Horizontal type device for reheating semi-solid metal blank material

A semi-solid metal, secondary heating technology, applied in the direction of forging furnaces, furnaces, furnace types, etc., can solve the problems that the liquid phase fraction of the billet cannot be very high, it is difficult to form complex parts, and the mechanical transmission method is complicated, etc., to achieve heating and temperature The distribution of the field is uniform and reasonable, the distribution of the temperature field is uniform, and the effect of avoiding coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

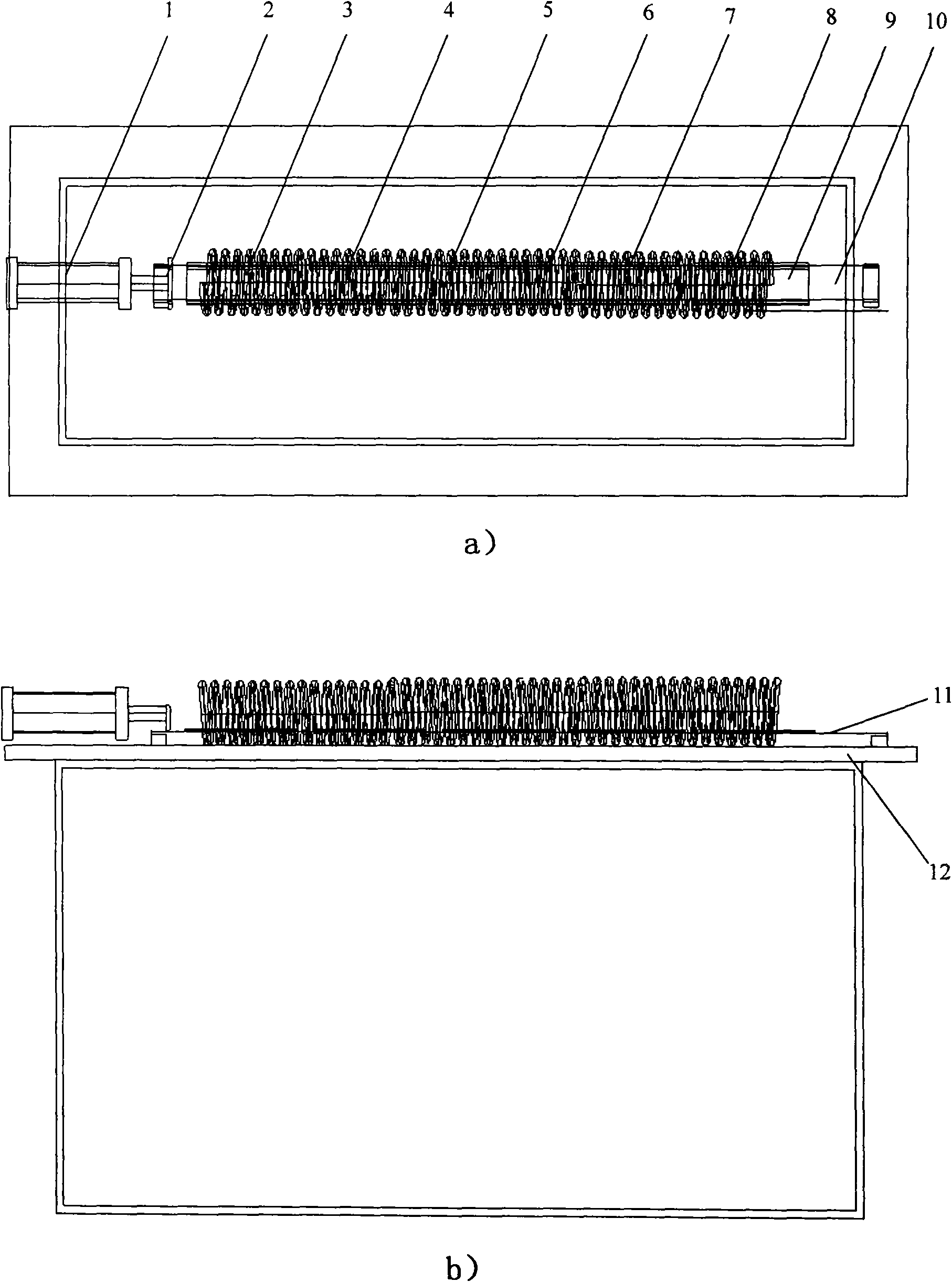

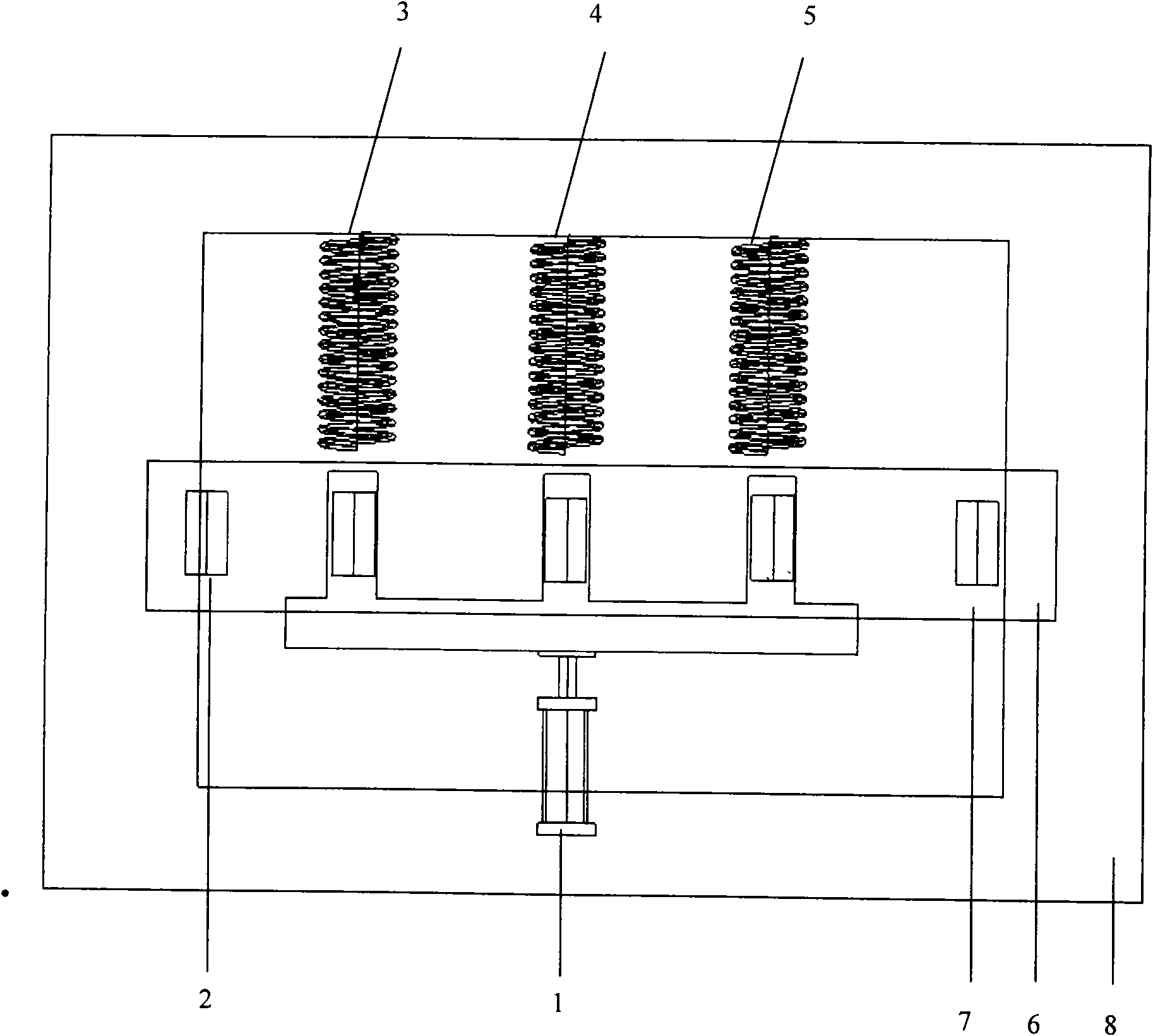

[0023] Such as figure 1 , figure 2 As shown, the horizontal device for secondary heating of semi-solid metal blanks in the present invention is composed of an induction heating power supply, an induction heating mechanism and a blank carrying mechanism, and the induction heating power supply provides power for the induction heating mechanism.

[0024] The electromagnetic induction heating power supply can be a thyristor power supply, an IGBT power supply or other power supplies, and the frequency of the power supply is 200-1500 Hz.

[0025] Each horizontal device for secondary heating of semi-solid metal blanks is equipped with at least three heating stations, five stations for placing and discharging materials, and three sections of induction heating that are placed horizontally and connected to each other are installed on the stations for heating materials. coil.

[0026] The induction heating coils that are electrically connected to each other above are connected in seri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com