Efficient steam boiler

A steam boiler, high-efficiency technology, applied in the direction of steam generation method using pressure combustion, etc., can solve the problems of insignificant improvement of heat transfer efficiency and combustion efficiency, low combustion efficiency, and large environmental pollution, so as to improve thermal cycle efficiency , Good vaporization effect, good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

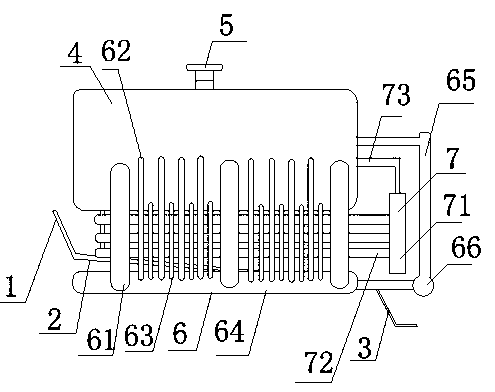

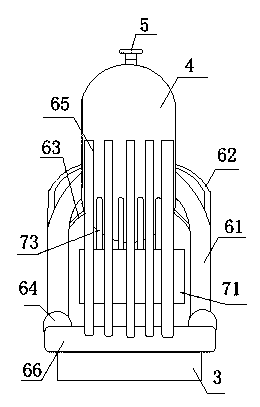

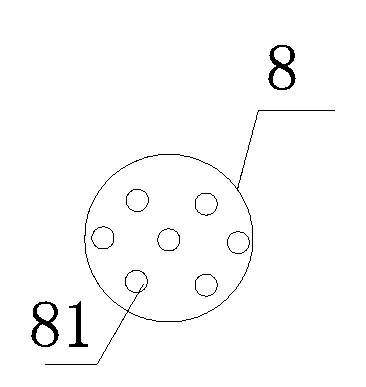

[0028] Example 1, such as figure 1 , figure 2 Shown: a high-efficiency steam boiler, including a feed port 1, a combustion chamber 2, and a discharge port 3 arranged in sequence according to the material conveying direction, and a water tank 4 is provided directly above the combustion chamber 2, and a safety valve is provided on the water tank 4 5. The high-efficiency steam boiler also includes a steam surround system 6 arranged around the combustion chamber 2 to increase the temperature in the combustion chamber 2 and an air induction device 7 that attracts high-temperature air and flames in the combustion chamber 2 to flow toward the discharge port 3 . The user pours the material to be burned from the inlet 1, and the material enters the combustion chamber 2 and is conveyed towards the outlet 3. The bottom surface of the combustion chamber 2 is inclined, and gradually approaches the ground according to the forward direction of material conveyance. The composition of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com