System enabling boiler oxygen-rich combustion to be combined with electrolytic hydrogen production peak and frequency regulation apparatus

An oxygen-enriched combustion, peak-shaving and frequency-regulating technology, which is applied in the direction of combustion methods, combustion control, lighting and heating equipment, etc., to achieve the effects of reducing fuel costs, realizing effective utilization, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

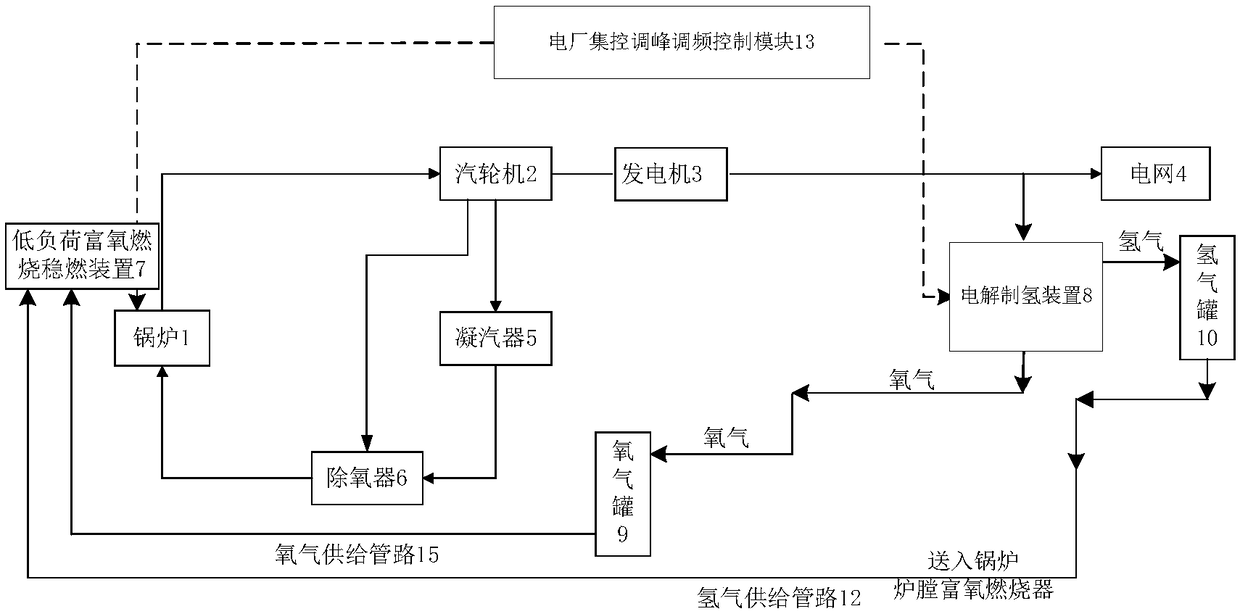

[0035] like figure 1 As shown, a system of boiler oxygen-enriched combustion combined with electrolytic hydrogen production peak-shaving and frequency-regulating equipment, the system includes:

