Multifunctional fuel magnetizer

A magnetizer and multi-functional technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of unsmooth exhaust, cavitation, insufficient magnetization effect, etc., to improve the utilization rate of magnetic energy and reduce exhaust emissions , to avoid the effect of fuel corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

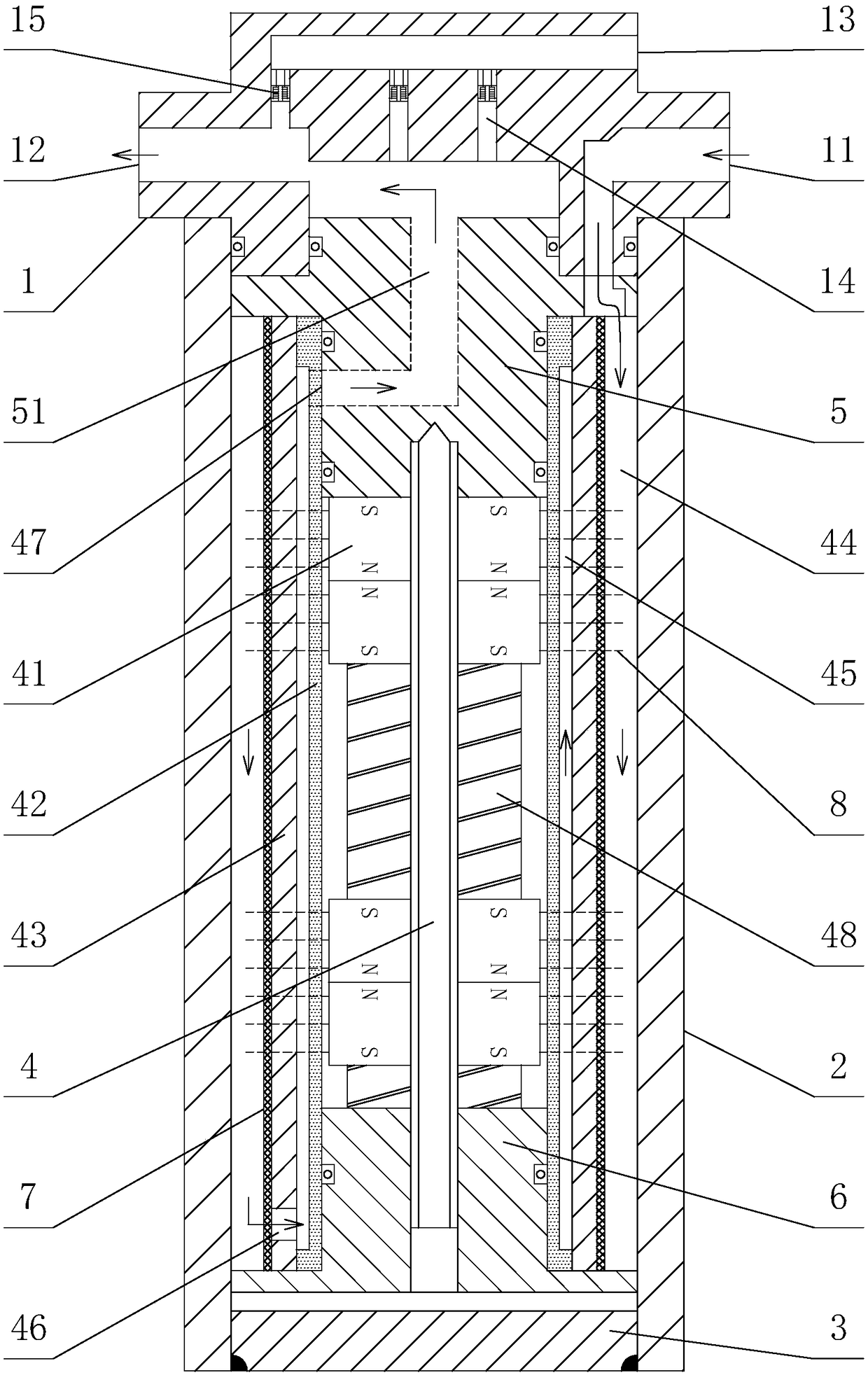

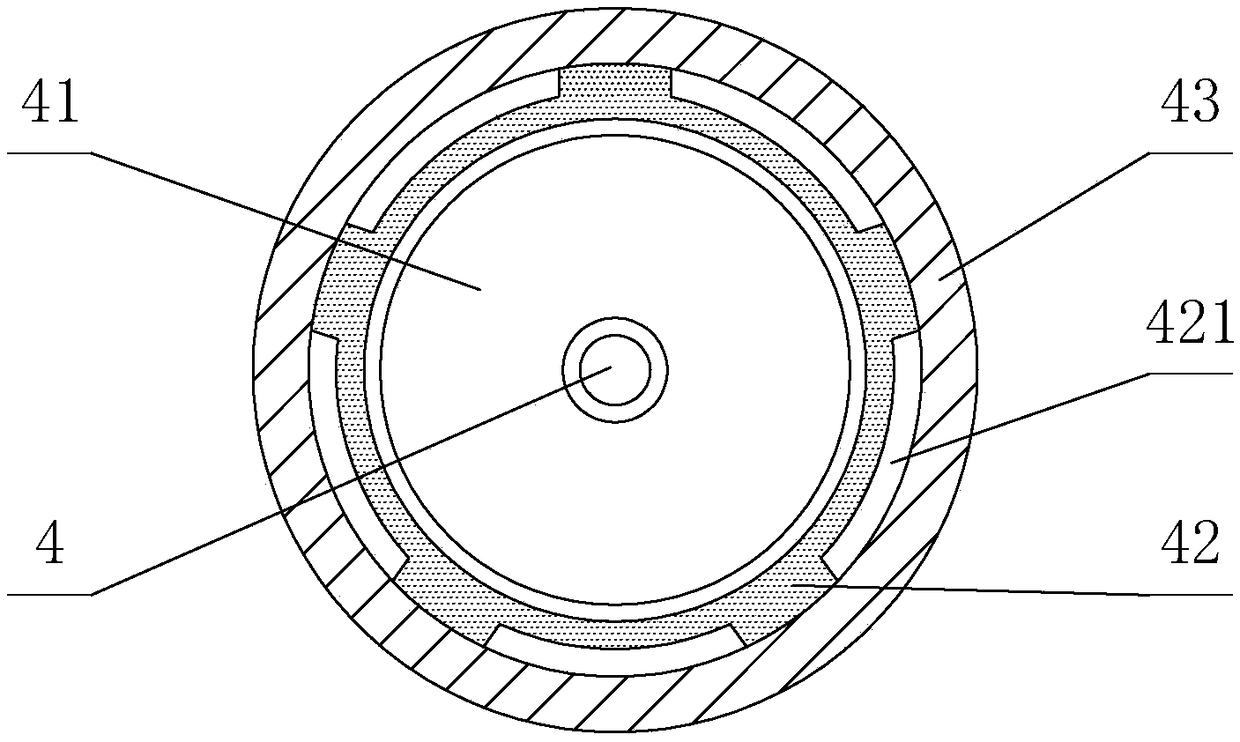

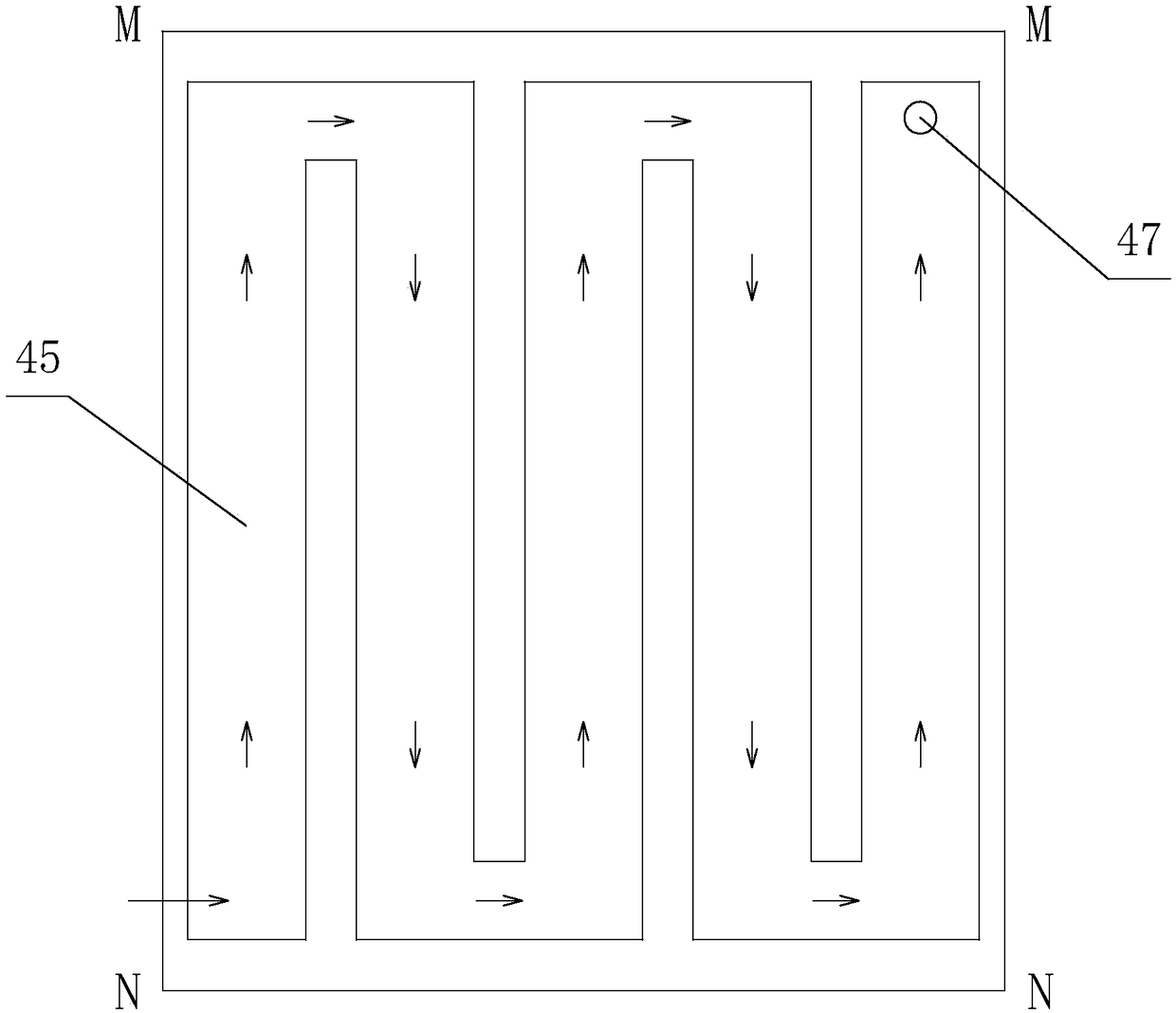

[0029] A multifunctional fuel magnetizer, such as figure 1 As shown, it includes an end cap 1, an outer cylinder body 2, an outer cylinder body rear cover 3 and a magnetization device, the outer cylinder body 2 is a cylinder, and the end cap 1 and the outer cylinder body rear cover 3 are respectively assembled on the outer cylinder The upper and lower ends of the body 2, the magnetization device is arranged in the outer cylinder body 2, the outer oil inlet 11 connected with the outlet of the oil pump and the outer oil outlet 12 connected with the engine fuel injection nozzle are arranged on the end cover 1, the magnetization The upper end of the device is connected to the end cover 1 through the core cover connecting body 5, and the lower end is pressed tightly in the outer cylinder body 2 by a core body back cover 6. The core cover connecting body 5 is provided with a fuel inner passage 51, and the fuel inner passage 51 is connected to the The external oil outlet 12 of the e...

Embodiment 2

[0036] A multifunctional fuel magnetizer, the structure of which is basically the same as that of Embodiment 1, the difference is that there are 1, 3 or several groups of magnetic energy cores, and 2 or 4 exhaust pipes and exhaust valves. indivual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com