Incinerator

A technology of incinerators and combustion chambers, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as incomplete combustion, unsatisfactory working stability, and single types of waste treatment, and achieve good combustion effects and long service life , Good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

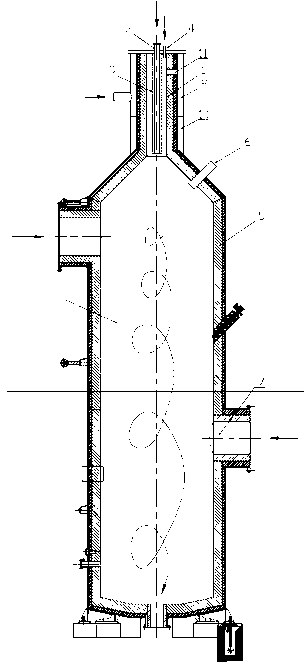

[0012] Embodiment: The structure of the incinerator of this embodiment is as attached figure 1 As shown, it includes an air chamber 1 and a combustion chamber 2. Its main features are that the air chamber 1 communicates with the combustion chamber 2; The air enters the jacket 8, and the air enters the jacket 8 and is provided with a through hole 11 communicating with the air chamber 1; the wall of the combustion chamber 2 is provided with a refractory material 5, the upper part of the combustion chamber 2 is provided with a gas inlet 6, and the combustion chamber is provided with The air inlet 7; the waste adding pipe 3 communicates with the combustion chamber 2, and the waste adding pipe 3 is wrapped with a cooling water jacket 9; a cooling water jacket 10 is provided on the periphery of the air chamber 1 at the junction with the combustion chamber 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com