Self-adjusting burner of gas cooker

An automatic adjustment, gas furnace technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of automatic control of the opening of the gas distribution port, tempering and deflagration of the mixture, unsafe use, etc., to avoid tempering and explosion. The effect of burning, effective heat, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

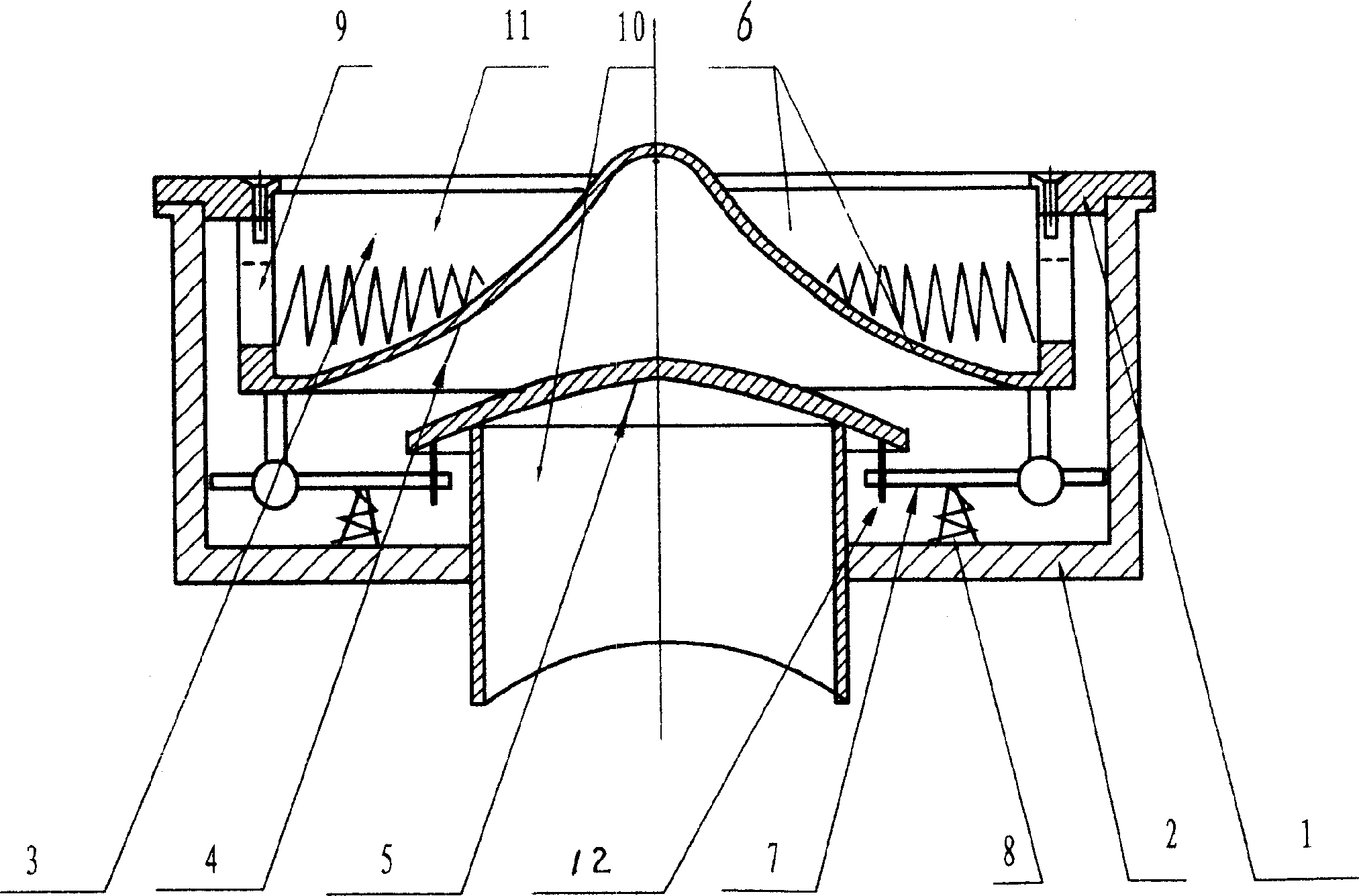

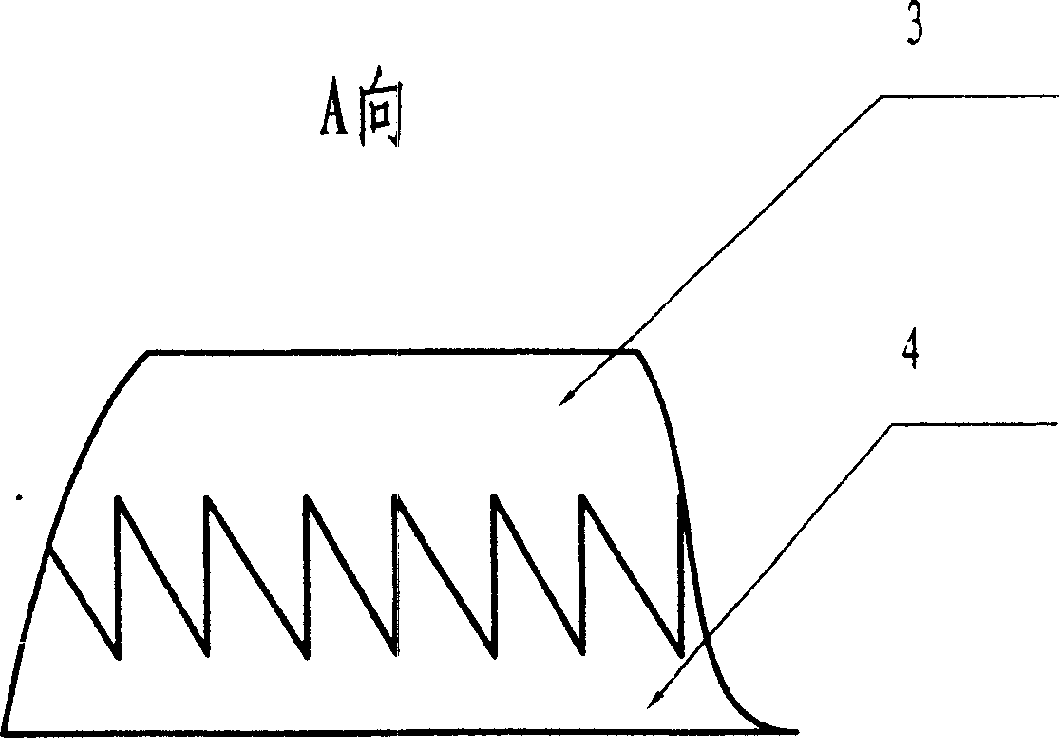

[0013] Example 1: Reference figure 1 with 2 , The gas stove automatic adjustment type burner has a casing 2, an ejector 6 and an upper gland 1, which is placed on the casing 2. The ejector 6 is provided with an air distribution port 9 communicating with the air distribution chamber 12. The structure of the ejector 6 is that the upper tooth body 3 meshes with the lower tooth seat 4. The variable backlash between the upper tooth body 3 and the lower tooth seat 4 is an adjustable air distribution port 9 of the ejector 6. The upper tooth body 3 of the ejector 6 is fixed to the upper gland 1 by screws. The cavity between the casing 2 and the ejector 6 is a gas distribution chamber 12, the cavity in the ejector 6 is a combustion chamber 11, and a mixed gas inlet 10 is provided at the bottom of the casing 2. An automatic adjustment mechanism with an adjustable valve port 9 is provided. The structure of the automatic adjustment mechanism of the adjustable valve port 9 is that a valve 5 i...

