Biomass burning furnace and air intake method

A biomass burning furnace and biomass technology, which is applied in household furnaces/stoves, climate sustainability, solid heating fuels, etc., can solve the problems of many operation steps and inconvenient use, and achieve good safety performance, sufficient combustion, quick fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

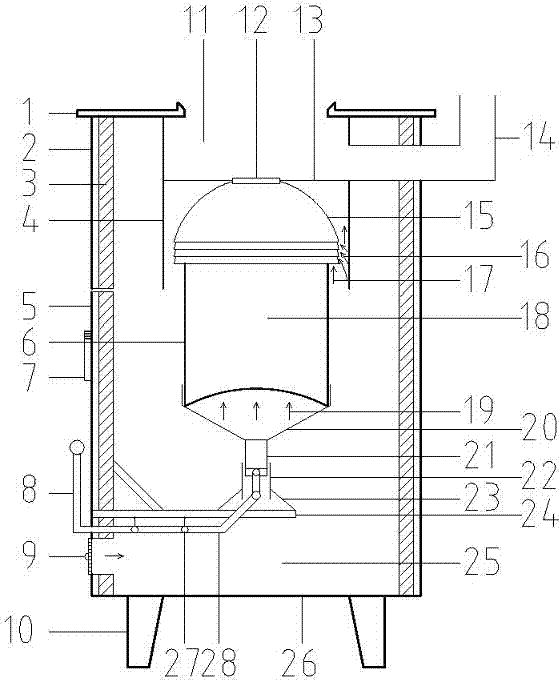

[0020] The lifter in this biomass burning furnace can be a device with a lifting function in various forms, considering that the functions are all the same. Therefore, this embodiment only takes the piston lifter as an example.

[0021] In the figure, the shell of the biomass combustion furnace consists of the hearth (1), the shell (2), the door (5), the door handle (7), the bottom plate (26), the flue gas outlet (14) and the heat insulation layer (3) The combustion system consists of an upper combustion tube (4), a gas baffle (13), a fire hole (12), a multi-layer air inlet cover (15) and a lower combustion tube (6), and the gas baffle (13), multiple The layer air intake cover (15) is installed in the upper combustion tube (4), the lifter is connected to the inner side of the door, the lifter operating part (8) is on the outer side of the door, and the piston lifter is supported by the lifter (20), the piston (21), piston bushing (22), piston bushing bracket (23), lifter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com