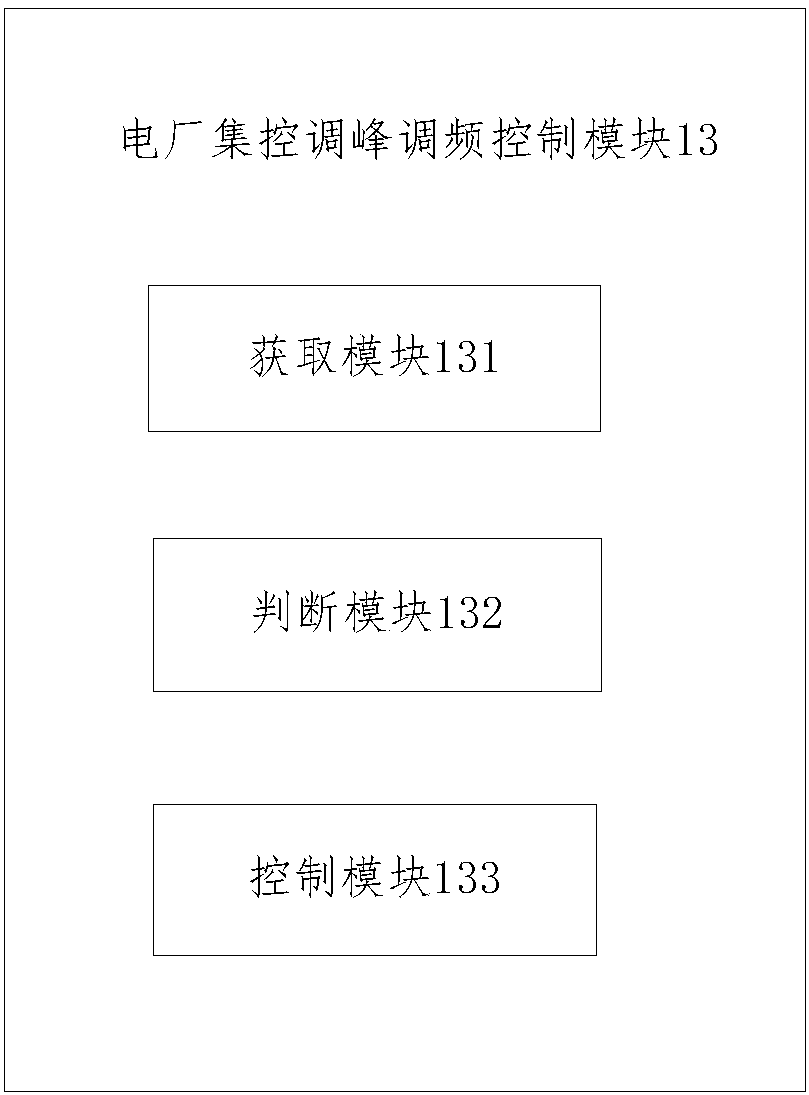

[0036] The power plant centralized control peak regulation and frequency regulation control module is used to obtain the current demand load of the power grid, compare it with the real-time power generation of the power plant, and issue peak regulation and frequency regulation instructions to the equipment in the plant according to the comparison results;

[0037] The boiler oxygen-enriched combustion module, including the low-load oxygen-enriched combustion and stable combustion device, is connected with the power plant centralized control peak regulation and frequency modulation control module, and is used to control the boiler fuel when the power plant centralized control peak regulation frequency regulation control module issues load increase and decrease operation instructions. I...

Embodiment 2

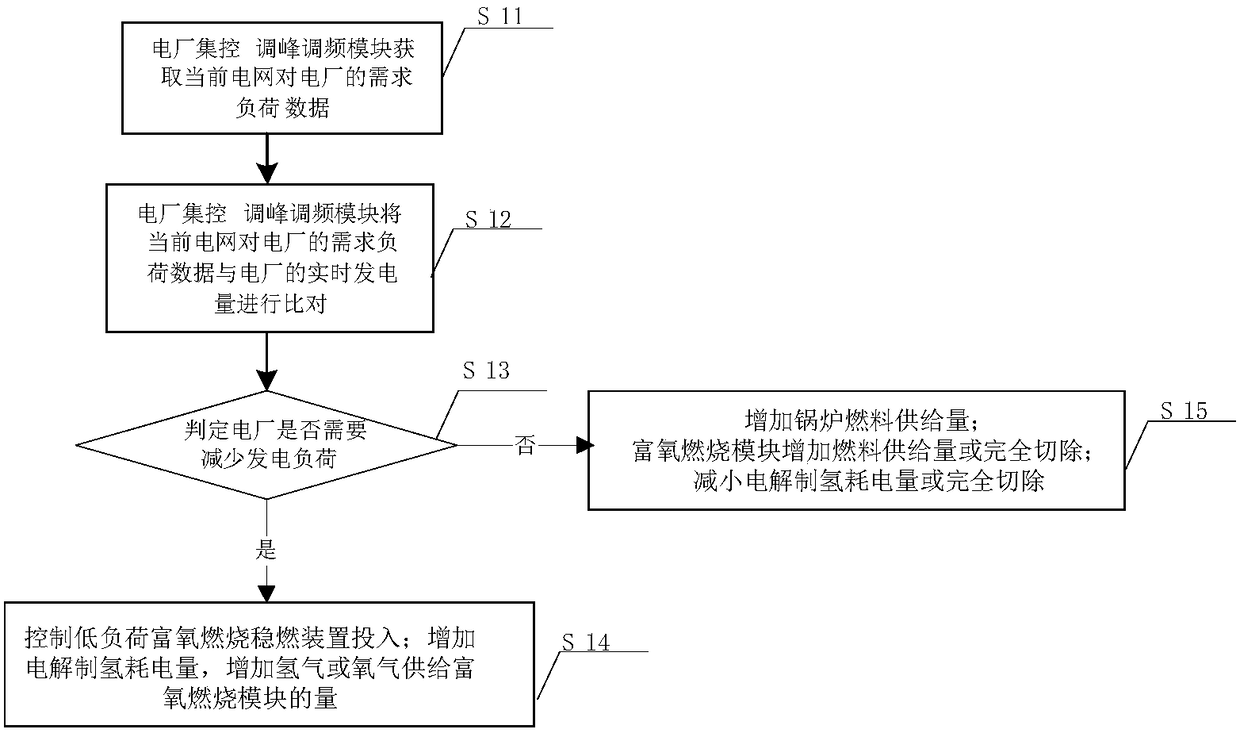

[0063] The basic structure of the system of this embodiment is similar to that of Embodiment 1, the difference is that, as Figure 4 As shown, a method for peak regulation and frequency regulation of a system of boiler oxygen-enriched combustion combined with electrolytic hydrogen production peak regulation and frequency regulation equipment includes:

[0064] Step S101: the power plant centralized control peak-shaving and frequency-regulating module obtains the current power grid's demand load data for the power plant;

[0065] Step S102: The power plant centralized control peak-shaving and frequency-regulating module compares the power load data required by the current power grid for the power plant with the real-time power generation of the power plant;

[0066] Step S103: The power plant centralized control peak regulation and frequency regulation module judges whether the power plant needs to increase or reduce the power generation load according to the comparison result;...

Embodiment 3

[0082] The basic structure of the system in this embodiment is similar to that of Embodiment 1, except that a hydrogen external output module 14 is added on the basis of Embodiment 1, and the final external output of hydrogen can be a hydrogen transport skid car, injected into a natural gas pipeline network, or a hydrogen fuel cell. Any one of gas source or compressed steel cylinder or carbon fiber bottle for external sales.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com