Lead-free borosilicate glass-based ceramic composite material and preparation method thereof

A ceramic composite material, lead-free borosilicate technology, applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., can solve the problems of lead content, unfriendly environment and human health, etc., and achieve high densification and excellent Microwave dielectric properties and good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

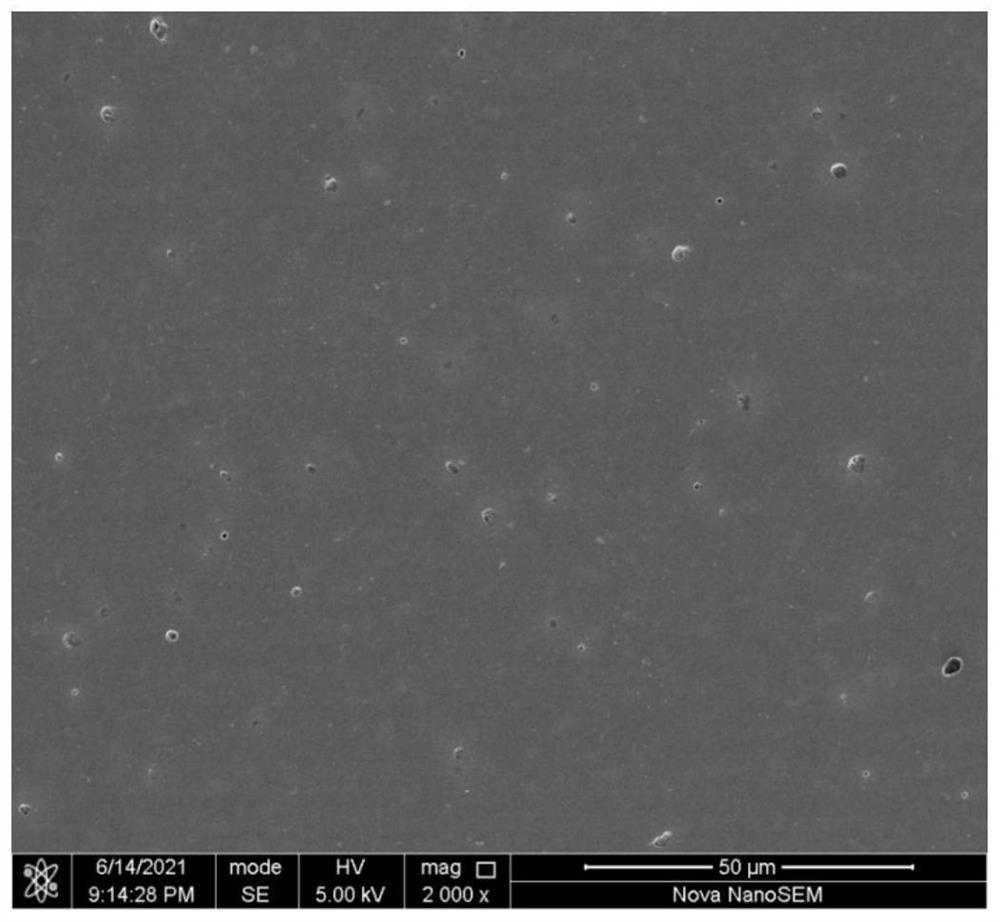

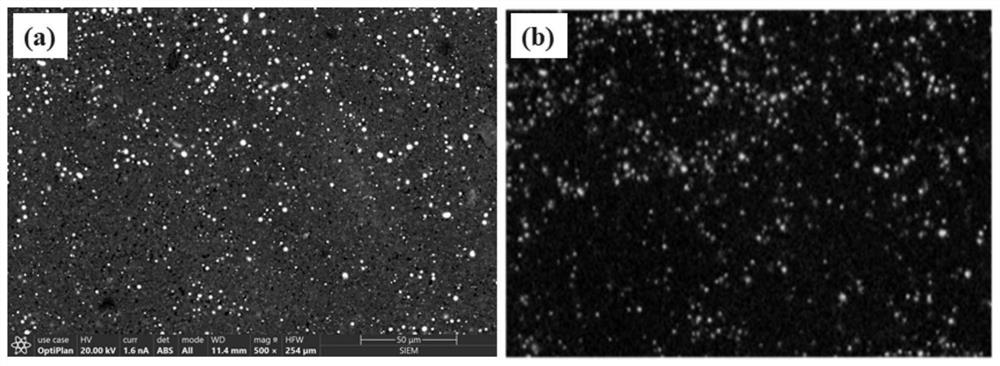

Image

Examples

Embodiment 1

[0060] In this example, SiO in the lead-free borosilicate glass-based ceramic composite material 2 -B 2 o 3 -AlF 3 -SrO glass, fused silica, Al 2 o 3 Ceramics, AlN ceramics and TiO 2 The mass fraction of ceramics is 55wt.%, 23wt.%, 10wt.%, 10wt.% and 2wt.%. The preparation method is as follows:

[0061] (1) Mix the weighed glass raw material powder with ethanol as a solvent ball mill for 24 hours, the speed is 500rpm, the ball milling medium is a zirconium ball with a diameter of 15mm, and the mass ratio is glass raw material powder: ethanol: zirconium ball = 1:2: 4. Take the uniformly mixed raw materials, press filter, dry at 80°C for 24 hours, pass through a 100-mesh sieve, and then smelt at 1500°C for 2 hours, and quench the glass melt in distilled water to obtain glass slag;

[0062] (2) The glass slag is crushed by a planetary ball mill to obtain glass powder, the rotating speed is 500rpm, and the time is 12h; the ball milling medium is zirconium balls, and the solv...

Embodiment 2

[0070] In this example, SiO in the lead-free borosilicate glass-based ceramic composite material 2 -B 2 o 3 -AlF 3 -SrO glass, fused silica, Al 2 o 3 , AlN and TiO 2 The mass fraction of is 54wt.%, 10wt.%, 30wt.%, 5wt.% and 1wt.%, and preparation process is as follows:

