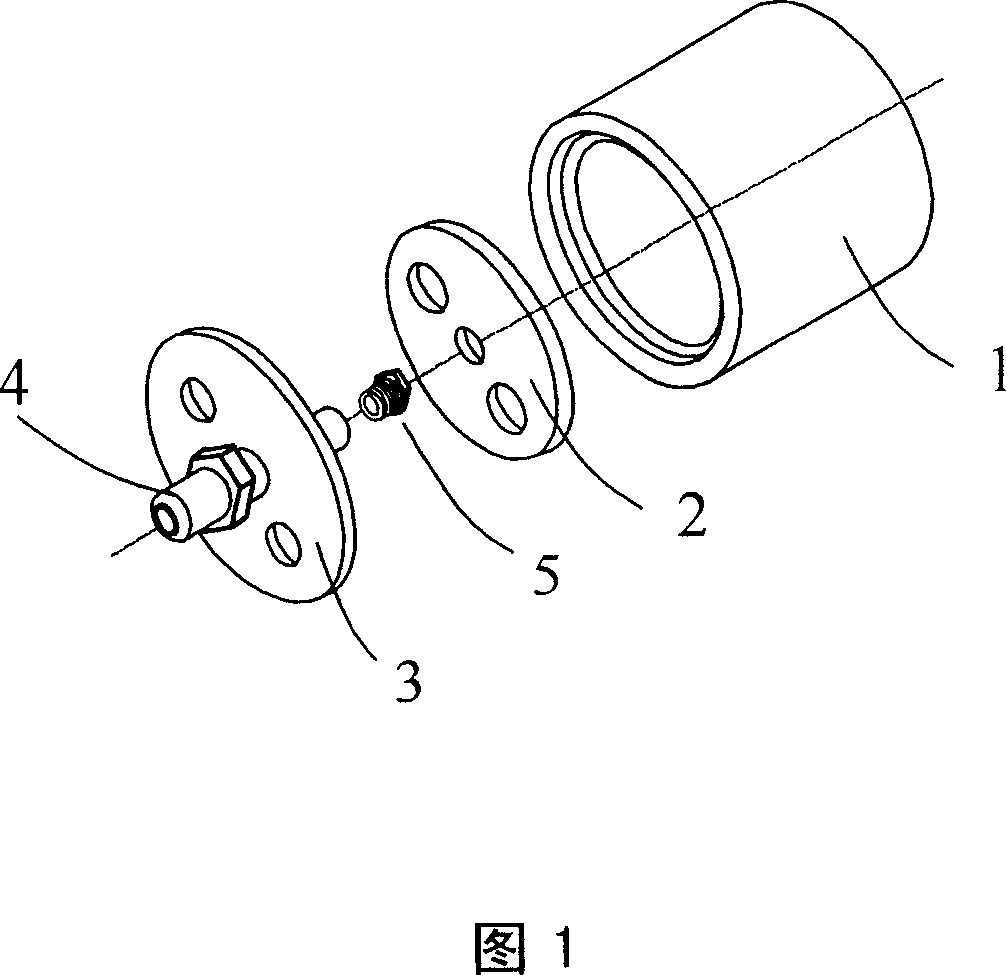

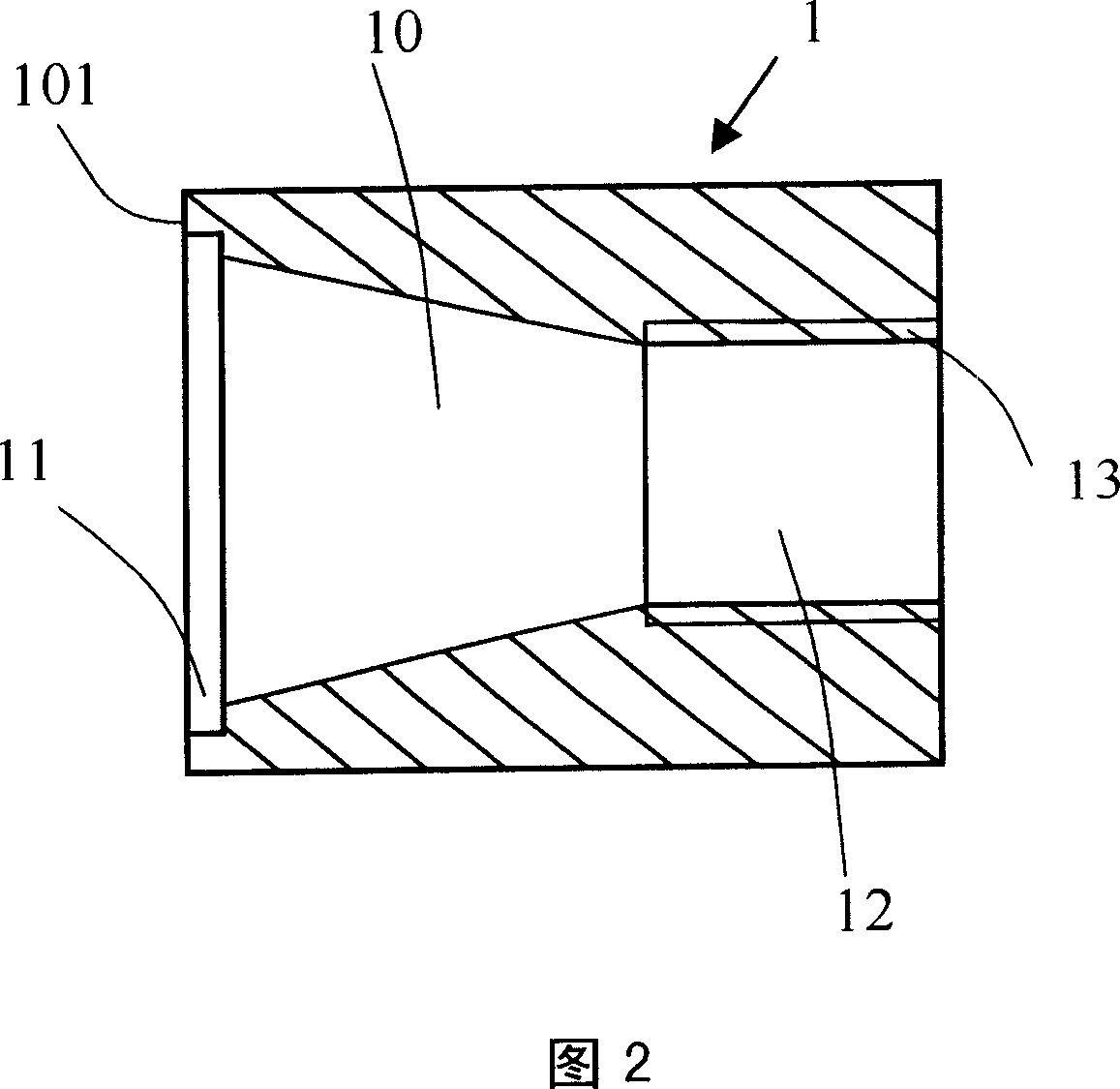

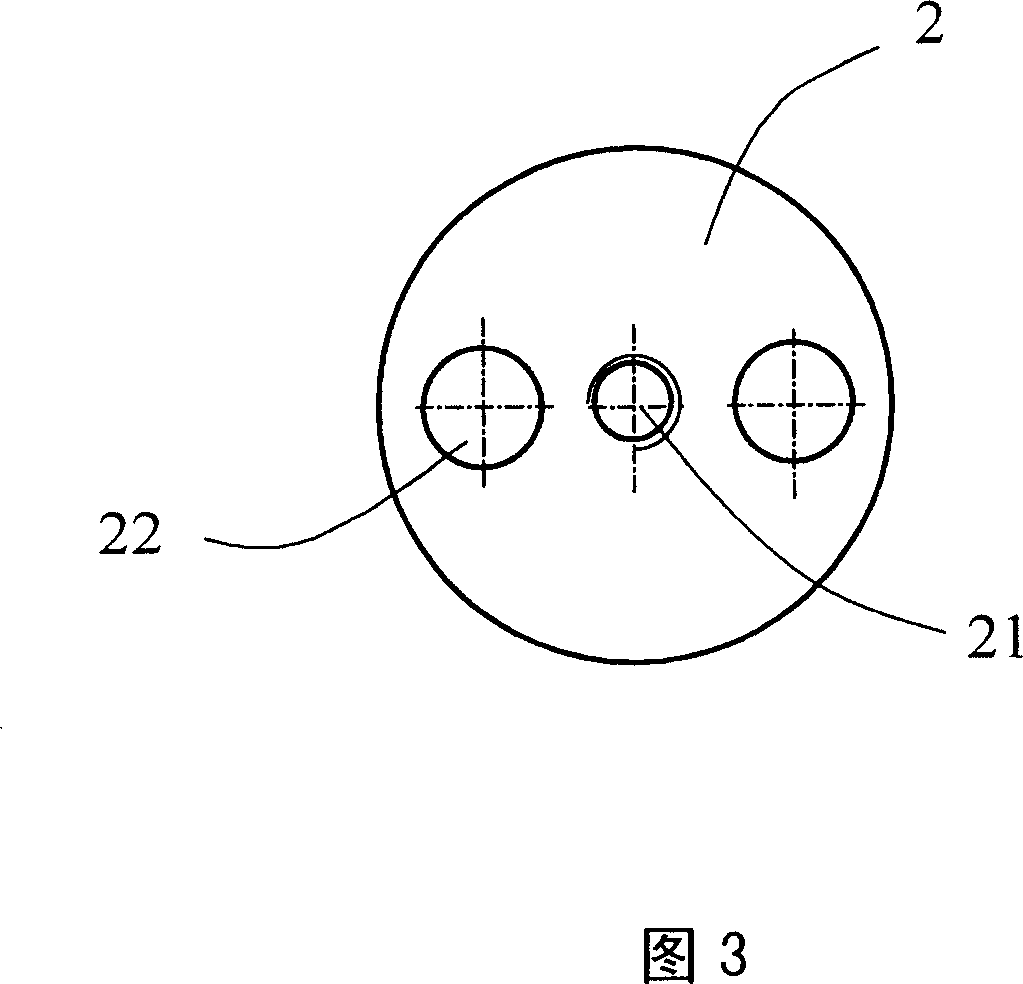

[0017] Please refer to Fig. 1, the present invention provides a kind of fuel injection device, and this device connects a gas regulator with a stove or other appliance of gas heat generating equipment, and preferred embodiment is a kind of use open type stove A gas campfire that uses pressurized propane gas as fuel. However, it should be understood that the present invention is widely applicable to various fuels and equipment, especially suitable for various combustion equipment using high-pressure mixed gas. As shown in the figure, the fuel injection device includes a valve cap 1 , a cover plate 2 , an adjustment plate 3 , an injection valve 4 and a nozzle element 5 . Wherein, the valve cap 1 is a hollow cylindrical configuration, please refer to FIG. 2 and refer to FIG. And mix the injected fuel gas and air, the outer side of the mixing chamber 10 near the outer end surface 101 of the valve cap 1 is set as a cover plate hole 11 with a rectangular cross-section for fixing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com