Multifunctional multi-level turbulence strong combustion device

A multifunctional and turbulent technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of insufficient combustion and black smoke in the incinerator, and achieve uneven oxygen supply, good combustion effect, and increased turbulence degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

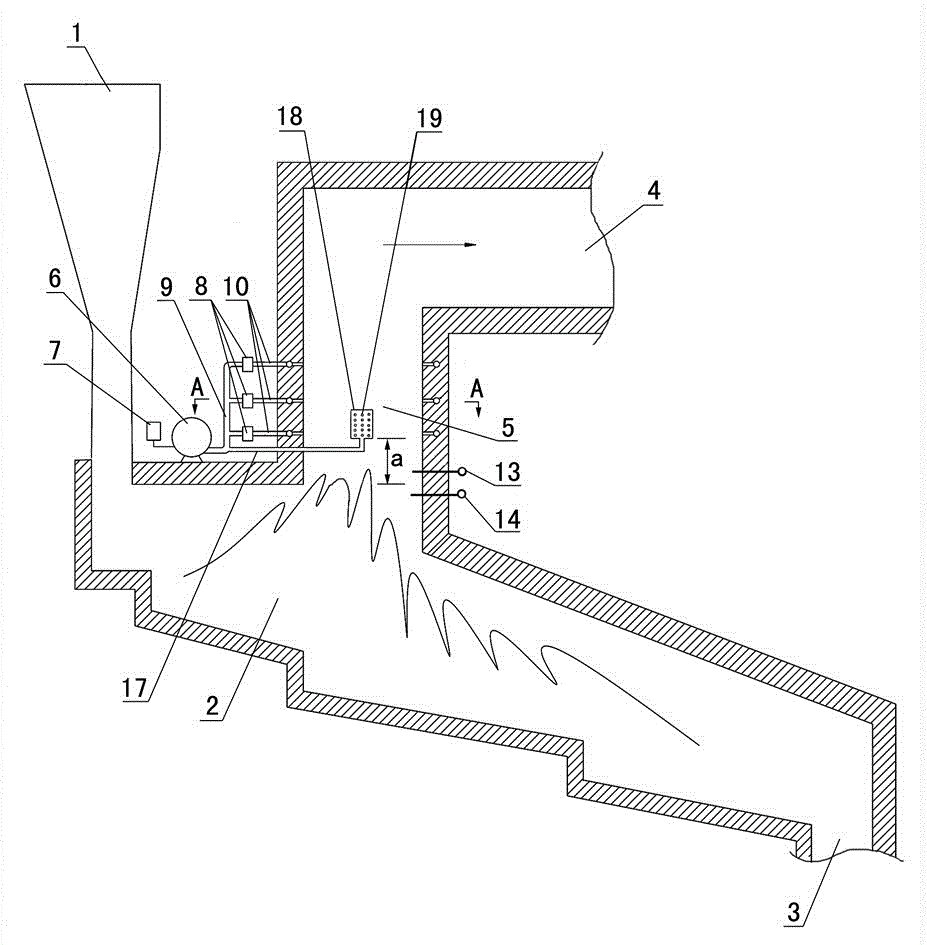

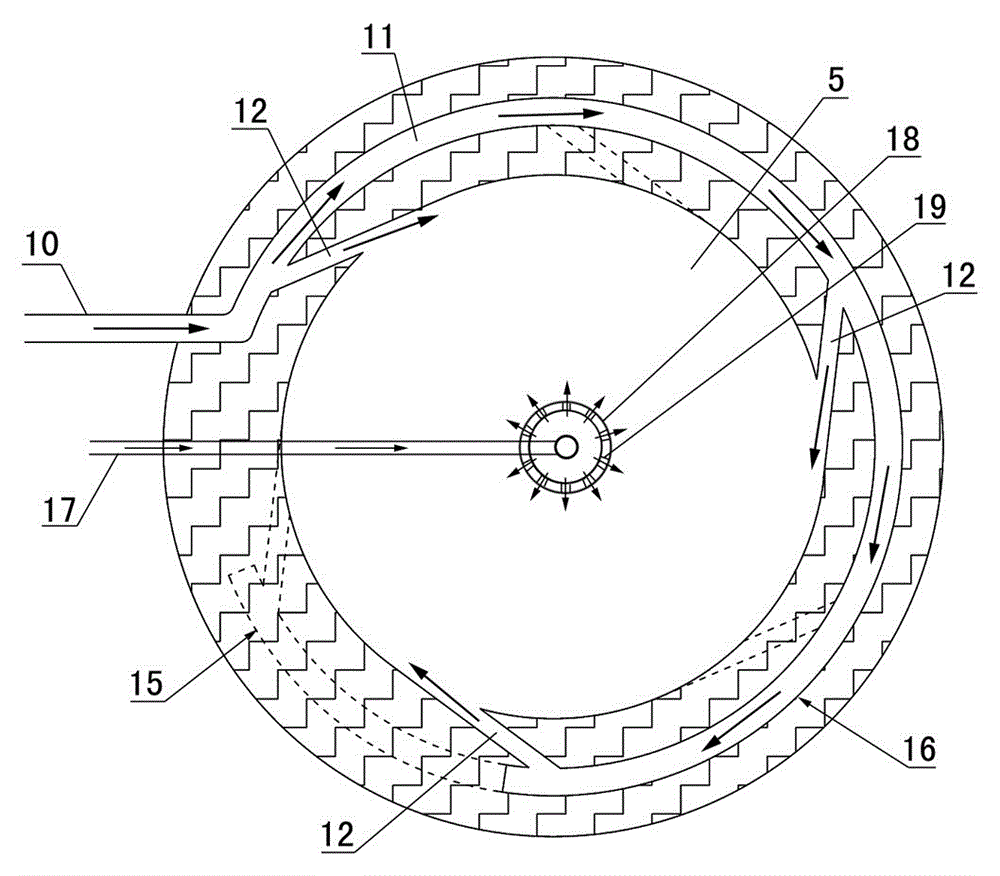

[0028] Examples see figure 1 , figure 2 As shown, this multi-functional multi-stage turbulent strong combustion device is arranged on the fire outlet of the incinerator hearth 2 of the incinerator, and includes a strong combustion chamber wall, a vertical cylindrical strong combustion chamber positioned at the inside of the strong combustion chamber wall. Combustion chamber 5 and blower 6 positioned at the outside of the strong combustion chamber wall, the bottom of the cylindrical strong combustion chamber 5 communicates with the incinerator hearth 2 through the fire outlet, and the top of the cylindrical strong combustion chamber 5 passes through the burner smoke The gas discharge channel 4 communicates with the waste heat utilization system. A turbulent oxygen supply channel is provided in the wall of the strong combustion chamber. The air outlet of the turbulent oxygen supply channel communicates tangentially with the cylindrical strong combustion chamber 5. The air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com