Induction quenching system and method for bearing cylindrical face of self-limiting seat of heavy truck plate spring

A leaf spring, induction hardening technology, applied in the direction of improving process efficiency, furnace type, furnace, etc., can solve the problems of unhardened area, uneven depth of hardened layer, affecting the service life of products, etc., to achieve uniform heating temperature and accurate Positioning and uniform heating, ensuring the effect of relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention is described in detail below in conjunction with accompanying drawing:

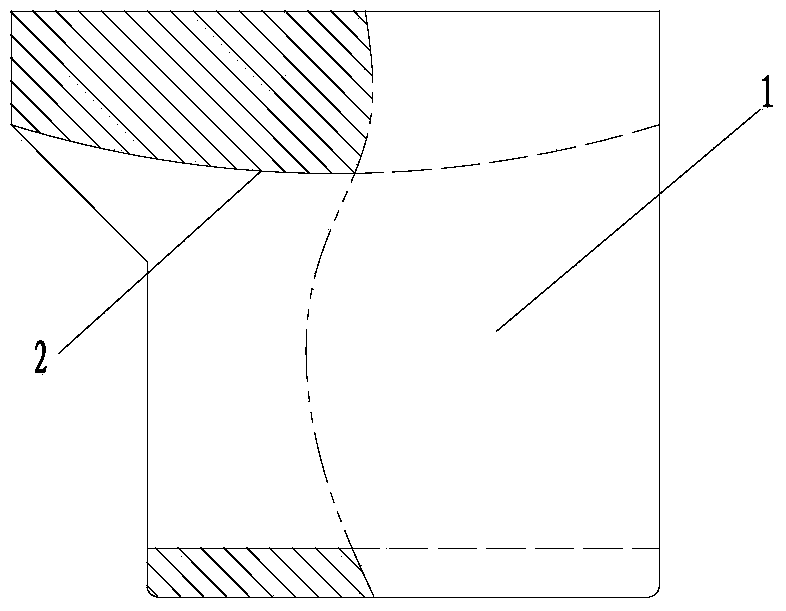

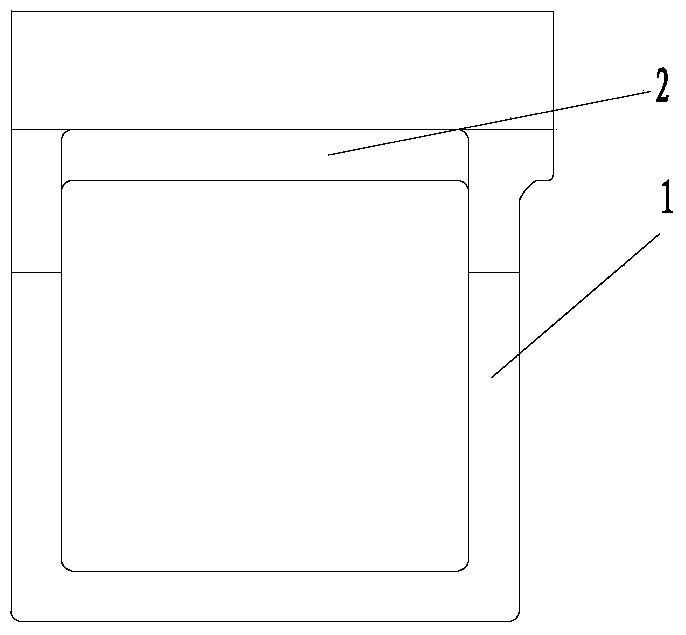

[0040] Such as figure 1 , figure 2 Shown is the structural diagram of the self-limiting seat 1 of the leaf spring, wherein the self-limiting seat of the leaf spring carries a cylindrical curved surface 2, which is an induction hardened processing surface. The self-limiting seat is a rectangular frame, and the inner side of the top of the rectangular frame is a bearing cylindrical surface, and its shape is consistent with that of the leaf spring.

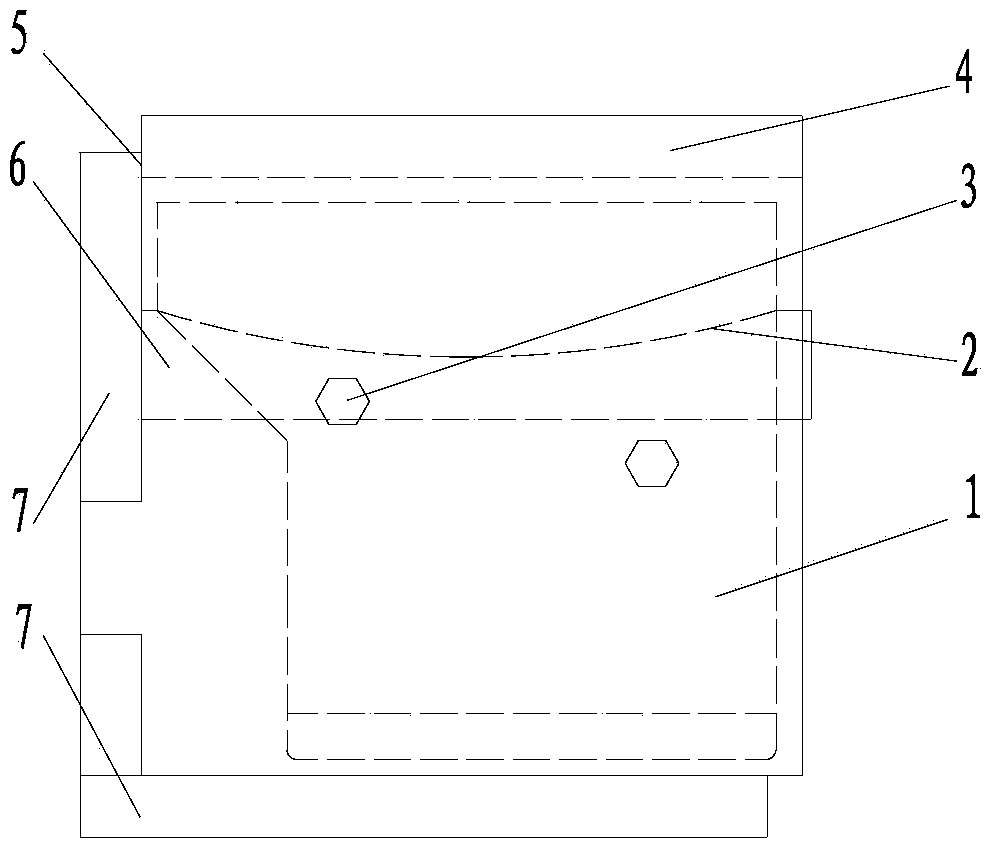

[0041] Such as image 3 , Figure 4 As shown, the structural diagram of the self-positioning device of the cast leaf spring self-limiting seat includes a horizontal bottom plate I, and a side plate I perpendicular to it is provided on the horizontal bottom plate I. On the side plate I There is a positioning probe arm parallel to the bottom plate and fixed on the side plate. A pair of clamping and clamping bolts 3 on each side of the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com