Gas burner

a burner and gas technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of serious hazard to the user and others around the burner, insufficient burning effect, etc., and achieve the effect of maintaining efficient burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

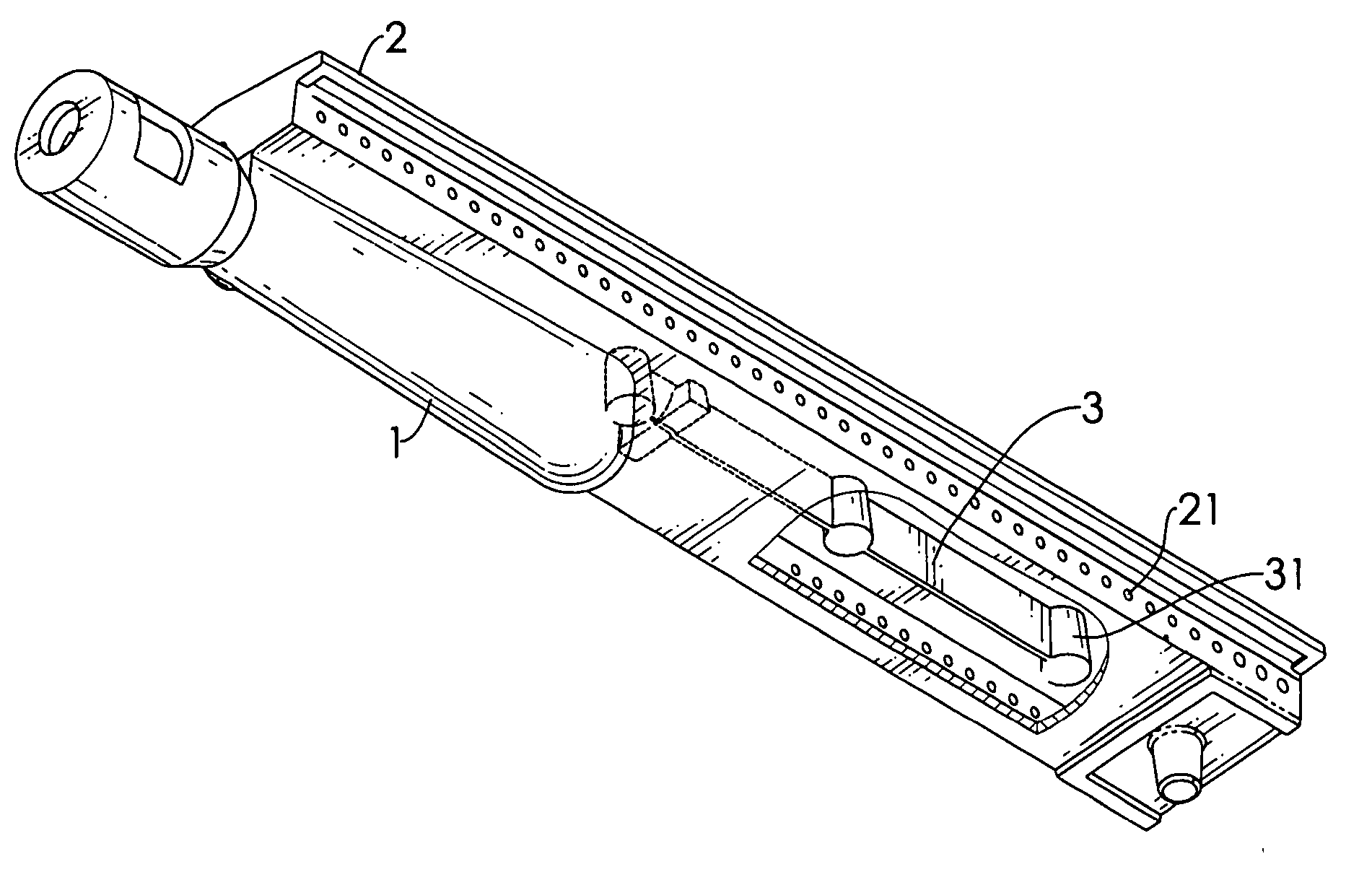

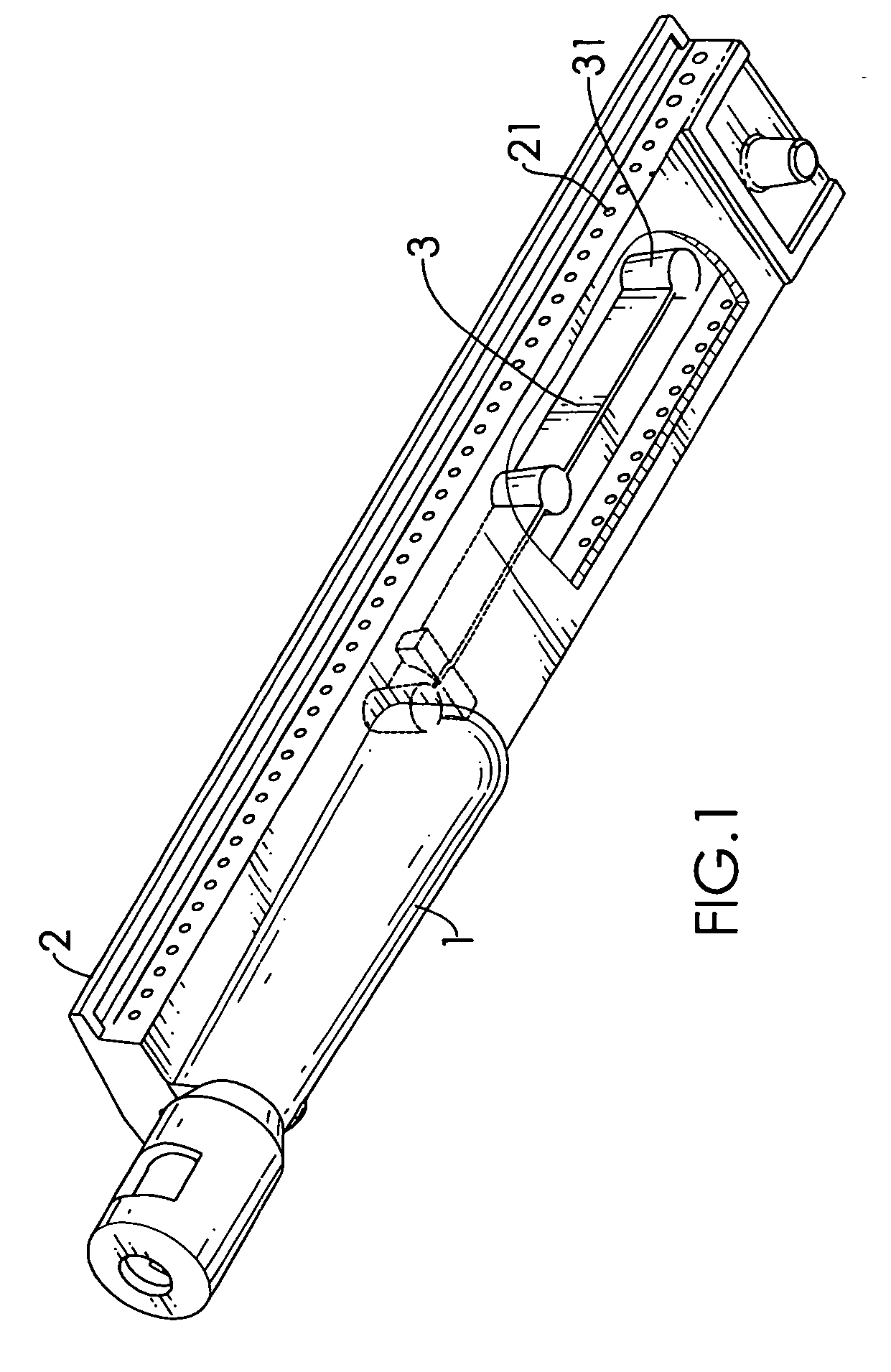

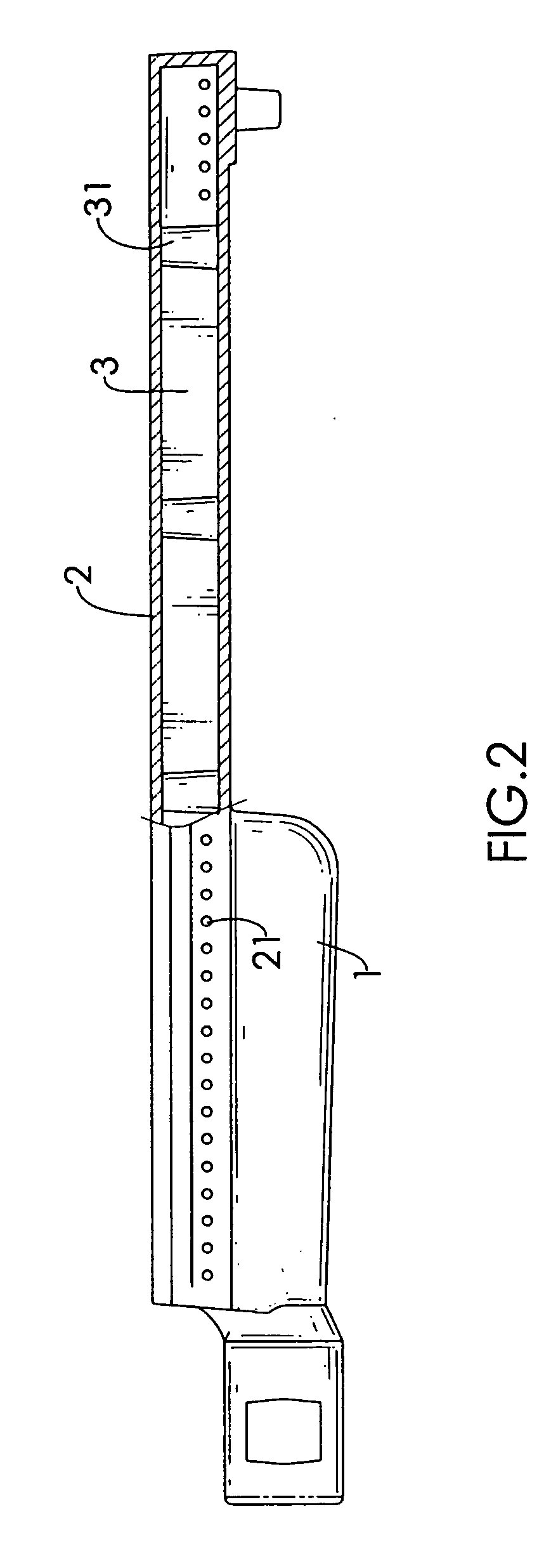

[0015] With reference to FIGS. 1, 2 and 3, it is noted that the gas burner in accordance with the present invention includes a cylindrical hollow body (1) and a top casing (2) integrally mounted on top of the body (1) and having multiple through holes (21) defined in two opposed side faces of the top casing (2) to communicate with an interior of the body (1). A supporting baffle (3) is formed inside the top casing (2) to engage with a bottom face and a top face thereof so as to increase the rigidity and stiffness of the top casing (2). Furthermore, multiple supporting posts (31) are formed along the supporting baffle (3) to increase the supporting effect of the supporting baffle (3). Furthermore, because the supporting baffle is made of a material having a melting point and rigidity higher than those of the material for the hollow body (1) and the top casing (2), the gas burner of the present invention is not easily distorted.

[0016] It is noted from the above description that with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com