Medium-speed mill self-starting and self-stopping control system suitable for deep peak regulation of direct blowing type coal-fired unit

A coal-fired unit and control system technology, which is applied in the direction of combustion control, fuel supply adjustment, block/powder fuel preparation, etc., can solve the problem of longer load lifting time, slow response to grid side load, and coal mill temperature. Advanced problems, to achieve the effect of reducing the amount of generation, reducing the impact of the boiler system, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

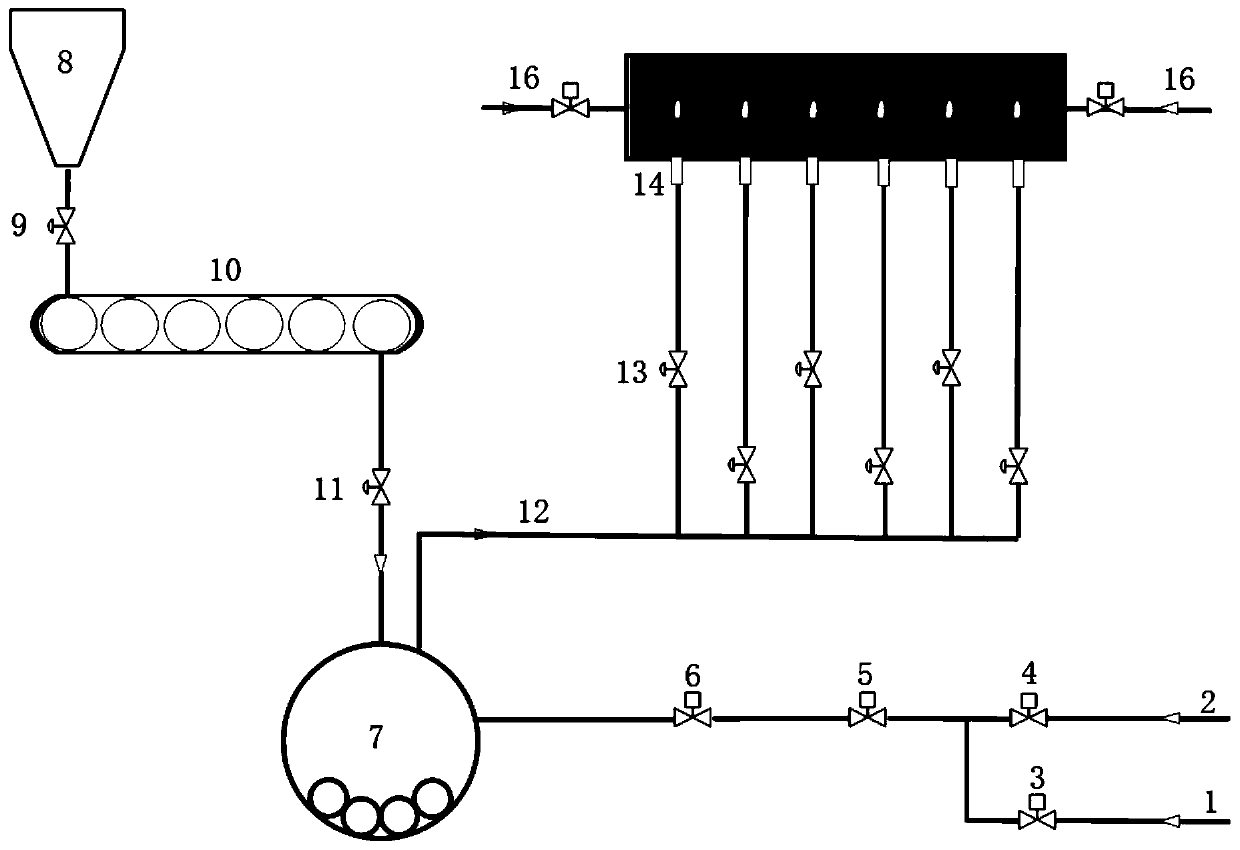

[0045] Such as figure 1 As shown, the present invention is applicable to the direct-blown coal-fired unit units of the front and rear walls opposing combustion boilers, and each unit is typically equipped with six medium-speed mills, figure 1 It is a typical thermal system of a medium-speed mill for a direct-blown coal-fired unit, including a hot primary air duct 1 passing through the air preheater, and another cold primary air duct 2; the hot primary air duct 1 and the cold primary air duct 2 are respectively installed There are coal mill hot air adjustment baffle 3 and coal mill cold air adjustment baffle 4; the outlets of hot primary air pipe 3 and cold primary air pipe 4 are connected to the entrance of coal mill 7 after confluence, and the hot primary air pipe and cold primary air After the pipes converge, the primary air adjustment baffle plate 5 and damper baffle plate 6 of the coal mill are set on the air duct; the raw coal is sent from the raw coal bunker 8 to the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com