Environment-friendly waste gas combustion furnace

A waste gas combustion and environmental protection technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of corrosive equipment, unreasonable design, poor waste gas treatment effect, etc., and achieve good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

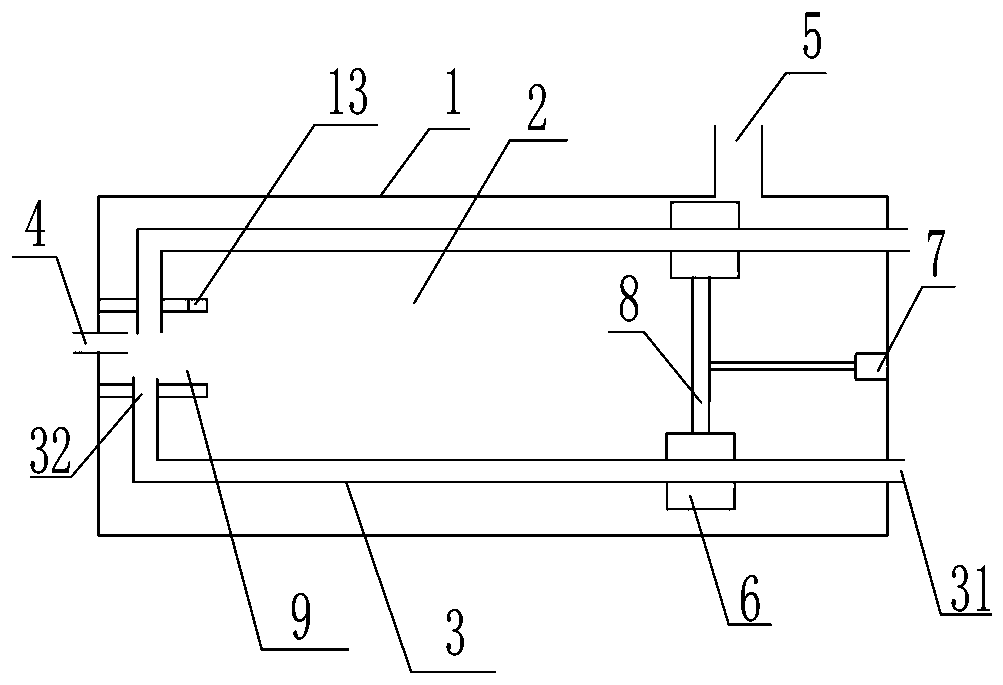

[0030] Such as figure 1 and image 3 As shown, the present invention discloses an environment-friendly waste gas combustion furnace, which includes a furnace body 1, which encloses a combustion chamber 2, and a waste gas preheating pipe 3 is arranged in the combustion chamber 2. The waste gas preheating pipe 3 is arranged along the length of the furnace body 1. One end of the waste gas preheating pipe 3 is provided with a preheating pipe waste gas inlet 31, and the preheating pipe waste gas inlet 31 passes through the furnace body 1, and the other end is provided with a preheating pipe. The pipe exhaust gas outlet 32 and the preheating pipe exhaust gas outlet 32 are located inside the combustion chamber 2 .

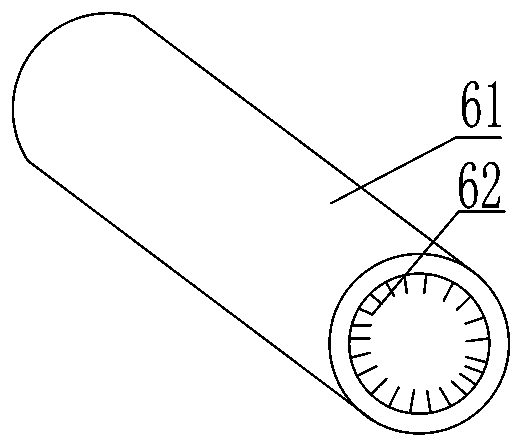

[0031] The exhaust gas preheating pipe 3 is provided with a dust removal brush 6 that can slide along the exhaust gas preheating pipe 3 , and the dust removal brush 6 is sleeved on the exhaust gas preheating pipe 3 .