[0071] (1) Mix the weighed glass raw material powder with ethanol as a solvent ball mill for 24 hours, the speed is 500rpm, the ball milling medium is a zirconium ball with a diameter of 15mm, and the mass ratio is glass raw material powder: ethanol: zirconium ball = 1:2: 4. The ball milling medium is zirconium balls with a diameter of 15mm; take the uniformly mixed raw materials, press filter, dry at 80°C for 24 hours, pass through a 100-mesh sieve, and then smelt at 1500°C for 2 hours, and the glass melt is quenched in distilled water to obtain glass slag;

[0072] (2) The glass slag is crushed by a planetary ball mill to obtain glass powder, the rotating speed is 500rpm, and the time is 12h; the ball...

Embodiment 3

[0078] In this example, SiO in the lead-free borosilicate glass-based ceramic composite material 2 -B 2 o 3 -AlF 3 -SrO glass, fused silica, Al 2 o 3 Ceramics, AlN ceramics and TiO 2 The mass fraction of ceramics is 54wt.%, 5wt.%, 15wt.%, 25wt.% and 1wt.%, and the preparation process is as follows:

[0079] (1) Mix the weighed glass raw material powder with ethanol as a solvent ball mill for 24 hours, the speed is 500rpm, the ball milling medium is a zirconium ball with a diameter of 15mm, and the mass ratio is glass raw material powder: ethanol: zirconium ball = 1:2: 4. The diameter of the zirconium ball is 15mm; take the uniformly mixed raw materials, press filter, dry at 80°C for 24 hours, pass through a 100-mesh sieve, and then smelt at 1500°C for 2 hours, and the glass melt is quenched in distilled water to obtain glass slag;

[0080] (2) The glass slag is crushed by a planetary ball mill to obtain glass powder, the rotating speed is 500rpm, and the time is 12h; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com