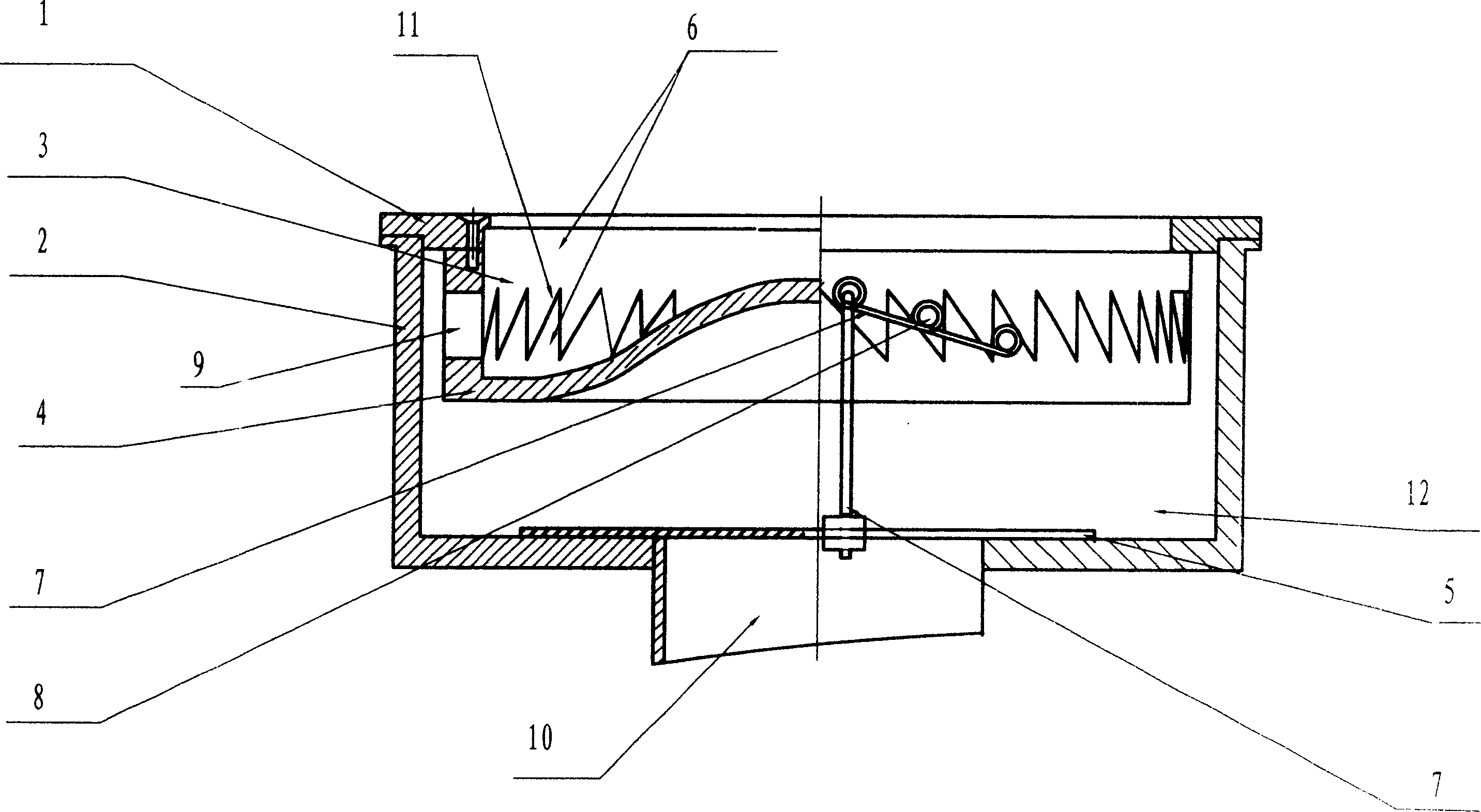

Embodiment 2

[0014] Example 2: Reference image 3 The gas stove automatic adjustment burner of embodiment 2 is basically the same as that of embodiment 1, except that the fulcrum 8 of embodiment 2 is set on the upper tooth body 3 of the ejector 6.

[0015] Use attached below figure 1 Briefly describe the automatic adjustment process of the automatic adjustment burner of the gas stove: when the gas stove is not used, the upper tooth body 3 of the ejector 6 meshes with the lower tooth seat 4 without backlash. When the valve of the gas furnace is opened, the pressure of the mixture of gas and air acts on the valve 5, and the mixture enters the gas distribution chamber 12 from the mixed gas inlet 10, so that the lever of the automatic adjustment mechanism of the adjustable gas distribution port 9 drives down The tooth holder 4 moves down in parallel, thereby changing the tooth gap between the upper tooth body 3 and the lower tooth holder 4, realizing automatic gas distribution, and automatically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com