[0032] The furnace body 1 is provided with a ga...

Embodiment 2

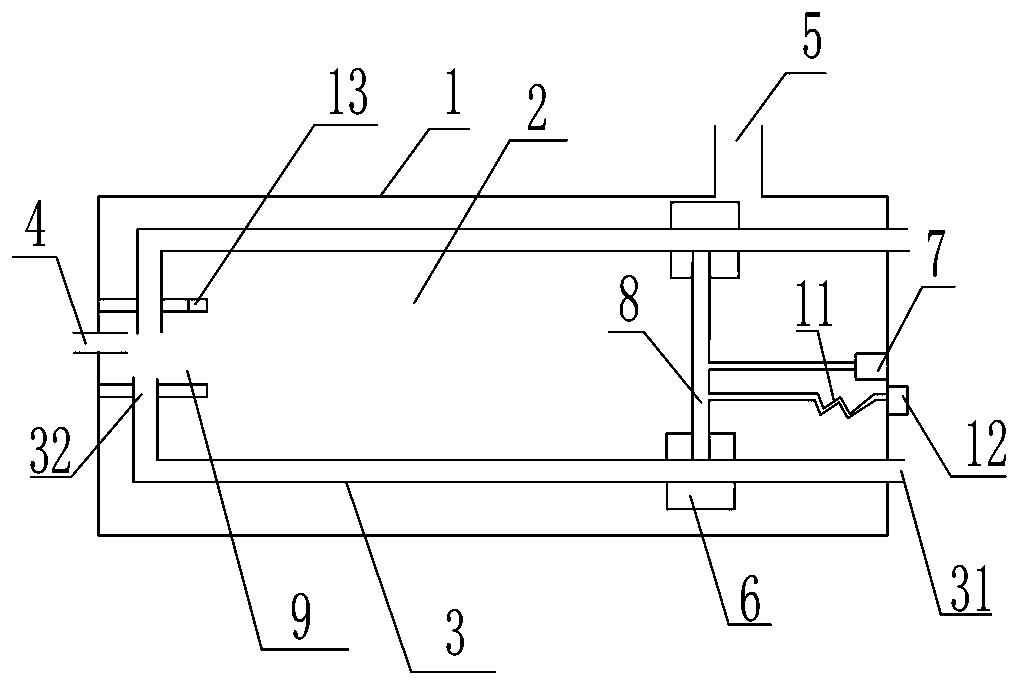

[0042] Such as Figure 4As shown, in order to fully mix the gas and the preheated exhaust gas, and then make the combustion more complete, on the basis of Embodiment 1, a further improvement is made. The end of the furnace body 1 provided with the gas inlet 4 is provided with a gas mixing chamber 9, The chamber wall of the gas mixing chamber 9 includes a part of the furnace body 1 and a side wall fixedly connected with the furnace body 1, and the side wall is surrounded by a circular tubular structure or a tubular rectangular parallelepiped structure. Of course, the structure of the combustion chamber can also be in other shapes. Both the gas inlet 4 and the exhaust gas outlet 32 of the preheating pipe communicate with the gas mixing chamber 9 , which is located in the combustion chamber 2 , and the gas mixing chamber 9 communicates with the combustion chamber 2 in the direction facing the driving device 7 . A burner 10 is embedded on the furnace body 1 or on the wall of th...

Embodiment 3

[0050] Such as Figure 6 As shown, the difference from Embodiment 2 is that in this embodiment, the flexible hose is connected to the air supply equipment outside the combustion furnace through an air duct, and the other end of the branch pipe connected to the flexible pipe 11 passes through the first plate 101, With this design, after the combustion is completed, before closing the air mixing chamber, when the first plate 101 of the smoke guiding part is close to the air mixing chamber, the air mixing chamber can be sprayed into the air mixing chamber through a flexible pipe to clean up, further preventing dust accumulation . It also prevents further gas diffusion in the event of gas leaks due to damage to gas and exhaust gas pipes.

[0051] As a further improvement, in another embodiment, a plurality of air injection holes are distributed on the hollow connecting rod 8. When the air is blown to clean the air mixing chamber, the air injection holes on the connecting rod perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com