Open back water reciprocating flue type normal pressure boiler

A flue-type, normal-pressure technology, applied in the direction of water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of reduced heat absorption of hot water, low heat utilization rate, difficult to maintain coal, etc., to achieve the use of The effect of extended life, high heat utilization rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

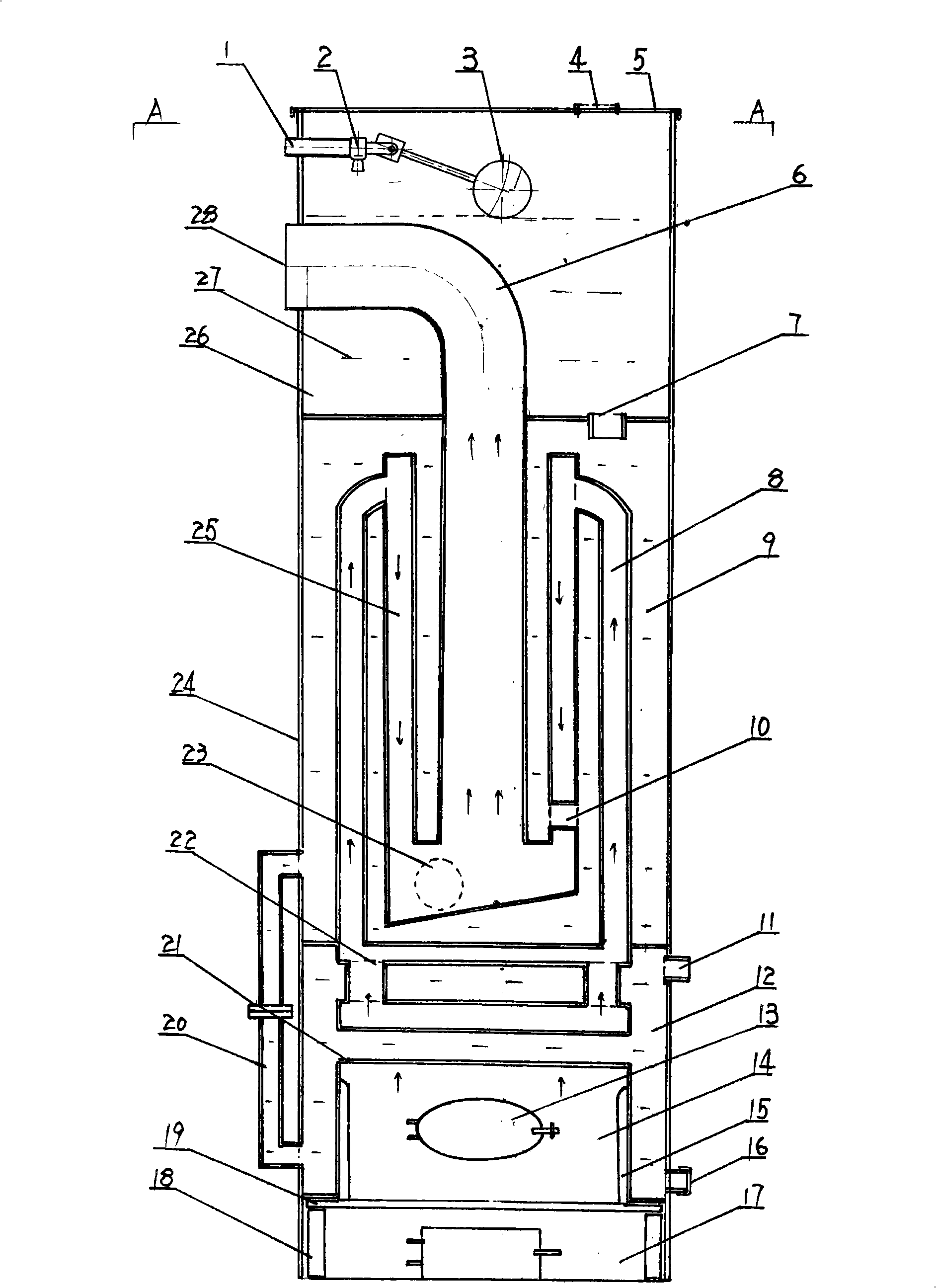

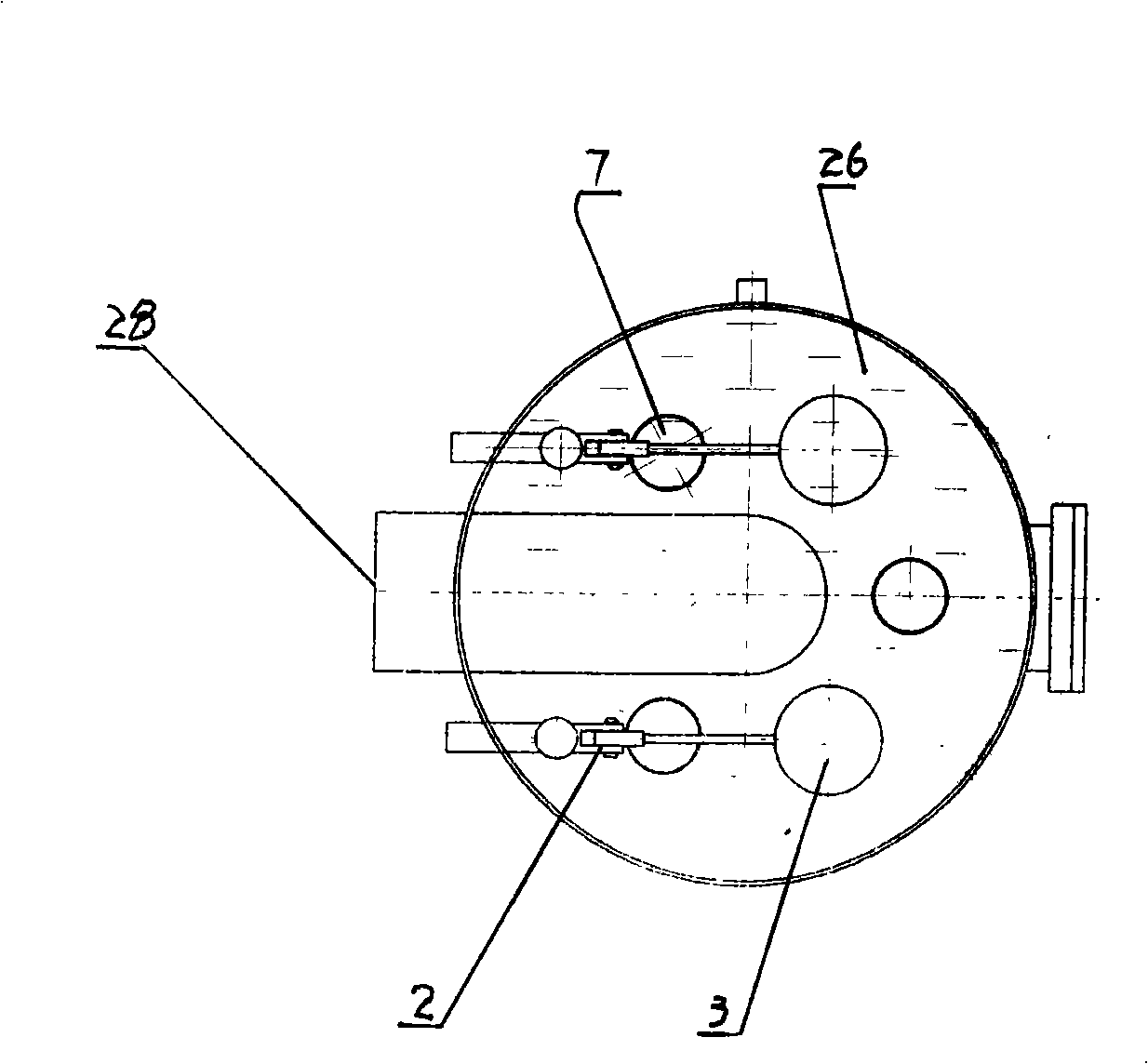

[0009] Such as figure 1 with figure 2 Shown, a kind of open back water reciprocating flue type normal pressure boiler is made up of body of heater 24, water storage tank 26, water inlet and outlet, fire grate 19 and smoke outlet 28.

[0010] Water 27 (indicated by horizontal -- in the figure) enters the furnace body from the upper part of the furnace body and flows out of the furnace body from the lower part of the furnace body by means of a pump;

[0011] Furnace body, the furnace body is divided into three parts, the upper part of the furnace body is a water storage tank, the water storage tank is an open type, its upper end can be provided with a cover 5, and an air outlet 4 can be provided on the cover to remove the gas in the water tank of the upper furnace body . Bottom of the furnace body is the lower furnace body water tank 12 and the furnace 14, and the furnace body around the furnace is provided with a chamber mud layer 15 to prevent coal burning from burning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com