Automatic-regualting burner for gas furnace

An automatic adjustment and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of inability to adapt to changes in parameters of the combustion process, tempering and deflagration of the mixture, and poor combustion effect, and achieves simple structure, Safe to use and avoid the effect of tempering and deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below using the embodiments shown in the accompanying drawings.

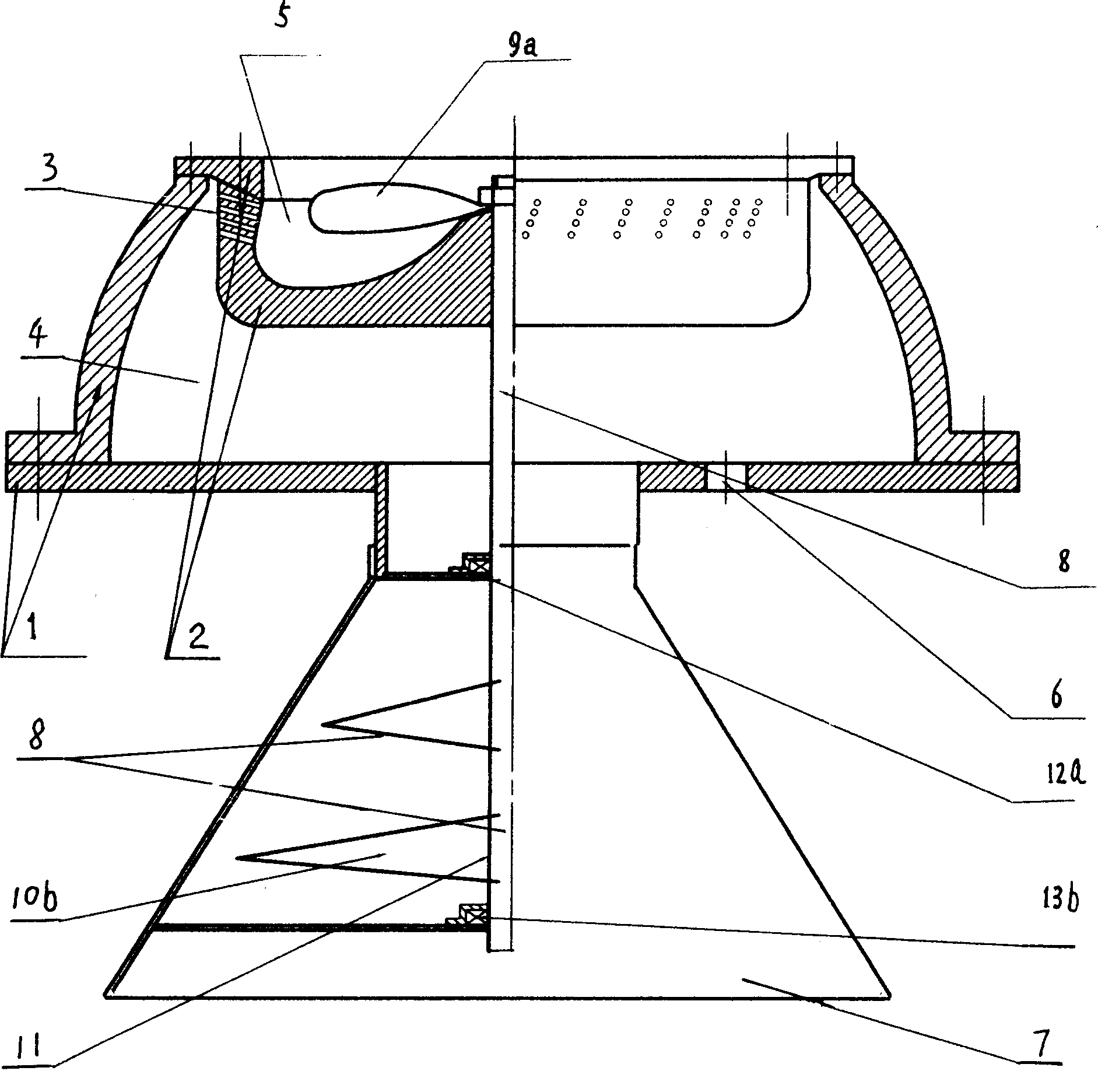

[0009] refer to figure 1 , an automatic adjustable burner for a gas furnace has a shell 1, an ejector 2, and the shell 1 and the ejector 2 are connected by screws. The cavity between the housing 1 and the injector 2 is the gas mixture chamber 4, and the cavity in the injector 2 is the combustion chamber 5. On the peripheral wall of the injector 2, there are several gas chambers communicating with the gas mixture chamber 4. A gas distribution hole 3, a gas inlet 6 and an air inlet 7 are respectively arranged at the bottom of the housing 1, and a linkage fan 8 is arranged in the combustion chamber 5 and the air inlet 7. The structure of the linked fan 8 is that it is installed on the central axis 11 of the combustion chamber 5, the mixed air chamber 4 and the air inlet 7, and is located on the two sections of the central axis 11 of the combustion chamber 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com